Mesin Pemotong Laser Serat Logam sing Ekonomis

Mesin Pemotong Laser Serat Logam sing Ekonomis

Karakter Mesin Pemotong Laser Logam

●Servo ganda struktur gantry penggerak:Mesin laser struktur gantry jembatan, penggerak rel rak, nggunakake piranti pelumasan terpusat, lan gampang diurus;

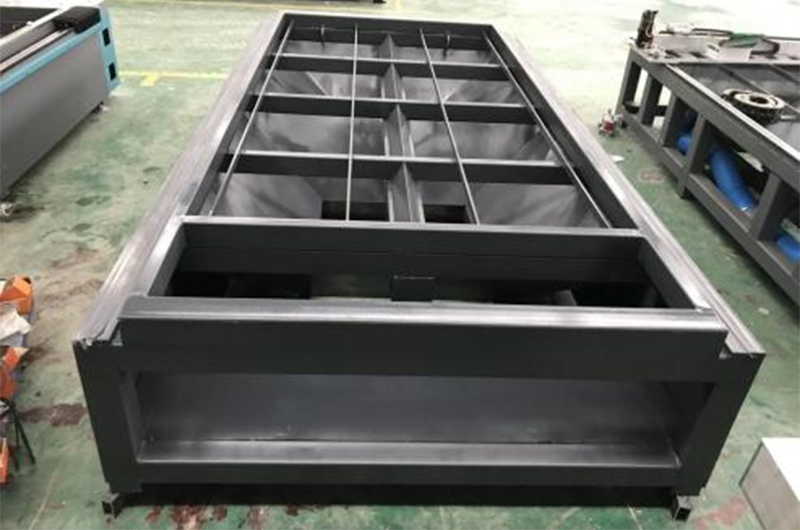

●Ppraktis lan Stabil: Amben mesin las sing dikuatake, perawatan tempering suhu dhuwur kanggo ngilangi stres. Deformasi mesin bisa dikontrol ing ± 0,02mm;

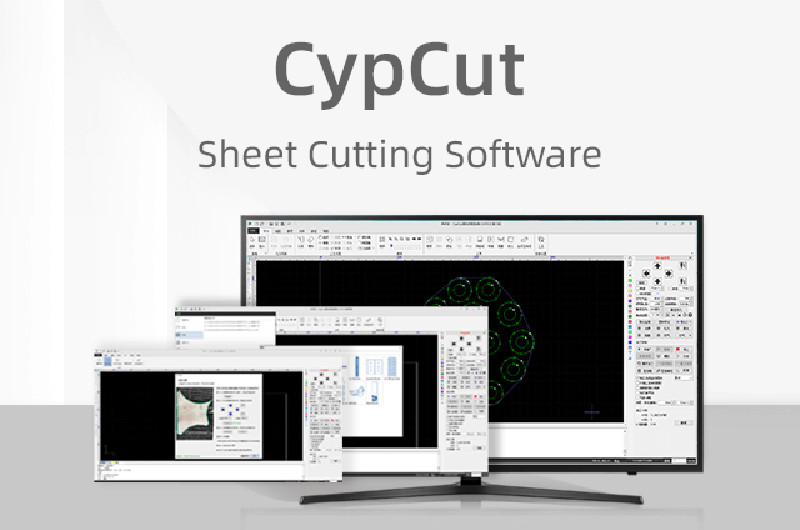

●Operasine prasaja: Luwih saka 23000 pangguna nggunakake sistem pemotongan CNC profesional iki. Sistem operasi iki nduweni fungsi pangaturan daya laser kanggo njamin kualitas pemotongan;

●Desain estetika industri: Standar ekspor ing Eropa lan Amerika, tampilan desain estetika ndadekake ditampa ing pasar global;

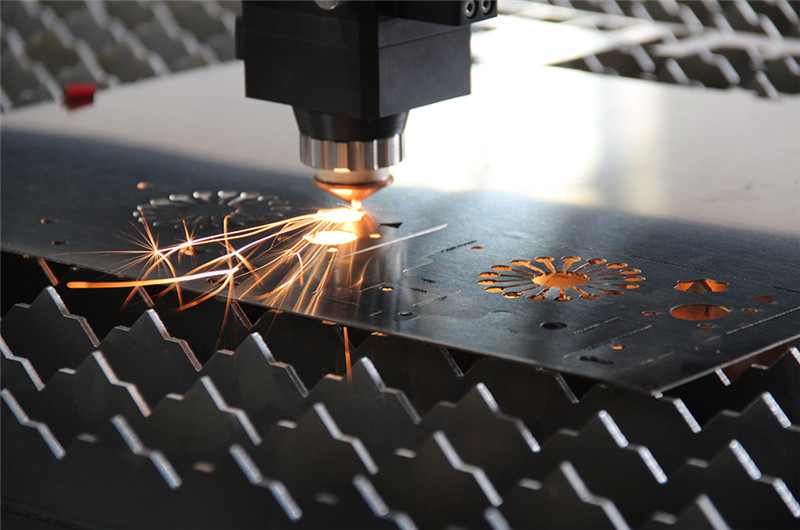

●Pemotongan kualitas dhuwur:Kepala pemotong laser profesional anti-tabrakan presisi dhuwur njamin efek pemotongan paling apik kanggo benda kerja lan proyek sampeyan;

●Bahan sing efisien:Digunakake ing spesifikasi standar pemotongan lembaran logam, ngirit wektu lan biaya;

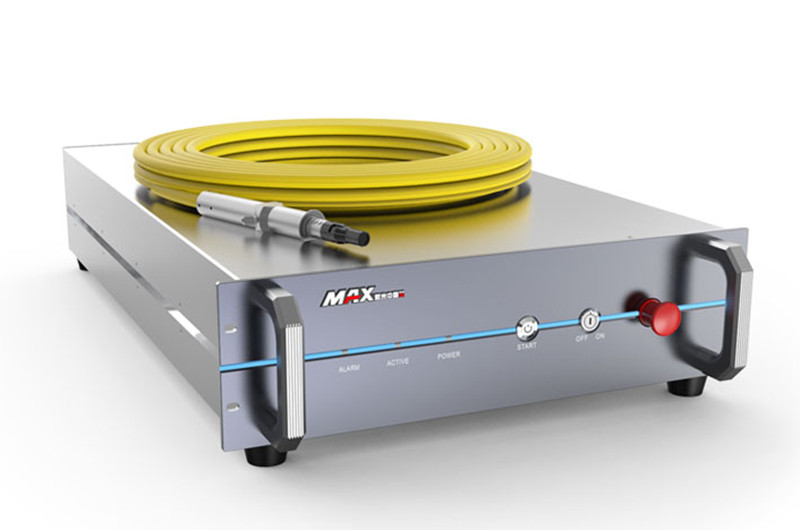

●Laser serat: Gunakake sumber laser serat Maxphotonics (laser merek liyane opsional), daya sing stabil lan dipercaya, kinerja dijamin;

| Konfigurasi mesin | |

| Model | Mesin Pemotong Laser Serat Seri FL-S |

| Wilayah Kerja | 3000mm * 1500mm |

| Sumber laser | Maks. 1000w |

| Sistem Pemotongan CNC | Sistem operasi Sipcut 1000 |

| Kepala laser | Fokus manual OSPRI |

| Amben mesin | Laser Rejeki |

| Rak gir sumbu X/Y | Laser Rejeki |

| Pandhuan linier presisi | ROUST |

| Penggerak Motor | Motor Servo Yaskawa Jepang (X750W/Y750W/Z400W) |

| Komponen elektronik | Prancis Schneider |

| Sistem reduksi | PHILANDE |

| Komponen pneumatik | SMC Jepang |

| Aksesoris amben mesin | Laser Rejeki |

| Pendingin banyu | Hanli |

| Piranti daur ulang sampah | Laser Rejeki |

Cathetan: Konfigurasi mesin iki mung kanggo referensi sampeyan, akeh merek liyane kanggo saben bagean mesin sing opsional adhedhasar kabutuhan lan anggaran sampeyan. Monggo hubungi kita kanggo rincian luwih lengkap.

Parameter Mesin

| Model | FL-S2015 | FL-S3015 | FL-S4020 | FL-S6020 |

| Wilayah Kerja (P*L) | 2000*1500mm | 3000*1500mm | 4000*2000mm | 6000*2000mm |

| Akurasi Posisi Sumbu X/Y | ±0,03mm/1000mm | ±0,03mm/1000mm | ±0,03mm/1000mm | ±0,03mm/1000mm |

| Akurasi Posisi Ulangan Sumbu X/Y | ±0,02mm | ±0,02mm | ±0,02mm | ±0,02mm |

| Kacepetan Obah Maksimum | 80000mm/menit | 80000mm/menit | 80000mm/menit | 80000mm/menit |

| Akselerasi Maksimum | 1.2g | 1.2g | 1.2g | 1.2g |

| Bobot Muatan Maks. | 600kg | 800kg | 1200kg | 1500kg |

| Catu Daya | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz |

| Daya Sumber Laser (Opsional) | 1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW/8kW/10kW/12kW/15kW/20kW | |||

Aplikasi

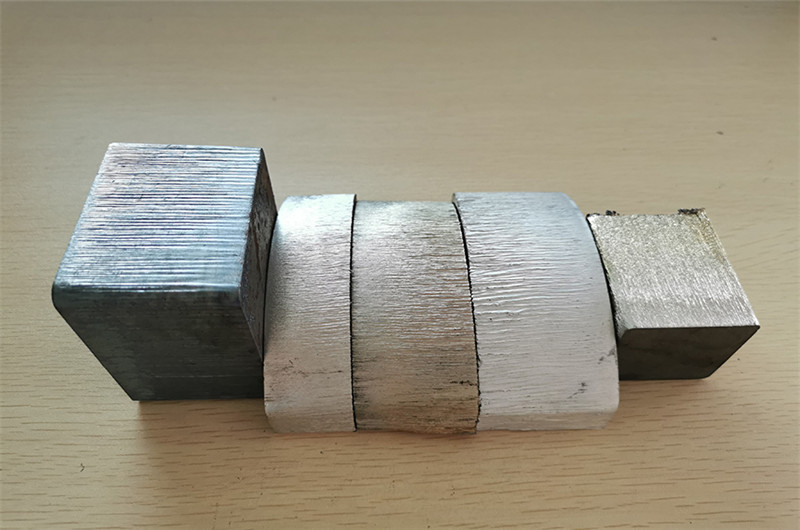

Cocok kanggo ngolah lembaran logam kayata baja tahan karat, baja karbon, baja paduan, baja silikon, pelat baja galvanis, paduan nikel-titanium, inconel, paduan titanium, lan liya-liyane.

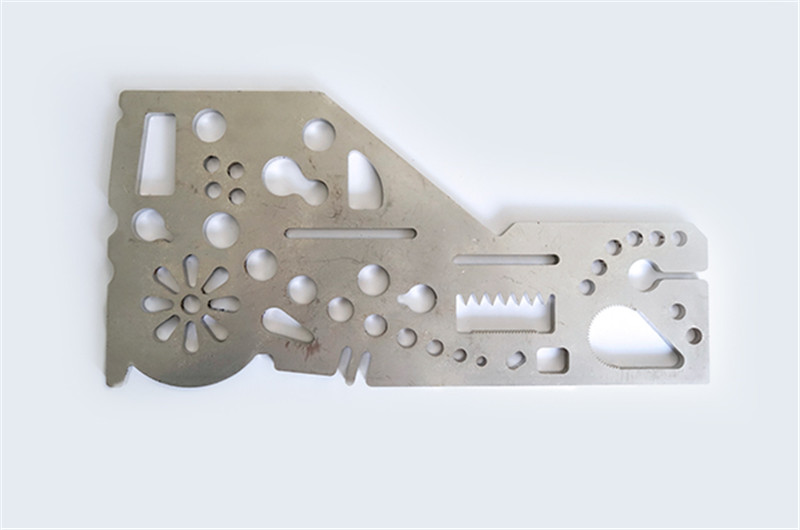

Tampilan Sampel

Parameter Proses Pemotongan Sumber Laser Maks.

| Cathetan 1: Diameter inti serat output laser 1000W ~ 1500W ing data pemotongan yaiku 50 mikron; diameter inti serat output 2000 ~ 4000W yaiku 100 mikron; | |||||||||

| Cathetan 2: Data pemotongan iki nganggo sirah pemotongan Raytools, dawa fokus lensa kolimasi/fokus: 100mm/125mm; | |||||||||

| Cathetan 3: Amarga beda konfigurasi peralatan lan proses pemotongan (alat mesin, pendinginan banyu, lingkungan, nozzle pemotongan lan tekanan gas) sing diadopsi dening pelanggan sing beda-beda, data iki mung kanggo referensi; | |||||||||

| Mmateri | Kekandelan (mm) | Gminangka Jinis | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| kacepetan(m/menit) | kacepetan(m/menit) | kacepetan(m/min) | kacepetan(m/menit) | kacepetan(m/menit) | kacepetan(m/menit) | kacepetan(m/menit) | |||

| Baja Tahan Karat | 1 | N2 | 20~24 | 28~32 | 38 | 30 | 50 | 42~43 | 70~75 |

| 2 | N2 | 5.4 | 7.5 | 12 | 10 | 13 | 19~20 | 25~30 | |

| 3 | N2 | 2.2 | 4 | 7 | 6 | 8 | 11~12 | 12~15 | |

| 4 | N2 | 1.2 | 2 | 4 | 4 | 5 | 6.5~7.5 | 7.5~9 | |

| 5 | N2 |

| 1.1 | 2 | 2.5 | 2.5 | 4~5 | 6~7.5 | |

| 6 | N2 |

| 0.8 | 1.5 | 1.5 | 1.5 | 2~3 | 5~6.5 | |

| 8 | N2 |

|

| 0.8 | 0.7 | 1 | 1.5~2 | 3.5~4.5 | |

| 10 | N2 |

|

| 0.5 | 0.5 | 0.8 | 1 | 2.1 | |

| 12 | N2 |

|

|

|

| 0.5 | 0.8 | 1.1 | |

| 14 | N2 |

|

|

|

|

|

| 0.9 | |

| Mmateri | Kekandelan (mm) | Gminangka Jinis | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| kacepetan(m/menit) | kacepetan(m/menit) | kacepetan(m/min) | kacepetan(m/menit) | kacepetan(m/menit) | kacepetan(m/menit) | kacepetan(m/menit) |

| Baja Karbon | 1 | udhara | 9~12 | 27~30 | 27~30 | 30 | 50 | 43 | 70~75 |

| 2 | udhara | 6~8 | 8~10 | 10~12 | 12 | 13 | 20 | 25~30 | |

| 3 | O2 | 3 | 3 | 3 | 4 | 4.5 | 4.5 | 4.5 | |

| 4 | O2 | 2 | 2.5 | 3.1 | 3.3 | 3.5 | 3.8 | 3.8 | |

| 5 | O2 | 1.6 | 2 | 2.5~3 | 2.5 | 3 | 3.5 | 3.7 | |

| 6 | O2 | 1.4 | 1.8 | 2.2 | 2.3 | 2.5 | 2.8 | 3.3 | |

| 8 | O2 | 1.1 | 1.3 | 1.5 | 1.5 | 2 | 2.3 | 2.8 | |

| 10 | O2 | 0.9 | 1.1 | 1 | 1.2 | 1.4 | 1.8 | 2.1 | |

| 12 | O2 | 0.7 | 0.9 | 0.8 | 1 | 1.1 | 1.5 | 1.6 | |

| 14 | O2 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.95 | ||

| 16 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 0.85 | ||

| 18 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.75 | |||

| 20 | O2 | 0.4 | 0.5 | 0.6 | 0.7 | 0.65 | |||

| 22 | O2 | 0.4 | 0.5 | 0.5 | 0.5 | ||||

| Aluminium | 1 | udhara | 12~13 | 15 | 17~18 | 29 | 45 | 35~37 | 70~75 |

| 2 | udhara | 4~4.5 | 6 | 7.5 | 8.5 | 11 | 15 | 25~30 | |

| 3 | udhara | 1~1.5 | 3 | 5 | 5 | 7 | 8~9 | 15 | |

| 4 | udhara | 0.8~1 | 2 | 3 | 4 | 6 | 10 | ||

| 5 | udhara | 1 | 1.5 | 3 | 8 | ||||

| 6 | udhara | 0.6 | 1 | 2 | 5.5 | ||||

| 8 | udhara | 0.5 | 1 | 2.5 | |||||

| 10 | udhara | 0.5 | 1.3 | ||||||

| 12 | udhara | 0.9 | |||||||

| Kuningan | 1 | udhara | 10 | 12 | 15 | 24 | 40 | 30~33 | 65~70 |

| 2 | udhara | 3 | 5 | 6 | 7.5 | 10 | 13 | 20~25 | |

| 3 | udhara | 0.5 | 2 | 3 | 4 | 4 | 7 | 5 | |

| 4 | udhara | 0.5 | 1.5 | 2 | 3 | 5 | 4 | ||

| 5 | udhara | 0.5 | 1 | 1.5 | 2 | 3 | |||

| 6 | udhara | 0.5 | 0.8 | 1.5 | 2 | ||||

| 8 | udhara |

| 0.8 | 1.2 | |||||

| 10 | udhara |

|

| 0.5 |

Syarat Lingkungan Kerja

1. Syarat kelembapan yaiku 40%-80%, ora ana kondensasi.

2. Syarat jaringan listrik: 380V; 50Hz/60A.

3. Fluktuasi jaringan catu daya: 5%, kabel ground jaringan memenuhi syarat internasional.

4. Motong nganggo gas bantu: Udara kompres sing resik lan garing lan oksigen (O2) lan nitrogen (N2) kanthi kemurnian dhuwur, kemurnian ora kurang saka 99,9%.

5. Ora kena ana gangguan elektromagnetik sing kuwat cedhak karo peralatan instalasi.

6. Aja nggunakake pemancar radio utawa stasiun relay ing sekitar lokasi instalasi.

7. Resistensi pentanahan daya: ≤ 4 ohm. Amplitudo pentanahan: kurang saka 50um; akselerasi getaran: kurang saka 0,05g.

8. Aja nggunakake akeh mesin perkakas kayata mesin stamping ing sacedhake kono.

9. Tekanan udara: 86-106kpa.

10. Kebutuhan papan peralatan dijamin bebas saka asap lan bledug, ngindhari lingkungan kerja sing kebak bledug kayata polesan lan panggilingan logam.

11. Lantai anti-statis kudu dipasang lan kabel sing dilindhungi kudu disambungake.

12. Kualitas banyu saka banyu sirkulasi pendinginan sing digunakake pancen dibutuhake, lan banyu murni, banyu deionisasi utawa banyu suling kudu digunakake.