Njengoba amandla okushisela kanye nezidingo zokubukeka kokushisela kwensimbi eshidi zikhuphuka kakhulu, ikakhulukazi ezingxenyeni ezinenani eliphezulu kanye nezidingo zekhwalithi ephezulu yokushisela, izindlela zokushisela zendabuko zizoholela ekuguqukeni komsebenzi ngenxa yokufaka ukushisa okukhulu, njll. Inkinga, idinga izindlela eziningi zokugaya nokubumba, okuholela ekukhuphukeni kwezindleko.

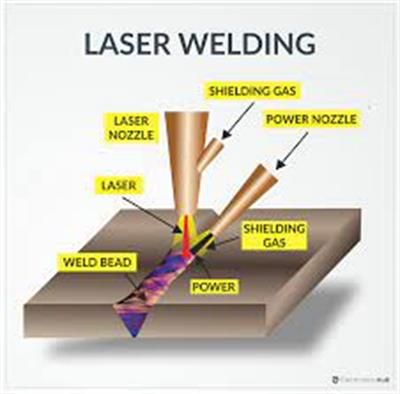

Nokho,ukushisela nge-laserinesisindo samandla aphezulu kakhulu kanye nendawo ephansi kakhulu ethinteke kakhulu ekushiseni, okungagcini nje ngokuthuthukisa ukusebenza kahle kokushisela, kodwa futhi kuthuthukisa ikhwalithi futhi kunciphisa isikhathi sokucubungula ngemva kokucubungula.

Ngakho-ke, ukusetshenziswa kokushisela nge-laser ekukhiqizweni kwensimbi yesimanje kuya ngokuya kuthandwa kakhulu. Amakhasimende amaningi akhathazekile ngezindleko zokuthenga imishini, ukusebenza kahle kokushisela kanye nekhwalithi, isivinini sokugaya, izinto ezisetshenziswayo ngemuva kokucubungula, ukusetshenziswa kwamandla, ubunzima bokusebenza, ukuvikelwa kokuphepha, izindleko zangemva kokuthengisa kanye nezinye izici eziningi.

Kunezinhlobo eziningi zemishini yokushisela emakethe. Amakhasimende kumele acabangele lezi zici ezilandelayo lapho ekhetha umshini wokushisela nge-laser:

1. Izici zokukhanya: usayizi webala (ububanzi benduku yelaser, ububanzi befayibha kanye nohlobo, amapharamitha ekhanda lokuphuma), ukuphakama kwendiza egxile, ukujula kwensimu, isikhundla sebala, i-engeli yebala lokwenzeka;

2. Izici zokulawula: ukukhethwa kwemodi yokulawula impendulo kanye ne-waveform yamandla.

Ngemva kokuqhathanisa izindlela ezahlukene zokushisela, inkampani yethu yethule izinhlobo ezintathu zemishini yokushisela nge-laser: ukushisela okuzenzakalelayo kwe-fiber optic okunezinhlangothi ezine, ukushisela okuzenzakalelayo kwe-robot, kanyeukushisela nge-laser okubanjwe ngesandlangezidingo ezahlukene zemboni yensimbi eshidi. Imithombo yokukhanya yamadivayisi amathathu isebenzisa ama-fiber lasers, akukho okudliwayo futhi ukulungiswa kuyadingeka, ikhwalithi ye-beam ilungile, futhi isivinini sokushisela siyashesha, okuyisimiso esihle kakhulu sokucubungula embonini yensimbi eshidi.

Ukukhethwa kwemishini

01. Ukushiswa kwefayibha okuzenzakalelayog

Ububanzi besicelo:Isetshenziswa kakhulu kumaqoqo amakhulu ensimbi ejwayelekile encane nephakathi nendawo, umkhiqizo unokunemba okuphezulu, futhi ukucutshungulwa kwamaqoqo kungenziwa ngamathuluzi amahle kanye nezinto zokwakha.

Ukuzenzakalela okusebenza kahle kakhulu:umkhiqizo we-laser onamandla aphezulu, indawo ephindaphindwayo enembile kakhulu, ibhentshi lokusebenza elikude elinezinhlangothi ezine, uhlelo lokusebenza olulula kakhulu, ukugxila okuzenzakalelayo kanye nokujikeleza kwekhanda lokushisela, kuqaphela isilinganiso sokusebenza kahle kakhulu sokucubungula kanye nokwenza okuzenzakalelayo kokukhiqiza;

Iqinile futhi iyinhle:i-weld inesilinganiso esiphakeme (esijulile nesincane), akudingeki ucingo lokugcwalisa, ukungcola kwendawo yokuncibilikisa kuncane, i-weld inamandla aphezulu nokuqina (idlula ngisho nezinto eziyisisekelo), futhi ikhanya futhi iyinhle;

Ithonya elincane lokushisa:amandla e-laser aphezulu, futhiinqubo yokushiselakuyashesha kakhulu, ngakho-ke ukufakwa kokushisa endaweni yokusebenza kuphansi kakhulu, indawo ethintekile ekushiseni incane, futhi indawo yokusebenza ayiguquguquki;

Ukuminyana okuphezulu:igesi iphuma ngokushesha lapho kwakheka umthungo wokushisela, futhi umthungo wokushisela ongenawo ama-pores. Ngaphezu kwalokho, ukupholisa okusheshayo ngemva kokushisela kwenza isakhiwo sokushisela sibe sincane futhi ubuningi bokushisela bube phezulu kakhulu.

Ukulawula:Ingalawula yonke imisebenzi efana nokubeka umthungo wokushisela, usayizi webala, ukudluliselwa kwe-beam, ukulungiswa kwamandla okukhanya, ukulawula ukushaywa yisifo sohlangothi, ukuma okuphuthumayo okusheshayo, njll.;

Ukusebenza okulula:ukusebenza okuphakathi kwezinkinobho, ukuqapha okubonakalayo kwesikrini, ukusebenza okulula nokusheshayo;

Ukusebenza okuzinzile:Umshini ulawulwa ngokuqinile yithimba lobuchwepheshe elisezingeni eliphezulu kusukela ezingxenyeni kuya kuwo wonke umshini, futhi uzohlolwa kahle futhi uhlolwe ngaphambi kokuphuma efektri, ngakho ukusebenza komshini kuzinzile kakhulu;

Uhla olubanzi lwezicelo:ukuxhumanisa okune-axis four long-stroke, ama-waveform ahlukene angasethwa ngamapharamitha enqubo ngokuya ngezinto ezahlukene zokushisela, ukuze amapharamitha okushisela avumelane nezidingo zokushisela. Kufanelekela ukushisela ezimbonini, emikhiqizweni nasezindleleni ezahlukahlukene.

Ikhanda lokujika:usayizi kanye nesimo sendawo yokukhanya kungalungiswa, okungasetshenziswa kabanzi futhi kungashintshwa ukuze kusetshenziswe ukushisela imikhiqizo ehlukahlukene.

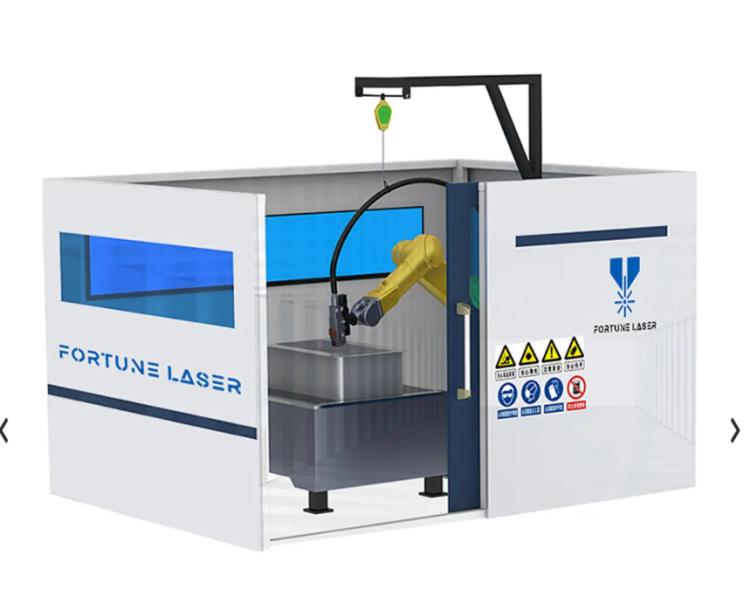

02. Ukushisela amarobhothi

Izicelo: Isetshenziswa kakhulu kumaqoqo amakhulu ensimbi ejwayelekile ephakathi nendawo kanye nenkulu. Inokunemba okuphezulu kokubeka kanye nokunyakaza okuguquguqukayo. Ifaneleka ezintweni zokusebenza ezahlukahlukene ezinama-engeli ayinkimbinkimbi okulandelana. Ingenziwa ibe yiziteshi eziningi ukuthuthukisa ukusebenza kahle kokushisela. Yiyona kuphela indlela yokushintsha umsebenzi wezandla nokunciphisa umfutho womsebenzi.

Ukusebenzisa ingalo yerobhothi enezingqimba eziyisithupha, ububanzi bokushisela bubanzi.

Ukunemba kokubeka okuphindaphindiwe kuphakeme, kufika ku-0.05 mm.

Irobhothi linokuqina okuhle kanye nokuphila isikhathi eside.

Ukusebenza kahle kokukhiqiza kuthuthukisiwe kakhulu, futhi kungasebenza ngokuqhubekayo amahora angama-24. Uma kuhlanganiswa namathuluzi kanye nomugqa wokuhlanganisa, kungafeza ukukhiqizwa kwesisindo okuzenzakalelayo.

Ikhanda lokujika: usayizi nesimo sendawo yokukhanya kungalungiswa, okungasetshenziswa kabanzi futhi kungashintshwa ukuze kuhambisaneukushisela okuhlukahlukeneimikhiqizo.

03. Ukushisela nge-laser okubanjwe ngesandla

Izicelo:Isetshenziswa kakhulu ensimbini engajwayelekile. Kunezinhlobo eziningi zemikhiqizo, ezingafaneleki ezinhlotsheni ezahlukene, gwema ukutshalwa kwezimali ngokweqile. Ukunemba kokugoba komkhiqizo akuphakeme, futhi igebe likhulu kakhulu, okuxazulula inkinga yokuqashwa okunzima. Lo modeli uzuze udumo oluningi kumakhasimende.

Ukusebenza okulula:Iumshini wokushisela we-laser ophathwa ngesandlaKulula ukuyifunda nokusebenzisa, futhi umqhubi angathola kalula imiphumela yokushisela esezingeni eliphezulu.

Ukusebenza kahle kokushisela okuphezulu:Ukushisela nge-laser okubanjwe ngesandla kushesha kakhulu kunokushisela nge-argon arc. Ngokusekelwe ekusindiseni abasebenzi ababili bokushisela, ukusebenza kahle kokukhiqiza kungaphindeka kabili kalula

Azikho izinto zokusetshenziswa zokushisela:Ukushisela kungaqedwa kalula ngaphandle kocingo lokugcwalisa ngesikhathi sokusebenza, okunciphisa izindleko zezinto zokwakha ekukhiqizeni nasekucubunguleni.

Umphumela omuhle wokushisela:Ukushisela nge-laser okubanjwe ngesandla kuwukushisela okuncibilikisiwe. Uma kuqhathaniswa nokushisela kwendabuko, ukushisela nge-laser kunamandla aphezulu kanye nomphumela ongcono.

Ukuguqulwa kokusebenza kahle kwamandla okuphezulu:Ukusebenza kahle kokuguqulwa kwe-photoelectric kwe-laser kufinyelele ku-30%, futhi ukusetshenziswa kwamandla kuphansi.

Kulula ukuyisebenzisa futhi iguquguquka:ukushisela nge-laser okubanjwe ngesandla, ububanzi obukhululekile nobuguquguqukayo, obufinyelelekayo

Imithungo yokushisela ayidingi ukupholishwa: ukushisela okuqhubekayo, okubushelelezi ngaphandle kwezikali zezinhlanzi, okuhle futhi okungenazibazi, okunciphisa izinqubo zokugaya ezilandelayo.

Ikhanda lokujika:usayizi kanye nesimo sendawo yokukhanya kungalungiswa, okungasetshenziswa kabanzi futhi kungashintshwa ukuze kusetshenziswe ukushisela imikhiqizo ehlukahlukene.

Uma ukhetha i-laser power waveform, ngokuvamile, ngaphansi kwesisekelo sokukhipha amandla e-laser afanayo, ububanzi be-pulse buyanda, indawo yokushisela iba nkulu; lapho amandla aphezulu e-laser power waveform ephezulu, kulapho indawo yokushisela ijula khona. Njengamanje, azikho isethi ephelele yezindlela zokusetha i-laser power waveform. Abasebenzisi bangahlola kancane kancane enkambisweni yokusebenzisa ukuthola i-laser power waveform efanele imikhiqizo yabo.

Ukukhetha umshini wokushisela nge-laser kubaluleke kakhulu esilinganisweni sokukhiqizwa kwe-batch processing; ngakho-ke, uma izimo zivuma, abasebenzisi bangasebenzisa umshini wokushisela we-laser real-time negative feedback ngangokunokwenzeka ukuze bathuthukise izinga elihle lemikhiqizo.

Uma ufuna ukufunda kabanzi ngokushisela nge-laser, noma ufuna ukuthenga umshini wokushisela nge-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Feb-17-2023