Okwamanje,imishini yokushisela i-laser ngesandlazithandwa kakhulu embonini yokushisela, futhi intengo yemishini yokushisela i-laser nayo ayilingani.Intengo iphakeme kunezinye izinto zokushisela.Yebo, zikhona futhi ezishibhile.Kungcono ukubiza?Singazithenga kanjani izinto zokusebenza ezinhle ngemali efanayo?Masifunde mayelana nolwazi olufanele mayelana nokuthengaumshini wokushisela we-laser ophethwe ngesandla.

Izici zomkhiqizo wemishini yomshini wokushisela we-laser ophathwa ngesandla zimi kanje:

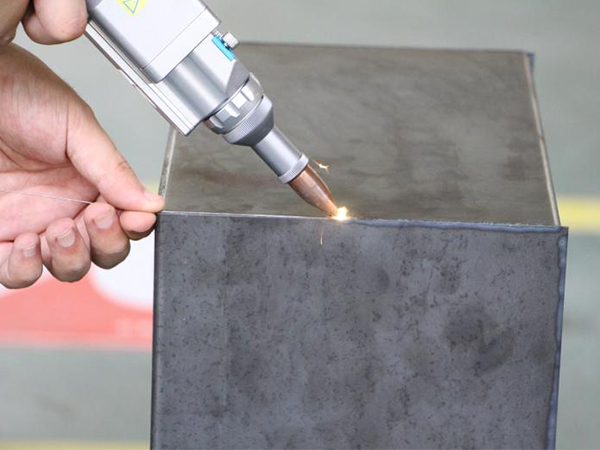

1. Ikhanda le-welding elibanjwe ngesandla lithatha indawo yendlela yangaphambilini ye-optical engaguquki, eguquguqukayo futhi elula, eqaphela i-laser welding yebanga elide, futhi inqoba ukulinganiselwa kwendawo yokuhamba yebhentshi lomsebenzi;

2. Ikhanda le-welding elibanjwe ngesandla lilula futhi liyavumelana nezimo, kulula ukusebenza, futhi lihlangana ne-welding kuma-engeli ahlukahlukene kanye nezikhundla;

3. Ikhanda lokushisela eliphathwa ngesandla lingahlonyiswa nge-fiber optical engenisiwe engu-5m/10m/15m, eguquguqukayo futhi elungele ukushisela ngaphandle;

4. Ukuma kwe-infrared kusetshenziselwa ukulinganisa isikhundla sekhanda lokushisela kanye nokuqinisekiswa kwesikhundla ngesikhathi sokushisela.Isikhundla sokushisela sinembile futhi i-weld seam inhle kakhulu;

5. Ukujula kokushisela kukhulu futhi ukushisela kuqinile;

6. Akulula ukuguqula, ukugaya kalula nokupholisha, okuxazulula izinkinga zekhwalithi zokushisela ezifana nokungena kwe-welding kanye nezigaxa zokushisela ezenzeka ku-ammonia arc welding.

Lezi zici nazo ziyizizathu zokuthi kunganiimishini yokushisela ephathwayozithandwa kakhulu.

Olunye ulwazi okufanele ukwazi lapho uthenga imishini yokushisela i-laser ephathwayo:

Isinyathelo sokuqala, udinga ukwazi ukuthi yiziphi izinhloboimishini yokushisela laserakhona.

Kunezinhlobo ezimbili zemishini yokushisela i-laser, othomathikhi kanye ne-manual.

Phakathi kwe-othomathikhi, umshini wokushisela we-laser othomathikhi wokuxhumanisa ama-axis amane wenziwa ngokuya ngezidingo ezihlukene zenqubo,

Umshini wokushisela we-laser othomathikhi we-fiber, umshini wokushisela we-fiber optical galvanometer laser, njll.

Phakathi kwalezi zezandla, umshini wokuthunga we-laser we-mold wenziwa ngokuvumelana nezidingo ezahlukene zokucubungula,

Umshini wokushisela ubucwebe be-laser, umshini wokushisela we-laser okhethekile wezinhlamvu zokukhangisa, njll.

Esinyathelweni sesibili, udinga ukucacisa ukuthi yiluphi uhlobo lomkhiqizo ofuna ukuwucubungula,

Bese ukhetha umshini wokushisela we-laser ofanele ngokuya ngezidingo zakho zobuchwepheshe bokucubungula kanye nezinhlobo zomkhiqizo.

Lapho uthenga izinto zokusebenza, kufanele uqonde izinto ezisetshenziswayo eziyinhloko.Kubaluleke kakhulu ukuthenga okulungile kunokuthenga okulungile.Ngaphambi kokuthenga, ungatshela umphakeli ubukhulu bento oyidingayo ukuyishisela, bese ubacela ukuthi batuse amandla omshini afanele wena.Futhi ubabuze ukuthi banayo yini ireferensi yevidiyo ye-welding efanele, ukuze kube lula ukuqinisekisa umphumela wokushisela.

Isinyathelo sesithathu ukukhetha umshini wokushisela we-laser ofanele ngokuya ngohlobo lomkhiqizo wakho, ubuchwepheshe bokucubungula kanye nezidingo zokucubungula.

Ngemva kokunquma ukuthi yiluphi uhlobo lomshini we-laser welding okufanele siwuthenge, sidinga ukukhetha umenzi womshini ofanele.

Ungazithola endaweni yangakini, noma ku-inthanethi.Lapho uyifuna, kufanele uqonde iwaranti kanye nokuthengiswa kwangemva kokuthengisaumshini wokushisela we-laser ophethwe ngesandla esikhathini sakamuva.Lapho uthenga ucezu lwesisetshenziswa, kufanele uqonde iwaranti yangemva kokuthengisa.Ngokuvamile, iwaranti ivamise ukuba unyaka owodwa kuya kwemibili, kanye nokugcinwa kwamahhala phakathi nesikhathi sewaranti esebenzayo.Abasebenzisi abaningi baziba leli phuzu lapho bethenga izinto zokusebenza.Izisebenzi eziqeqeshiwe zangemuva kokuthengisa azitholakali ukuze zilungiswe ngokuhamba kwesikhathi, futhi kunezindleko ezengeziwe zokusebenzisa.Lokhu kufanele kunakwe ngaphambi kokuthenga.Kulabo abangakwazi ukuhlinzeka ngamasevisi wendawo, kufanele futhi kuqinisekiswe ukuthi isevisi ye-inthanethi ngemva kokuthengisa iyasekelwa yini.

Okokugcina, nquma ukuthi yimuphi umkhiqizo ongawuthenga ngokusekelwe kumandla omphakeli, indawo yefekthri, ukuqhathaniswa kwentengo, nokuqhathaniswa kwesevisi yangemuva kokuthengisa.

Ngokuqondene nomshini, wonke umuntu unaka inani.Kunezici ezimbalwa ezithinta intengo yemishini ye-laser okufanele icatshangelwe:

1. Ivolumu yokukhiqiza yomkhiqizo: kufaka phakathi inani elizoshiselwa nsuku zonke, nokuthi hlobo luni lwenqubo yokushisela edingekayo.

2. Bheka umthelela wemikhiqizo namasevisi wenye ingxenye, nokuthi igama lihle yini.

3. Uma uqhathanisa amanani, bheka imingcele enemininingwane yomshini: amandla, ukumisa, ukusebenza, njll.

4. Isevisi yemishini ngemva kokuthengisa: Lokhu kubaluleke kakhulu.Azikho izinto ezisetshenziswayo ezingasoze zehluleke, futhi isikhathi sokuphendula sesevisi yomkhiqizi ngemva kokuthengisa kufanele sinakwe.

Uma ufuna ukufunda okwengeziwe mayelana ne-laser welding, noma ufuna ukukuthengela umshini we-laser welding ongcono kakhulu, sicela ushiye umlayezo kuwebhusayithi yethu futhi usithumele i-imeyili ngokuqondile!

Isikhathi sokuthumela: Dec-19-2022