Ukuvela kwamafoni ahlakaniphile kushintshe kakhulu indlela yokuphila yabantu, kanti ukuthuthuka okuqhubekayo kwezindinganiso zokuphila kwabantu nakho kubeke phambili izidingo eziphakeme zamafoni ahlakaniphile: ngaphezu kokuthuthukiswa okuqhubekayo kwesistimu, ihadiwe kanye nokunye ukucushwa okusebenzayo, ukubonakala kwamafoni aphathekayo nakho kube yinto ebalulekile ekuncintisaneni phakathi kwabakhiqizi bamafoni aphathekayo. Enkambisweni yokusungula izinto zokubukeka, izinto zengilazi zamukelwa abakhiqizi ngezinzuzo zazo eziningi ezifana nokwakheka okushintshashintshayo, ukumelana okuhle komthelela, kanye nezindleko ezingalawuleki. Zisetshenziswa kakhulu kumafoni aphathekayo, kufaka phakathi izembozo zangaphambili zefoni ephathekayo, izembozo zangemuva, njll. Izimbozo, izembozo zekhamera, izihlungi, amafilimu okuqaphela izigxivizo zeminwe, ama-prism, njll.

Nakuba izinto zengilazi zinezinzuzo eziningi, izici zazo ezibuthakathaka ziletha ubunzima obuningi enkambisweni yokucubungula, njengokuqhekeka kanye nemiphetho ebukhali. Ngaphezu kwalokho, ukusika okunesimo esikhethekile kwe-earpiece, ikhamera yangaphambili, ifilimu yeminwe, njll. nakho kubeka phambili izidingo eziphakeme zobuchwepheshe bokucubungula. Indlela yokuxazulula izinkinga zokucubungula izinto zengilazi nokuthuthukisa isivuno somkhiqizo isibe umgomo ovamile embonini, futhi kuyaphuthuma ukukhuthaza ukusungula izinto ezintsha kubuchwepheshe bokusika ingilazi.

Ukuqhathaniswa kwenqubo yokusika ingilazi

Ukusika ingilazi yommese wendabuko

Izinqubo zendabuko zokusika ingilazi zifaka phakathi ukusika amasondo ommese kanye nokusika ukugaya nge-CNC. Ingilazi enqunywe yisondo lokusika inemiphetho emikhulu kanye nemiphetho erhabaxa, okuzothinta kakhulu amandla engilazi. Ngaphezu kwalokho, ingilazi enqunywe yisondo lokusika inesivuno esiphansi kanye nesilinganiso esiphansi sokusetshenziswa kwezinto. Ngemva kokusika, kudingeka izinyathelo eziyinkimbinkimbi zokucubungula ngemuva. Isivinini kanye nokunemba kwesondo lokusika kuzokwehla kakhulu lapho kusika izimo ezikhethekile. Ezinye izikrini zesikrini esigcwele ezimise okwehlukile azikwazi ukunqunywa ngesondo lokusika ngoba ikona lincane kakhulu. I-CNC inokunemba okuphezulu kunesondo lokusika, ngokunemba okungu-≤30 μm. Ukunqunywa komphetho kuncane kunesondo lokusika, cishe ama-μm angu-40. Okubi ukuthi isivinini sihamba kancane.

Ukusika ingilazi ye-laser yendabuko

Ngokuthuthuka kobuchwepheshe be-laser, ama-laser nawo avele ekusikeni kwengilazi. Ukusika kwe-laser kuyashesha futhi kunembe kakhulu. Ukusikwa akunawo ama-burrs futhi akunqunyelwe ukuma. Ukuqhekeka komphetho ngokuvamile kungaphansi kwama-μm angu-80.

Ukusikwa kwengilazi nge-laser yendabuko kusebenzisa indlela yokukhipha ukungcola, kusetshenziswa i-laser enamandla aphezulu ukuze kuncibilikiswe noma kushiswe ingilazi, kanye negesi esekelayo enomfutho ophezulu ukuze kuphucwe i-slag esele. Ngenxa yokuthi ingilazi iyaphuka, indawo yokukhanya enesilinganiso esiphezulu sokugqokwa izoqoqa ukushisa okweqile engilazini, okubangela ukuba ingilazi iqhekeke. Ngakho-ke, i-laser ayikwazi ukusebenzisa indawo yokukhanya enesilinganiso esiphezulu sokugqokwa kokugqokwa okukodwa. Ngokuvamile, i-galvanometer isetshenziselwa ukuskena ngesivinini esikhulu ukusika ungqimba lwengilazi ngesendlalelo. Ukususwa kwesendlalelo, isivinini sokusika esijwayelekile singaphansi kuka-1mm/s.

Ukusika ingilazi ye-laser okusheshayo kakhulu

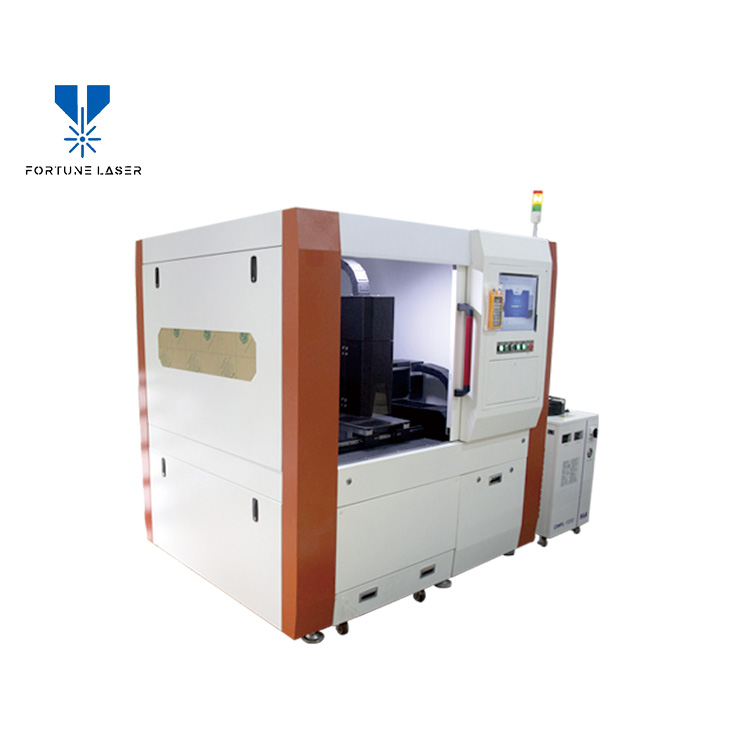

Eminyakeni yamuva nje, ama-laser asheshayo (noma ama-laser asheshayo e-pulse) athole intuthuko esheshayo, ikakhulukazi ekusetshenzisweni kokusika ingilazi, okuye kwafeza ukusebenza okuhle kakhulu futhi kungagwema izinkinga ezifana nokuqhekeka komphetho kanye nokuqhekeka okuvame ukwenzeka ezindleleni zokusika komshini zendabuko. Inezinzuzo zokunemba okuphezulu, ukungabi nemifantu emincane, izinkinga eziphukile noma eziqhekekile, ukumelana nemifantu emikhulu, kanye nokungabi nesidingo sezindleko zokukhiqiza zesibili njengokuwasha, ukugaya, kanye nokupholisha. Inciphisa izindleko ngenkathi ithuthukisa kakhulu isivuno somsebenzi kanye nokusebenza kahle kokucubungula.

Isikhathi sokuthunyelwe: Meyi-17-2024