Intsimbi engagqwaliyo isetyenziswa kakhulu kumashishini ahlukeneyo ngenxa yeempawu zayo ezikhethekileyo ezifana nokumelana nokugqwala kunye nokukwazi ukwakheka. Ngokuhambela phambili kwetekhnoloji, ukuwelda nge-laser kuye kwaba yindlela entsha yokuwelda, enezibonelelo ezininzi xa kuthelekiswa neendlela zokuwelda zendabuko. Nangona kunjalo, enye yeengxaki zokuweldaukuwelda nge-laserkukuguquka kwentsimbi engagqwaliyo. Kweli nqaku, siza kuxoxa ngendlela yokuphepha ukuguqulwa kwe-laser welding yentsimbi engagqwaliyo size sihlolisise izinto ezinxulumene nayo.

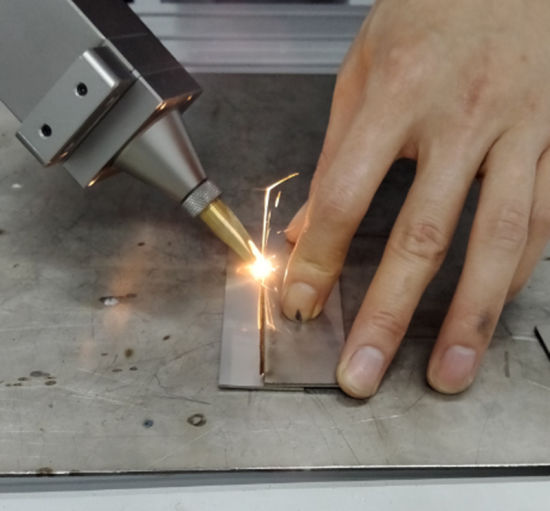

Okokuqala, kubalulekile ukuqonda ukuba kutheni ukuwelda nge-laser kubangela ukuguguleka kwentsimbi engagqwaliyo. Ukuwelda nge-laser kubandakanya ukusebenzisa umqadi we-laser onamandla aphezulu ukunyibilikisa nokudibanisa imiphezulu yeziqwenga ezibini zesinyithi kunye. Ngexesha lale nkqubo, ukufudumeza nokupholisa ngokukhawuleza kubangela ukuguguleka kobushushu, okubangela ukuguguleka kwendawo eweldayo. Nangona oku kubonakala kungenakuphepheka, kukho amanyathelo amaninzi anokuthathwa ukunciphisa okanye ukuphelisa ukuguguleka.

Elinye lamanyathelo okuqala okuphephaukuwelda nge-laserUkugqwethwa kukukhetha ngononophelo iiparameter zokuwelda zelaser ezifanelekileyo. Izinto ezinje ngamandla elaser, isantya sokuwelda, kunye nokugxila kwemitha kufuneka ziphuculwe ukuze kufezekiswe umgangatho we-weld oyifunayo. Ngokulungisa ezi parameter, igalelo lobushushu linokulawulwa kwaye ukuguqulwa kobushushu okubangela ukugqwethwa kunokunciphisa. Ukongeza, ukusebenzisa imo ye-pulsed endaweni yemo ye-continuous wave kunceda ukunciphisa indawo echaphazelekileyo kubushushu kunye nokuguqulwa okulandelayo.

Enye into ebalulekileyo ekufuneka iqwalaselwe kukuyilwa kwesixhumi ngokwaso. Imilo, ubungakanani kunye nokwakheka kwesixhumi kunokuchaphazela kakhulu ubungakanani bokuguquguquka okwenzekayo ngexeshaukuwelda nge-laserUkuze kuncitshiswe ukugqwetheka, kucetyiswa ukusebenzisa ii-welds ezibanzi kwaye kuthintelwe iikona ezibukhali okanye ezibukhali. Oku kusasaza ubushushu ngokulinganayo kwaye kunciphisa uxinzelelo lobushushu. Ukongeza, ukusetyenziswa kwee-fillet welds (ii-welds ezineemilo ezigobileyo okanye ezigobileyo) kunceda ekunciphiseni ukugqwetheka.

Ukongeza kwiiparamitha zokuwelda kunye noyilo lwamalungu, ukukhetha ubukhulu bezinto ezisetyenziswayo kudlala indima ebalulekileyo ekuphepheni ukugqwetheka. Amaphepha entsimbi engagqwethwayo atyebileyo anokuba nokuguquguquka ngenxa yokuqhuba kwawo okuphezulu kobushushu. Ukunciphisa oku, kucetyiswa ukusebenzisa amaphepha entsimbi engagqwethwayo okanye ukusebenzisa isinki yobushushu okanye inkqubo yokupholisa ngexesha lenkqubo yokutywina. Ezi ndlela zokupholisa zinceda ekususeni ubushushu obugqithisileyo kwaye zinciphise ukugqwetheka kobushushu, zinciphise ukugqwetheka.

Ukongeza, ukusebenzisa iindlela ezifanelekileyo zokulungisa nokubopha kunokunceda kakhulu ekuphepheni ukugqwetheka kwe-laser welding. Le nto ibhekisa ekubekweni nasekulungisweni kwento yokusebenza ngexesha lenkqubo yokubopha. Kubalulekile ukuqinisekisa ukuba into yokusebenza ixhaswe kwaye ilungelelaniswe ngokwaneleyo ukuthintela nayiphi na intshukumo okanye ukugoba ngexesha lokubopha. Kwelinye icala, ukugoba kubandakanya ukubamba into yokusebenza endaweni yayo kusetyenziswa iijigi okanye izinto zokusebenza ezilungiselelwe ngokukodwa. Ukugoba ngokufanelekileyo kunceda ukugcina inqanaba elifunekayo lokulungelelanisa kwaye kunciphisa amathuba okugoba.

Okokugqibela, unyango lobushushu emva kokuwelda lungasetyenziselwa ukunciphisa uxinzelelo olushiyekileyo nokunciphisa ukugqwetheka. Ukuqhoboshela, ukunciphisa uxinzelelo, kunye neenkqubo ezilula zokupholisa umoya zinceda ukuzinzisa izakhiwo eziweldayo kunye nokunciphisa ukugqwetheka. Ukusetyenziswa kwezixhobo kunye neendlela zonyango lobushushu ezikhethekileyo kunokubonelela ngokujikeleza kobushushu okufunekayo ukuqinisekisa ukuba intsimbi engagqwaliyo eweldayo ihlala izinzile kwaye ayinakugqwetheka.

Isishwankathelo,ukuwelda nge-laserInika iingenelo ezininzi kuneendlela zemveli zokuwelda ngokwesantya, ukuchaneka kunye nomgangatho. Nangona kunjalo, ukuguquka kwentsimbi engagqwaliyo kuzisa imingeni kwinkqubo yokuwelda nge-laser. Ukuguqulwa kwentsimbi engagqwaliyo kunokusingathwa ngempumelelo ngokukhetha ngononophelo kunye nokwenza ngcono iiparameter zokuwelda, uyilo lwemilo efanelekileyo yokudibanisa, ukuqwalaselwa kobukhulu bezinto, ukusetyenziswa kweendlela ezifanelekileyo zokulungisa kunye nokubopha, kunye nokusetyenziswa konyango lobushushu emva kokuwelda. La manyathelo, kunye neempawu zentsimbi engagqwaliyo, anegalelo kwi-welds ezikumgangatho ophezulu ezinokuphazamiseka okuncinci.

Ukuba ufuna ukufunda okungakumbi malunga nokuwelda nge-laser, okanye ufuna ukuthenga umatshini wokuwelda we-laser ongcono kuwe, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngokuthe ngqo!

Ixesha lokuposa: Julayi-18-2023