Ukuwelda nge-laseryenye yezona zinto zibalulekileyo ekusetyenzisweni kwetekhnoloji yokucubungula izinto ze-laser. Isetyenziswa kakhulu ekudibaniseni izinto ezixineneyo kunye nokuwelda ngesantya esiphantsi. Inkqubo yokuwelda iluhlobo lokuqhuba ubushushu, oko kukuthi, imitha ye-laser ifudumeza umphezulu wesixhobo somsebenzi, kwaye ubushushu bomphezulu buyasasazeka ngaphakathi ngokuqhuba ubushushu. Ngokulawula iiparameter ezifana nobubanzi, amandla, amandla aphezulu kunye nokuphindaphinda kwe-laser pulse, isixhobo somsebenzi siyanyibilika ukuze senze ichibi elithile elinyibilikisiweyo. Sisetyenziswa kakhulu kwimveliso yoomatshini, kwi-aerospace, kwishishini leemoto, kwi-powder metallurgy, kwishishini le-biomedical microelectronics nakwamanye amasimi.

Ngenxa yokukhula okukhulu kwezithuthi ezintsha zamandla, ukwanda kwemveliso yebhetri yamandla kuye kwakhokelela ekukhuleni kwe-laser welding. Ukusukela kwisiqingatha sesibini sowama-2018, i-handheld laser welding iye yafumana udumo kancinci kancinci, kwaye iye yaba yindawo eqaqambileyo kwimarike ye-laser welding kwisiqingatha sokuqala salo nyaka. Ngenxa yenqanaba lobuchwephesha langoku kunye neemeko zokusetyenziswa kwe-ukuwelda nge-laser ephathwayo, kusenokwenzeka ukuba ithathe indawo yemarike yomatshini wokuwelda we-TIG wendabuko (i-argon arc welding).

Kule minyaka yangoku,iileyiza zefayibhabenze inkqubela phambili enkulu, kwaye iingenelo zabo ziquka ikakhulu: izinga eliphezulu lokuguqulwa kwe-photoelectric, ukusasazwa kobushushu ngokukhawuleza, ukuguquguquka okuhle, amandla aqinileyo okulwa nokuphazamiseka, ixabiso eliphantsi, ubomi obude, akukho hlengahlengiso, akukho londolozo, uzinzo oluphezulu, ubungakanani obuncinci, Izixhobo zokuwelda ze-laser eziphathwa ngesandla kusetyenziswa ii-fiber lasers nazo ziye zaphuhliswa kancinci kancinci.

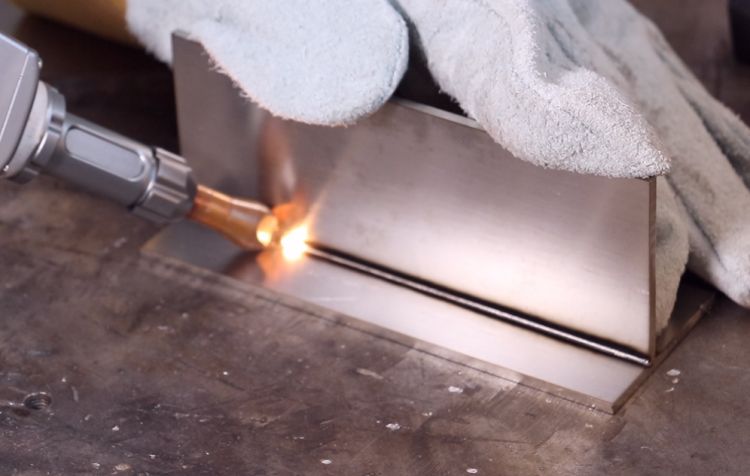

Ukuwelda nge-laserifuna ukuchaneka okuphezulu kwendibano yomsebenzi, kwaye umthungo we-weld unokuba neziphene. Ukusombulula le ngxaki, umyili ubhekisa kwizixhobo ze-laser welding zendiza ekhethekileyo ukuze aphuhlise izixhobo ze-laser welding eziphathwa ngesandla ezineendawo ezijikajikayo. I-laser ikwimo ye-"8" okanye "0" uhlobo lwe-swing lunokunciphisa ukuchaneka kwendibano yomsebenzi kwaye lwandise ukungena kwe-welding. Emva kochungechunge lokwenziwa ngcono nokuphuculwa, izixhobo ze-laser welding eziqhelekileyo zangoku zinamandla e-0.5-1.5KW, kwaye ubukhulu kunye nobunzima bezixhobo zilingana noomatshini be-argon arc welding, abanokufaka iipleyiti zesinyithi ze-3mm okanye ngaphantsi. Ukuze kusonjululwe ukusilela kwamandla angonelanga e-weld kwizakhiwo ze-laser welding, kwiminyaka yakutshanje, abavelisi bezixhobo badibanise izixhobo zokondla iingcingo ngokuzenzekelayo ngokusekelwe kwi-laser welding, kwaye baphuhlise izixhobo ze-laser welding ezizaliswa ngesandla ezinokondla iingcingo ngokuzenzekelayo, ezihlangabezana neemfuno zeepleyiti zesinyithi ezincinci ezingaphantsi kwe-4m. Ukuwelda ngokusisiseko kunokutshintsha nokugqitha ukuwelda kwe-argon arc, kufezekise isantya esiphezulu, ubushushu obuphantsi, ukuguqulwa okuncinci, ukuwelda kokhuseleko lokusingqongileyo okungabizi kakhulu, kwaye iindleko zokuvelisa ziphantsi kunezo zokuwelda kwe-argon arc phantsi kweemeko ezifanayo.

Xa isebenza, intloko yomatshini wokuwelda ebanjwe ngesandla inobubanzi bokuskena, kwaye ububanzi bayo buncinci, ngoko ke xa iwelda, iskena ukusuka kwenye indawo ukuya kwenye umgca ngomgca, ngaloo ndlela yenza i-weld bead. Xa kuthelekiswa nomatshini wokuwelda obandayo wendabuko, isantya sokuwelda somatshini wokuwelda we-laser obanjwe ngesandla siya kukhawuleza, kwaye inkqubo yokuwelda ye-one-shot igqiba ukuba ifanelekile ngakumbi ekuwelda ngobuninzi bee-seams ezinde ezithe tye.

Kwaye umatshini wokuwelda we-laser ophathwa ngesandla awuthathi ndawo ingako, kwaye uhlala uxhotyiswe ngeentloko ezahlukeneyo eziphathwa ngesandla. Ngokweemfuno ezahlukeneyo zezixhobo zesinyithi ezifana nokuwelda kwangaphandle, ukuwelda kwangaphakathi, ukuwelda kwe-engile yasekunene, ukuwelda komphetho omxinwa, kunye nokuwelda okukhulu, iintloko ezahlukeneyo zokuwelda eziphathwa ngesandla zinokukhethwa. Iimveliso ezinokuwelda zahlukahlukene, kwaye imo yemveliso iguquguquka ngakumbi. Kwiiworkshop zemveliso ezibandakanyeka ekucutshungulweni okuncinci kunye nokuwelda okungekuko okukhulu, oomatshini bokuwelda be-laser abaphathwa ngesandla ngokuqinisekileyo lolona khetho lubalaseleyo.

Izinto zesinyithi ezahlukeneyo zineendawo ezahlukeneyo zokunyibilika: ukuseta iiparamitha zokuwelda kwiintlobo ezahlukeneyo zezinto zokuwelda kunzima kakhulu, kwaye iipropati ze-thermophysical zezinto zokuwelda ziya kubonisa umahluko owahlukileyo ngotshintsho lobushushu; izinga lokufunxwa kweentlobo ezahlukeneyo zezinto ze-laser nalo liya kwahluka. Utshintsho lobushushu lubonisa umahluko owahlukileyo; ukunyibilika kwejoyinti ye-solder kunye nokuguquka kwesakhiwo sendawo echaphazelekileyo bubushushu ngexesha lokuqina kwe-weldment; iziphene zamalungu omatshini wokuwelda we-laser obanjwe ngesandla, uxinzelelo lokubandakanyeka kwe-welding kunye nokuguquguquka kobushushu, njl. Kodwa eyona ibalulekileyo yimpembelelo yomahluko kwiipropati zezinto zokuwelda kwiipropati ezinkulu nezincinci ze-weld.

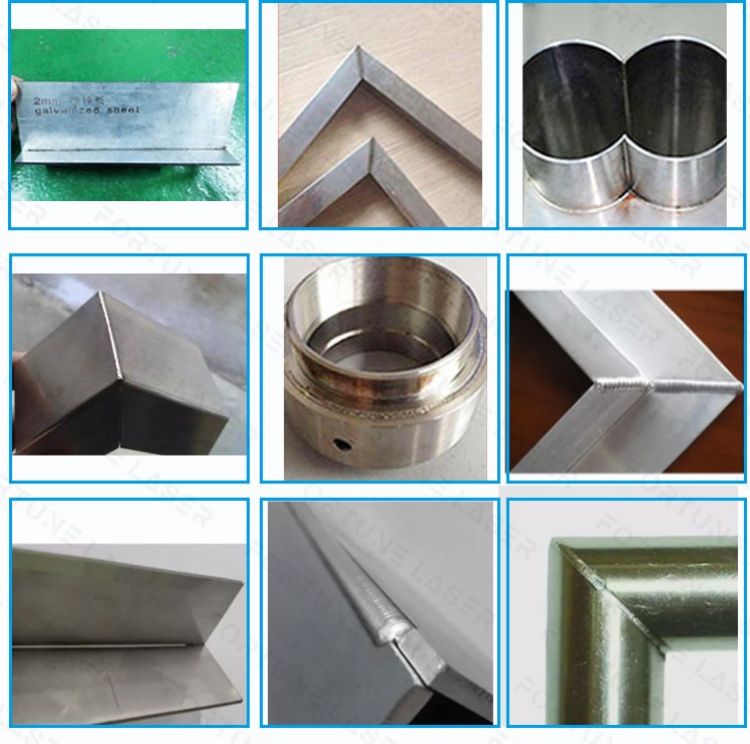

Zeziphi izinto ezinokwenziwaumatshini wokuwelda we-laser ophathwa ngesandlaukuwelda?

1. Intsimbi engatyiwayo

Intsimbi engagqwaliyo inomlinganiselo ophezulu wokwanda kobushushu, kwaye idla ngokugqithisela kakhulu ngexesha lokuwelda. Xa indawo echaphazelekileyo bubushushu inkulu kancinci, iya kubangela iingxaki ezinkulu zokuguquguquka. Nangona kunjalo, ubushushu obuveliswa ngumatshini wokuwelda welaser ophathwayo ngexesha lonke lenkqubo yokuwelda buphantsi. Xa kudibene nokuqhuba kobushushu okuphantsi, izinga eliphezulu lokufunxwa kwamandla kunye nokusebenza kakuhle kokunyibilika kwentsimbi engagqwaliyo, ii-welds ezenziwe kakuhle, ezigudileyo nezintle zinokufunyanwa emva kokuwelda.

2. Intsimbi yekhabhoni

Intsimbi yekhabhoni eqhelekileyo inokudityaniswa ngokuthe ngqo nge-laser welding ebanjwe ngesandla, isiphumo siyafana ne-stainless steel welding, kwaye indawo echaphazeleka bubushushu incinci, kodwa xa kudityaniswa intsimbi yekhabhoni ephakathi nephezulu, ubushushu obuseleyo buphezulu, ngoko ke kusafuneka ukudityaniswa ngaphambi kokudityaniswa. Ukufudumeza nokugcina ubushushu emva kokudityaniswa ukuze kuncitshiswe uxinzelelo kwaye kuthintelwe imingxunya. Apha singathetha ngomatshini wokudityaniswa obandayo. Intsimbi yekhabhoni ephakathi nephezulu inokudityaniswa okanye ilungiswe ngesantya esicothayo nge-cold welding kunye ne-cast iron welding wire. Ngokuphathelele ulawulo lobushushu, ulawulo lobushushu, kunye nolawulo lobushushu, umatshini wokudityaniswa obandayo unokufundisa ukudityaniswa kwe-laser ebanjwe ngesandla ukusebenza ngcono kwi-heat residue emva kokudityaniswa.

3. Isinyithi sedayi

Ifanelekile ukuwelda iintlobo ngeentlobo zentsimbi eyomileyo, kwaye isiphumo sokuwelda silungile kakhulu.

4. I-aluminium kunye ne-aluminium alloy

Ii-aluminium kunye nee-aluminium alloys zizinto ezikhanyayo kakhulu, kwaye i-porosity inokuvela kwidama elinyibilikisiweyo okanye kwingcambu ngexesha lokuwelda. Xa kuthelekiswa nezinto zesinyithi zangaphambili, ii-aluminium kunye nee-aluminium alloys zinemfuno ephezulu yeeparameter, kodwa lo gama nje iiparameter zokuwelda ezikhethiweyo zifanelekile, umthungo wokuwelda oneempawu ezifanayo zoomatshini njengesinyithi esisisiseko unokufunyanwa.

5. I-Copper kunye ne-copper alloy

Ukuqhuba kobushushu kobhedu kunamandla kakhulu, kwaye kulula ukubangela ukungena okungaphelelanga kunye nokudibana okungaphelelanga ngexesha lokuwelda. Ngokwesiqhelo, izinto zobhedu ziyafudunyezwa ngexesha lenkqubo yokuwelda ukunceda ukuwelda. Apha sithetha ngezinto zobhedu ezibhityileyo. I-laser welding can ephathwa ngesandla ngqo Ukuwelda, ngenxa yamandla ayo aqinileyo kunye nesantya sokuwelda esikhawulezayo, akuchaphazeleki kakhulu kukuqhutywa kobushushu okuphezulu kobhedu.

6. Ukuwelda phakathi kwezinto ezahlukeneyo

Umatshini wokuwelda we-laser ophathwa ngesandla ungenziwa phakathi kweendidi ezahlukeneyo zeesinyithi, ezifana ne-copper-nickel, i-nickel-titanium, i-copper-titanium, i-titanium-molybdenum, i-brass-copper, i-low carbon steel-copper kunye nezinye iisinyithi ezahlukeneyo. Ukuwelda kwe-laser kungenziwa phantsi kwayo nayiphi na imeko (igesi okanye ubushushu).

Umatshini wokuwelda we-laser ophathwa ngesandla okwangoku yimveliso esetyenziswa kakhulu kushishino lokuwelda, ikakhulu kuba nangona esi sixhobo sibonakala sibiza kakhulu, sinokonga iindleko zomsebenzi kakuhle. Iindleko zomsebenzi zabawelda zibiza kakhulu. Ukusebenzisa oku Le mveliso isombulula ingxaki yokuqeshwa kwabawelda okubizayo nokunzima. Ngaphezu koko, umatshini wokuwelda we-laser ophathwa ngesandla ufumene udumo olukhulu kumawaka abathengi ngenxa yobomi bawo obude kunye nokusetyenziswa kwamandla aphantsi.

Ukuba ufuna ukufunda okungakumbi malunga nokucoca nge-laser, okanye ufuna ukuthenga umatshini wokucoca nge-laser ongcono kuwe, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngokuthe ngqo!

Ixesha lokuthumela: Disemba-03-2022