Fortune Laser Automatic 300W Yag Laser Mold Welding Machine

Fortune Laser Automatic 300W Yag Laser Mold Welding Machine

Basic Misimboti Laser Machine

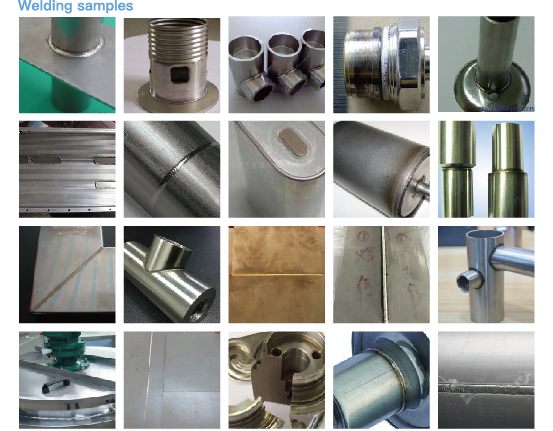

Ina-axis yekubatanidza laser welding muchina unotora advanced single-lambi ceramic reflector cavity, simba rine simba, programmable laser pulse uye hungwaru system management.Iyo Z-axis yetabhenakeri inogona kufambiswa kumusoro uye pasi kuti itarise, inodzorwa nePC yemaindasitiri.Yakashongedzwa neyakajairika yakaparadzaniswa X/Y/Z axis matatu-dimensional otomatiki inofamba tafura, yakashongedzerwa neyekunze yekutonhodza system.Imwe sarudzo inotenderera inotenderera (80mm kana 125mm modhi inosarudzika).Iyo yekutarisa sisitimu inotora microscope uye CCD

300w otomatiki Laser Welding Machine Hunhu

Fortune Laser Automatic Laser Welding Machine Technical Parameters

| Model | FL-Y300 |

| Laser Simba | 300W |

| Cooling Way | Mvura Kutonhora |

| Laser Wavelength | 1064nm |

| Laser Kushanda Medium Nd 3+ | Nhoroondo ye YAG Ceramic Conde |

| Spot Diameter | φ0.10-3.0mm inogona kugadziriswa |

| Pulse Width | 0.1ms-20ms inogadziriswa |

| Welding Depth | ≤10mm |

| Machine Power | 10KW |

| Kudzora System | PLC |

| Chinangwa uye Positioning | Maikorosikopu |

| Worktable Stroke | 200×300mm (Z-axis electric lift) |

| Power Demand | Customized |