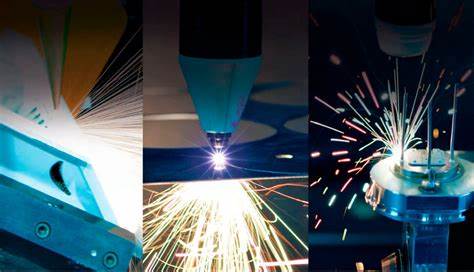

Simbi isina ngura inoshandiswa zvakanyanya mumaindasitiri akasiyana-siyana nekuda kwehunhu hwayo hwakasiyana hwakadai sekudzivirira ngura uye kugona kwayo kugadzira zvinhu. Nekufambira mberi kwetekinoroji, kusanganisa nelaser kwave nzira itsva yekusanganisa, ine mabhenefiti akawanda kana tichienzanisa nehunyanzvi hwechinyakare hwekusanganisa. Zvisinei, chimwe chezvinetso zvewelding nelaserndiko kuchinja kwesimbi isingatsvi. Munyaya ino, tichakurukura maitiro ekudzivirira kuchinja kwesimbi isingatsvi nelaser welding uye kuongorora zvinhu zvine chekuita nazvo.

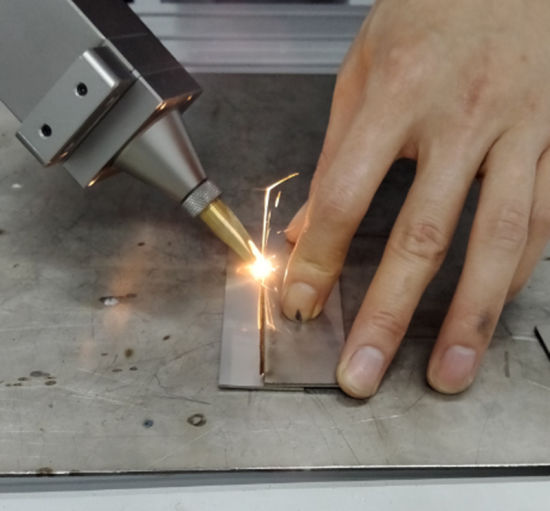

Kutanga, zvakakosha kunzwisisa kuti sei kupinza nelaser kuchikonzera kuchinja kwesimbi isingatsvi. Kupinza nelaser kunosanganisira kushandisa danda relaser rine simba guru kunyungudutsa nekubatanidza pamusoro pesimbi mbiri pamwe chete. Munguva iyi, kupisa nekukurumidza nekutonhodza kunokonzera kuchinja kwekupisa, izvo zvinokonzera kuchinja kwenzvimbo yakasungirirwa. Kunyange zvazvo izvi zvichiita sezvisingadzivisiki, kune matanho akati wandei anogona kutorwa kuderedza kana kutobvisa kukanganisa.

Imwe yenhanho dzekutanga mukudzivirirawelding nelaserKukanganiswa kusarudzwa nokungwarira kwezviyero zve laser welding zvakakodzera. Zvinhu zvakaita sesimba re laser, kumhanya kwe welding, uye kutarisa kwe beam zvinofanirwa kugadziriswa kuti zviwane hunhu hwe weld hunodiwa. Nekugadzirisa izvi, kupisa kunogona kudzorwa uye thermal deformation inokonzera kukanganiswa kunogona kuderedzwa. Pamusoro pezvo, kushandisa pulsed mode pane continuous wave mode kunobatsira kuderedza nzvimbo inokonzerwa nekupisa uye deformation inotevera.

Chimwe chinhu chakakosha kufunga nezvacho idhizaini yechinobatanidza pachacho. Chimiro, saizi uye magadzirirwo ejoinhi zvinogona kukanganisa zvakanyanya huwandu hwekushanduka kunoitika panguva yekushanda kwejoinhi.welding nelaserKuti uderedze kukanganiswa, zvinokurudzirwa kushandisa ma weld akafara uye kudzivirira makona akapinza kana akapinza. Izvi zvinoparadzira kupisa zvakaenzana uye zvinoderedza kupisa kwakanyanya. Pamusoro pezvo, kushandiswa kwe fillet welds (ma weld ane maumbirwo akakombama kana akakombama) kunobatsirawo kuderedza kukanganiswa.

Pamusoro pekugadzirisa ma "welding parameters" uye dhizaini yemajoini, kusarudzwa kwehukobvu hwezvinhu kunoitawo basa rakakosha mukudzivirira kukanganiswa. Machira esimbi asina ngura akakora anowanzo shanduka nekuda kwekupisa kwawo kwakanyanya. Kuti uderedze izvi, zvinokurudzirwa kushandisa machira esimbi asina ngura akatetepa kana kushandisa "heat sink" kana "cooling system" panguva yekusanganisa. Aya ma "cooling mechanisms" anobatsira kubvisa kupisa kwakanyanya uye kuderedza kupisa, zvichideredza kukanganiswa.

Pamusoro pezvo, kushandisa nzira dzakakodzera dzekugadzirisa nekubatanidza zvinogona kubatsira zvikuru kudzivirira kukanganisa kwewelding nelaser. Chigadziko ichi chinoreva nzvimbo uye kugadzirisa kwechinhu chebasa panguva yekusanganisa. Zvakakosha kuve nechokwadi chekuti chinhu chebasa chakanyatsotsigirwa uye chakarongeka kudzivirira kufamba kana kuchinjika panguva yekusanganisa. Kubatanidza, kune rumwe rutivi, kunosanganisira kubata chinhu chebasa panzvimbo uchishandisa majig kana zvinhu zvakagadzirwa zvakananga. Kubatanidza kwakakodzera kunobatsira kuchengetedza mwero waunoda wekuchinjika uye kunoderedza mukana wekuchinjika.

Chekupedzisira, kurapwa kwekupisa mushure mekusveta kunogona kushandiswa kuderedza kushushikana kwakasara uye kuderedza kukanganiswa. Kuisa simbi, kuderedza kushushikana, uye kunyange maitiro ari nyore ekutonhodza mhepo anobatsira kudzikamisa zvivakwa zvakasveta uye kuderedza kukanganiswa. Kushandiswa kwemidziyo yekurapa kupisa yakasarudzika uye matekiniki kunogona kupa kutenderera kwekupisa kunodiwa kuti simbi isina tsvina yakasveta irambe yakasimba uye isina kusvibiswa.

Muchidimbu,welding nelaserinopa mabhenefiti akawanda pamusoro penzira dzechinyakare dzekuwelda maererano nekumhanya, kunyatsorongeka uye mhando. Zvisinei, kushanduka kwesimbi isingatsvinda kunokonzera matambudziko pakuita kwewelding nelaser. Kukanganiswa kwewelding nelaser yesimbi isingatsvinda kunogona kugadziriswa zvinobudirira nekusarudza nekungwarira uye kugadzirisa maparamita ewelding, kugadzira marongero akakodzera ejoints, kufunga nezvekukora kwezvinhu, kushandisa matekiniki akakodzera ekugadzirisa uye ekubatanidza, uye kushandisa kurapwa kwekupisa mushure mekuwelda. Matanho aya, pamwe chete nehunhu hwesimbi isingatsvinda, anobatsira pakuwelda kwemhando yepamusoro pasina kukanganisa kwakanyanya.

Kana muchida kudzidza zvakawanda nezve laser welding, kana kuti muchida kutenga muchina we laser welding wakanakisisa kwamuri, ndapota siyai meseji pawebhusaiti yedu uye titumirei email zvakananga!

Nguva yekutumira: Chikunguru-18-2023