Kushongedza neLaserndeimwe yezvinhu zvakakosha pakushandiswa kwetekinoroji yekugadzirisa zvinhu zve laser. Inonyanya kushandiswa pakushongedza zvinhu zvine madziro matete uye pakushongedza nekukurumidza. Maitiro ekushongedza ndeemhando yekupisa, kureva kuti, mwaranzi ye laser inopisa pamusoro pechinhu chebasa, uye kupisa kwepamusoro kunopararira mukati kuburikidza nekudzora kupisa. Nekudzora maparamita akadai sehupamhi, simba, simba repamusoro uye kudzokorora kwekurova kwe laser, chinhu chebasa chinonyunguduka kuti chigadzire dziva rakanyungudutswa. Chinonyanya kushandiswa mukugadzira michina, aerospace, mota, powder metallurgy, biomedical microelectronics industry nedzimwe nzvimbo.

Nekukura kuri kuita mota itsva dzinoshandisa simba, kuwedzera kwekugadzirwa kwemabhatiri emagetsi kwakakonzera kukura kwe laser welding. Kubva muhafu yechipiri ya2018, laser welding inobatwa nemaoko yave ichizivikanwa zvishoma nezvishoma, uye yave nzvimbo yakajeka mumusika we laser welding muhafu yekutanga yegore rino. Nedanho rehunyanzvi razvino uye mamiriro ekushandiswa kwewelding nelaser inobatwa nemaoko, zvingangoita kuti ichatsiva musika weTIG welding muchina wekare (argon arc welding).

Mumakore achangopfuura,malaser efaibhaVafambira mberi zvikuru, uye zvakanakira zvavo zvinosanganisira: mwero wekuchinja kwemagetsi ane photoelectric, kupisa kunokurumidza kupera, kuchinjika kwakanaka, kugona kwakasimba kudzivirira kukanganiswa, mutengo wakaderera, kurarama kwenguva refu, pasina kugadzirisa, pasina kugadzirisa, kugadzikana kwakanyanya, saizi diki, Midziyo yekuwedhesa laser inobata nemaoko ichishandisa fiber lasers yavewo ichikura zvishoma nezvishoma.

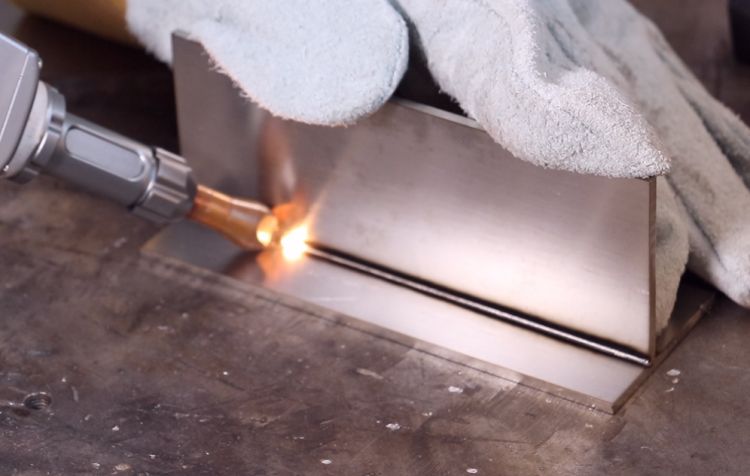

Kushongedza neLaserinoda kunyatsogadzirwa kwechinhu chebasa, uye musono we weld unowanzo kanganisa. Kuti agadzirise dambudziko iri, mugadziri anotaura nezvemidziyo ye laser welding yeplane yakakosha kuti agadzire michina ye laser welding inobatwa neruoko ine nzvimbo inotenderera. Laser iri muchimiro che "8" kana "0" type swing inogona kuderedza kunyatsogadzirwa kwechinhu chebasa uye kuwedzera kupinda kwe welding. Mushure mekugadzirisa nekuvandudza, michina ye laser welding inobatwa neruoko iripo ine simba re 0.5-1.5KW, uye saizi nehuremu hwemidziyo yakaenzana nemichina ye argon arc welding, iyo inogona weld simbi plates dze 3mm kana pasi. Kuti vagadzirise zvikanganiso zvekusakwana kwesimba re weld rezvivakwa zve laser welding, mumakore achangopfuura, vagadziri vemidziyo vakabatanidza michina ye automatic feeding zvichibva pa laser welding, uye vakagadzira michina ye laser yekuzadza waya inobatwa nemaoko inogona kupa waya otomatiki, iyo inosangana nezvinodiwa zvesimbi plates dzakatetepa dziri pasi pe 4m. Kupinza kunogona kutsiva nekupfuura kupinza argon arc, kuita kumhanya kukuru, kupisa kwakaderera, kushanduka kudiki, kupinza kuchengetedzwa kwezvakatipoteredza kusingadhuri, uye mutengo wekugadzira wakaderera pane wekubatanidza argon arc pasi pemamiriro akafanana.

Pakushanda, musoro wemuchina wekubatanidza simbi unobatwa neruoko une upamhi hwekuskena, uye dhayamita yawo idiki, saka pakubatanidza simbi, inoskena kubva pane imwe nzvimbo kuenda kune imwe mutsetse nemutsetse, nokudaro ichigadzira weld bead. Kana tichienzanisa nemuchina wekubatanidza simbi unotonhora wekare, kumhanya kwekubatanidza simbi we laser welding inobatwa neruoko kuchakurumidza, uye maitiro ekubatanidza simbi anotora kamwe chete anoratidza kuti akakodzera kubatanidza simbi dzakawanda dzemisungo mirefu yakatwasuka.

Uye muchina wekucheka welaser unobatwa nemaoko hautore nzvimbo yakawanda, uye unowanzo shongedzwa nemisoro yakasiyana-siyana inobatwa nemaoko. Zvichienderana nezvinodiwa zvakasiyana zvezvikamu zvesimbi zvakaita sekucheka kwekunze, kucheka kwemukati, kucheka kwekona yekurudyi, kucheka kwemucheto wakamanikana, uye kucheka kwenzvimbo hombe, misoro yakasiyana inobatwa nemaoko inogona kusarudzwa. Zvigadzirwa zvinogona kubatanidzwa zvakasiyana-siyana, uye chimiro chechigadzirwa chinochinjika zviri nyore. Kune maworkshop ekugadzira anoitwa mukugadzira zvinhu zvidiki uye kwete kucheka kukuru, michina yekucheka yelaser inobatwa nemaoko ndiyo sarudzo yakanakisa.

Zvinhu zvakasiyana zvesimbi zvine nzvimbo dzakasiyana dzekunyunguduka: kugadzwa kwezviyero zvekuwelda zvemhando dzakasiyana dzezvinhu zvekuwelda kwakaoma, uye hunhu hwethermophysical hwezvinhu zvekuwelda hucharatidza kusiyana kwakasiyana nekuchinja kwetembiricha; mwero wekunyudzwa kwemhando dzakasiyana dzezvinhu zvelaser uchasiyanawo. Kuchinja kwetembiricha kunoratidza kusiyana kwakasiyana; kunyunguduka kwejoini rekusolder uye kushanduka kwechimiro chenzvimbo inokanganiswa nekupisa panguva yekusimba kweweldment; zvikanganiso zvejoini yemuchina wekuwelda welaser unobatwa nemaoko, kushushikana kwekubatanidzwa kwewelding uye kushanduka kwekushisa, nezvimwewo. Asi chinonyanya kukosha ndechekukanganisa kwehunhu hwezvinhu zvekuwelda pahunhu hwemacro nemicro hweweld.

Zvinhu zvipi zvinogonamuchina wekunamira we laser unobata nemaokokunamira?

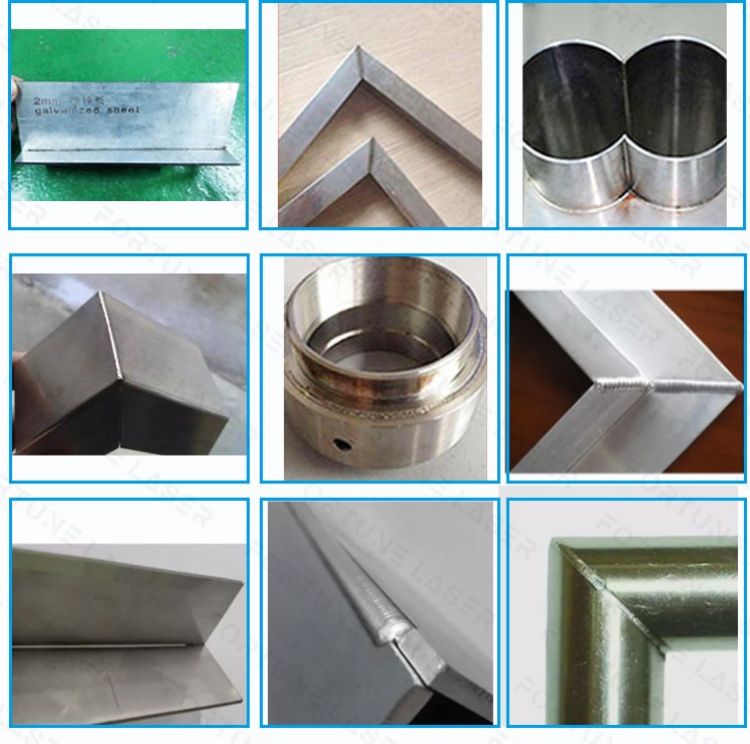

1. Simbi isina ngura

Simbi isina ngura ine mwero wekuwedzera kwekupisa, uye inowanzo pisa panguva yekuwelda. Kana nzvimbo inokanganiswa nekupisa yakakura zvishoma, inokonzera matambudziko akakomba ekushanduka. Zvisinei, kupisa kunokonzerwa nemuchina wekuwelda welaser unobatwa nemaoko panguva yese yekuwelda kwakaderera. Pamwe chete nekufambiswa kwekupisa kwakaderera, mwero wesimba rakawanda uye kushanda zvakanaka kwekunyunguduka kwesimbi isina ngura, maweld akaumbwa zvakanaka, akapfava uye akanaka anogona kuwanikwa mushure mekuwelda.

2. Simbi yekabhoni

Simbi yekabhoni yakajairika inogona kusungirirwa zvakananga nekushandisa laser welding nemaoko, mhedzisiro yacho inofanana nesimbi isina ngura, uye nzvimbo inokanganiswa nekupisa idiki, asi kana uchibatanidza simbi yekabhoni yepakati neyakakwira, tembiricha yasara inenge yakakwira, saka zvichiri kudikanwa kusungirirwa usati wabatanidza. Kupisa nekuchengetedza kupisa mushure mekusanganisa kuti uderedze kushushikana uye kudzivirira kutsemuka. Pano tinogona kutaura nezvemuchina wekusanganisa cold welding. Simbi yepakati neyakakwira kabhoni inogona kusungirirwa kana kugadziriswa nekukurumidza zvishoma nezvishoma ne cold welding uye cast iron welding wire. Panyaya yekudzora tembiricha, kudzora tembiricha, uye kudzora tembiricha, muchina wekusanganisa cold welding unogona kudzidzisa laser welding nemaoko kuti ishande zvakanaka pane kupisa kwasara mushure mekusanganisa.

3. Simbi yesimbi

Yakakodzera kusanganisa mhando dzakasiyana dzesimbi, uye mhedzisiro yekusanganisa yakanaka kwazvo.

4. Aruminiyamu nearuminiyamu chiwanikwa

Aruminiyamu nearuminiyamu zvinhu zvinopenya zvakanyanya, uye porosity inogona kuoneka mudziva rakanyungudutswa kana pamudzi panguva yekusanganisa. Zvichienzaniswa nezvinhu zvesimbi zvekare, aruminiyamu nearuminiyamu zvine zvinodiwa zvakanyanya zvema parameter, asi chero bedzi ma parameter ekubatanidza akasarudzwa akakodzera, musono we weld une hunhu hwakafanana nesimbi yekutanga unogona kuwanikwa.

5. Mhangura nemhangura yesimbi

Kufambiswa kwemafuta emhangura kwakasimba kwazvo, uye zviri nyore kukonzera kupinda kusina kukwana uye kusanganiswa zvishoma panguva yekupinza. Kazhinji, zvinhu zvemhangura zvinodziiswa panguva yekupinza kuti zvibatsire kupinza. Pano tiri kutaura nezvezvinhu zvemhangura zvakatetepa. Kupinza kwemafuta nelaser kunobata ruoko zvakananga, nekuda kwesimba rayo rakasimba uye kumhanya kwekubatanidza, hakukanganisi zvakanyanya nekupisa kwakanyanya kwemafuta emhangura.

6. Kusonerera pakati pezvinhu zvakasiyana

Muchina we laser welding unobatwa nemaoko unogona kuitwa pakati pemhando dzakasiyana dzesimbi, dzakadai se copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, low carbon steel-copper nedzimwe simbi dzakasiyana. Laser welding inogona kuitwa pasi pechero mamiriro (gasi kana tembiricha).

Muchina wekucheka welaser unobatwa nemaoko parizvino unoshandiswa zvakanyanya muindasitiri yekucheka, kunyanya nekuti kunyangwe michina iyi ichitaridzika kunge inodhura, inogona kuchengetedza mari yevashandi zvakanaka. Mari yevashandi vekucheka welders inodhura zvakanyanya. Kushandisa izvi Chigadzirwa ichi chinogadzirisa dambudziko rekudhura uye kwakaoma kutsvaga vekucheka welders. Uyezve, muchina wekucheka welaser unobatwa nemaoko wakawana rumbidzo kubva kuzviuru zvevatengi nekuda kwehupenyu hwawo hwekushanda kwenguva refu uye kushandiswa kwesimba shoma.

Kana muchida kudzidza zvakawanda nezvekuchenesa nelaser, kana kuti muchida kutenga muchina wekuchenesa nelaser wakanakisisa, ndapota siyai meseji pawebhusaiti yedu uye titumirei email zvakananga!

Nguva yekutumira: Zvita-03-2022