Umshini wokushisela we-laser uhlobo lwemishini yokushisela evame ukusetshenziswa ekukhiqizweni kwezimboni, futhi futhi uwumshini obalulekile ekucutshungulweni kwezinto ze-laser. Kusukela ekuthuthukisweni kokuqala komshini wokushisela we-laser kuya kubuchwepheshe bamanje, kuye kwavuthwa kancane kancane, kuye kwatholakala izinhlobo eziningi zemishini yokushisela, okuhlanganisa nomshini wokushisela we-laser ophathwayo osetshenziswa kabanzi, umsizi onamandla wemisebenzi yokushisela.

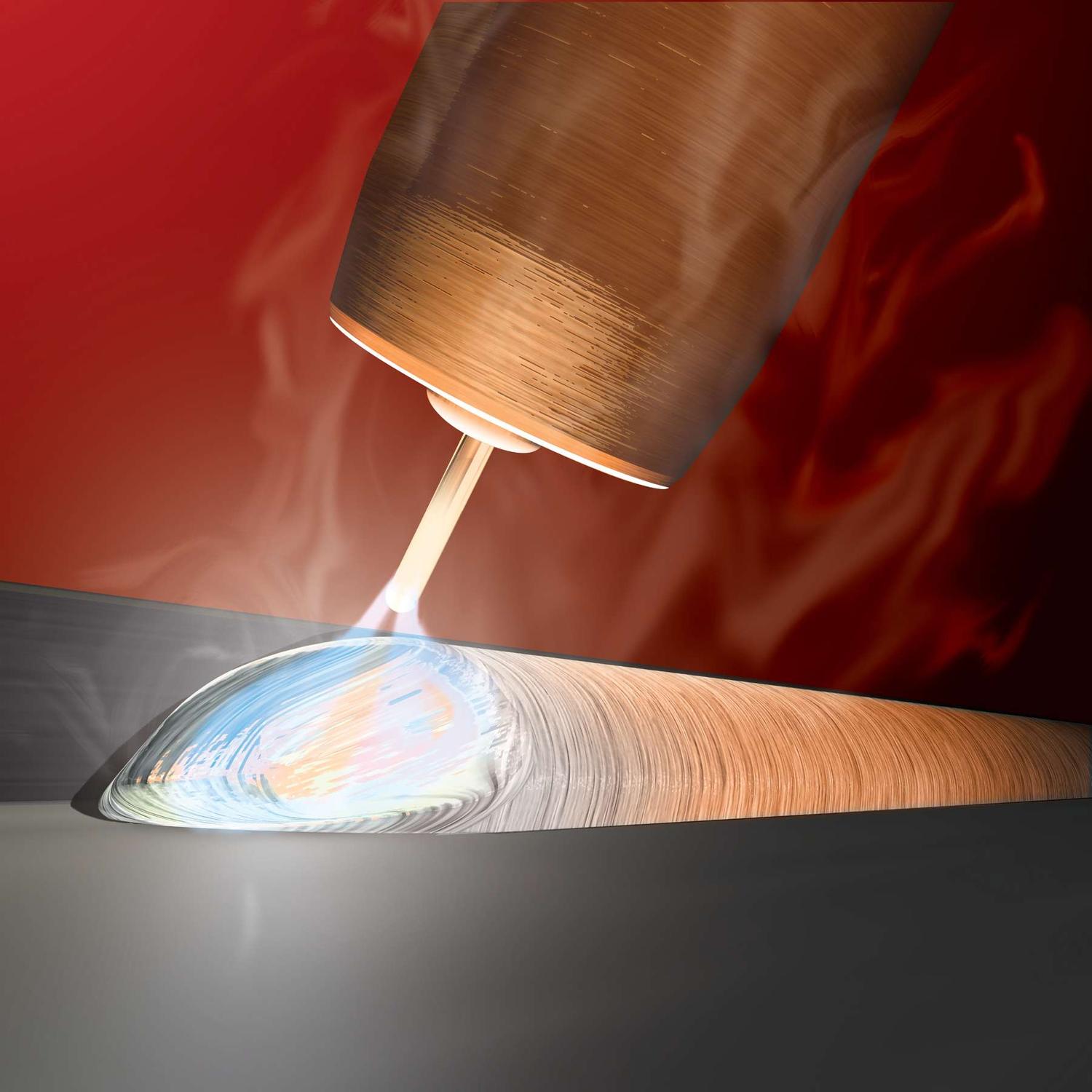

Kungani usebenzisa igesi yokuvikela lapho ushisela ngomshini wokushisela we-laser ophathwa ngesandla? Umshini wokushisela we-laser ophathwa ngesandla uhlobo olusha lwendlela yokushisela, ikakhulukazi yokushisela izinto ezicijile ezinodonga oluncane kanye nezingxenye eziqondile, ezingafeza ukushisela okuqondile, ukushisela okuqondile, ukushisela okuqondile, ukushisela okuqondile, njll., ngesilinganiso sokujula okuphezulu, ububanzi obuncane bokushisela, kanye nokushisa. Indawo encane ethintekile, ukuguqulwa okuncane, isivinini sokushisela esisheshayo, umthungo wokushisela obushelelezi nomuhle, asikho isidingo sokubhekana noma sokudinga ukwelashwa okulula ngemva kokushisela, umthungo wokushisela wekhwalithi ephezulu, akukho mbobo, ukulawula okuqondile, indawo encane yokugxila, ukunemba okuphezulu kokubeka, ukwenza okuzenzakalelayo okulula ukukubona.

1. Kungavikela ilensi yokugxila ekungcolisweni komhwamuko wensimbi kanye nokuchitheka kwamaconsi oketshezi

Igesi yokuvikela ingavikela ilensi yokugxila yomshini wokushisela nge-laser ekungcolisweni komhwamuko wensimbi kanye nokuchitheka kwamaconsi oketshezi, ikakhulukazi ekushiseni okunamandla amakhulu, ngoba ukuphuma kuba namandla kakhulu, futhi kudingeka kakhulu ukuvikela ilensi ngalesi sikhathi.

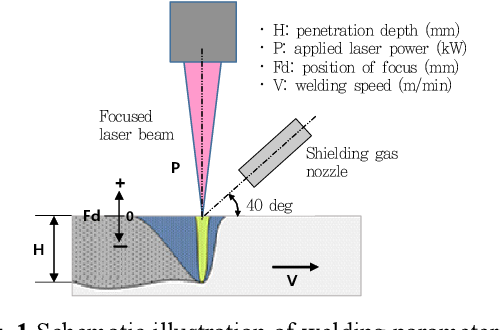

2. Igesi yokuvikela iyasebenza ekuqedeni ukuvikela kwe-plasma ekushiseni kwe-laser enamandla aphezulu

Umhwamuko wensimbi umunca umsebe we-laser bese u-ionize ube yifu le-plasma, kanti igesi evikelayo ezungeze umhwamuko wensimbi nayo i-ionize ngenxa yokushisa. Uma kukhona i-plasma eningi kakhulu, umsebe we-laser udliwa yi-plasma. I-plasma ikhona endaweni yokusebenza njengamandla esibili, okwenza ukungena kungajulile futhi ubuso bechibi lokushisela bube banzi.

Izinga lokuhlanganiswa kwama-electron landa ngokwandisa ukushayisana kwama-electron ngemizimba emithathu nama-ion nama-athomu angathathi hlangothi ukuze kuncishiswe ukuminyana kwama-electron ku-plasma. Uma ama-athomu angathathi hlangothi elula, kulapho imvamisa yokushayisana iphakama khona futhi izinga lokuhlanganiswa liphakama; ngakolunye uhlangothi, igesi evikelayo kuphela enamandla aphezulu e-ionization ngeke ikhulise ukuminyana kwama-electron ngenxa ye-ionization yegesi ngokwayo.

3. Igesi elivikelayo lingavikela umsebenzi wokusebenza ekungcolisweni ngesikhathi sokushisela

Umshini wokushisela nge-laser kumele usebenzise uhlobo oluthile lwegesi ukuvikelwa, futhi uhlelo kufanele lusethwe ngendlela yokuthi igesi evikelayo ikhishwe kuqala bese kukhishwa i-laser, ukuze kuvinjelwe ukushiswa kwe-laser eshukunyiswayo ngesikhathi sokucubungula okuqhubekayo. Igesi engasebenzi ingavikela ichibi elincibilikisiwe. Uma ezinye izinto zishiswa kungakhathaliseki ukushiswa kwendawo, ukuvikelwa kungase kungacatshangwa, kodwa ezisetshenziswa eziningi, i-helium, i-argon, i-nitrogen kanye namanye amagesi kuvame ukusetshenziswa njengesivikelo ukuvimbela umsebenzi ukuthi ungashiswa ngesikhathi sokushiswa.

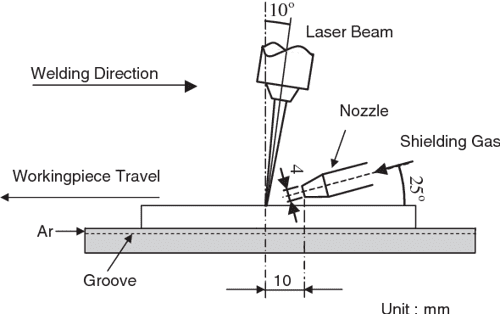

4. Umklamo wezimbobo ze-nozzle

Igesi yokuvikela ifakwa ngengcindezi ethile nge-nozzle ukuze ifinyelele ebusweni bento yokusebenza. Ukuma kwe-hydrodynamic kwe-nozzle kanye nobubanzi bendawo yokukhipha kubaluleke kakhulu. Kumelwe ibe nkulu ngokwanele ukushayela igesi yokuvikela efafaziwe ukuze imboze ubuso bokushisela, kodwa ukuze kuvikelwe ngempumelelo ilensi futhi kuvinjelwe umusi wensimbi ekungcoleni noma ekuchithekeni kwensimbi ekulimazeni ilensi, ubukhulu be-nozzle kufanele bulinganiselwe. Izinga lokugeleza kufanele futhi lilawulwe, ngaphandle kwalokho ukugeleza kwe-laminar kwegesi yokuvikela kuzoba nokuphazamiseka, futhi umoya uzohileleka echibini elincibilikisiwe, ekugcineni kwakheke ama-pores.

Ekushiseni nge-laser, igesi yokuvikela izothinta ukuma kwe-weld, ikhwalithi ye-weld, ukungena kwe-weld kanye nobubanzi bokungena. Ezimweni eziningi, igesi yokuvikela evuthelayo izoba nomthelela omuhle ku-weld, kodwa futhi ingase ibe nomthelela omubi.

Indima Enhle:

1) Ukushaywa kahle kwegesi yokuvikela kuzovikela ngempumelelo ichibi lokushisela ukuze kuncishiswe noma kugwenywe ukushiswa;

2) Ukushaywa kahle kwegesi yokuvikela kunganciphisa ngempumelelo ukuchitheka okukhiqizwa ngesikhathi sokushisela;

3) Ukushaywa kahle kwegesi evikelayo kungakhuthaza ukusabalala okufanayo kwechibi lokushisela lapho liqina, okwenza isimo sokushisela sifane futhi sibe sihle;

4) Ukushaywa kahle kwegesi evikelayo kunganciphisa ngempumelelo umphumela wokuvikela we-spume yensimbi noma ifu le-plasma ku-laser, futhi kwandise izinga lokusetshenziswa ngempumelelo kwe-laser;

5) Ukushaywa kahle kwegesi yokuvikela kunganciphisa ngempumelelo ukugoba kokushisela.

Uma nje uhlobo lwegesi, izinga lokugeleza kwegesi, ukukhetha imodi yokuvunguza kulungile, kungathola umphumela ofanele. Kodwa-ke, ukusetshenziswa okungalungile kwegesi evikelayo nakho kuzoletha imiphumela emibi ekushiseleni.

Umphumela Omubi:

1) Ukungafakwa kahle kwegesi yokuvikela kungabangela ukushintshwa okungekuhle:

2) Ukukhetha uhlobo olungalungile lwegesi kungabangela imifantu ku-weld, futhi kungaholela ekunciphiseni kwezakhiwo ze-weld;

3) Ukukhetha izinga lokugeleza elingalungile lokuqhuma kwegesi kungaholela ekungcolisweni okukhulu kwe-weld (kungakhathaliseki ukuthi izinga lokugeleza likhulu kakhulu noma lincane kakhulu), futhi kungabangela nokuthi insimbi yedamu le-weld iphazanyiswe kakhulu amandla angaphandle, okuholela ekuweni kwe-weld noma ukwakheka okungalingani;

4) Ukukhetha indlela yokujova igesi engalungile kuzokwenza ukuthi i-weld yehluleke ukufeza umphumela wokuvikela noma ingabi nomthelela wokuvikela noma ibe nomthelela omubi ekwakhekeni kwe-weld;

5) Ukugcwala kwegesi evikelayo kuzoba nomthelela othile ekungeneni kwe-weld, ikakhulukazi lapho kushintshwa amapuleti amancane, kuzonciphisa ukungena kwe-weld.

Ngokuvamile, i-helium isetshenziswa njengegesi evikelayo, engacindezela i-plasma ngezinga elikhulu, ngaleyo ndlela yandise ukujula kokungena futhi yandise isivinini sokushisela; futhi ilula ngesisindo futhi ingaphuma, futhi akulula ukubangela ama-pores. Yiqiniso, kusukela kumphumela wethu wangempela wokushisela, umphumela wokusebenzisa ukuvikelwa kwe-argon awumubi.

Uma ufuna ukufunda kabanzi ngokushisela nge-laser, noma ufuna ukuthenga umshini wokushisela nge-laser ongcono kakhulu kuwe,sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Feb-04-2023