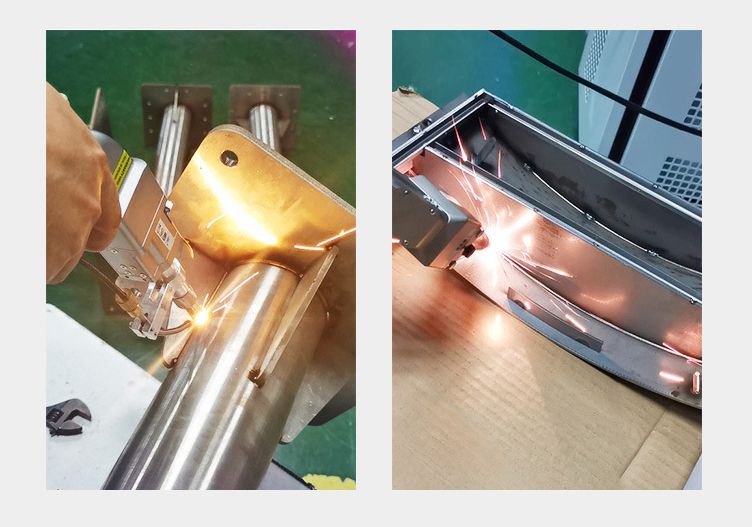

Njengamanje, emkhakheni wokushisela insimbi, imishini yokushisela ye-laser ephathwa ngesandla isetshenziswa kabanzi. Ngokuyisisekelo, izinsimbi ezingashiselwa ngokushisela kwendabuko zingashiselwa nge-laser, futhi umphumela wokushisela kanye nesivinini kuzoba ngcono kunezinqubo zokushisela zendabuko. Ukushisela kwendabuko kunzima ukushisela izinto zensimbi ezingenayo i-ferrous njenge-aluminium alloy, kodwa ukushisela kwe-laser kunezinhlelo zokusebenza eziningi, futhi i-aluminium alloy nezinye izinto nazo zingashiselwa kalula.

Ugongolo lwe-laser lunamandla anele, futhi lufakwa entweni nge-optical fiber, lumuncwa futhi luboniswe ngokufanayo, futhi amandla okukhanya amuncwayo azoqedela ukuguqulwa kokushisa okuhambisanayo, ukusabalala, ukuhanjiswa, ukulethwa kanye nemisebe, futhi into izothinteka ukukhanya ukuze ikhiqize ukushisa okuhambisanayo - Ukuncibilika - Ukushisa - Izinguquko kuma-microfacet ensimbi.

Uhla lokusetshenziswa kwemishini yokushisela ye-laser ephathwayo luya luba lukhulu kakhulu. Isetshenziswa emakhabetheni asekhishini nawasendlini yokugezela, ifenisha yensimbi engagqwali, amabhokisi okusabalalisa, izindonga zomnyango nefasitela zensimbi engagqwali, kanye nezitebhisi nama-lifti. Uma uyisebenzisa, udinga ukunaka ngokukhethekile ukuphepha.

Ngakho-ke yiziphi izinyathelo zokuphepha zokusetshenziswa ngokuphephile kwemishini yokushisela ye-laser ephathwayo?

1. Uma usebenzisa umshini wokushisela we-laser ophathwa ngesandla, umqhubi kumele aqeqeshwe ngokuqinile ngaphambi kokusebenza emsebenzini. I-laser ayikwazi ukushaya abantu noma izinto ezizungezile, ngaphandle kwalokho ingaletha imiphumela emibi kakhulu. , njengokusha, noma imililo, lokhu kuyingozi kakhulu, wonke umuntu kumele anake ngokukhethekile ukuphepha.

2. Nakuba inqubo yokushisela yomshini wokushisela we-laser ophathwa ngesandla isebenza ngokumelene nomsebenzi, izoqhubeka nokukhiqiza ukukhanya okuphezulu. Ngakho-ke, umqhubi kumele ahlonyiswe ngezibuko zokukhanya ezikhethekile zokuvikela amehlo akhe. Uma engagqoki izibuko zokubona, akuvunyelwe ukusebenzisa umshini wokushisela we-laser ophathwa ngesandla.

3. Uma usebenzisa umshini wokushisela we-laser ophathwa ngesandla, hlola njalo ingxenye yokuxhuma yentambo kagesi. Ezindaweni zohlangothi lokufaka kanye nohlangothi lokukhipha, kanye nezingxenye zokuxhuma zentambo yangaphandle kanye nezingxenye zokuxhuma zentambo yangaphakathi, njll., kubalulekile ukuhlola ngokucophelela ukuthi kukhona yini ukukhululeka kwezikulufu zokuxhuma. Uma kutholakala ukugqwala, ukugqwala kufanele kususwe ngokushesha. Susa ukuze kugcinwe ugesi omuhle futhi kuvinjelwe izingozi zokushaqeka kukagesi.

4. Faka i-ferrule yokuvikela. Ukusetshenziswa komshini wokushisela we-laser ophathwa ngesandla kudinga ne-ferrule yokuvikela, ukuze igesi ikwazi ukuphuma ngokulinganayo, ngaphandle kwalokho ithoshi lokushisela lingasha ngenxa yesekethe esifushane.

Uma usebenzisa umshini wokushisela we-laser ophathwa ngesandla, ungabhekisela endleleni engenhla yokusebenza, ukuze uqinisekise ukuphepha kokusetshenziswa futhi ugweme izingozi ngangokunokwenzeka. Imishini ye-laser izobangela ukulahlekelwa okuthile ngesikhathi sokusetshenziswa, futhi ukulungiswa okufanele kunganciphisa ukulahlekelwa nokwehluleka. Lokhu kudinga ukuhlolwa njalo kwemishini ye-laser.

Yiziphi izinyathelo zokulungisa imishini yokushisela nge-laser ephathwayo kanye nama-chiller?

1. Hlola njalo ukunikezwa kwamandla kwemishini. Ukuthi izintambo zikhululekile yini, ukuthi ukuvala ucingo kukhululekile noma kususiwe.

2. Hlanza uthuli njalo. Indawo yokusebenza yomshini wokushisela inothuli, futhi uthuli olungaphakathi komshini wokushisela lungahlanzwa njalo. Izikhala phakathi kwekhoyili yokusabela kanye namakhoyili ekhoyili, kanye nama-semiconductor anamandla kufanele zihlanzwe ngokukhethekile. I-chiller idinga ukuhlanza uthuli esikrinini sothuli kanye namafindo e-condenser.

3. Ithoshi lokushisela liyingxenye ebalulekile yomshini wokushisela, okufanele ihlolwe futhi ishintshwe njalo. Ngenxa yokuguguleka, imbobo ye-nozzle iba nkulu, okuzobangela ukungazinzi kwe-arc, ukuwohloka kokubonakala kwentambo yokushisela noma yokunamathela (ukusha emuva); ukuphela kwethiphu lokuxhumana kunamathele ekuchithekeni, futhi ukuphakelwa kwentambo kuzoba okungalingani; ithiphu lokuxhumana aliqiniswanga kahle. , uxhumano olunezintambo luzoshisa futhi lufakwe ku-weld lufe. Ithoshi elonakele kufanele lishintshwe njalo. I-chiller idinga ukushintsha amanzi ajikelezayo cishe kanye ngenyanga.

4. Naka izinga lokushisa elizungezile. Izinga lokushisa lendawo yokusebenza yethoshi lokushisela kanye ne-chiller akufanele libe phezulu kakhulu, elilodwa lizothinta ukushabalaliswa kokushisa kanye nokupholisa kwe-chiller, kanti elinye lizothinta ukusebenza okuvamile komshini wokushisela. Ikakhulukazi ehlobo elishisayo, kufanele kunakwe kakhulu izinga lokushisa legumbi, futhi imishini kufanele isetshenziswe endaweni enomoya omningi ngangokunokwenzeka. Izinga lokushisa ebusika akufanele libe phansi kakhulu, uma izinga lokushisa lamanzi ajikelezayo liphansi kakhulu, i-chiller ayikwazi ukuqaliswa.

Ngemva kokulungiswa kwansuku zonke, ikhwalithi yokushisela yomshini wokushisela we-laser ophathwa ngesandla iba ngcono, umphumela wokupholisa we-chiller uba ngcono, futhi isikhathi senkonzo singandiswa.

Lokhu okungenhla kuyiphuzu elibalulekile lendlela yokwenza ukulungiswa kwansuku zonke komshini wokushisela we-laser ophathwa ngesandla. Kufanele kuqashelwe ukuthi uma usebenzisa umshini wokushisela we-laser ophathwa ngesandla, umqhubi kumele aqeqeshwe ngobungcweti ukuze aqonde ukusetshenziswa okuqondile kwesibani ngasinye sesikhombisi sesistimu kanye nenkinobho ngayinye, futhi ajwayelane nolwazi oluyisisekelo lwemishini.

Uma ufuna ukufunda kabanzi mayelanaukushisela nge-laser, noma ufuna ukuthenga umshini wokushisela we-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Jan-10-2023