Umshini wokuhlanza we-Fortune Laser CW 1000W/1500W/2000W ububanzi, ongu-650mm, onefomethi enkulu

Umshini wokuhlanza we-Fortune Laser CW 1000W/1500W/2000W ububanzi, ongu-650mm, onefomethi enkulu

Ukusetshenziswa komshini wokuhlanza nge-laser ekukhiqizeni kwezimboni

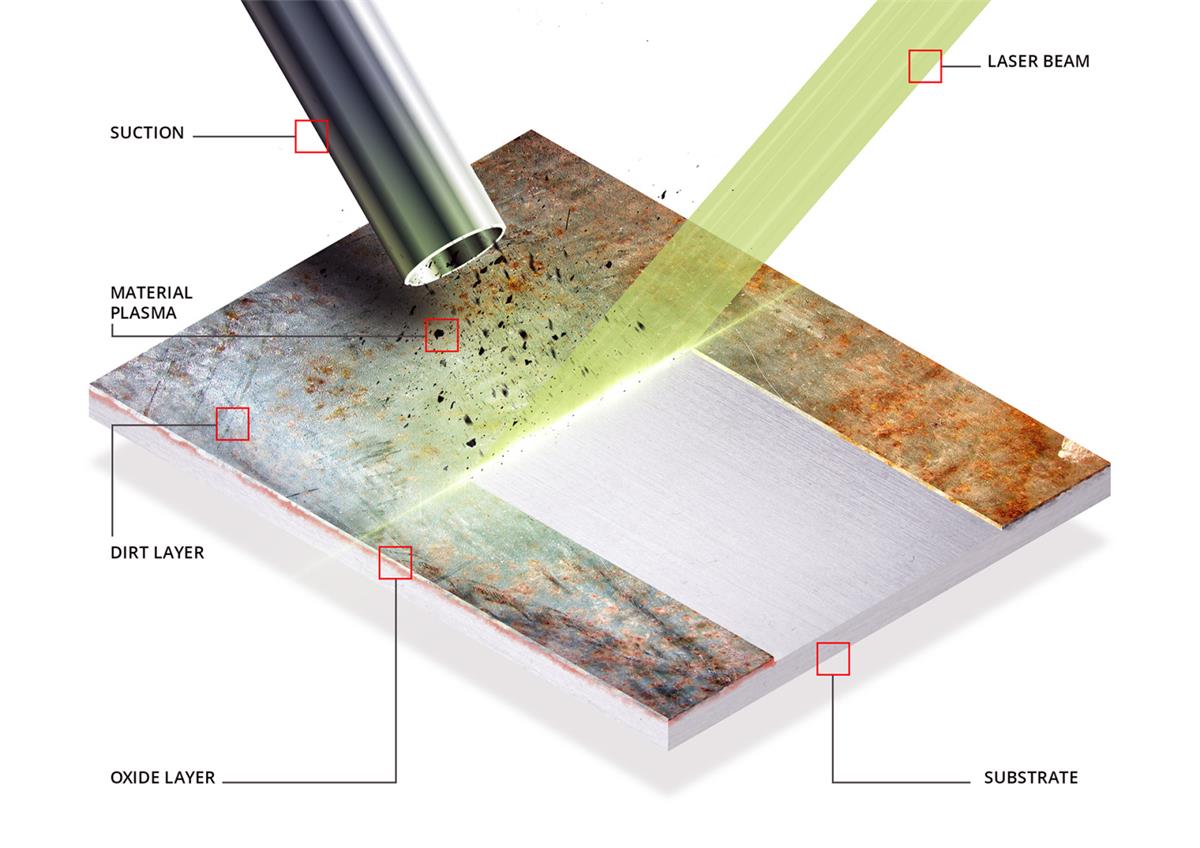

Enkambisweni yokukhiqiza nokukhiqiza ezimbonini, ukuze kuqinisekiswe ikhwalithi yomkhiqizo, kuyadingeka ukuhlanza amabala, amabala kawoyela, ukugqwala kanye nezinye izinto ezingcolisayo ebusweni bomkhiqizo. Izindlela zokuhlanza zesihlabathi zendabuko kanye nezindlela zokuhlanza ezihudulayo zibangele ukungcola okukhulu kanye nomonakalo emvelweni kanye nezinto ngokwazo, okungafanele ukulungiswa nokusetshenziswa kamuva. Manje ukusetshenziswa kobuchwepheshe obusha bokuhlanza nge-laser kwenza ukuhlanza ekukhiqizeni kwezimboni kube lula.

Izici Zomshini Wokuhlanza I-Laser we-1000W 1500W 2000W

Amapharamitha Obuchwepheshe Bokuhlanza Umshini We-Fortune Laser Mini Laser

Ukucushwa okuyinhloko

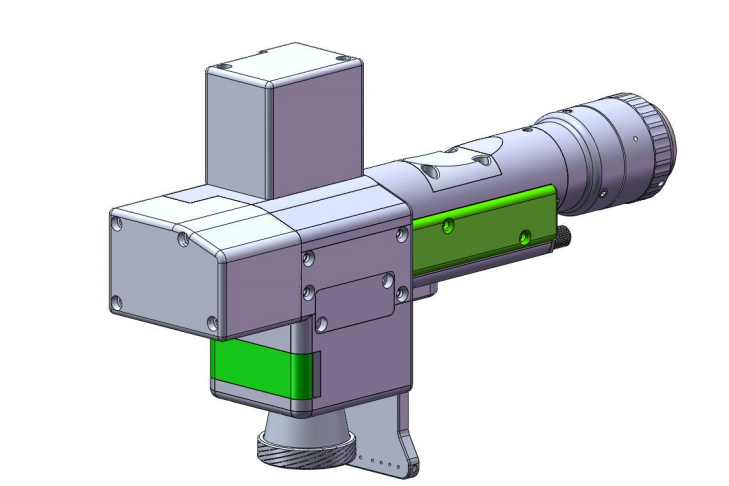

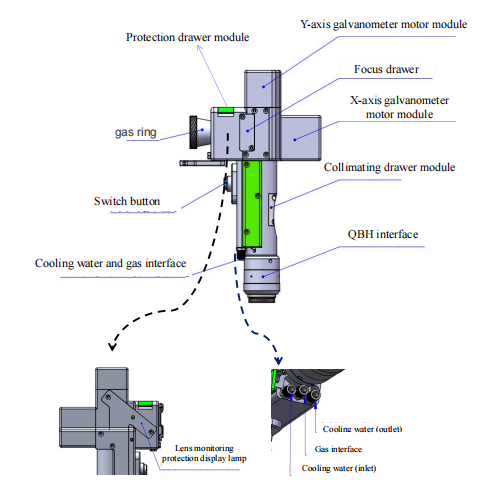

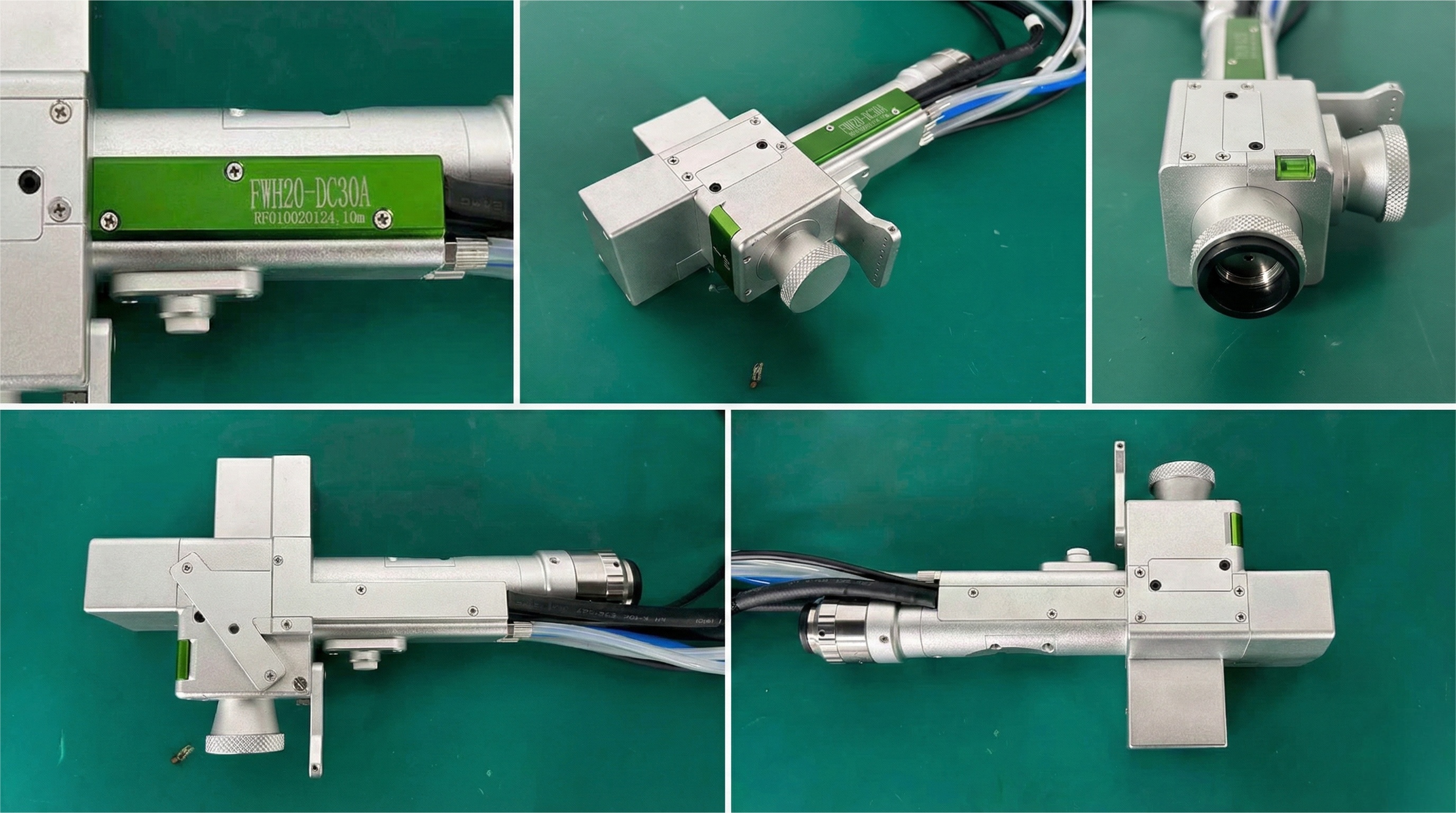

● Ikhanda le-laser elinezinhloso ezimbili. Eliphathwa ngesandla futhi elizenzakalelayo, ikhanda le-laser le-2D. Kulula ukubamba nokuhlanganisa nokwenza izinto ngokuzenzakalela; kulula ukusebenza futhi linemisebenzi eyahlukahlukene;

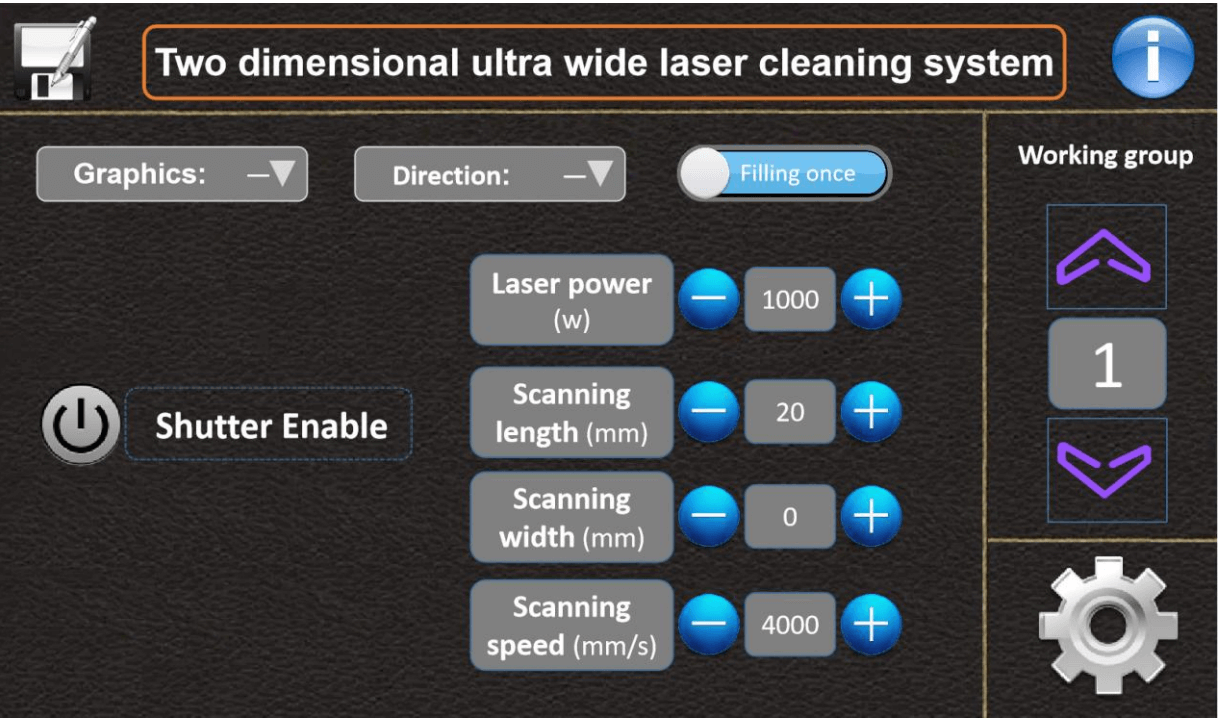

● Isofthiwe ye-AIMPLE

ISITOLO SEZITHOMBE EZIHLUKENE ZAMAPHARAMETHA

1. Isofthiwe elula khetha amapharamitha alungisiwe kusengaphambili ngqo

2. Ukulondoloza kusengaphambili zonke izinhlobo zesithombe sepharamitha izinhlobo eziyisithupha zehluzo zingakhethwa umugqa oqondile/ojikelezayo/ indilinga/unxande/ukugcwalisa unxande/ukugcwalisa indilinga

3. Kulula ukuyisebenzisa futhi isebenza

4. Isikhombikubona esilula

5. Ulimi lungaba yisiNgisi/isiShayina noma ezinye izilimi (uma kudingeka)

Ikhanda Le-Laser Ngenisa

Cindezela inkinobho eyinhloko yesikrini bese ucindezela inkinobho yokuphepha, bese isibani esibomvu sizojika ukuze sibuke kuqala. Uma udinga ukushintsha ihluzo kanye neminye imingcele, udinga ukufaka iphasiwedi ukuze ufake isikhombikubona esithuthukisiwe. Qaphela: Ngemva kokucindezela inkinobho yokuphepha, inkinobho yemvume yokukhipha igesi isesimweni esivulekile, bese ucindezela inkinobho yokulawula, ukukhanya kungakhishwa.

Uyazi izindlela ezi-5 zokusebenzisa imishini yokuhlanza nge-laser ekukhiqizeni kwezimboni?

1. Ukuhlanza embonini ye-elekthronikhi

Imboni ye-elekthronikhi isebenzisa ama-laser ukuhlanza izinto ezi-oxidating, futhi imboni ye-elekthronikhi ifanelekela ukusebenzisa ama-laser ukuhlanza izinto ezi-oxidating. Ngaphambi kokuba ibhodi lesifunda lifakwe i-solder, amaphini ezingxenye kumele afakwe i-oxidation ngokugcwele ukuqinisekisa umphumela wokuxhumana kagesi, futhi amaphini akufanele onakale ngesikhathi senqubo yokususa ukungcola. Ukuhlanzwa kwe-laser kungahlangabezana nezidingo zokusetshenziswa, futhi ukusebenza kahle komsebenzi kuphezulu kakhulu. Inaliti idinga ukushiswa nge-laser kanye kuphela.

2. Ukwelashwa kwangaphambi kokufaka i-brazing kanye nokushisela.

Ukulungiswa kokushisela nge-laser kungenye yezindlela eziningi zokuhlanza nge-laser, okuwusizo ekuhlanzeni ungqimba olungaphezulu lwensimbi ne-aluminium kusuka ezintweni ezingcolisayo njengezinsimbi ze-ferrous nezingezona eze-ferrous, izinto zokugcoba, njll., ukulungiselela ukushisela kwekhwalithi ephezulu. Kuphinde kuqinisekise amalunga abushelelezi futhi angenazo izimbobo.

3. Ukuhlanza isikhunta

Ukuhlanzwa kwezinhlobo zesikhunta zamathayi ngesikhathi sokukhiqiza kumele kuphephe futhi kuthembeke ukuze kuncishiswe isikhathi sokungasebenzi. Ngenxa yokuthi indlela yokuhlanza nge-laser ingaxhunywa nge-optical fiber ukuze kuhlanzwe i-engeli efile noma izingxenye zezinhlobo zesikhunta okunzima ukuzihlanza ezibangelwa ukukhanya, kulula kakhulu ukuyisebenzisa.

4. Ukuhlanzwa kopende wendiza endala

Ngemva kokuba indiza isisebenze isikhathi esithile, ubuso bendiza budinga ukupendwa kabusha, ngakho-ke kuyadingeka ukuthola indlela yokususa upende omdala. Indlela yendabuko yokuhlanza nokupenda ngomshini kulula ukulimaza ubuso bensimbi bendiza, okubangela izingozi ezifihliwe ekundizeni kwendiza. Akulula ukulimaza ungqimba lobuso uma usebenzisa umshini wokuwasha.

5. Ukwembozwa kokuhlanza kwendawo

Ukuhlanza nge-laser kungahlanza izembozo kanye nopende ekukhiqizweni kwezimboni njengezimoto, kugcinwe ubuqotho bezinto ezingaphansi komhlaba.

Ukuphathwa kokungajwayelekile

1. I-alamu yokupholisa amanzi ne-laser:

(1) I-alamu yelasi: Isiqandisi samanzi asivuliwe. Vala ilasi bese uyivula futhi.

(2) I-alamu yokupholisa amanzi: Izinga lokushisa lethangi lamanzi liphezulu kakhulu, i-compressor yokupholisa amanzi yonakele, i-refrigerant ayikho, noma indlela yokupholisa amanzi ayinawo amandla okupholisa anele. Uma izinga lamanzi ethangini lamanzi linganele i-alamu, engeza amanzi okupholisa.

2Isikrini esingavamile:

Uma isikrini sivaliwe, hlola ukuthi izintambo ezine eziyinhloko zebhokisi lokulawula kanye nesikrini zixhunywe kahle yini nokuthi kukhona yini ukuxhumana okubonakalayo.

3. Akukho ukukhanya okukhiphiwe:

(1) Ukuthi i-laser iqalwa ngendlela evamile yini.

(2) Ukuthi isikrini sinemvume yokuqalisa noma cha.

(3) Ukuthi isikrini sokubonisa siyasebenza yini uma kukhishwa ukukhanya.

(4) Ingabe kukhona inkinga ngokuxhumeka kwe-laser.

(5) Ilensi yokuvikela engcolile: ukukhanya kwangempela kubuthakathaka futhi akubonakali.

(6) Ukuthi indlela ye-optical iphakathi nendawo yini.

4Ukuphela kokukhanya okuphumayo ngokuzumayo ngesikhathi sokucubungula:

I-alamu ye-laser (izinkinga ezivamile: izinga lokushisa le-laser liphezulu kakhulu)

Yini okufanele uyinake lapho uthenga umshini wokuhlanza nge-laser?

1. Ngokuvamile, intengo yomshini wokuhlanza nge-laser ihlobene namandla awo, uma amandla e-laser ephezulu, intengo ibiza kakhulu. Kodwa ukuthengwa kwe-laser kusaxhomeke ezidingweni zakho ezithile, njengokuhlanza okulula kokugqwala okuntantayo, umshini wokuhlanza nge-laser onamandla aphansi ungakwanelisa, kodwa umshini wokuhlanza nge-laser onamandla aphezulu ungabangela umonakalo emsebenzini.

2. Ukuze kufezwe umphumela omuhle kakhulu wokuhlanza we-substrate ehambisanayo ezohlanzwa, ngokuvamile kuyadingeka ukulungisa amapharamitha ahambisanayo njengobude be-fiber, ukujula kwe-field lens focal, amandla okukhipha, ububanzi be-pulse kanye nesivinini sokuskena ngokwezici ze-substrate ezahlukene.

3. Imishini yokuhlanza nge-laser ihlukaniswe ngemishini yokuhlanza nge-laser ephathwa ngesandla kanye nemishini yokuhlanza nge-laser yedeskithophu emikhulu. Imishini yokuhlanza nge-laser ehlukene inemisebenzi nezindawo ezahlukene. Isibonelo, eminye imishini yokuhlanza nge-laser ephathwa ngesandla ifanelekela kuphela imishini ye-semiconductor, ngoba indawo ye-semiconductor idinga ukuvikelwa okukhulu kwemvelo, futhi ukungcola kwamakhemikhali akukwazi ukuvela. Kodwa-ke, eminye imikhumbi emikhulu ihlukile, futhi indawo ihlukile, futhi kuzoba nezikhala ezahlukahlukene emkhakheni wokusetshenziswa. Kuphela ngokukhetha imishini yokuhlanza eqondiwe futhi efanelekile lapho singafinyelela khona umphumela ofiselekayo.

4. Iziqu zomenzi womshini wokuhlanza nge-laser zizohlobana nochungechunge lwezinkinga zesevisi. Njengomshini wokuhlanza, imishini yokuhlanza nge-laser inezidingo ezithile zenqubo. Intengo izohluka kakhulu kuye ngenqubo, futhi kuyiqiniso nangemishini yezimboni. Ngaphambi kokukhetha imishini yokuhlanza, kunconywa ukuthi ucabangele iziqu zabakhiqizi bemishini yokuhlanza nge-laser. Kungcono kakhulu ukuhlonza kabusha amakhono abo ngokuvakashela amakhasimende abambisene nabo abakhona.