Mochini oa ho hloekisa oa Fortune Laser CW 1000W/1500W/2000W o nang le bophara ba 650mm o moholo oa ho hloekisa

Mochini oa ho hloekisa oa Fortune Laser CW 1000W/1500W/2000W o nang le bophara ba 650mm o moholo oa ho hloekisa

Tšebeliso ea mochini oa ho hloekisa laser tlhahisong ea indasteri

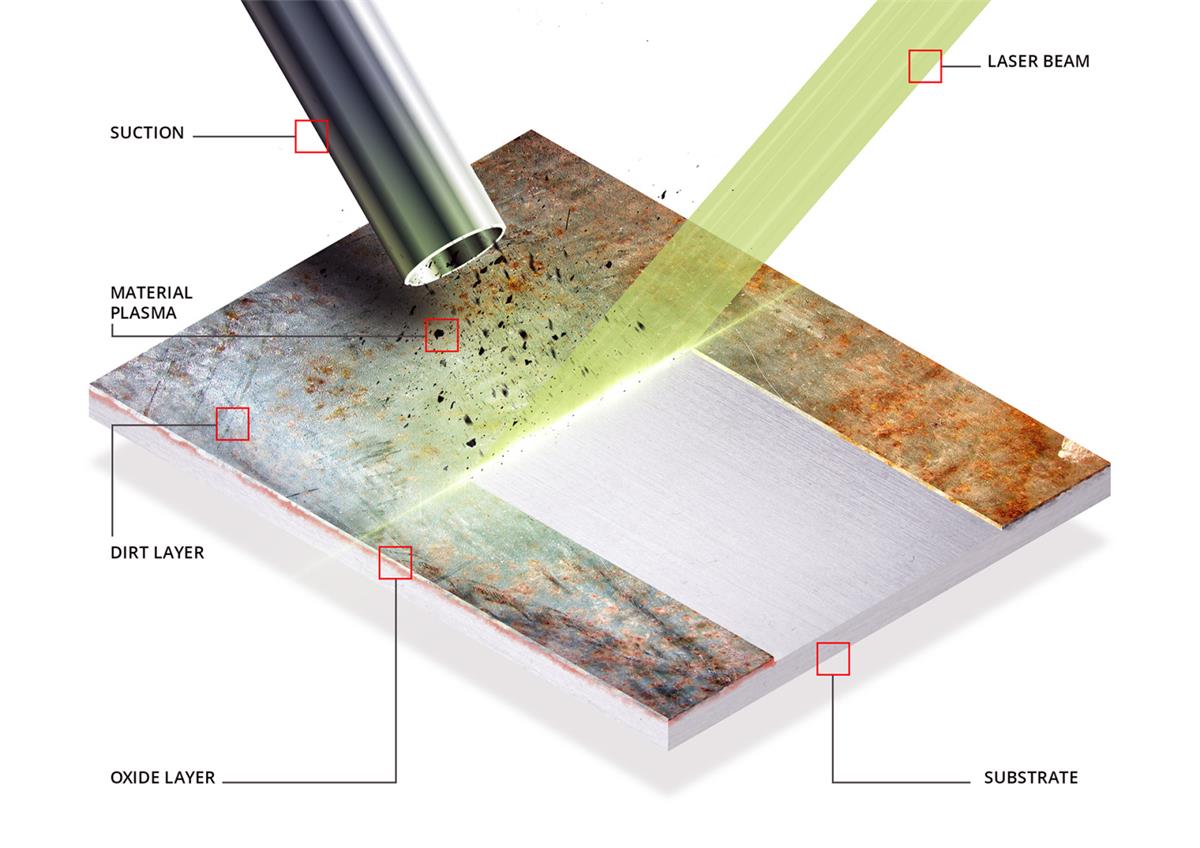

Mokgweng wa tlhahiso le tlhahiso ya diindasteri, e le ho netefatsa boleng ba sehlahiswa, ho hlokahala ho hlwekisa matheba, matheba a oli, mafome le ditshila tse ding tse hodima sehlahiswa. Mekhoa ya setso ya ho tjhesa lehlabathe le ho hlwekisa ka ho kgohla e bakile tshilafatso e kgolo le tshenyo tikolohong le thepa ka boyona, e leng se sa lokisetseng tlhokomelo le tshebediso ya yona hamorao. Jwale tshebediso ya theknoloji e ntjha ya ho hlwekisa ka laser e etsa hore ho hlwekisa tlhahisong ya diindasteri ho be bonolo.

Likarolo tsa Mochini oa ho Hloekisa Laser oa 1000W 1500W 2000W

Liparamente tsa Tekheniki tsa Mochini oa ho Hloekisa oa Lesea la Fortune Laser Mini

Tlhophiso e ka sehloohong

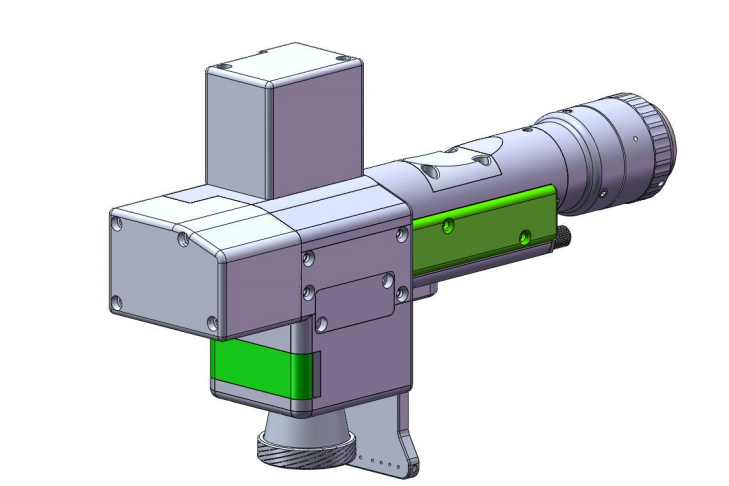

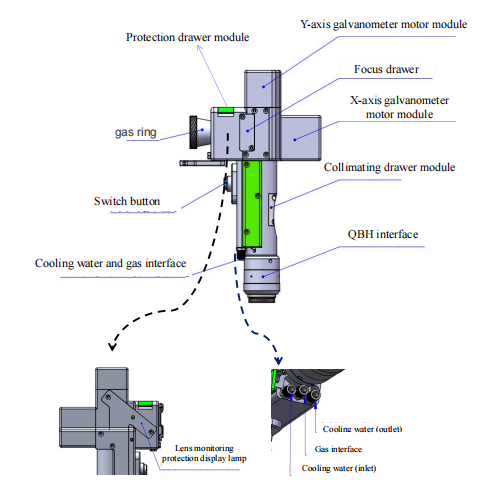

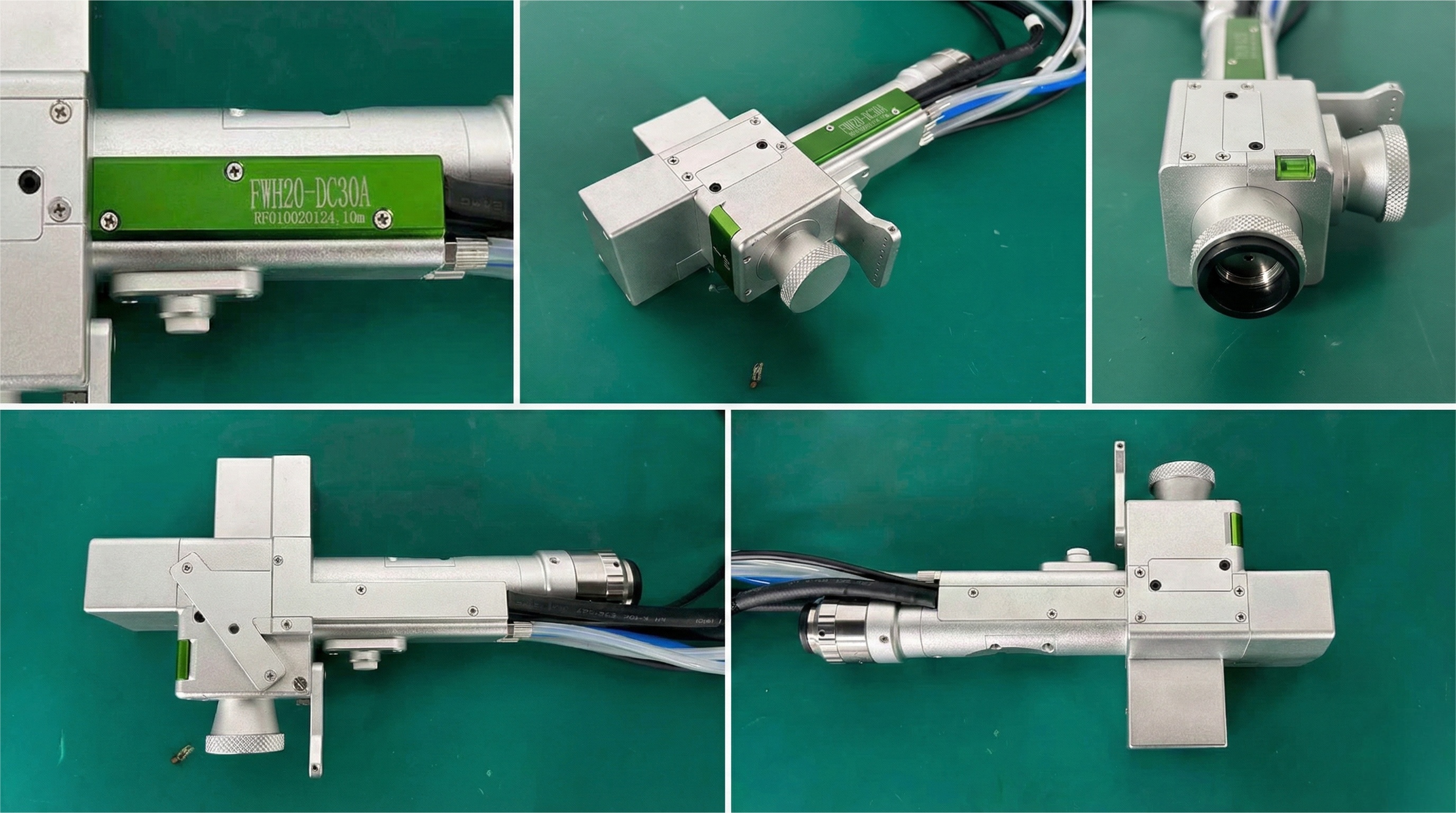

● Hlooho ea laser e nang le merero e 'meli e tšoaroang ka letsoho le e iketsang, hlooho ea laser ea 2D. Ho bonolo ho e tšoara le ho e kopanya le othomathiki; ho bonolo ho e sebelisa 'me e na le mesebetsi e fapaneng;

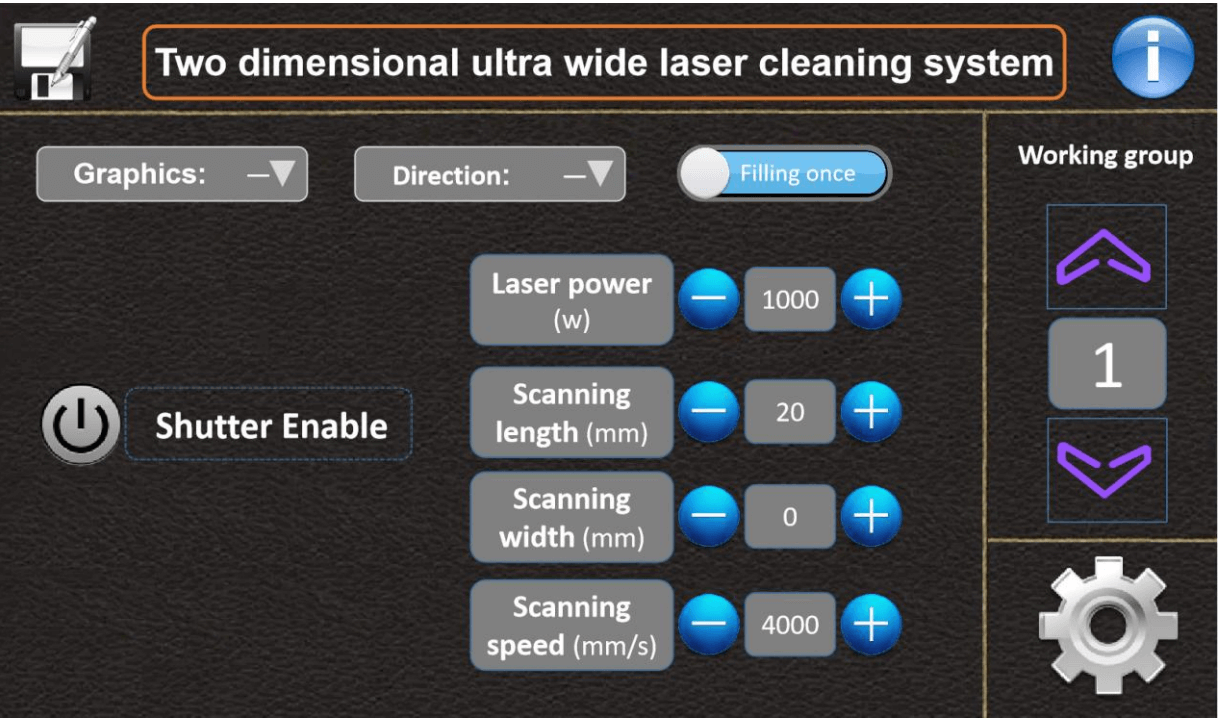

● SOFTWARE EA AIMPLE

PRESTORE EA LITŠOANTŠISO TSE FAPANENG TSA PARAMERATER

1. Software e bonolo e khetha liparamente tse tsosolositsoeng esale pele ka kotloloho

2. Boloka mefuta eohle ea litšoantšo tsa paramethara pele, mefuta e tšeletseng ea litšoantšo e ka khethoa mola o otlolohileng/o potileng/ selika-likoe/o kgutlonne/o tlatsang ka kgutlonne/o tlatsang ka selikalikoe

3. Ho bonolo ho e sebelisa le ho e sebelisa

4. Sebopeho se bonolo

5. Puo e ka ba Senyesemane/Sechaena kapa lipuo tse ling (haeba ho hlokahala)

Hlooho ea Laser e Hlahisa

Tobetsa switch e kgolo ya skrine ebe o tobetsa switch ya polokeho, mme lebone le lefubedu le tla suthela ho ya ponelopele. Haeba o hloka ho fetola ditshwantsho le diparamithara tse ding, o hloka ho kenya phasewete ho kenya sebopeho se tswetseng pele. Hlokomela: Kamora ho tobetsa senotlolo sa polokeho, switch ya tumello ya ho ntsha mosi e butswe, ebe o tobetsa switch ya taolo, lebone le ka ntshuwa.

Na u tseba mekhoa e 5 ea ho sebelisa mechine ea ho hloekisa ka laser tlhahisong ea indasteri?

1. Ho hlwekisa indastering ea lisebelisoa tsa elektroniki

Indasteri ea lisebelisoa tsa elektroniki e sebelisa li-laser ho hloekisa lintho tse oxidating, 'me indasteri ea lisebelisoa tsa elektroniki e loketse ho sebelisa li-laser ho hloekisa lintho tse oxidating. Pele boto ea potoloho e tšeloa ka har'a solder, li-pin tsa likarolo li lokela ho oxidating ka botlalo ho netefatsa phello ea ho kopana le motlakase, 'me li-pin ha lia lokela ho senyeha nakong ea ts'ebetso ea ho tlosa litšila. Ho hloekisa ka laser ho ka fihlela litlhoko tsa ts'ebeliso, 'me katleho ea mosebetsi e phahame haholo. Nalete e hloka ho khantšoa ka laser hanngoe feela.

2. Kalafo ea pele bakeng sa ho betla le ho tjheseletsa.

Ho lokisa ho tjheseletsa ka laser ke e 'ngoe ea lits'ebetso tse ngata tsa ho hloekisa ka laser, e leng molemo ho hloekisa bokaholimo ba tšepe le aluminium ho tsoa linthong tse litšila tse kang litšepe tsa ferrous le tse se nang ferrous, mafura, jj., ho lokisetsa ho tjheseletsa ka boleng bo holimo. E boetse e netefatsa manonyeletso a boreleli le a se nang masoba.

3. Ho hlwekisa hlobo

Ho hlwekisa hlobo ea mabili nakong ea tlhahiso ho tlameha ho bolokeha le ho tšepahala ho fokotsa nako ea ho sebetsa. Hobane mokhoa oa ho hloekisa ka laser o ka hokahanngoa ka faeba ea optical ho hloekisa sekhutlo se shoeleng kapa likarolo tse thata ho li hloekisa tsa hlobo tse bakoang ke khanya, ho bonolo haholo ho li sebelisa.

4. Ho hlwekisa pente ea khale ea lifofane

Kamora hore sefofane se sebetse ka nako e itseng, bokaholimo ba sefofane bo hloka ho pentoa bocha, kahoo ho hlokahala ho fumana mokhoa oa ho tlosa pente ea khale. Mokhoa oa setso oa ho hloekisa le ho penta ka mechine o bonolo ho senya bokaholimo ba tšepe ba sefofane, o baka likotsi tse patehileng ho fofa ha sefofane. Ha ho bonolo ho senya bokaholimo ha u sebelisa mochini o hlatsoang.

5. Seaparo sa ho hlwekisa sa lehae

Ho hlwekisa ka laser ho ka hlwekisa masela le dipente tlhahisong ya diindasteri tse kang dikoloi, ho boloka boleng ba thepa ya substrate.

Ho sebetsana le mokhelo o tloaelehileng

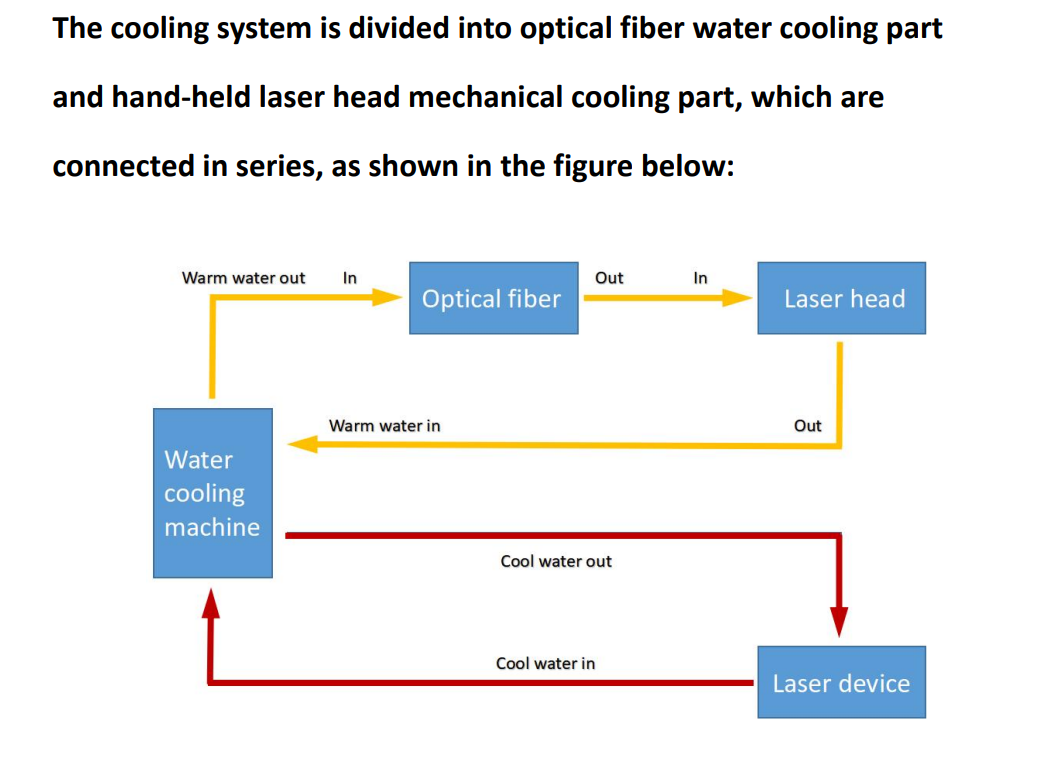

1. Alamo ea ho pholile ka laser le metsi:

(1) Alamo ea laser: Sehatsetsi sa metsi ha se butsoe. Tima laser ebe u e bulela hape.

(2) Alamo ea ho pholisa metsi: Mocheso oa tanka ea metsi o phahame haholo, compressor ea ho pholisa metsi e senyehile, sehatsetsi ha se eo, kapa mokhoa oa ho pholisa metsi ha o na matla a ho pholisa a lekaneng. Haeba boemo ba metsi tanka ea metsi bo sa lekana alamo, eketsa metsi a pholisang.

2. Sekirini se sa tloaelehang:

Haeba skrine e timme, hlahloba hore na lithapo tse 'ne tsa mantlha tsa lebokose la taolo le skrine li hokahane hantle le hore na ho na le likhokahano tsa sebele.

3. Ha ho leseli le ntšoang:

(1) Hore na laser e qalisoa ka tsela e tloaelehileng.

(2) Hore na skrine e na le tumello ea ho e qala.

(3) Hore na skrine sa pontsho se a sebetsa ha lesedi le ntshuwa.

(4) Hore na ho na le bothata bofe kapa bofe ka khokahano ea laser.

(5) Lense e sirelletsang e litšila: leseli la 'nete le fokola ebile ha le bonahale.

(6) Hore na tsela ea optical e bohareng.

4Ho ema ha khanya ka tshohanyetso nakong ya tshebetso:

Alamo ea laser (mathata a tloaelehileng: mocheso oa laser o phahame haholo)

Ke eng e lokelang ho eloa hloko ha u reka mochini oa ho hloekisa oa laser?

1. Ka kakaretso, theko ea mochini o hloekisang ka laser e amana le matla a oona, ha matla a laser a phahame, theko e bitsa chelete e ngata. Empa ho reka laser ho ntse ho itšetlehile ka litlhoko tsa hau tse ikhethileng, joalo ka ho hloekisa mafome a phaphametseng habonolo, mochini o hloekisang ka laser o nang le matla a tlase o ka khotsofatsa, empa mochini o hloekisang ka laser o nang le matla a phahameng o ka baka tšenyo mosebetsing.

2. E le ho fihlela phello e ntle ka ho fetisisa ea ho hloekisa bakeng sa substrate e tsamaellanang le eona e lokelang ho hloekisoa, hangata ho hlokahala ho fetola liparamente tse tsamaellanang le eona tse kang bolelele ba faeba, botebo ba lense ea tšimo, matla a tlhahiso, bophara ba pulse le lebelo la ho skena ho latela litšobotsi tsa substrate tse fapaneng.

3. Mechini ea ho hloekisa ka laser e arotsoe ka mechine ea ho hloekisa ka laser e tšoaroang ka letsoho le mechine e meholo ea ho hloekisa ka laser ea desktop. Mechini e fapaneng ea ho hloekisa ka laser e na le mesebetsi le libaka tse fapaneng. Mohlala, mechine e meng ea ho hloekisa ka laser e tšoaroang ka letsoho e loketse feela lisebelisoa tsa semiconductor, hobane tikoloho ea semiconductor e hloka tšireletso e kholo ea tikoloho, 'me litšila tsa lik'hemik'hale li ke ke tsa hlaha. Leha ho le joalo, likepe tse ling tse kholo li fapane, 'me tikoloho e fapane, 'me ho tla ba le likheo tse fapaneng sebakeng sa ts'ebeliso. Ke ka ho khetha lisebelisoa tsa ho hloekisa tse reretsoeng le tse loketseng feela re ka fihlelang phello e lakatsehang.

4. Litšoaneleho tsa moetsi oa mochini oa ho hloekisa ka laser li tla amana le letoto la litaba tsa litšebeletso. Joaloka mochini oa ho hloekisa, lisebelisoa tsa ho hloekisa ka laser li na le litlhoko tse itseng tsa ts'ebetso. Theko e tla fapana haholo ho latela ts'ebetso, 'me ho joalo le ka lisebelisoa tsa indasteri. Pele u khetha lisebelisoa tsa ho hloekisa, ho khothaletsoa ho nahana ka litšoaneleho tsa bahlahisi ba lisebelisoa tsa ho hloekisa ka laser. Ho loketse haholoanyane ho tsebahatsa bokhoni ba bona hape ka maeto a latelang ho bareki ba teng ba tšebelisano-'moho.