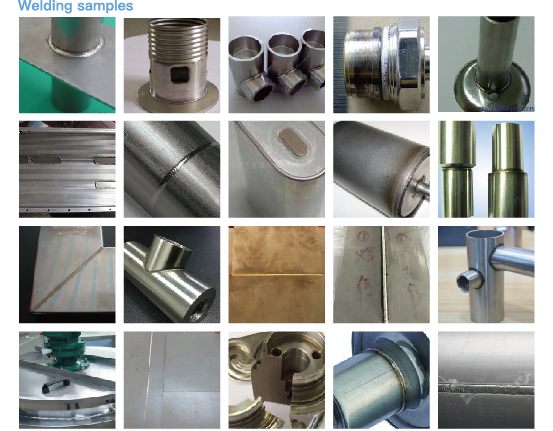

ʻO Fortune Laser Automatic 300W Yag Laser Mold Welding Machine

ʻO Fortune Laser Automatic 300W Yag Laser Mold Welding Machine

Kumu Kumu o ka Mīkini Laser

ʻEhā-axis linkage laser welding machine e hoʻohana i ka lua-lamp ceramic reflector cavity, mana ikaika, programmable laser pulse a me ka hoʻokele ʻōnaehana naʻauao.Hiki ke hoʻoneʻe ʻia ka Z-axis o ka papa hana i luna a i lalo i ka nānā ʻana, i hoʻomalu ʻia e kahi PC ʻenehana.Hoʻolako ʻia me kahi pākaukau hoʻoneʻe ʻokoʻa maʻamau X/Y/Z i hoʻokaʻawale ʻia, i hoʻolako ʻia me kahi ʻōnaehana hoʻoluʻu waho.ʻO kahi mea hoʻololi ʻē aʻe koho (80mm a i ʻole 125mm nā hiʻohiʻona he koho).Hoʻohana ka ʻōnaehana nānā i ka microscope a me ka CCD

ʻO 300w ʻO ke ʻano o ka mīkini hoʻoheheʻe laser ʻakomi

ʻO Fortune Laser Automatic Laser Welding Machine Nā Kūlana ʻenehana

| Hoʻohālike | FL-Y300 |

| Mana Laser | 300W |

| Ala Hooluu | Hooluu wai |

| Loihi Hawewe Laser | 1064nm |

| ʻAno Hana Laser Nd 3+ | ʻO YAG Conde Ceramic |

| Anawaena kiko | φ0.10-3.0mm hiki ke hoʻololi |

| Pulse Laulā | 0.1ms-20ms hiki ke hoʻololi |

| Hohonu welding | ≤10mm |

| Mana Mikini | 10KW |

| Pūnaehana Mana | PLC |

| ʻO ka pahuhopu a me ke kūlana | Microscope |

| Paʻi Papa Hana | 200×300mm (Z-axis uila hāpai ʻia) |

| Koi Mana | Hoʻopilikino ʻia |