Mashiinka Jarida Laser-ka ee Fiber-ka ee Dhaqaale

Mashiinka Jarida Laser-ka ee Fiber-ka ee Dhaqaale

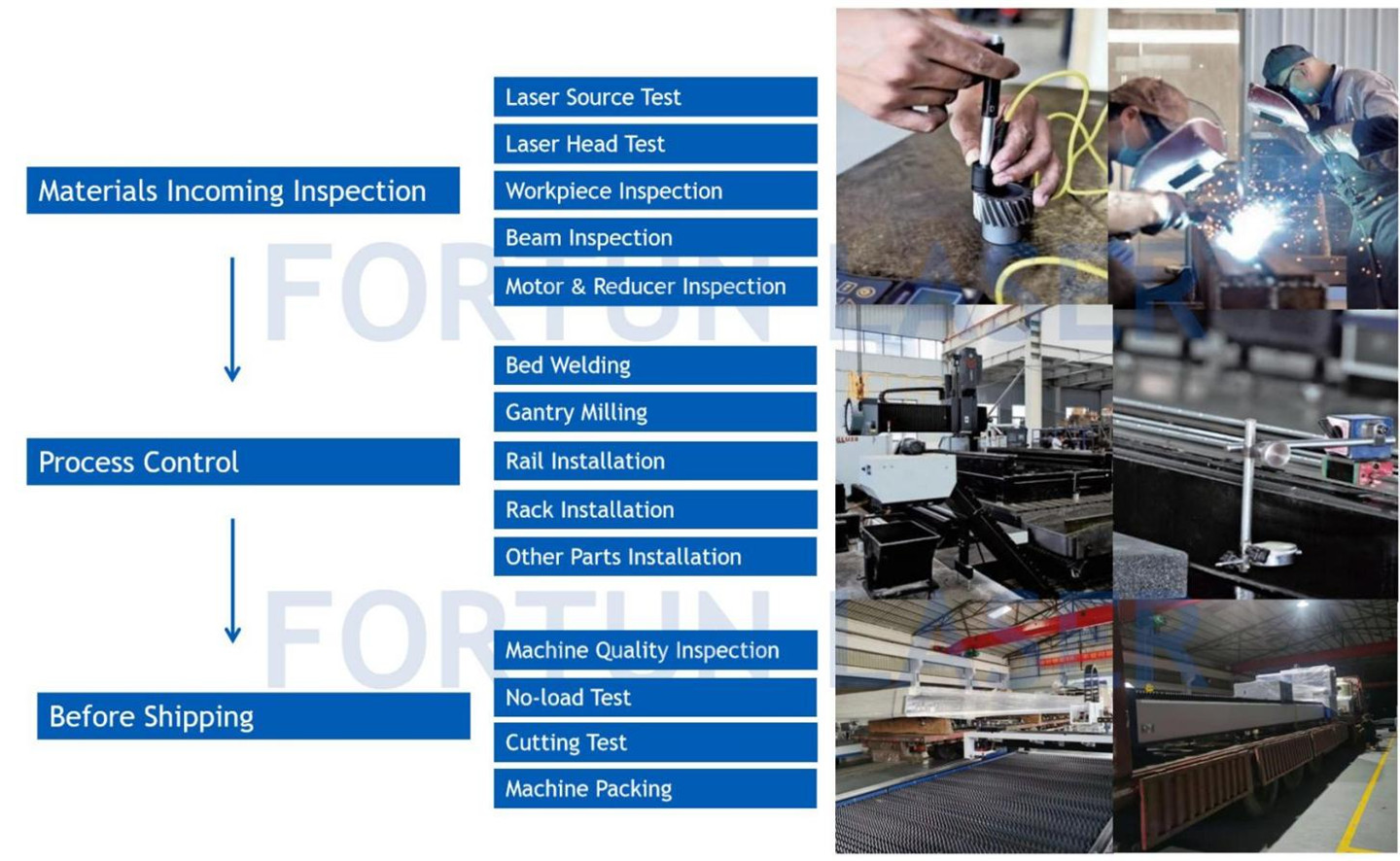

Astaamaha Mashiinka Jarida Laser-ka Birta ah

●Servo laba-laab ah qaab-dhismeedka gaantry-ga wadista:Mashiinka laser-ka ee qaab-dhismeedka buundada, wadista tareenka rack-ka, isticmaalka aaladda saliidaynta dhexe, waana mid si fudud loogu dayactiri karo;

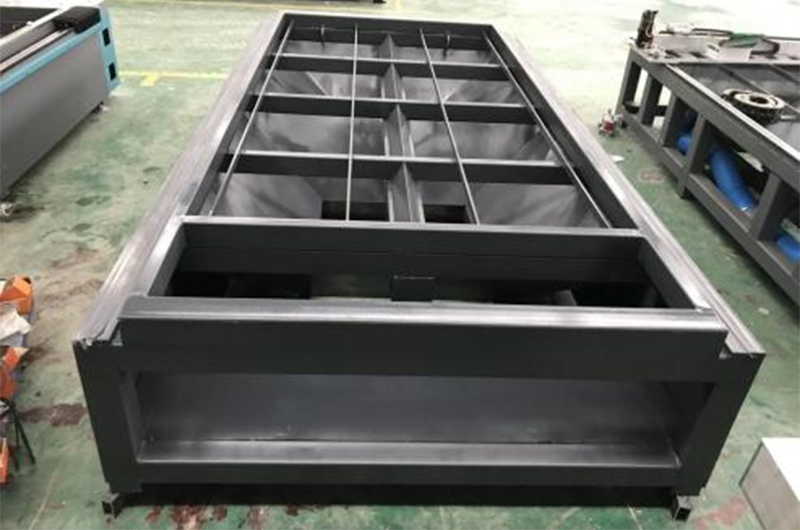

●Pxagjirnimo iyo Xasilloon: Sariirta mashiinka alxanka ee la xoojiyay, gariirka daaweynta heerkulka sare si loo baabi'iyo cadaadiska. Isbeddelka qalabka mashiinka waxaa lagu xakameyn karaa ± 0.02mm;

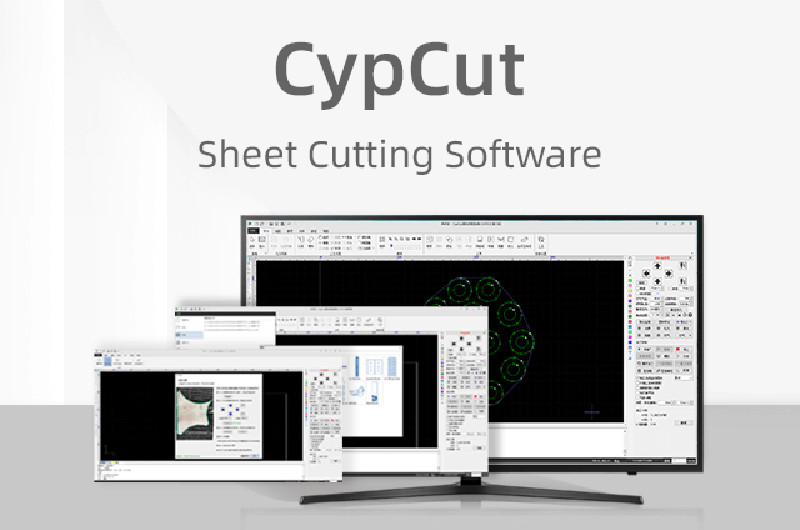

●Hawlgalku waa mid fudud: In ka badan 23000 oo isticmaale ayaa isticmaala nidaamkan jarista CNC ee xirfadda leh. Nidaamkan hawlgalka wuxuu leeyahay shaqada hagaajinta awoodda laysarka si loo hubiyo tayada jarista;

●Naqshadeynta bilicda warshadaha: Heerarka dhoofinta ee Yurub iyo Ameerika, muuqaalka naqshadeynta bilicda ayaa ka dhigaya mid lagu soo dhaweynayo suuqa adduunka;

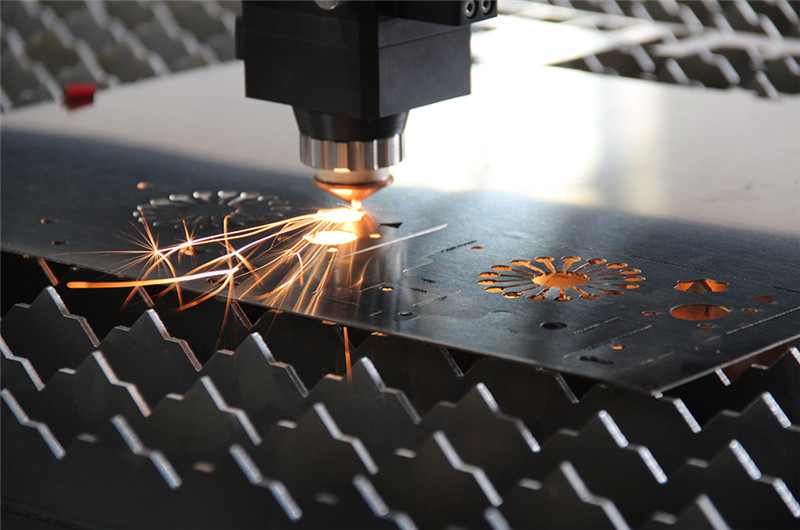

●Goynta tayo sare leh:Madaxa jarista laser-ka ee xirfadlaha ah ee ka hortagga isku dhaca ayaa hubiya saameynta ugu fiican ee goynta qaybaha shaqadaada iyo mashaariicdaada;

●Agab wax ku ool ah:Waxaa loo isticmaalaa qeexitaannada caadiga ah ee jarista xaashida birta, waqtiga iyo kharashkana waa la badbaadiyaa;

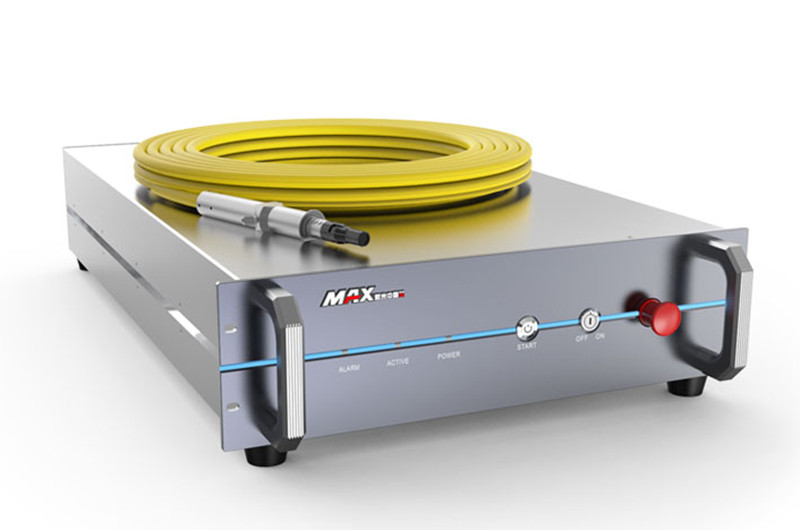

●Laser-ka faybarka: Adeegso ilo laser fiber Maxphotonics ah (Noocyada kale ee laser-ka waa ikhtiyaari), awood deggan oo la isku halleyn karo, waxqabad la damaanad qaaday;

| Qaabeynta mashiinka | |

| Moodel | Mashiinka Jarida Fiber Laser Taxanaha FL-S |

| Goobta Shaqada | 3000mm*1500mm |

| Isha laysarka | 1000w ugu badnaan |

| Nidaamka Jarida CNC | Nidaamka hawlgalka Cypcut 1000 |

| Madaxa laysarka | Diiradda gacanta ee OSPRI |

| Sariirta mashiinka | Laydhka Fortune |

| Qalabka gear-ka ee X/Y dhidibka | Laydhka Fortune |

| Tilmaamaha toosan ee saxda ah | ROUST |

| Darawalka Mootada | Matoorka Japan Yaskawa Servo (X750W/Y750W/Z400W) |

| Qaybaha elektarooniga ah | Faransiiska Schneider |

| Nidaamka dhimista | PHILANDE |

| Qaybaha pneumatic | Jaban SMC |

| Qalabka sariirta mashiinka ah | Laydhka Fortune |

| Qaboojiyaha biyaha | Hanli |

| Qalabka dib u warshadaynta qashinka | Laydhka Fortune |

Fiiro gaar ah: Qaabeynta mashiinkan waa mid adiga kuu gaar ah, noocyo kale oo badan oo loogu talagalay qayb kasta oo ka mid ah mashiinnada waa ikhtiyaari iyadoo lagu saleynayo shuruudahaaga iyo miisaaniyaddaada. Fadlan xor u noqo inaad nala soo xiriirto si aad u hesho faahfaahin dheeraad ah.

Cabbirrada Mashiinka

| Moodel | FL-S2015 | FL-S3015 | FL-S4020 | FL-S6020 |

| Goobta Shaqada (L*W) | 2000 * 1500mm | 3000*1500mm | 4000*2000mm | 6000 * 2000mm |

| Saxnaanta Booska X/Y ee dhidibka | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

| Saxnaanta Booska X/Y ee Ku Celinta | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Xawaaraha ugu Badan ee Dhaqdhaqaaqa | 80000mm/daqiiqo | 80000mm/daqiiqo | 80000mm/daqiiqo | 80000mm/daqiiqo |

| Dardargelinta Ugu Badan | 1.2g | 1.2g | 1.2g | 1.2g |

| Miisaanka ugu Badan ee Rarista | 600kg | 800kg | 1200kg | 1500kg |

| Koronto Bixinta | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz |

| Awoodda Isha Laysarka (Ikhtiyaar) | 1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW/8kW/10kW/12kW/15kW/20kW | |||

Codsiyada

Ku habboon in lagu farsameeyo xaashida birta sida birta aan daxalka lahayn, birta kaarboon, birta daxalka leh, birta silikoon, saxan bir galvanized ah, birta nikkel-titanium, inconel, birta titanium, iwm.

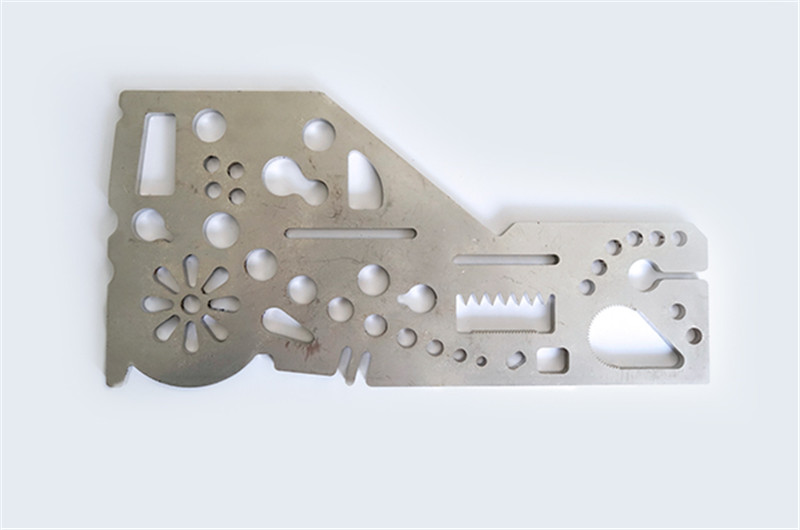

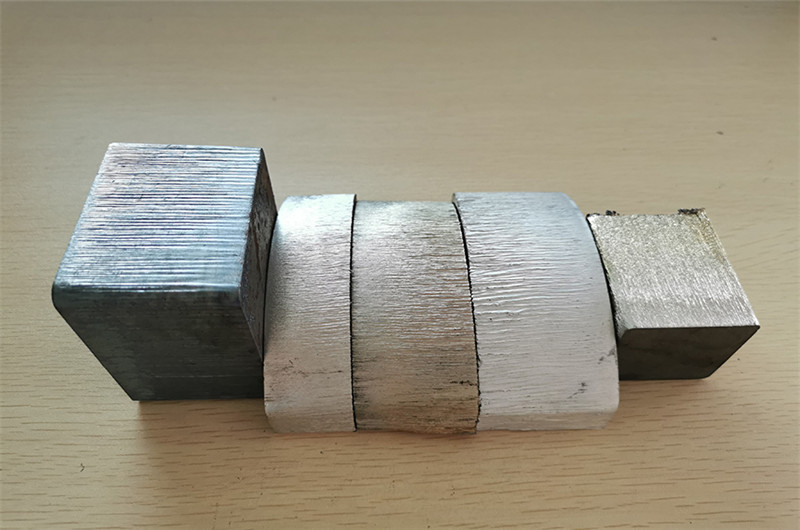

Muujinta Muunadaha

Xawaaraha ugu sarreeya ee Laser-ka ee Goynta

| Fiiro gaar ah 1: Dhexroorka xudunta ee fiilada wax soo saarka laysarka ee 1000W ~ 1500W ee xogta jarista waa 50 microns; dhexroorka xudunta ee fiilada wax soo saarka ee 2000 ~ 4000W waa 100 microns; | |||||||||

| Fiiro gaar ah 2: Xogtan jarista waxay qaadanaysaa madaxa jarista Raytools, dhererka diiradda/diiradda muraayadda: 100mm/125mm; | |||||||||

| Fiiro gaar ah 3: Sababtoo ah kala duwanaanshaha habka qaabeynta qalabka iyo habka jarista (qalabka mashiinka, qaboojinta biyaha, deegaanka, afka jarista iyo cadaadiska gaaska) oo ay qaateen macaamiisha kala duwan, xogtan waxaa loogu talagalay tixraac keliya; | |||||||||

| Msagxad sare | Dhumuc (mm) | GNoocyada sida | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| xawaare(m/daqiiqad) | xawaare(m/daqiiqad) | xawaare(m/min) | xawaare(m/daqiiqad) | xawaare(m/daqiiqad) | xawaare(m/daqiiqad) | xawaare(m/daqiiqad) | |||

| Bir aan Daxal lahayn | 1 | N2 | 20~24 | 28~32 | 38 | 30 | 50 | 42~43 | 70-75 |

| 2 | N2 | 5.4 | 7.5 | 12 | 10 | 13 | 19~20 | 25~30 | |

| 3 | N2 | 2.2 | 4 | 7 | 6 | 8 | 11~12 | 12~15 | |

| 4 | N2 | 1.2 | 2 | 4 | 4 | 5 | 6.5~7.5 | 7.5~9 | |

| 5 | N2 |

| 1.1 | 2 | 2.5 | 2.5 | 4~5 | 6~7.5 | |

| 6 | N2 |

| 0.8 | 1.5 | 1.5 | 1.5 | 2~3 | 5~6.5 | |

| 8 | N2 |

|

| 0.8 | 0.7 | 1 | 1.5~2 | 3.5~4.5 | |

| 10 | N2 |

|

| 0.5 | 0.5 | 0.8 | 1 | 2.1 | |

| 12 | N2 |

|

|

|

| 0.5 | 0.8 | 1.1 | |

| 14 | N2 |

|

|

|

|

|

| 0.9 | |

| Msagxad sare | Dhumuc (mm) | GNoocyada sida | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| xawaare(m/daqiiqad) | xawaare(m/daqiiqad) | xawaare(m/min) | xawaare(m/daqiiqad) | xawaare(m/daqiiqad) | xawaare(m/daqiiqad) | xawaare(m/daqiiqad) |

| Kaarboon Bir ah | 1 | hawada | 9~12 | 27~30 | 27~30 | 30 | 50 | 43 | 70-75 |

| 2 | hawada | 6~8 | 8~10 | 10~12 | 12 | 13 | 20 | 25~30 | |

| 3 | O2 | 3 | 3 | 3 | 4 | 4.5 | 4.5 | 4.5 | |

| 4 | O2 | 2 | 2.5 | 3.1 | 3.3 | 3.5 | 3.8 | 3.8 | |

| 5 | O2 | 1.6 | 2 | 2.5~3 | 2.5 | 3 | 3.5 | 3.7 | |

| 6 | O2 | 1.4 | 1.8 | 2.2 | 2.3 | 2.5 | 2.8 | 3.3 | |

| 8 | O2 | 1.1 | 1.3 | 1.5 | 1.5 | 2 | 2.3 | 2.8 | |

| 10 | O2 | 0.9 | 1.1 | 1 | 1.2 | 1.4 | 1.8 | 2.1 | |

| 12 | O2 | 0.7 | 0.9 | 0.8 | 1 | 1.1 | 1.5 | 1.6 | |

| 14 | O2 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.95 | ||

| 16 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 0.85 | ||

| 18 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.75 | |||

| 20 | O2 | 0.4 | 0.5 | 0.6 | 0.7 | 0.65 | |||

| 22 | O2 | 0.4 | 0.5 | 0.5 | 0.5 | ||||

| Aluminium | 1 | hawada | 12~13 | 15 | 17~18 | 29 | 45 | 35~37 | 70-75 |

| 2 | hawada | 4~4.5 | 6 | 7.5 | 8.5 | 11 | 15 | 25~30 | |

| 3 | hawada | 1~1.5 | 3 | 5 | 5 | 7 | 8~9 | 15 | |

| 4 | hawada | 0.8~1 | 2 | 3 | 4 | 6 | 10 | ||

| 5 | hawada | 1 | 1.5 | 3 | 8 | ||||

| 6 | hawada | 0.6 | 1 | 2 | 5.5 | ||||

| 8 | hawada | 0.5 | 1 | 2.5 | |||||

| 10 | hawada | 0.5 | 1.3 | ||||||

| 12 | hawada | 0.9 | |||||||

| Naxaas | 1 | hawada | 10 | 12 | 15 | 24 | 40 | 30-33 | 65~70 |

| 2 | hawada | 3 | 5 | 6 | 7.5 | 10 | 13 | 20~25 | |

| 3 | hawada | 0.5 | 2 | 3 | 4 | 4 | 7 | 5 | |

| 4 | hawada | 0.5 | 1.5 | 2 | 3 | 5 | 4 | ||

| 5 | hawada | 0.5 | 1 | 1.5 | 2 | 3 | |||

| 6 | hawada | 0.5 | 0.8 | 1.5 | 2 | ||||

| 8 | hawada |

| 0.8 | 1.2 | |||||

| 10 | hawada |

|

| 0.5 |

Shuruudaha Deegaanka Shaqada

1. Shuruudaha qoyaanka waa 40%-80%, ma jiraan wax uumi-bax ah.

2. Shuruudaha shabagga korontada: 380V; 50Hz/60A.

3. Isbeddelka shabakadda korontada: 5%, siligga dhulka ee shabakadda ayaa buuxiya shuruudaha caalamiga ah.

4. Jarista gaaska kaalmaynta: Hawo nadiif ah oo qalalan oo la cadaadiyey iyo oksijiin saafi ah oo sare (O2) iyo naytaroojiin (N2), daahirnimo aan ka yarayn 99.9% daahirnimo.

5. Waa in aysan jirin faragelin koronto oo xooggan oo u dhow qalabka rakibidda.

6. Ka fogow qalabka gudbiya raadiyaha ama xarumaha gudbinta ee ku wareegsan goobta rakibaadda.

7. Iska caabbinta dhulka ee korontada ku shaqeeya: ≤ 4 ohms. Ballaca dhulka: ka yar 50um; dardargelinta gariirka: ka yar 0.05g.

8. Ka fogow tiro badan oo qalabka mashiinka ah sida shaambad ku tuurista agagaarka.

9. Cadaadiska hawada: 86-106kpa.

10. Shuruudaha booska qalabka waxaa la damaanad qaaday inay ka xor yihiin qiiqa iyo boodh la'aan, iyadoo laga fogaanayo jawiga shaqada ee boodhka leh sida nadiifinta birta iyo shiidideeda.

11. Waa in la rakibaa dabaq ka hortag ah oo fiilada gaashaanka ku xiran tahay.

12. Tayada biyaha ee biyaha qaboojinta ee shaqeynaya ayaa si adag loogu baahan yahay, waana in la isticmaalaa biyo saafi ah, biyo la nadiifiyey ama biyo la dhalaaliyey.