Kuwotcherera kwa laserndi chimodzi mwazinthu zofunika kwambiri pakugwiritsa ntchito ukadaulo wokonza zinthu pogwiritsa ntchito laser. Amagwiritsidwa ntchito makamaka powotcherera zinthu zokhala ndi makoma ochepa komanso kuwotcherera mwachangu. Njira yowotcherera ndi ya mtundu wa kutentha, ndiko kuti, kuwala kwa laser kumatenthetsa pamwamba pa workpiece, ndipo kutentha kwa pamwamba kumafalikira mkati kudzera mu kutentha. Mwa kuwongolera magawo monga m'lifupi, mphamvu, mphamvu yayikulu komanso kubwerezabwereza kwa kugunda kwa laser, workpiece imasungunuka kuti ipange dziwe linalake losungunuka. Amagwiritsidwa ntchito kwambiri popanga makina, ndege, makampani opanga magalimoto, zitsulo za ufa, makampani opanga ma microelectronics azachipatala ndi madera ena.

Ndi kukula kwakukulu kwa magalimoto atsopano amphamvu, kufalikira kwa kupanga mabatire amphamvu kwapangitsa kuti ntchito yowotcherera laser ikule. Kuyambira theka lachiwiri la chaka cha 2018, kugwiritsa ntchito laser yowotcherera ndi manja kwakhala kotchuka pang'onopang'ono, ndipo kwakhala malo abwino pamsika wowotcherera laser mu theka loyamba la chaka chino. Ndi mulingo waukadaulo wamakono komanso momwe zinthu zikuyendera pakali pano.kuwotcherera kwa laser kogwiritsidwa ntchito ndi manja, mwina ilowa m'malo mwa makina ochizira a TIG (argon arc welding) omwe amagwiritsidwa ntchito kale.

Mzaka zaposachedwa,ma laser a ulusiapita patsogolo kwambiri, ndipo ubwino wawo makamaka ndi: kusinthasintha kwakukulu kwa kuwala kwa dzuwa, kutenthetsa kutentha mwachangu, kusinthasintha kwabwino, kuthekera kwamphamvu koletsa kusokoneza, mtengo wotsika, moyo wautali, wopanda kusintha, wopanda kukonza, wokhazikika kwambiri, wochepa kukula, Zipangizo zowotcherera za laser zogwiritsidwa ntchito ndi manja pogwiritsa ntchito fiber lasers nazonso zakula pang'onopang'ono.

Kuwotcherera kwa laserPamafunika kulondola kwambiri kwa ntchito yogwirira ntchito, ndipo msoko wa weld umakhala ndi zolakwika. Pofuna kuthetsa vutoli, wopangayo amatanthauza zida zolumikizira laser za ndege yapadera kuti apange zida zolumikizira laser zogwira ntchito zokhala ndi malo ozungulira. Laser ili mu mawonekedwe a "8" kapena "0" mtundu wa swing ingachepetse kulondola kwa ntchito yogwirira ntchito ndikuwonjezera kulowa kwa weld. Pambuyo pa kukonza ndi kukonza zingapo, zida zolumikizira laser zogwira ntchito zomwe zimagwiritsidwa ntchito pano zimakhala ndi mphamvu ya 0.5-1.5KW, ndipo kukula ndi kulemera kwa zidazo ndizofanana ndi makina olumikizira argon arc, omwe amatha kulumikiza mbale zachitsulo za 3mm kapena zochepa. Pofuna kuthetsa zofooka za mphamvu yokwanira ya weld ya zomangamanga zolumikizira laser, m'zaka zaposachedwa, opanga zida aphatikiza zida zolumikizira mawaya zokha pogwiritsa ntchito laser weld, ndikupanga zida zolumikizira waya zodzaza ndi laser zomwe zimatha kudyetsa mawaya zokha, zomwe zimakwaniritsa zosowa za mbale zoonda zachitsulo zosakwana 4m. Kuwotcherera kumatha kusintha ndikupambana kuwotcherera kwa argon arc, kuzindikira liwiro lalikulu, kutentha kochepa, kusintha pang'ono, kuwotcherera koteteza chilengedwe kotsika mtengo, ndipo mtengo wopanga ndi wotsika kuposa wa kuwotcherera kwa argon arc pansi pa mikhalidwe yomweyi.

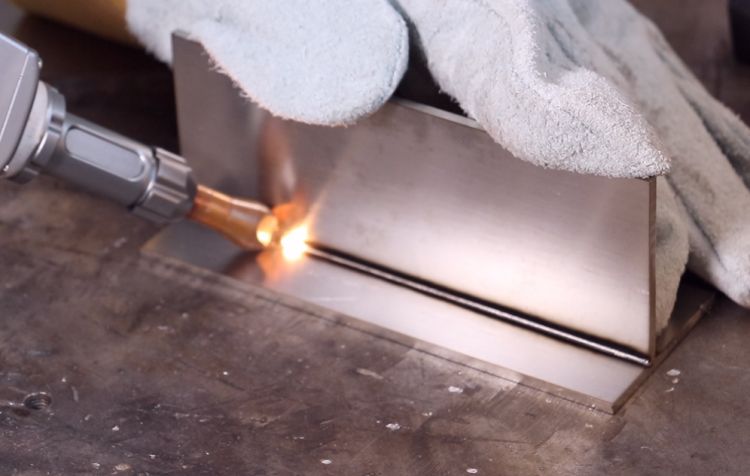

Pogwira ntchito, mutu wa makina ochapira wogwiridwa ndi manja umakhala ndi m'lifupi mwake, ndipo m'mimba mwake ndi wochepa, kotero akachapira, amachapira kuchokera pamalo amodzi kupita kwina mzere ndi mzere, motero amapanga mkanda wochapira. Poyerekeza ndi makina ochapira ozizira achikhalidwe, liwiro lachapira lochapira la makina ochapira wogwiridwa ndi manja lidzakhala lachangu, ndipo njira yochapira yowombera kamodzi imatsimikizira kuti ndiyoyenera kwambiri kuchapa mowirikiza mipata yayitali yolunjika.

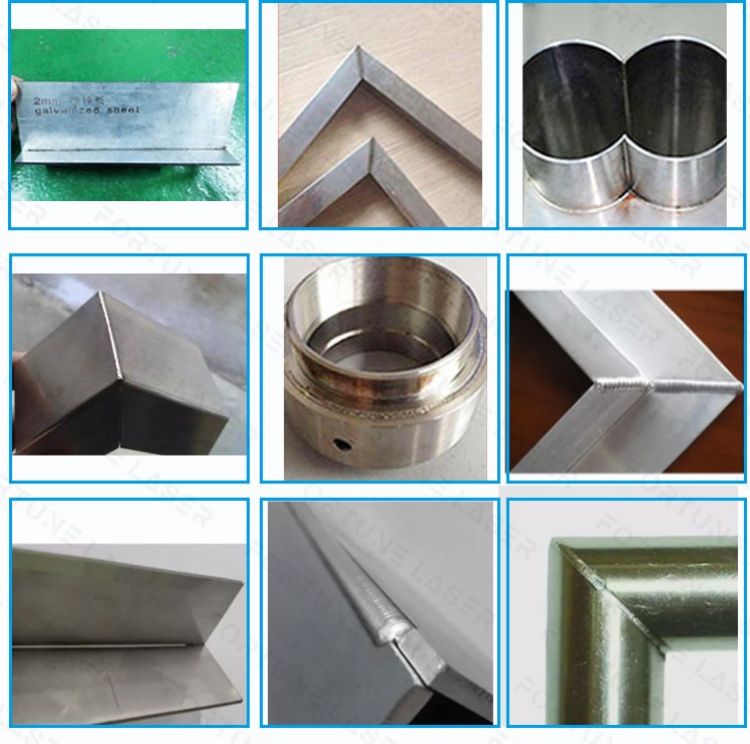

Ndipo makina ochapira a laser ogwiridwa ndi manja satenga malo ambiri, ndipo nthawi zambiri amakhala ndi mitu yosiyanasiyana yogwiridwa ndi manja. Malinga ndi zosowa zosiyanasiyana za zigawo zachitsulo monga kuwotcherera kunja, kuwotcherera mkati, kuwotcherera mbali yakumanja, kuwotcherera m'mphepete mopapatiza, ndi kuwotcherera malo akuluakulu, mitu yosiyanasiyana yochapira yogwiridwa ndi manja imatha kusankhidwa. Zinthu zomwe zingawotcheredwe zimakhala zosiyanasiyana, ndipo mawonekedwe a chinthucho ndi osinthasintha. Pa ma workshop opanga omwe amagwira ntchito zokonza zazing'ono komanso zosakhala zazikulu, makina ochapira a laser ogwiridwa ndi manja ndi chisankho chabwino kwambiri.

Zipangizo zosiyanasiyana zachitsulo zimakhala ndi malo osiyanasiyana osungunula: kukhazikitsidwa kwa magawo olumikizirana a mitundu yosiyanasiyana ya zida zolumikizirana ndizovuta, ndipo mawonekedwe a thermophysical a zida zolumikizirana adzawonetsa kusiyana kosiyana ndi kusintha kwa kutentha; kuchuluka kwa kuyamwa kwa mitundu yosiyanasiyana ya zida za laser kudzasiyananso ndi Kusintha kwa kutentha kukuwonetsa kusiyana kosiyana; kusungunuka kwa cholumikizira cha solder ndi kusintha kwa kapangidwe ka malo omwe akhudzidwa ndi kutentha panthawi yolimbitsa weldment; zolakwika zolumikizirana za makina olumikizirana a laser ogwiridwa ndi dzanja, kupsinjika kwa kutenga nawo mbali pa weld ndi kusintha kwa kutentha, ndi zina zotero. Koma chofunikira kwambiri ndi momwe zinthu zolumikizirana zimakhudzira kusiyana kwa mphamvu ya macro ndi micro properties a weld.

Kodi zipangizo ziti zomwe zingathemakina owotcherera a laser ogwiritsidwa ntchito ndi manjakusungunula?

1. Chitsulo chosapanga dzimbiri

Chitsulo chosapanga dzimbiri chimakhala ndi kutentha kwakukulu, ndipo chimatha kutenthedwa kwambiri panthawi yowotcherera. Pamene malo omwe akhudzidwa ndi kutentha ali akulu pang'ono, zimayambitsa mavuto aakulu osinthika. Komabe, kutentha komwe kumapangidwa ndi makina owotcherera a laser ogwiritsidwa ntchito m'manja panthawi yonse yowotcherera kumakhala kochepa. Kuphatikiza ndi kutentha kochepa, mphamvu zambiri zomwe zimayamwa komanso kusungunuka bwino kwa chitsulo chosapanga dzimbiri, ma weld opangidwa bwino, osalala komanso okongola amatha kupezeka mutawotcherera.

2. Chitsulo cha kaboni

Chitsulo cha kaboni wamba chikhoza kuwongoleredwa mwachindunji pogwiritsa ntchito laser yogwiridwa ndi manja, zotsatira zake zimakhala zofanana ndi kuwongoleredwa ndi chitsulo chosapanga dzimbiri, ndipo malo omwe amakhudzidwa ndi kutentha ndi ochepa, koma powongoleredwa ndi chitsulo chapakati ndi cha kaboni wambiri, kutentha kotsala kumakhala kokwera kwambiri, kotero ndikofunikirabe kuwongoleredwa musanawongolere. Kutenthetsa ndi kusunga kutentha pambuyo powongoleredwa kuti muchepetse kupsinjika ndikupewa ming'alu. Apa titha kulankhula za makina owongoleredwa ozizira. Chitsulo chapakati ndi chapamwamba chikhoza kuwongoleredwa kapena kukonzedwa pang'onopang'ono pogwiritsa ntchito welding yozizira ndi waya wowongoleredwa ndi chitsulo chopangidwa ndi chitsulo. Ponena za kuwongolera kutentha, kuwongolera kutentha, ndi kuwongolera kutentha, makina owongoleredwa ozizira amatha kuphunzitsa welding yogwiridwa ndi laser yogwiridwa ndi manja kukhala yothandiza kwambiri pa zotsalira za kutentha pambuyo powongoleredwa.

3. Chitsulo chachitsulo

Ndi yoyenera kuwotcherera mitundu yosiyanasiyana ya chitsulo chofewa, ndipo zotsatira zake zowotcherera ndi zabwino kwambiri.

4. Aluminiyamu ndi aluminiyamu yopangidwa ndi aluminiyamu

Aluminiyamu ndi aluminiyamu ndi zinthu zowala kwambiri, ndipo ma porosity amatha kuwoneka mu dziwe losungunuka kapena pa muzu panthawi yowotcherera. Poyerekeza ndi zipangizo zam'mbuyomu zachitsulo, aluminiyamu ndi aluminiyamu ali ndi zofunikira kwambiri pa magawo, koma bola ngati magawo osankhidwa a kuwotcherera ali oyenera, msoko wowotcherera wokhala ndi mphamvu zofanana ndi zachitsulo choyambira ungapezeke.

5. Mkuwa ndi aloyi wa mkuwa

Mphamvu ya kutentha kwa mkuwa ndi yamphamvu kwambiri, ndipo n'zosavuta kuyambitsa kulowa kosakwanira komanso kusakanikirana pang'ono panthawi yowotcherera. Nthawi zambiri, zinthu zamkuwa zimatenthedwa panthawi yowotcherera kuti zithandize kuwotcherera. Pano tikulankhula za zinthu zopyapyala zamkuwa. Chitoliro chowotcherera cha laser chogwira m'manja mwachindunji Chowotcherera, chifukwa cha mphamvu zake zokhazikika komanso liwiro lake lowotcherera mwachangu, sichimakhudzidwa kwambiri ndi mphamvu yayikulu ya kutentha kwa mkuwa.

6. Kuwotcherera pakati pa zinthu zosiyana

Makina ogwiritsira ntchito laser ogwiritsidwa ntchito ndi manja amatha kuchitidwa pakati pa zitsulo zosiyanasiyana zosiyana, monga mkuwa-nickel, nickel-titanium, mkuwa-titanium, titanium-molybdenum, mkuwa-mkuwa, chitsulo-mkuwa wochepa ndi zitsulo zina zosiyana. Kuwotcherera kwa laser kumatha kuchitika pansi pa mikhalidwe iliyonse (mpweya kapena kutentha).

Makina ochapira a laser ogwiritsidwa ntchito m'manja pakadali pano ndi chinthu chomwe chimagwiritsidwa ntchito kwambiri mumakampani ochapira, makamaka chifukwa chakuti ngakhale kuti zidazi zikuwoneka zokwera mtengo, zimatha kusunga ndalama zogwirira ntchito bwino. Mtengo wa ogwira ntchito a ochapira ndi wokwera mtengo. Kugwiritsa ntchito izi kumathetsa vuto la kufunafuna ochapira okwera mtengo komanso ovuta. Kuphatikiza apo, makina ochapira a laser ogwiritsidwa ntchito m'manja atchuka kwambiri ndi makasitomala ambiri chifukwa cha nthawi yayitali yogwira ntchito komanso kugwiritsa ntchito mphamvu zochepa.

Ngati mukufuna kudziwa zambiri zokhudza kuyeretsa pogwiritsa ntchito laser, kapena mukufuna kugula makina abwino kwambiri oyeretsera pogwiritsa ntchito laser, chonde titumizireni uthenga patsamba lathu ndipo titumizireni imelo mwachindunji!

Nthawi yotumizira: Disembala-03-2022