Ịgbado ọkụ laserbụ otu n'ime akụkụ dị mkpa nke ojiji nke teknụzụ nhazi ihe nhazi laser. A na-ejikarị ya eme ihe maka ịgbado ihe ndị dị gịrịgịrị na ịgbado ọkụ dị ala. Usoro ịgbado ọkụ bụ nke ụdị nnyefe okpomọkụ, ya bụ, radieshon laser na-ekpo elu nke ọrụ ahụ, okpomọkụ elu na-agbasakwa n'ime site na nnyefe okpomọkụ. Site na ijikwa paramita dịka obosara, ike, ike kachasị elu na ugboro ugboro nke pulse laser, workpiece ahụ na-agbaze iji mepụta ọdọ mmiri a gbazere agbaze. A na-ejikarị ya eme ihe n'ịmepụta igwe, ụgbọelu, ụlọ ọrụ ụgbọ ala, igwe ntụ ntụ, ụlọ ọrụ microelectronics biomedical na ubi ndị ọzọ.

Site na mmụba dị egwu nke ụgbọ ala ike ọhụrụ, mmụba nke mmepụta batrị ike emeela ka mmụba nke ịgbado ọkụ laser dịkwuo elu. Kemgbe ọkara nke abụọ nke 2018, ịgbado ọkụ laser ejiri aka aghọọla ewu ewu nke ukwuu, ọ ghọwokwa ebe na-egbuke egbuke n'ahịa ịgbado ọkụ laser na ọkara mbụ nke afọ a. Site na ọkwa teknụzụ ugbu a na ọnọdụ ngwa nkeaka na ịgbado ọkụ laser, o yikarịrị ka ọ ga-anọchi ahịa igwe ịgbado ọkụ TIG ọdịnala (argon arc welding).

N'afọ adịbeghị anya,eriri lasersEnweela nnukwu ọganihu, uru ha gụnyere: oke mgbanwe fotoelectric dị elu, mbelata okpomọkụ ngwa ngwa, ezigbo mgbanwe, ikike mgbochi nnyonye anya siri ike, ọnụ ala dị ala, ogologo ndụ, enweghị mgbanwe, enweghị mmezi, nkwụsi ike dị elu, obere nha, Ngwa njikọta laser ejiri aka na-eji laser eriri etolitekwala nwayọ nwayọ.

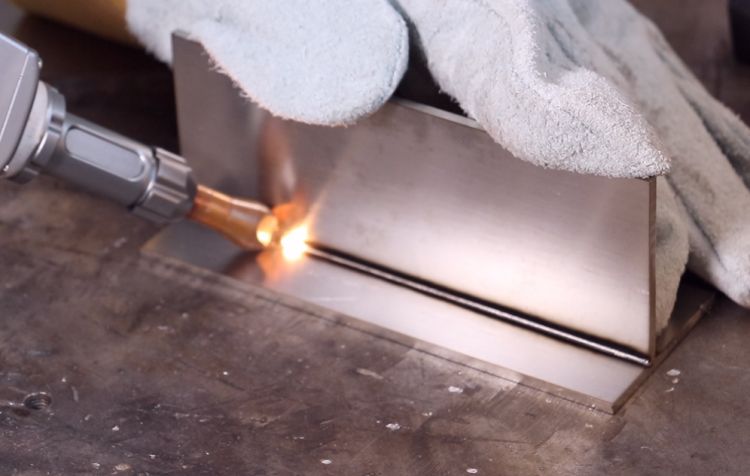

Ịgbado ọkụ laserỌ chọrọ ka ihe eji arụ ọrụ ahụ dị elu nke ọma, ebe a na-ejikọkwa ihe ndị nwere ntụpọ. Iji dozie nsogbu a, onye na-emepụta ihe na-ezo aka na ngwa ịgbado ọkụ laser nke ụgbọelu pụrụ iche iji mepụta ngwa ịgbado ọkụ laser aka nwere ebe a na-agbagharị agbagharị. Laser ahụ dị n'ụdị "8" ma ọ bụ "0" ụdị swing nwere ike ibelata izi ezi nke ihe eji arụ ọrụ ahụ ma mee ka ọ dịkwuo mma. Mgbe usoro nhazi na mmezi gasịrị, ngwa ịgbado ọkụ laser aka a na-ahụkarị ugbu a nwere ike nke 0.5-1.5KW, nha na ibu nke ngwa ahụ hà nhata igwe ịgbado ọkụ argon arc, nke nwere ike ịgbado efere ígwè nke 3mm ma ọ bụ ihe na-erughị ya. Iji dozie adịghị ike nke ike ịgbado ọkụ nke usoro ịgbado ọkụ laser ezughi oke, n'afọ ndị na-adịbeghị anya, ndị na-emepụta akụrụngwa ejikọtala ngwaọrụ nri waya akpaka dabere na ịgbado ọkụ laser, ma mepụta ngwa ịgbado ọkụ laser aka nke nwere ike inye waya na akpaghị aka, nke na-egbo mkpa nke efere ígwè dị gịrịgịrị n'okpuru 4m. N'ụzọ bụ isi, ịgbado ọkụ nwere ike dochie ma gafere ịgbado ọkụ argon arc, nweta ọsọ dị elu, obere ntinye okpomọkụ, obere mgbanwe, ịgbado ọkụ gburugburu ebe obibi dị ọnụ ala, ọnụ ahịa nrụpụta dịkwa ala karịa nke ịgbado ọkụ argon arc n'okpuru otu ọnọdụ ahụ.

Mgbe ọ na-arụ ọrụ, isi igwe ịgbado ọkụ nke aka ya nwere obosara nyocha, dayameta ntụpọ ya dịkwa obere, yabụ mgbe ọ na-agbado ọkụ, ọ na-enyocha site n'otu isi ruo na nke ọzọ site na ahịrị, si otú a na-emepụta bead weld. Ma e jiri ya tụnyere igwe ịgbado ọkụ oyi ọdịnala, ọsọ ịgbado ọkụ nke ịgbado ọkụ laser nke aka ga-adị ngwa ngwa, usoro ịgbado ọkụ otu-ose na-achọpụta na ọ dabara adaba maka ịgbado ọkụ nke ogologo ogologo.

Igwe ịgbado ọkụ laser nke ejiri aka na-ejide anaghị ewere obere oghere, a na-ejikwa ya ọtụtụ isi aka. Dịka mkpa dị iche iche nke akụkụ ígwè dị ka ịgbado ọkụ mpụga, ịgbado ọkụ n'ime, ịgbado ọkụ n'akụkụ aka nri, ịgbado ọkụ n'akụkụ dị warara, na ịgbado ọkụ n'ebe buru ibu si dị, enwere ike ịhọrọ isi ịgbado ọkụ dị iche iche ejiri aka na-ejide. Ngwaahịa ndị enwere ike ịgbado ọkụ dị iche iche, ọdịdị ngwaahịa ahụ na-agbanwe agbanwe karị. Maka ogbako mmepụta nke na-arụ ọrụ na nhazi obere na ịgbado ọkụ na-abụghị nnukwu, igwe ịgbado ọkụ laser nke ejiri aka na-eji bụ nhọrọ kacha mma.

Ihe dị iche iche e ji ígwè mee nwere ebe ịgbaze dị iche iche: ntọala nke paramita ịgbado ọkụ maka ụdị ihe dị iche iche e ji agbado ọkụ dị mgbagwoju anya, ihe ndị na-eme ka ihe na-agbado ọkụ ga-egosi ọdịiche dị iche iche na mgbanwe okpomọkụ; ọnụego nnabata nke ụdị ihe dị iche iche maka laser ga-adịkwa iche na Mgbanwe okpomọkụ na-egosi ọdịiche dị iche iche; mgbaze nkwonkwo solder na mgbanwe nhazi nke mpaghara okpomọkụ metụtara n'oge ịgbado ọkụ; ntụpọ nkwonkwo nke igwe ịgbado ọkụ laser ejiri aka, nrụgide isonye na ịgbado ọkụ na mgbanwe okpomọkụ, wdg. Mana nke kachasị mkpa bụ mmetụta nke ọdịiche dị na ihe ndị e ji agbado ọkụ na ihe ndị dị na macro na micro nke ịgbado ọkụ.

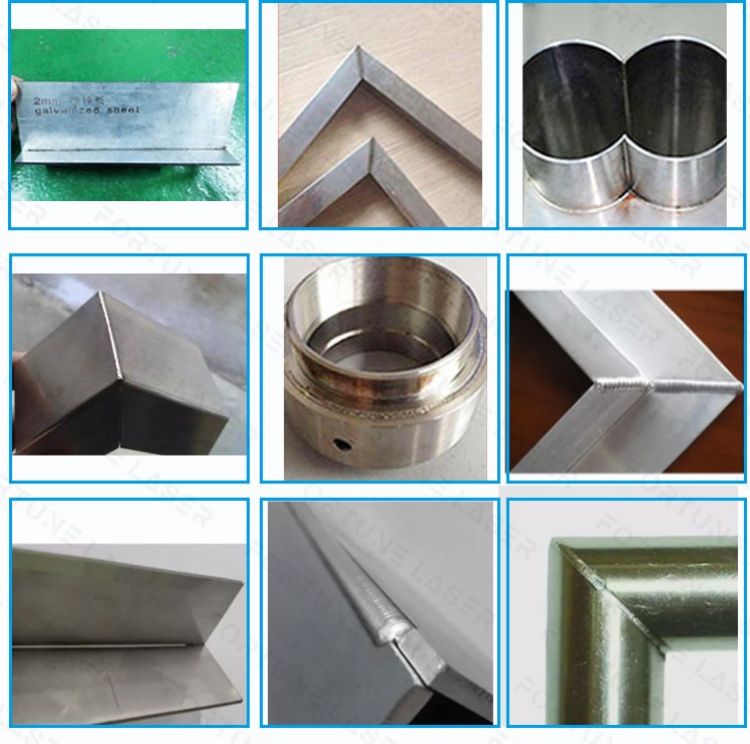

Kedu ihe nwere ike imeigwe ịgbado ọkụ laser akaịgbado ọkụ?

1. Ígwè anaghị agba nchara

Ígwè anaghị agba nchara nwere oke mmụba okpomọkụ, ọ na-adịkarịkwa oke okpomọkụ n'oge ịgbado ọkụ. Mgbe mpaghara okpomọkụ metụtara ntakịrị buru ibu, ọ ga-akpata nnukwu nsogbu mgbanwe. Agbanyeghị, okpomọkụ nke igwe ịgbado ọkụ laser aka na-emepụta n'oge usoro ịgbado ọkụ niile dị obere. Tinyere obere ike okpomọkụ, oke ike nnabata na arụmọrụ ịgbaze nke ígwè anaghị agba nchara, enwere ike nweta njikọta nke ọma, dị ire ụtọ ma mara mma mgbe ịgbado ọkụ gasịrị.

2. Ígwè carbon

Enwere ike ịgbado ígwè carbon nkịtị ozugbo site na iji laser blending aka, mmetụta ya dị ka ịgbado ígwè anaghị agba nchara, ebe okpomọkụ metụtara dịkwa obere, mana mgbe a na-agbado ígwè ọkara na elu carbon, okpomọkụ fọdụrụ dị elu, yabụ ọ ka dị mkpa ịgbado ọkụ tupu ịgbado ọkụ. Ịkpo ọkụ na nchekwa okpomọkụ mgbe ịgbado ọkụ gasịrị iji belata nrụgide ma zere mgbawa. N'ebe a, anyị nwere ike ikwu maka igwe ịgbado ọkụ oyi. Enwere ike ịgbado ọkụ ma ọ bụ rụzie ígwè carbon dị ọkara na elu na ọsọ dị nwayọ site na iji waya ịgbado ọkụ oyi na ígwè a kpụrụ akpụ. N'ihe gbasara njikwa okpomọkụ, njikwa okpomọkụ, na njikwa okpomọkụ, igwe ịgbado ọkụ oyi nwere ike ịkụziri ịgbado ọkụ laser aka ka mma na ihe fọdụrụ na okpomọkụ mgbe ịgbado ọkụ gasịrị.

3. Ígwè anwụ

Ọ dabara adaba maka ịgbado ụdị ígwè dị iche iche, mmetụta ịgbado ọkụ dịkwa mma nke ukwuu.

4. Aluminom na aluminom alloy

Aluminom na aluminom alloys bụ ihe na-egosipụta nke ọma, porosity nwekwara ike ịpụta n'ọdọ mmiri gbazere agbaze ma ọ bụ n'ime mgbọrọgwụ ya mgbe a na-agbakọta ya. Ma e jiri ya tụnyere ihe ndị e ji ígwè rụọ n'oge gara aga, aluminom na aluminom alloys nwere ihe achọrọ dị elu maka paramita, mana ọ bụrụhaala na paramita njikọta ahọpụtara kwesịrị ekwesị, enwere ike nweta njikọta njikọta njikọta nke nwere otu ihe eji arụ ọrụ dịka ígwè ntọala.

5. Ihe e ji ọla kọpa na ọla kọpa mee

Ọkpọkọ ọkụ nke ọla kọpa siri ike nke ukwuu, ọ dịkwa mfe ime ka a banye n'ime ya nke ọma ma jikọta ya nke ọma n'oge ịgbado ọkụ. Ọtụtụ mgbe, a na-ekpo ọkụ ihe ọla kọpa n'oge ịgbado ọkụ iji nyere aka ịgbado ọkụ. N'ebe a, anyị na-ekwu maka ihe ọla kọpa dị gịrịgịrị. Ịgbado ọkụ laser nke ejiri aka mee nwere ike ozugbo Ịgbado ọkụ, n'ihi ike ya siri ike na ọsọ ịgbado ọkụ ngwa ngwa, anaghị emetụta oke okpomọkụ nke ọla kọpa.

6. Ịgbado ọkụ n'etiti ihe dị iche iche

Igwe ịgbado ọkụ laser nke ejiri aka rụọ nwere ike ịrụ n'etiti ọtụtụ ọla dị iche iche, dịka ọla kọpa-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, obere carbon steel-copper na ọla ndị ọzọ dị iche. Enwere ike ịgbado ọkụ laser n'ọnọdụ ọ bụla (gas ma ọ bụ okpomọkụ).

Igwe ịgbado ọkụ laser aka bụ ngwaahịa a na-ejikarị eme ihe ugbu a n'ụlọ ọrụ ịgbado ọkụ, n'ihi na ọ bụ ezie na akụrụngwa a dị oke ọnụ, ọ nwere ike ịchekwa ụgwọ ọrụ nke ọma. Ọnụ ego ọrụ nke ndị ịgbado ọkụ dị oke ọnụ. Iji nke a Ngwaahịa a na-edozi nsogbu nke iwere ndị ịgbado ọkụ dị oke ọnụ ma sie ike. Ọzọkwa, igwe ịgbado ọkụ laser aka enwetala otuto zuru oke site n'aka ọtụtụ puku ndị ahịa n'ihi ogologo ndụ ọrụ ya na obere oriri ike.

Ọ bụrụ na ịchọrọ ịmatakwu gbasara nhicha laser, ma ọ bụ ịchọrọ ịzụta igwe nhicha laser kacha mma maka gị, biko hapụ ozi na weebụsaịtị anyị ma zitere anyị email ozugbo!

Oge ozi: Disemba-03-2022