Fitowar wayoyin salula ta canza salon rayuwar mutane sosai, kuma ci gaba da inganta yanayin rayuwar mutane ya kuma sanya buƙatu mafi girma ga wayoyin salula: baya ga ci gaba da haɓaka tsarin, kayan aiki da sauran tsare-tsare masu aiki, bayyanar wayoyin salula ta zama abin da ake fafatawa a tsakanin masana'antun wayoyin salula. A cikin tsarin ƙirƙirar kayan kwalliya, masana'antun suna maraba da kayan gilashi saboda fa'idodi da yawa kamar siffofi masu canzawa, juriya mai kyau ga tasiri, da farashin da za a iya sarrafawa. Ana ƙara amfani da su a wayoyin salula, gami da murfin gaba na wayar salula, murfin baya, da sauransu. Murfi, murfin kyamara, matattara, fina-finan gane sawun yatsa, firam, da sauransu.

Duk da cewa kayan gilashi suna da fa'idodi da yawa, halayensu masu rauni suna kawo matsaloli da yawa ga tsarin sarrafawa, kamar tsagewa da gefuna masu kaifi. Bugu da ƙari, yanke belun kunne na musamman, kyamarar gaba, fim ɗin sawun yatsa, da sauransu suma suna gabatar da buƙatu mafi girma don fasahar sarrafawa. Yadda ake magance matsalolin sarrafa kayan gilashi da inganta yawan samfura ya zama babban buri a masana'antar, kuma yana da gaggawa a haɓaka kirkire-kirkire a fasahar yanke gilashi.

Kwatanta tsarin yanke gilashi

Yanke gilashin wuka na gargajiya

Tsarin yanke gilashi na gargajiya ya haɗa da yanke ƙafafun wuka da yanke niƙa na CNC. Gilashin da aka yanke ta hanyar da aka yanke yana da manyan guntu da gefuna masu kauri, wanda zai yi tasiri sosai ga ƙarfin gilashin. Bugu da ƙari, gilashin da aka yanke ta hanyar da aka yanke tana da ƙarancin yawan amfani da kayan aiki. Bayan yankewa, ana buƙatar matakai masu rikitarwa bayan sarrafawa. Sauri da daidaiton ƙafafun yanke zai ragu sosai lokacin yanke siffofi na musamman. Ba za a iya yanke wasu allon allo mai siffar musamman da dabaran yanke ba saboda kusurwar ta yi ƙanƙanta. CNC tana da daidaito mafi girma fiye da ƙafafun yankewa, tare da daidaito na ≤30 μm. Guntun gefen ya fi ƙanƙanta fiye da ƙafafun yankewa, kimanin 40 μm. Rashin kyau shine saurin yana da jinkiri.

Yanke gilashin Laser na gargajiya

Tare da ci gaban fasahar laser, lasers suma sun bayyana a cikin yanke gilashi. Yanke laser yana da sauri kuma yana da daidaito sosai. Yankan ba su da burrs kuma ba a iyakance su da siffa ba. Gilashin gefuna gabaɗaya bai wuce 80 μm ba.

Yanke gilashin laser na gargajiya yana amfani da hanyar cirewa, ta amfani da laser mai ƙarfi mai yawa don narkewa ko ma tururi ya yi tururi, da kuma iskar gas mai ƙarfi don hura sauran slag. Saboda gilashin yana da rauni, wurin haske mai ƙarfi mai girma zai tara zafi mai yawa akan gilashin, wanda ke haifar da fashewar gilashin. Saboda haka, laser ɗin ba zai iya amfani da wurin haske mai girma mai girma ba don yankewa ɗaya. Yawanci, ana amfani da galvanometer don yin scanning mai sauri don yanke layin gilashin ta hanyar layi. Cire layuka, saurin yanke gabaɗaya bai wuce 1mm/s ba.

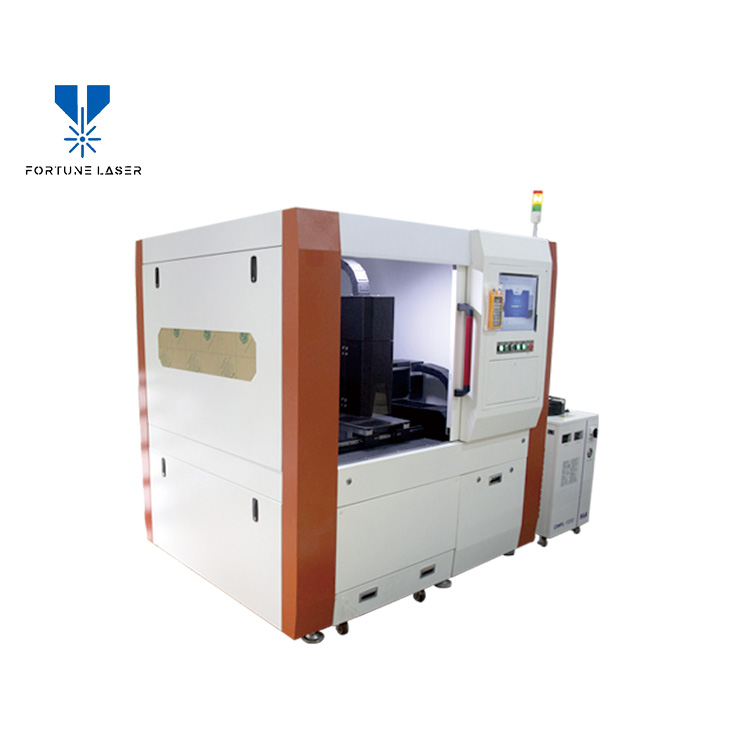

Yanke gilashin laser mai sauri sosai

A cikin 'yan shekarun nan, na'urorin laser masu sauri (ko na'urorin laser masu gajeren zango) sun sami ci gaba cikin sauri, musamman a fannin amfani da su wajen yanke gilashi, wanda ya sami kyakkyawan aiki kuma yana iya guje wa matsaloli kamar su yanke gefen da fasawa waɗanda ke iya faruwa a cikin hanyoyin yanke injin gargajiya. Yana da fa'idodin babban daidaito, babu ƙananan fasawa, matsalolin karyewa ko tsagewa, juriyar tsagewa mai ƙarfi, kuma babu buƙatar farashin masana'antu na biyu kamar wankewa, niƙa, da gogewa. Yana rage farashi yayin da yake inganta yawan amfanin kayan aiki da ingancin sarrafawa.

Lokacin Saƙo: Mayu-17-2024