Na'urar walda ta hannu ta Fortune Laser Fiber Laser

Na'urar walda ta hannu ta Fortune Laser Fiber Laser

Sigogi na Fasaha na Laser na Hannun Lasisin Fortune Laser

| Samfuri | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| Nau'in Laser | Laser ɗin Fiber 1070nm | ||

| Ƙarfin Laser mara iyaka | 1000W | 1500W | 2000W |

| Tsarin Sanyaya | Sanyaya Ruwa | ||

| Hanyar aiki | Ci gaba / Daidaitawa | ||

| Kewayon saurin walda | 0~120 mm/s | ||

| Diamita na Tabo Mai Mahimmanci | 0.5mm | ||

| Matsakaicin zafin jiki na yanayi | 15 ~ 35 ℃ | ||

| Tsarin zafi na muhalli | <70% ba tare da danshi ba | ||

| Kauri na walda | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| Bukatun gibin walda | ≤1.2mm | ||

| Wutar Lantarki Mai Aiki | AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Girman Majalisa | 120*60*120cm | ||

| Girman Kunshin Katako | 154*79*137cm | ||

| Nauyi | 285KG | ||

| Tsawon zare | Matsakaicin 10M, tsawon da aka keɓance shine 15M | ||

| Aikace-aikace | Walda da gyaran bakin karfe, ƙarfe mai carbon, da kuma ƙarfe mai aluminum. | ||

Mai walda na Laser na hannu mai ɗaukuwa don ƙarfe

| Kayan Aiki | Ƙarfin fitarwa (W) | Matsakaicin shigar ciki (mm) |

| Bakin karfe | 1000 | 0.5-3 |

| Bakin karfe | 1500 | 0.5-4 |

| Bakin karfe | 2000 | 0.5-5 |

| Karfe mai carbon | 1000 | 0.5-2.5 |

| Karfe mai carbon | 1500 | 0.5-3.5 |

| Karfe mai carbon | 2000 | 0.5-4.5 |

| Gilashin aluminum | 1000 | 0.5-2.5 |

| Gilashin aluminum | 1500 | 0.5-3 |

| Gilashin aluminum | 2000 | 0.5-4 |

| Takardar galvanized | 1000 | 0.5-1.2 |

| Takardar galvanized | 1500 | 0.5-1.8 |

| Takardar galvanized | 2000 | 0.5-2.5 |

Launuka Uku Don Zaɓuɓɓukanku

Abũbuwan amfãni na Injin Walda na Laser na Hannu

1. Faɗin kewayon walda:

Kan walda na hannu yana da zare na gani na asali mai girman 10M (tsawon da aka keɓance mafi tsawo shine 15M), wanda ke shawo kan iyakokin sararin aikin, kuma ana iya walda shi a waje da walda mai nisa;

2. Mai sauƙin amfani da kuma sassauƙa:

Walda ta laser da aka riƙe da hannu tana da injinan ƙwanƙwasa masu motsi, waɗanda ke da sauƙin riƙewa, kuma tana iya daidaita tashar a kowane lokaci, ba tare da tashar da aka saita ba, kyauta kuma mai sassauƙa, kuma ta dace da yanayi daban-daban na aiki.

3. Hanyoyi da yawa na walda:

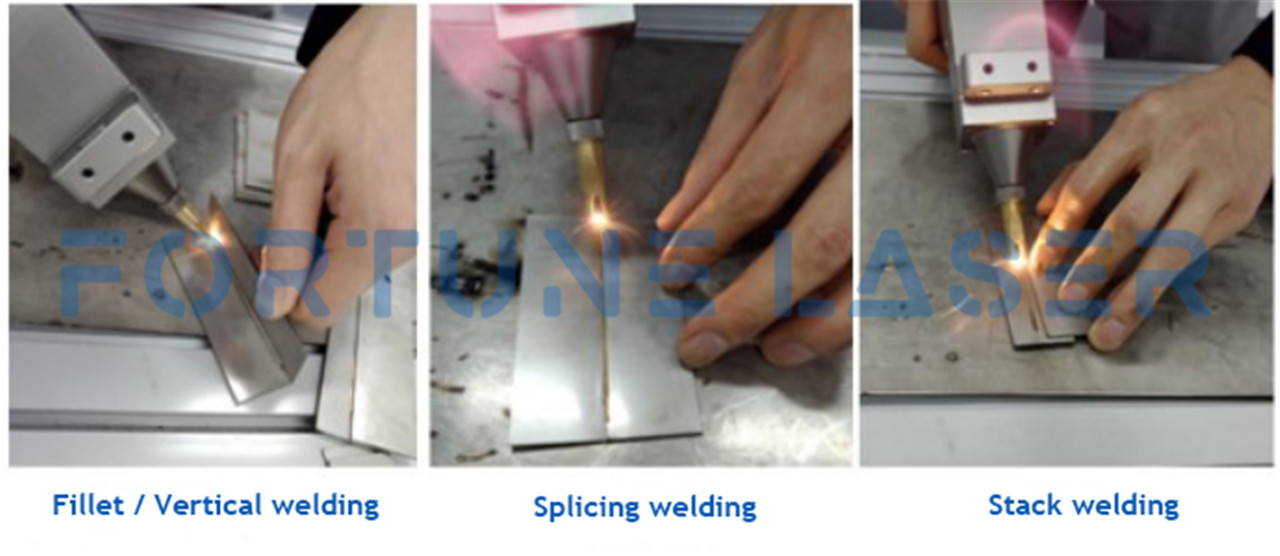

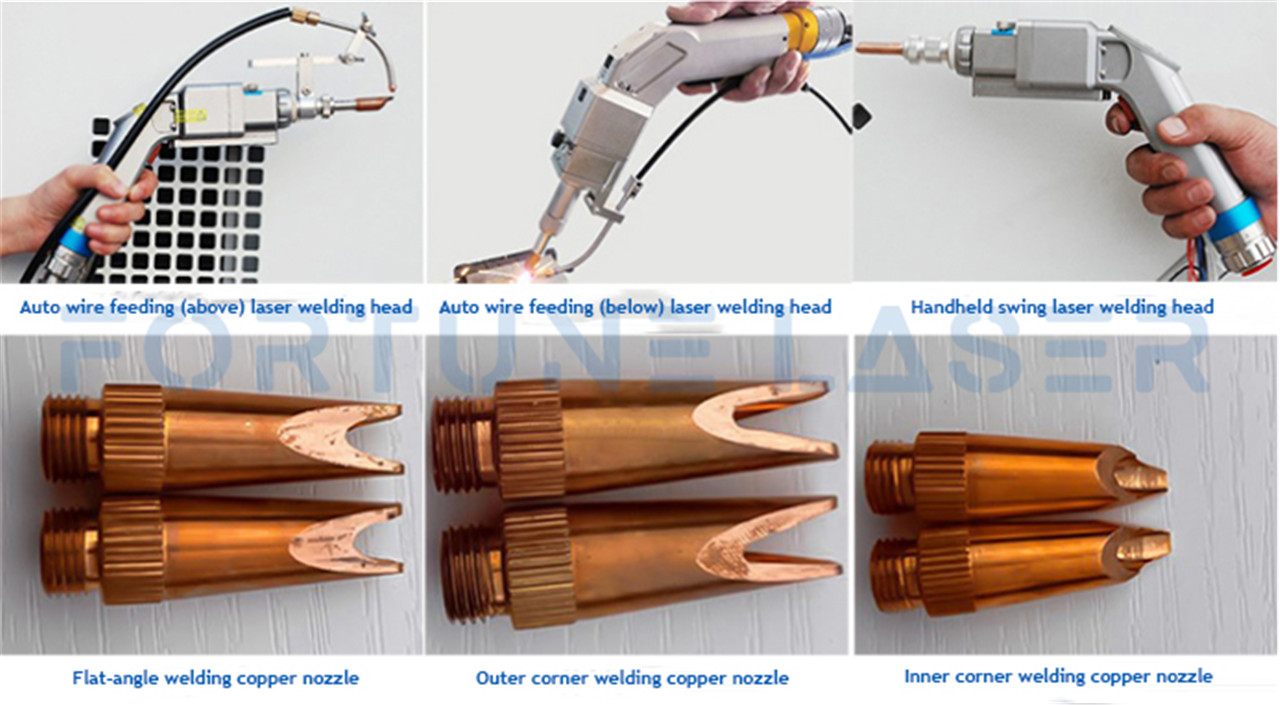

Ana iya yin walda a kowane kusurwa: walda mai haɗuwa, walda a kan duwawu, walda a tsaye, walda mai lebur, walda a kan duwawu na ciki, walda a kan duwawu na waje, da sauransu, kuma yana iya yin walda a kan duwawu daban-daban masu rikitarwa da manyan kayan aiki masu siffofi marasa tsari. Yi walda a kowane kusurwa. Bugu da ƙari, yana iya kammala yankewa, walda da yankewa ana iya canzawa cikin 'yanci, kawai canza bututun jan ƙarfe na walda zuwa bututun jan ƙarfe na yankewa, wanda ya dace sosai.

4. Kyakkyawan tasirin walda:

Walda ta laser da hannu tana da alaƙa da haɗakar zafi. Idan aka kwatanta da walda ta gargajiya, walda ta laser tana da ƙarfi sosai kuma tana iya samun sakamako mafi kyau na walda. Yankin walda ba shi da tasirin zafi sosai, ba shi da sauƙin lalacewa, baƙi ne, kuma yana da alamun a baya. Zurfin walda yana da girma, narkewar ya isa, kuma yana da ƙarfi kuma abin dogaro, kuma ƙarfin walda ya kai ko ya wuce ƙarfen tushe, wanda ba za a iya tabbatar da shi ta hanyar injunan walda na yau da kullun ba.

5. Ba sai an goge dinkin walda ba.

Bayan walda ta gargajiya, ana buƙatar a goge wurin walda don tabbatar da cewa yana da santsi kuma ba mai kauri ba. Walda ta laser da aka riƙe da hannu tana nuna ƙarin fa'idodi a cikin tasirin sarrafawa: walda mai ci gaba, santsi kuma babu sikelin kifi, kyau kuma babu tabo, da ƙarancin hanyoyin gogewa na bibiya.

6. Walda damai ciyar da waya ta atomatik.

A ra'ayin mutane da yawa, aikin walda shine "gilashin hannu na hagu, wayar walda ta hannun dama". Amma tare da injin walda na laser na hannu, ana iya kammala walda cikin sauƙi, wanda ke rage farashin kayan aiki wajen samarwa da sarrafawa.

7. Mafi aminci gamai aiki.

Tare da ƙararrawa da yawa na tsaro, ƙarshen walda yana aiki ne kawai lokacin da aka taɓa maɓallin lokacin da ya taɓa ƙarfe, kuma hasken yana kulle ta atomatik bayan an cire kayan aikin, kuma maɓallin taɓawa yana da na'urar auna zafin jiki. Tsaron yana da ƙarfi don tabbatar da amincin mai aiki yayin aiki.

8. Ajiye kuɗin aiki.

Idan aka kwatanta da walda ta baka, farashin sarrafawa zai iya raguwa da kusan kashi 30%. Aikin yana da sauƙi, mai sauƙin koyo, kuma yana da sauri don farawa. Matsakaicin fasaha na masu aiki ba shi da yawa. Ma'aikata na yau da kullun za su iya ɗaukar mukamansu bayan ɗan gajeren horo, wanda zai iya samun sakamako mai inganci cikin sauƙi.

9. Sauƙin canzawa daga hanyoyin walda na gargajiya zuwa walda na fiber laser.

Za ku iya koyon yadda ake amfani da injin walda na fiber laser na Fortune Laser cikin 'yan awanni kaɗan, kuma babu ciwon kai don neman ƙwararrun walda, babu damuwa game da jadawalin isar da kaya mai tsauri. Bugu da ƙari, tare da wannan sabuwar fasaha da saka hannun jari, za ku kasance a gaba a kasuwa kuma ku rungumi ƙarin riba fiye da hanyoyin walda na gargajiya.

Filayen Aikace-aikacen na Injin Walda na Laser na Hannu

Na'urar walda ta laser da hannu galibi an yi ta ne don manyan da matsakaicin girman ƙarfe, kabad, chassis, firam ɗin ƙofofi da tagogi na ƙarfe, kwano na wanke bakin ƙarfe da sauran manyan kayan aiki, kamar kusurwar dama ta ciki, kusurwar dama ta waje, walda mai faɗi, ƙaramin yanki da zafi ya shafa yayin walda, ƙaramin lahani, da zurfin walda.

Ana amfani da injunan walda na hannu na Fortune Laser a cikin tsarin walda mai rikitarwa da rashin tsari na masana'antar girki da banɗaki, masana'antar kayan gida, masana'antar talla, masana'antar mold, masana'antar kayayyakin ƙarfe, masana'antar injiniyan ƙarfe, masana'antar ƙofofi da tagogi, masana'antar sana'o'i, masana'antar kayan gida, masana'antar kayan daki, masana'antar sassan motoci, da sauransu.

Kwatanta Injin Walda na Laser da ke Hannun Hannu da Walda na Argon Arc

1. Kwatanta amfani da makamashi:Idan aka kwatanta da walda ta gargajiya, injin walda ta laser da hannu yana adana kusan kashi 80% zuwa 90% na wutar lantarki, kuma ana iya rage farashin sarrafawa da kusan kashi 30%.

2. Kwatanta tasirin walda:Walda da aka yi da hannu ta laser na iya kammala walda iri-iri ta ƙarfe da ƙarfe iri-iri. Saurin yana da sauri, sauye-sauyen ba su da yawa, kuma yankin da zafi ya shafa ƙarami ne. Dinkin walda yana da kyau, santsi, babu ko kaɗan da porosity, kuma babu gurɓatawa. Ana iya amfani da injin walda na laser na hannu don ƙananan sassa a buɗe da walda daidai.

3. Kwatanta tsarin bibiya:Ana iya samun ƙarancin zafi yayin walda ta hannu ta laser, ƙaramin nakasa na kayan aiki, kyakkyawan saman walda, babu magani mai sauƙi ko kawai (ya danganta da buƙatun tasirin saman walda). Injin walda ta laser na hannu zai iya rage farashin aiki na babban aikin gogewa da daidaita shi sosai.

| Nau'i | Walda ta Argon arc | Walda ta YAG | Mai riƙewa ta hannuLaserwalda | |

| Ingancin walda | Shigar da zafi | Babba | Ƙarami | Ƙarami |

|

| Nakasa/ƙasa a wurin aiki | Babba | Ƙarami | Ƙarami |

|

| Samar da walda | Tsarin sikelin kifi | Tsarin sikelin kifi | Santsi |

|

| Sarrafawa na gaba | Yaren mutanen Poland | Yaren mutanen Poland | Babu |

| Amfani da aikin | Gudun walda | A hankali | Tsakiya | Da sauri |

|

| Wahalar aiki | Mai Tauri | Mai sauƙi | Mai sauƙi |

| Kare muhalli da amincinsa | Gurɓatar muhalli | Babba | Ƙarami | Ƙarami |

|

| Lalacewar jiki | Babba | Ƙarami | Ƙarami |

| Kudin walda | Kayan amfani | Sanda mai walda | Fitilar Laser, fitilar xenon | Babu buƙata |

|

| Amfani da makamashi | Ƙarami | Babba | Ƙarami |

| Yankin bene na kayan aiki | Ƙarami | Babba | Ƙarami | |