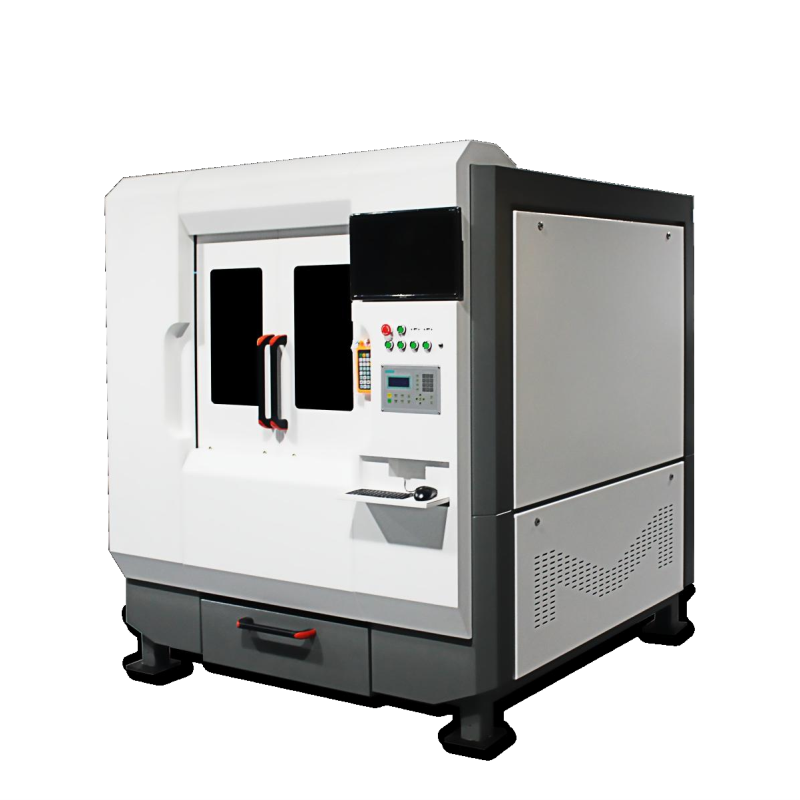

Njengoba izinga lokushisa likhuphuka ehlobo, yenza umsebenzi omuhle ekunakekelweni komshini wokusika nge-laser ukuze ugweme ukwehluleka kwemishini. Imishini yokusika nge-laser ivame ukuba nezinkinga ngenxa yokushisa okuphezulu ehlobo. Kulesi sihloko, sizoxoxa ngezizathu ezenza imishini yokusika nge-laser ibe nezinkinga ehlobo nokuthi ungayigcina kanjani ekushiseni okuphezulu. Ngaphezu kwalokho, sizobheka amakhono adingekayo ukuze uhlale usesimweni esihle.abasiki be-laseriphephile emazingeni okushisa aphezulu.

Imvula enkulu ehlobo kanye nomswakama ophezulu endaweni yokukhiqiza imishini kungabangela ukuthi imishini igqwale futhi ibole. Indawo enomswakama enjalo ingabangela ne-short circuit. Ukuze kugwenywe lezi zinkinga, kubalulekile ukugcina uhlelo lokupholisa kanye namanzi okupholisa. Futhi, ukuvikelwa kwesitimela, ukuhlanza kanye nokugcinwa kwe-circuit kubalulekile ukuze kugwenywe ukuminyana.

Uhlelo lokupholisa kanye namanzi okupholisa kudlala indima ebalulekile ekugcinweniumshini wokusika nge-laserendaweni enokushisa okuphezulu. Izinga lokushisa lamanzi okupholisa kumele ligcinwe lisezingeni elifanele, futhi ikhwalithi yamanzi kumele ihlanzeke. Imibhoshongo yokupholisa kufanele ihlolwe ukuze kutholakale ukuthi ingakanani i-skew kanye nokukhula kwe-algae, okungabangela ukuvinjelwa kwamapayipi. Amanzi kufanele ashintshwe njalo ukuze kuvinjelwe ukungcola ukuthi kungangeni emshinini futhi kubangele ukugqwala.

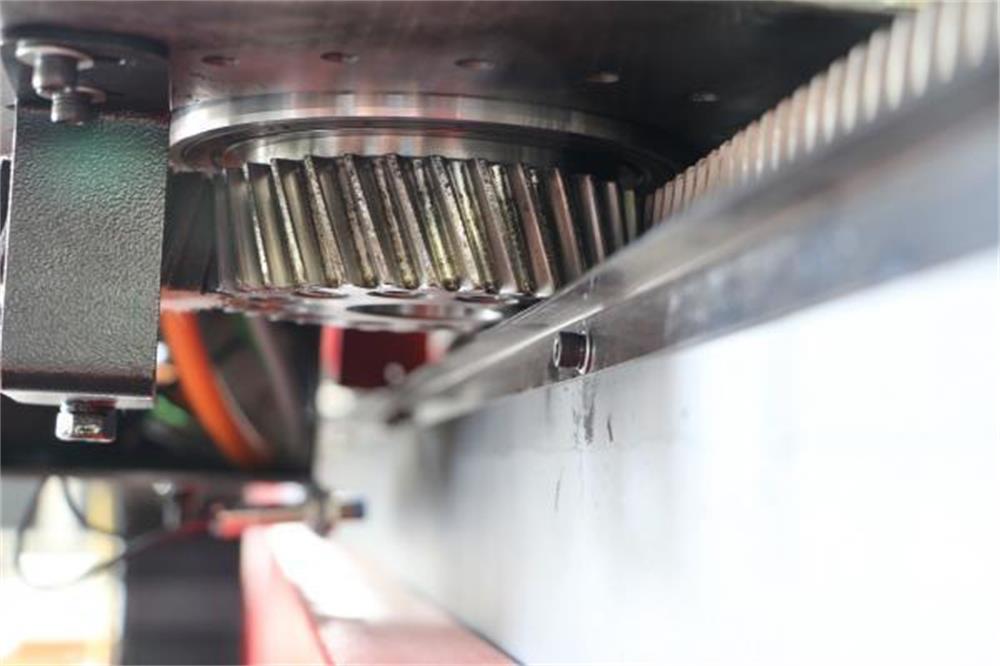

Ukuhlanzwa njalo komshini wakho wokusika nge-laser kuyadingeka ukuqinisekisa ukusebenza kwawo kwesikhathi eside. Ama-rails kufanele ahlolwe njalo ukuqinisekisa ukuthi asebenza kahle futhi avimbele ukugqwala. Ngaphezu kwalokho, noma yiluphi uthuli kanye nemfucumfucu emzimbeni wokusika nge-laser kumele kususwe ukuze kuvinjelwe umonakalo ekushiseni ngokweqile.

Ukunakekelwa kwesekethe kungenye isici esibalulekile sokugcina i-oda lakho liphephileumshini wokusika nge-laserngesikhathi sasehlobo. Amasekethe kufanele ahlolwe njalo ukuqinisekisa ukuthi azikho izimpawu zokugqwala noma ukugqwala. Isekethe kufanele ihlanzwe ukuze kususwe noma yikuphi ukungcola noma uthuli. Umshini kufanele ugweme ukungena koketshezi kanye nokujiya ukuze kuvinjelwe umonakalo wesekethe.

Ngaphezu kwalezi zinyathelo zokulungisa, kunezindlela ezimbalwa ongazisebenzisela ukugwema amazinga okushisa aphezulu kumsiki wakho we-laser. Elinye lalawo makhono ukusebenzisa amafeni okupholisa ukuhambisa umoya ngaphakathi komshini. Lokhu kusiza ukugwema ukwakheka kokushisa ezingxenyeni ezibalulekile futhi kugcina umshini usebenza ezingeni lokushisa eliphezulu. Futhi, kubalulekile ukuqinisekisa ukuthi indawo laphoumshiniigcinwe ingeniswe umoya kahle.

Elinye ikhono ukusebenzisa i-thermal insulation ukuvimbela ukulahleka kokushisa nokugcina izinga lokushisa elifanele lezingxenye ezingaphakathi kwe-laser cutter. Lezi zinto kufanele zisetshenziswe ezingxenyeni ezibalulekile njengezinhloko ze-laser, amatafula okusika kanye namayunithi okunikeza ugesi.

Ngamafuphi, ihloboumshini wokusika nge-laserithambekele ezinkingeni ngenxa yokushisa okuphezulu. Imishini yokusika nge-laser kumele igcinwe emazingeni okushisa aphezulu ukuqinisekisa ukusebenza kwayo kwesikhathi eside. Ukugcinwa kohlelo lokupholisa namanzi okupholisa, ukuvikelwa kwesitimela, ukuhlanza, ukulungiswa kwesekethe, kanye nokusebenzisa amakhono athile ukugwema amazinga okushisa aphezulu kubalulekile. Ukugcinwa okufanele kanye nokusetshenziswa ngobuchwepheshe kungasiza ekuvimbeleni umshini ukuthi uvale noma ubhekane nezinye izinkinga zemishini esikhathini esizayo.

Uma ufuna ukufunda kabanzi ngokusika nge-laser, noma ufuna ukuthenga umshini wokusika nge-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Juni-03-2023