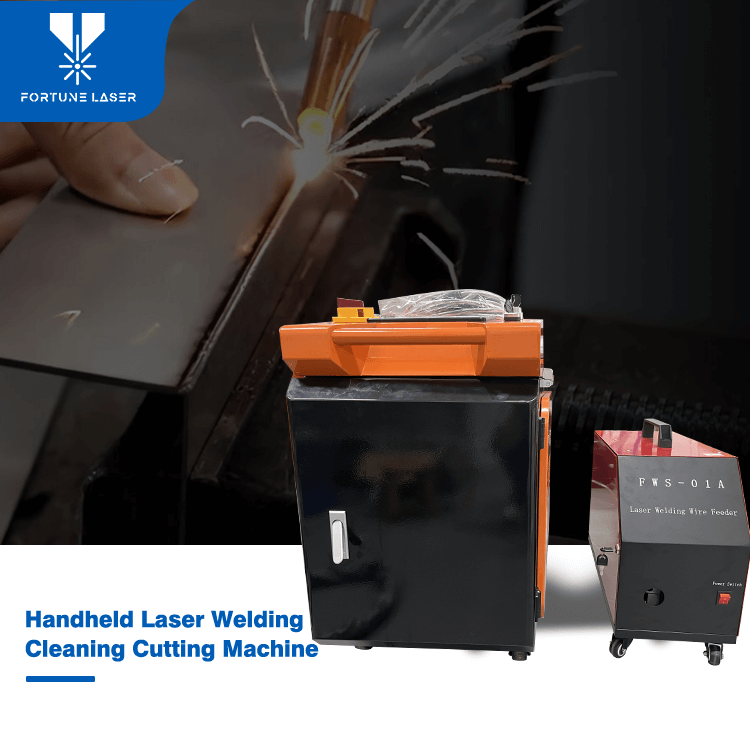

Njengoba ubuchwepheshe be-handheldimishini yokushisela nge-laserNjengoba iqhubeka nokuthuthuka, amabhizinisi amaningi aphendukela kule ndlela ngenxa yezidingo zawo zokushisela. Ububanzi bezinzuzo ezinikezayo, okuhlanganisa namakhono ayo angaphandle nakude, kwenza kube ukukhetha okuthandwayo ezimbonini eziningi. Lokho kusho ukuthi, ukulungiswa okufanele kuyisihluthulelo sokuqinisekisa ukusebenza okuhle kakhulu kusuka emshinini wakho wokushisela we-laser ophathwayo kanye ne-cooler.

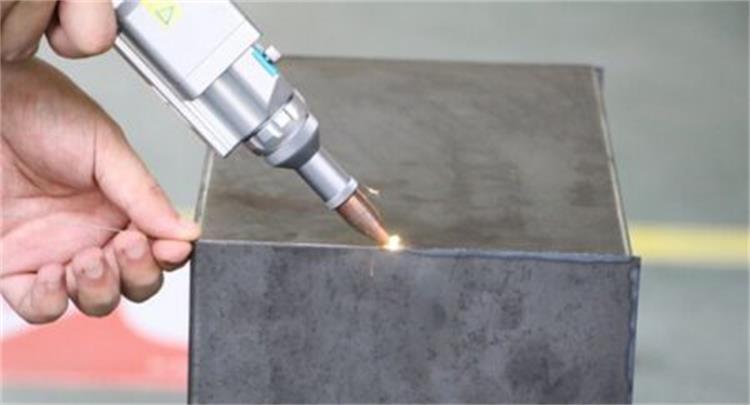

Enye yezinzuzo eziyinhloko ze-handheldumshini wokushisela nge-laserikhono layo lokusetshenziswa ekushiseleni nasekushiseleni ngaphandle ebangeni elide. Lesi sici siyenza ithuluzi elifanele lokushiseleni ezindaweni ezinzima nezikude. Kodwa-ke, ukuze umshini wakho usebenze kahle, kubalulekile ukuthi ugcinwe kahle. Ukuhlanza njalo nokuthambisa kuyadingeka ukuze umshini usebenze kahle.

Elinye inani le-umshini wokushisela we-laser ophathwa ngesandlakuyindlela yayo yokushisela ehlukahlukene, engasetshenziswa ukuqedela izinhlelo zokusebenza ezahlukahlukene zokushisela. Lokhu kufaka phakathi ukugoqa, ukushisela izinqe kanye nokushisela okuqondile, okuyisicaba, kwangaphandle nangaphakathi kwe-fillet. Kungakhathaliseki ukuthi kusebenza ezindaweni eziqinile noma kuma-engeli ayinselele, imishini yokushisela ye-laser ephathwa ngesandla ifanelekela imisebenzi eminingi yokushisela.

Ngoba i-handheldumshini wokushisela we-laserAkudingi izinto ezisetshenziswayo, ama-weld akudingeki agaywe. Lokhu kuyinzuzo enkulu njengoba kunciphisa isikhathi sokusebenza futhi kuholela enqubweni yokushisela esebenza kahle kakhulu. Ngaphezu kwalokho, lesi sici senza ama-weld afana kakhulu futhi abukeke kahle, okuholela ekubukekeni okuhlanzekile nokucwebezelayo.

Ukugcina i-chiller yakho kubaluleke njengokugcina umshini wakho wokushisela we-laser ophathwa ngesandla. I-cooler isiza ukugcina izinga lokushisa lokushisela le-laser lizinzile, ngaleyo ndlela yenza inqubo yokushisela ihambisane. Ukugcinwa kahle kwe-cooler kuqinisekisa ukuthi izinga lokushisa lihlala lizinzile futhi kuvimbela i-laser ekushiseni ngokweqile. Imisebenzi elula njengokuhlola amazinga okupholisa kanye nokuhlanza ama-cooler kungasiza ekwandiseni impilo yomshini wakho.

Ukusungula uhlelo lokulungisa kufanele kube yinto eza kuqala uma ufuna ukwandisa isikhathi somshini wakho wokushisela we-laser ophathwa ngesandla kanye nohlelo lokupholisa. Ukuhlolwa njalo, ukuthambisa, ukuhlanza kanye nokulinganisa kuzosiza ukuqinisekisa ukuthi umshini uyaqhubeka nokusebenza kahle kakhulu. Ukwenza kanjalo kusiza ukuvimbela ukwehluleka okubizayo futhi kugcina imishini isebenza emazingeni aphezulu okusebenza.

Ekuphetheni,imishini yokushisela ye-laser ephathwa ngesandlaZiyizinto ezibalulekile ezimbonini eziningi, futhi ngokunakekelwa okufanele, zingenza umsebenzi wazo ngaphandle kokuphazamiseka. Kungakhathaliseki ukuthi usebenzisa umshini wakho ukushisela ngaphandle noma ukushisela amabanga amade, ukuwugcina kahle kuzosiza ukuqinisekisa ukuthi uyaqhubeka nokusebenza kahle, ukhiqiza ukushisela okuhlanzekile nokuphumelelayo njalo. Khumbula ukuthi ukugcina umshini wakho kahle kufanelekile isikhathi nomzamo ukuze uwugcine usebenza kahle iminyaka ezayo.

Uma ufuna ukufunda kabanzi ngokushisela nge-laser, noma ufuna ukuthenga umshini wokushisela nge-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Ephreli-15-2023