Enqubweni yokusika yezimboni,imishini yokusika nge-laserseziyingxenye ebalulekile yezimboni ezahlukene. Le mishini inikeza ukunemba nokusebenza kahle, okwenza ifunwe kakhulu yizinkampani ezidinga ukusika okunembile. Kodwa-ke, ukukhetha umshini wokusika i-laser ofanele ibhizinisi lakho kungaba umsebenzi onzima. Njengoba kunezinketho eziningi emakethe, izici eziningana kumele zicatshangelwe ngaphambi kokwenza isinqumo. Lesi sihloko sizokuqondisa ngenqubo yokukhetha umshini wokusika i-laser ofanele kakhulu enkampanini yakho.

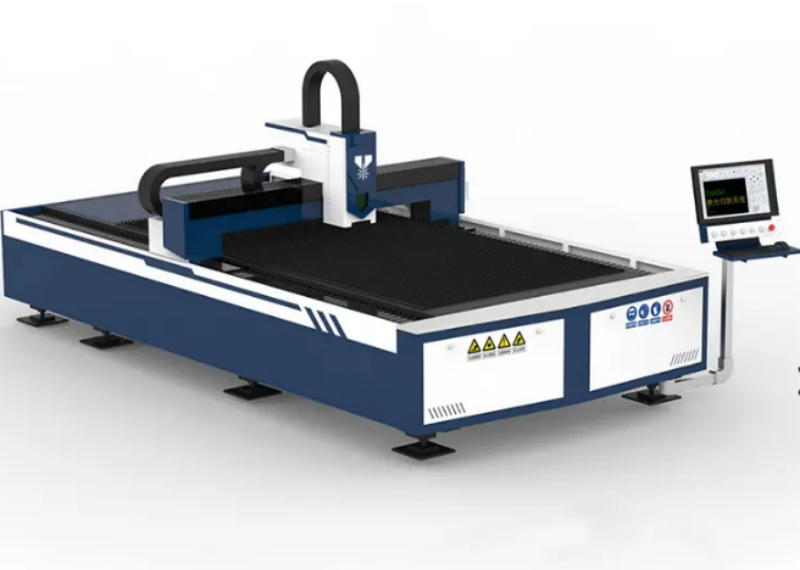

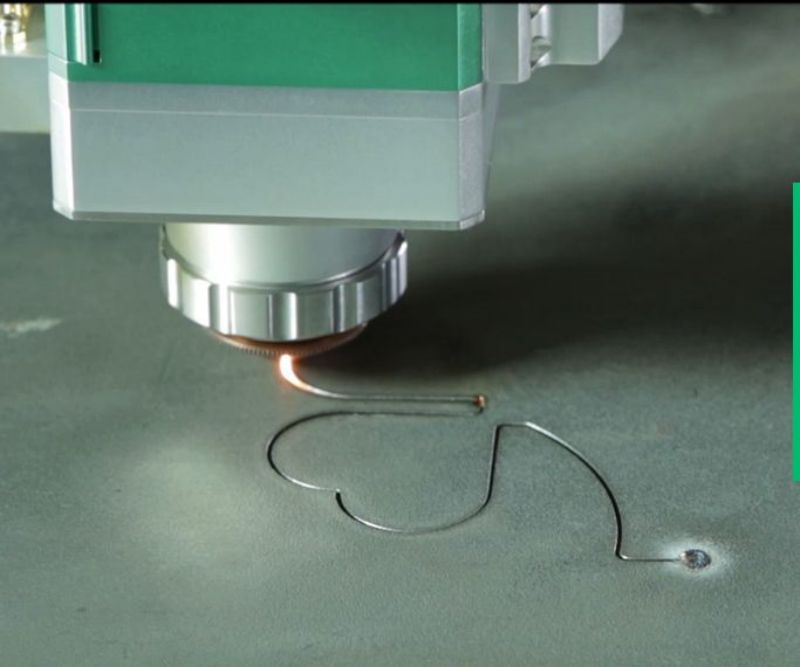

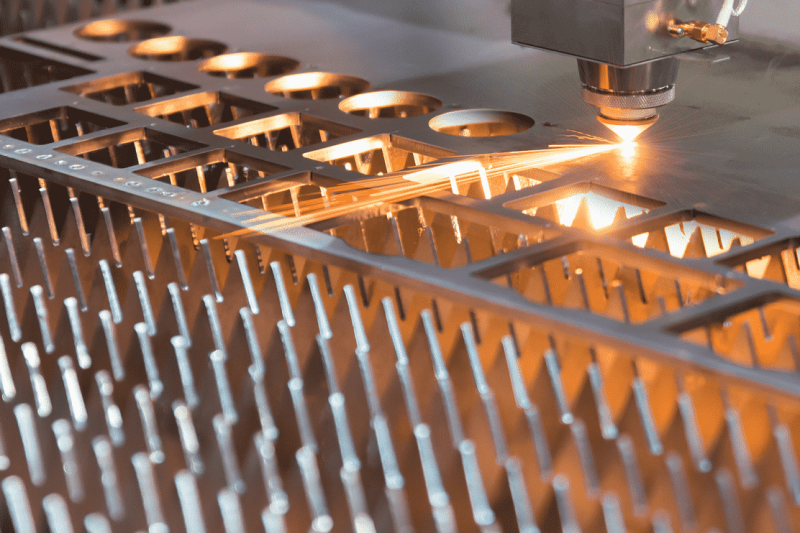

Isinyathelo sokuqala ekukhetheniumshini wokusika nge-laseriwukunquma izinto zokusika kanye nemingcele yokukhiqiza edingekayo enkambisweni yokukhiqiza. Imishini yokusika nge-laser ingasetshenziswa ukusika amashidi, amapuleti, amaphrofayili noma amaphaneli enziwe ngezinto ezahlukene njengensimbi, ipulasitiki noma izinto ezihlanganisiwe. Izinto ngazinye zinezidingo zazo ezithile zokusika, futhi ukuqonda lezi mingcele kuzokusiza ukuthi ubone umshini ongahlangabezana nezidingo zakho ngempumelelo.

Esinye isici esibalulekile okufanele usicabangele yikhwalithi iyonke yomsiki we-laser. Imakethe igcwele abakhiqizi abahlukahlukene, ngamunye ethi unikeza imishini esezingeni eliphezulu. Kodwa-ke, ukucwaninga nokuqhathanisa izinhlobo ezahlukene kubalulekile ukuqinisekisa ukuthi umshini otshala kuwo wakhelwe ukuqina, ukunemba kanye nokuthembeka. Ukufunda ukubuyekezwa kwamakhasimende, ukuhlola idumela lomkhiqizi, kanye nokucabangela izici zomshini kungakusiza wenze isinqumo esinolwazi.

Ingxenye yemakethe yeimishini yokusika nge-laserFuthi kuyisici esibalulekile okufanele usicabangele. Isabelo esikhulu semakethe somshini sibonisa ukuthi umshini uyamukelwa futhi uyathenjwa ngamakhasimende. Lokhu kukuqinisekisa ukuthi umshini uhlolwe futhi wavunyelwa ochwepheshe bemboni, okwandisa ukuzethemba kwakho ekusebenzeni kwawo nasekuthembekeni kwawo.

Insizakalo yangemva kokuthengisa ingenye into ebalulekile okufanele uyicabangele lapho uthenga umshini wokusika nge-laser. Ngisho nemishini esezingeni eliphezulu ingaba nezinkinga noma idinga ukulungiswa. Ngakho-ke, kubalulekile ukukhetha umenzi ohlinzeka ngensizakalo yangemva kokuthengisa esezingeni eliphezulu, okuhlanganisa ukwesekwa kobuchwepheshe, ukuhlinzekwa kwezingxenye ezisele kanye nosizo olufika ngesikhathi. Lokhu kuqinisekisa ukuthi imishini yakho inakekelwa kahle futhi noma yiziphi izinkinga zixazululwa ngokushesha, kunciphisa isikhathi sokungasebenzi futhi kwandise umkhiqizo.

Ukunquma okungcono kakhuluumshini wokusika nge-laserenkampanini yakho, kubalulekile ukuqonda ububanzi bokukhiqiza, izinto okufanele zicutshungulwe kanye nobukhulu bokusika obudingekayo enqubweni yakho yokukhiqiza. Umshini ngamunye unemikhawulo yawo maqondana nosayizi, amandla okusika kanye namandla, futhi ukunquma izidingo zakho ezithile kuzosiza ekunciphiseni izinketho zakho. Ochwepheshe bendawo bangenza ukulingisa endaweni noma banikeze izixazululo ezenzelwe wena ngokusekelwe ezidingweni zakho zokukhiqiza, okukuvumela ukuthi ukhethe imodeli efanele, ifomethi kanye nenani lemishini ongayithenga.

Ekuphetheni, ukukhetha okulungileumsiki we-laserebhizinisini lakho kudinga ukucatshangelwa ngokucophelela izici ezahlukahlukene. Ukuhlaziya izinto zokusika kanye nemingcele yokukhiqiza, ukuhlola ikhwalithi iyonke kanye nesabelo semakethe somshini, kanye nokuhlola insizakalo nokusekelwa kwangemva kokuthengisa kuyizinyathelo ezibalulekile ekwenzeni izinqumo ezinolwazi. Ngokuqonda ububanzi bokukhiqiza kanye nezidingo zokucubungula zenkampani yakho, unganquma uhlobo, imininingwane kanye nenani lemishini edingekayo. Funa usizo lochwepheshe uma kudingeka ukuqinisekisa ukuthi ukhetha umsiki we-laser ongcono kakhulu wezidingo zakho ezithile zokukhiqiza.

Isikhathi sokuthunyelwe: Julayi-22-2023