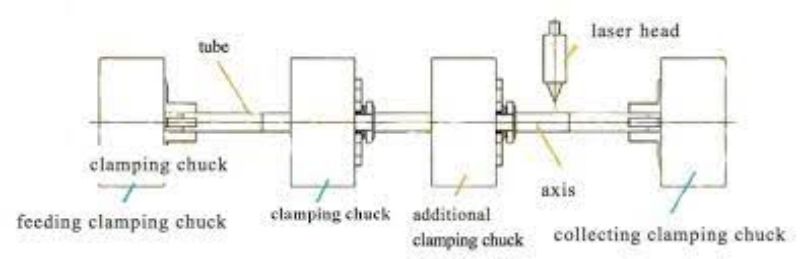

Ubuchwepheshe bokusika nge-laser bushintshe imboni yokusebenza ngensimbi ngokunemba kwayo okumangalisayo nemiphumela esezingeni eliphezulu. Enye yezindlela ezisetshenziswa kakhulu zokusika nge-laser ukusika nge-laserukusika amapayipi, enikeza indlela esheshayo nephumelelayo yokwenza amapayipi ensimbi ukuze kuhlangatshezwane nezidingo ezahlukene zezimboni. Nakuba, njengoba igama lisho, imishini yokusika amashubhu e-laser yenzelwe ngqo ukusika amashubhu ayindilinga, lobu buchwepheshe obusha bunokuguquguquka futhi bungasetshenziswa ukusika amashubhu anezimo nobukhulu obuhlukene.

Umshini wokusika ipayipi eliyindilinga nge-laser uhlonyiswe ngemisebenzi ethuthukisiwe nezindlela zokusika, eziwenza ukwazi ukuhlangabezana nezidingo ezahlukene zokusika ipayipi. Ngokulungisa amapharamitha okulawula ukusika, umshini ungahlangabezana nezidingo ezahlukahlukene zomkhakha futhi unikeze imikhiqizo eqediwe esezingeni eliphezulu. Awufanele nje kuphela ukusika amapayipi ayindilinga, kodwa futhi uyakwazi ukusika amapayipi ensimbi ajwayelekile. Lokhu kuguquguquka kwenza kube kuhle kakhulu ezinhlotsheni eziningi zezicelo.

Imodi yokusika yomshini wokusika ishubhu eliyindilinga le-laser iguquguquka kakhulu, ivumela ukusika okuqondile nokuhlanzekile ezinhlotsheni ezahlukene zezinto zokwakha. Kungakhathaliseki ukuthi insimbi engagqwali, insimbi yekhabhoni, i-aluminium noma enye insimbi, umshini uqinisekisa ukusika okuqondile nokuphumelelayo okuholela emaphethelweni abushelelezi nokunciphisa imfucuza. Ubuchwepheshe be-laser obusetshenziswa yilo mshini bungasika kalula imiklamo eyinkimbinkimbi kanye nezimo eziyinkimbinkimbi, bunikeza amathuba angenamkhawulo okudala nokwenza ngezifiso.

Ngaphezu komsebenzi wokusika, umshini wokusika ishubhu eliyindilinga le-laser ungahlanganiswa nohlelo lwerobhothi ukuze kufezwe ukuzenzekela okuphelele kokucubungula nokukhiqiza. Ngokuhambisana namarobhothi ahambisanayo, abakhiqizi bangandisa umkhiqizo kanye nokusebenza kahle ngenkathi benciphisa izindleko zabasebenzi. Umshini usebenza ngaphandle kokuphazamiseka ngengalo yerobhothi ephatha indawo kanye nokunyakaza kwepayipi, ukuqinisekisa ukusikeka okunembile kanye nokunciphisa ingozi yamaphutha.

Iukusika nge-laserIndlela esetshenziswa umshini wokusika ishubhu eliyindilinga inezinzuzo eziningana kunezindlela zokusika zendabuko. Ngokungafani nezindlela zendabuko ezihilela amandla omshini noma amandla okushisa, ukusika nge-laser kusebenzisa ukukhanya okugxilile ukuncibilikisa noma ukuhwamukisa izinto. Le ndlela yokusika engathintani ayidingi ukuthintana ngokomzimba, inciphisa ingozi yokulimala noma ukuguqulwa kwamapayipi. Iphinde inciphise ukudalwa kwendawo ethintekile ukushisa, okuholela ekusikeni okuhlanzekile kanye nokuphambuka okuncane kwezinto.

Ngaphezu kwalokho,ukusika nge-laserkuyinqubo ephumelelayo enganciphisa kakhulu isikhathi sokukhiqiza. Ngokwazi kwayo ukusika ngesivinini esikhulu, umshini wokusika amapayipi ayindilinga we-laser ungasika ngokushesha nangokunembile amapayipi ensimbi anobukhulu obuhlukahlukene. Lokhu kuvumela abakhiqizi ukuthi bafinyelele izikhathi zokuguqula ngokushesha futhi bahlangabezane nezinsuku zokugcina zokukhiqiza ngaphandle kokubeka engcupheni ikhwalithi yomkhiqizo oqediwe.

Imishini yokusika amashubhu e-laserakugcini nje ngokusika amapayipi. Kuyindlela eguquguqukayo engakha futhi isike amapayipi anezimo nobukhulu obuhlukene, kufaka phakathi amapayipi asikwele, angunxande, ngisho nanokwakheka okungajwayelekile. Amapharamitha okulawula ukusika alungisekayo omshini aqinisekisa ukuthi angashintshwa ukuze avumelane nezidingo ezithile zephrojekthi ngayinye, alethe ukusika okunembile kungakhathaliseki ukuma kwepayipi.

Ngamafuphi, iumshini wokusika ipayipi oyindilinga we-laseriyithuluzi elithuthukisiwe elihlinzeka ngamakhono okusika aphezulu ezidingweni ezahlukahlukene zokusika amapayipi. Ukuguquguquka kwalo, ukunemba kanye nokusebenza kahle kwenza kube yimpahla ebalulekile ezimbonini ezidinga imikhiqizo eqediwe esezingeni eliphezulu. Umshini awukhawulelwe ekusikeni amapayipi ayindilinga, kodwa futhi ungacubungula amapayipi ensimbi endabuko ukuze kusetshenziswe izinhlobo eziningi zokusetshenziswa. Ngekhono lawo lokuhlanganiswa nezinhlelo zamarobhothi, lenza abakhiqizi bakwazi ukwenza ngokuzenzakalelayo ukucubungula nokukhiqiza, bandise umkhiqizo futhi banciphise izindleko zabasebenzi. Indlela yokusika nge-laser esetshenziswa yilo mshini iqinisekisa ukusikwa okuhlanzekile, ukuphambuka okuncane kwezinto kanye nezikhathi zokushintsha ngokushesha. Embonini yokusebenza ngensimbi ekhula njalo, umshini wokusika ipayipi le-laser uwuphawu lokusungula izinto ezintsha kanye nokusebenza kahle.

Isikhathi sokuthunyelwe: Septhemba-04-2023