Umshini Wokushisela we-LAser we-Fortune Laser 200W weGolide weSiliva weCopper Jewelry YAG oneMicroscope

Umshini Wokushisela we-LAser we-Fortune Laser 200W weGolide weSiliva weCopper Jewelry YAG oneMicroscope

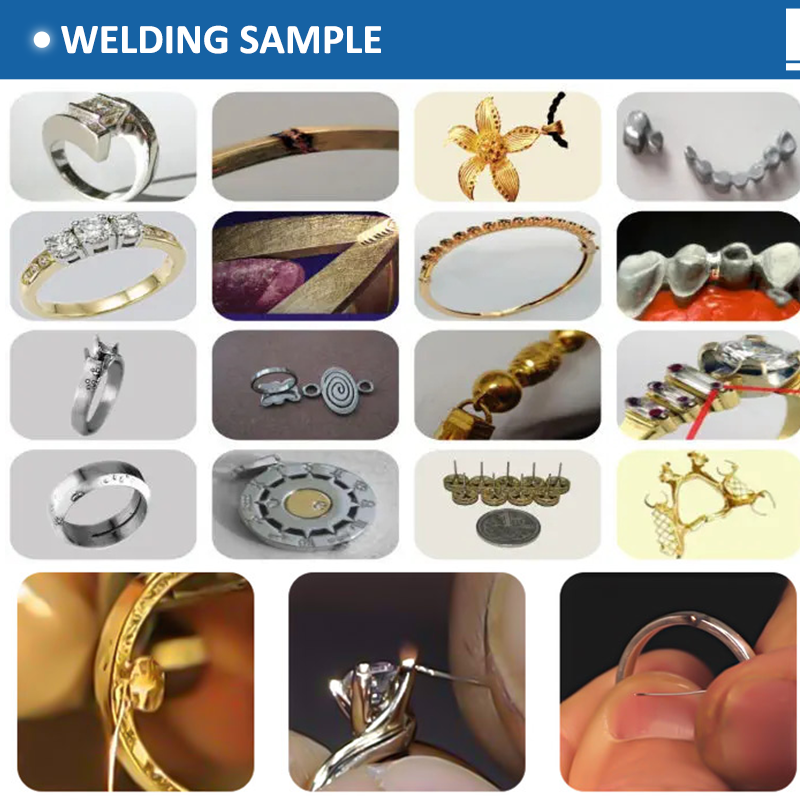

Umgomo wokusebenza womshini wokushisela ubucwebe

Ubucwebe bulokhu buyimboni ehlala njalo. Ukuphishekela kwabantu ubucwebe bekulokhu kuqhubeka nokuthuthuka, kodwa ubucwebe obuhle buvame ukuba nzima kakhulu ukwenza. Ngokuthuthuka kobuchwepheshe, izingcweti zobucwebe zendabuko ziyanyamalala kancane kancane. Ngenxa yenqubo yayo eyinkimbinkimbi, kunzima. Indlela yokugaya yenza izindleko zokucubungula zibe phezulu kanye nokusebenza kahle kube phansi, futhi ukubonakala komshini wokushisela we-laser spot kunciphisa inqubo yokucubungula embonini yobucwebe, okwenza ukucubungula ubucwebe kube yinto ewusizo.

Umshini wokushisela we-laser spot uwuhlobo lwemishini yokucubungula izinto ze-laser. Umshini wokushisela we-laser usebenzisa ama-laser pulse anamandla aphezulu ukuze kushiswe izinto endaweni encane. Amandla emisebe ye-laser asakazeka kancane kancane angene ngaphakathi kwezinto ngokuqhutshwa kokushisa. Ngemva kokufinyelela izinga lokushisa elithile, kwakhiwa ichibi elithile elincibilikisiwe ukuze kufezwe injongo yokushisela.

Ubucwebe buyingxenye encane kakhulu enkambisweni yokucubungula nokupholisha. Isibani se-xenon somshini wokupholisha we-laser ubucwebe sikhanyiswa kakhulu ugesi we-laser futhi sikhanyisa induku yekristalu ye-YAG. Ngesikhathi esifanayo, ipompo yomshini wokupholisha we-laser ubucwebe ingaba namandla athile wamandla e-laser ngesibuko esiphakathi nesibuko esigcwele, bese ilungisa ikhwalithi ye-laser nge-beam expander futhi ibonise i-laser ephumayo nge-galvanometer, engashintshwa ngqo engxenyeni yezinto ezibonakalayo.

Izici Zomshini Wokushisela I-Laser Yobucwebe Obungu-200W

● Ibhentshi lokusebenzela elilula, isivinini sokushisela esisheshayo kanye nokusebenza kahle okuphezulu.

● Umgodi wokugxila we-ceramic ongenisiwe, ukumelana nokugqwala, ukumelana nokushisa okuphezulu, ukusebenza kahle kokuguqulwa kwe-photoelectric ephezulu, impilo yesibani se-xenon izikhathi ezingaphezu kwezigidi ezingu-8.

● Ubuningi, ububanzi be-pulse, imvamisa, usayizi webala, njll. kungalungiswa ngaphakathi kobubanzi obukhulu ukuze kufezwe imiphumela ehlukahlukene yokushisela. Amapharamitha alungiswa yinduku yokulawula ekamelweni elivaliwe, okulula futhi okusebenzayo.

● Uhlelo oluthuthukisiwe lokufiphaza oluzenzakalelayo luqeda ukucasuka kwamehlo ngesikhathi sokusebenza.

● Njengoba inamandla okusebenza aqhubekayo amahora angama-24, wonke umshini usebenza kahle futhi awudingi ukulungiswa zingakapheli amahora ayi-10,000.

● Umklamo owenziwe ngabantu, i-ergonomics, ukusebenza isikhathi eside ngaphandle kokukhathala.