Usebenza kanjani umshini wokushisela nge-laser?

Umshini wokushisela nge-laser usebenzisa amandla amakhulu e-laser pulse ukushisa izinto ezizocutshungulwa endaweni encane, bese ekugcineni uzincibilikisa ukuze zakhe ichibi elithile elincibilikisiwe, elingakhiqiza ukushisela okungaqondile, ukushisela izinqe, ukushisela i-lap, ukushisela kokuvala, njll. Izinzuzo zalo eziyingqayizivele zivula insimu entsha yokusetshenziswa kokushisela nge-laser, okuhlinzeka ngokushisela okunembile kwezinto eziboshwe ngodonga oluncane nezingxenye ezincane.

Usetshenziselwani umshini wokushisela nge-laser?

1. Ukushisela

Inhloso eyinhloko yomshini wokushisela we-laser ngokungangabazeki ukushisela. Awukwazi ukushisela kuphela izinto zensimbi ezinodonga oluncane njengezingcwecwe zensimbi engagqwali, izingcwecwe ze-aluminium, nama-galvanized plate, kodwa futhi ungasetshenziswa ekushiseleni izingxenye zensimbi zeshidi, njengezitsha zasekhishini. Ifanelekela ukushisela okuyisicaba, okuqondile, okuqondile kanye nokushisela kwanoma yisiphi isimo kusetshenziswa kabanzi emishinini yokunemba, ubucwebe, izingxenye ze-elekthronikhi, amabhethri, amawashi, ukuxhumana, imisebenzi yezandla kanye neminye imboni. Ingaqeda ukushisela kahle ezindaweni ezahlukahlukene eziyinkimbinkimbi futhi inokusebenza kahle kokukhiqiza okuphezulu. Uma kuqhathaniswa nokushisela kwe-argon arc yendabuko kanye nokushisela kagesi. Ezinye izinqubo zinezinzuzo ezisobala kakhulu.

Ukusebenzisa umshini wokushisela we-laser, umthungo wokushisela unobubanzi obuncane, ukujula okukhulu, indawo encane yokushaqeka kokushisa, ukuguqulwa okuncane, umthungo wokushisela obushelelezi nomuhle, ikhwalithi ephezulu yokushisela, akukho zimbobo zomoya, ukulawula okunembile, ikhwalithi yokushisela ezinzile, asikho isidingo sokwelashwa noma ukwelashwa okulula ngemva kokushisela i-Can.

2. Ukulungisa

Ukusetshenziswa komshini wokushisela nge-laser akugcini nje ekushiseleni, kodwa futhi nasekulungiseni ukuguguleka, isici, ukuklwebheka kwesikhunta, kanye nomgodi wesihlabathi, ukuqhekeka, ukuguquka kanye nezinye iziphambeko zento yokusebenza yensimbi. Isikhunta sizoguga ngemva kwesikhathi eside sisetshenziswa. Uma silahlwa ngqo, ukulahlekelwa kuzoba kukhulu. Isikhunta esiyinkinga singasetshenziswa ngokugcwele futhi ngokulungisa isikhunta esinenkinga ngomshini wokushisela nge-laser, ikakhulukazi lapho kulungiswa indawo encane, kugwenywe izinkinga ezimbili zokucindezeleka kokushisa kanye nokwelashwa ngemva kokushisela. Inqubo eyodwa, esindisa kakhulu isikhathi sokukhiqiza kanye nezindleko zokukhiqiza.

Iyiphi inqubo yokushisela eyenziwa umshini wokushisela we-laser?

1. Ukushisela phakathi kwezingcezu

Kufaka phakathi ukushisela izinqe, ukushisela kokuphela, ukushisela kokuhlanganisa ukungena phakathi nendawo, kanye nokushisela kokuhlanganisa ukungena phakathi nendawo.

2. Ukushisela ucingo kuya ku-wire

Kufaka phakathi ukushisela izinqe zentambo, ukushisela okuphambene, ukushisela okuhambayo okulinganayo, kanye nokushisela okumise okwe-T.

3. Ukushisela izingxenye zocingo lwensimbi kanye nebhulokhi

Ukushisela nge-laser kungaphumelela ekufezekiseni ukuxhumana kwensimbi yensimbi kanye nezingxenye zamabhulokhi, futhi ubukhulu bezingxenye zamabhulokhi bungaba ngokungahleliwe. Kufanele kunakwe ubukhulu bejometri yezinto ze-filamentary ngesikhathi sokushisela.

4. Ukushisela izinsimbi ezahlukene

Ukushisela izinhlobo ezahlukene zezinsimbi kubhekana nobubanzi bemingcele yokushisela kanye nokushisela. Ukushisela nge-laser phakathi kwezinto ezahlukene kungenzeka kuphela ngokuhlanganiswa kwezinto ezithile.

Ungakhetha kanjani umthombo we-laser ofanele?

Umthombo we-laser we-Yg:

Insimbi eshidi, izixhumanisi zobucwebe begolide, ama-pacemaker e-titanium, ama-razor blades okushisela ngama-laser ashukunyiswayo.

Lolu hlobo lwe-laser luvimbela insimbi ekuncibilikeni noma ekuguquguqukeni.

Ngezinsimbi ezincane nezilula.

Umthombo we-laser we-CW:

Lokhu kubiza kakhulu uma kuqhathaniswa nama-laser ashukunyiswayo. Kuphinde kunciphise izindleko zokusebenza.

Isebenza kahle kakhulu ezinsimbini ezingaphikisi.

Kunconywa ukushisela izingxenye ezijiyile.

Kungabangela izinkinga uma kusetshenziswa ensimbini noma ezingxenyeni ezincane kakhulu. Kulokhu, i-laser ingalimaza, incibilikise noma ikhubaze ingxenye.

Yiziphi izinhlobo zemishini yokushisela ezikhona sezizonke?

Imishini yokushisela nge-laser yaziwa nangokuthi imishini yokushisela nge-laser kanye nemishini yokushisela nge-laser. Izigaba ezithile yilezi ezilandelayo:

1. Umshini wokushisela we-laser ophathwa ngesandla:

Lolu cishe uhlobo oluvame kakhulu lwemishini yokushisela emakethe. Ivame ukusetshenziselwa ukushisela amashidi ensimbi ahlukahlukene.

2. Umshini wokushisela we-laser spot:

Ingasetshenziswa ubucwebe begolide nesiliva, ukugcwaliswa kwemigodi yezingxenye ze-elekthronikhi, ama-blister okushisela amabala, ama-inlays okushisela, njll.

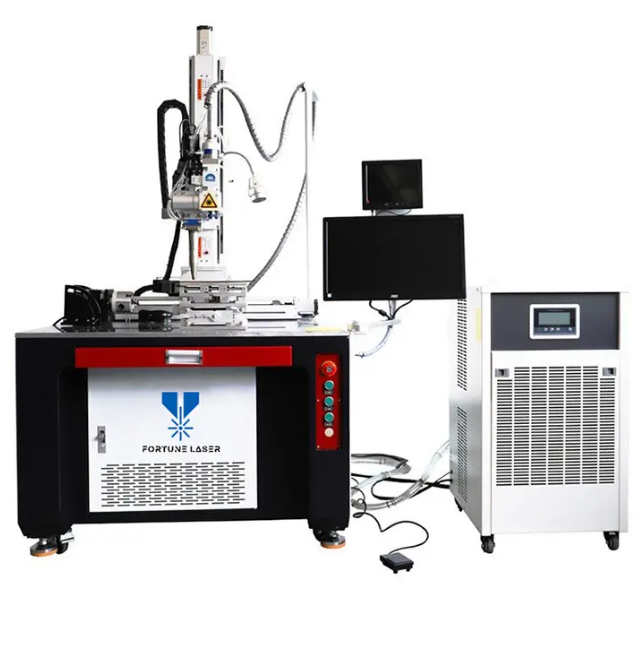

3. Umshini wokushisela we-laser ozenzakalelayo:

Ifanele ukushisela ngokuzenzakalelayo imigqa eqondile nezindilinga zezinto zokusebenza zensimbi, futhi ivame ukusetshenziswa ezimbonini ezifana namabhethri efoni ephathekayo, ubucwebe, izingxenye ze-elekthronikhi, izinzwa, amawashi namawashi, imishini yokunemba, ukuxhumana, kanye nemisebenzi yezandla.

4. Umshini wokushisela isikhunta se-laser:

Isetshenziswa kakhulu ekulungiseni isikhunta ezimbonini zokukhiqiza isikhunta kanye nokubumba njengezingcingo eziphathwayo, imikhiqizo yedijithali, izimoto kanye nezithuthuthu, futhi isetshenziswa kakhulu ekushiseleni ngesandla.

5. Umshini wokushisela we-laser wokudlulisa i-fiber optical:

Ezingxenyeni okunzima ukuzifinyelela ukuze zishiselwe, kusetshenziswe ukushiswa okungenakuthintana okuguquguqukayo, okunokuguquguquka okukhulu. Ugongolo lwe-laser lungahlukanisa isikhathi namandla, futhi lungacubungula imishayo eminingi ngesikhathi esisodwa, okunikeza izimo zokushiswa okunembile.

6. Umshini wokushisela we-laser we-galvanometer we-fiber optical:

Inhlanganisela ephelele yohlelo lokunyakaza lwe-galvanometer kanye nohlelo lokushisela nge-laser. Yonga isikhathi sokubeka esingenalutho ngesikhathi sokushisela ngephuzu elilodwa, futhi uthuthukise ukusebenza kahle ngokuphindwe ka-3-5 uma kuqhathaniswa nebhentshi lokusebenzela likagesi lendabuko.

Isingeniso ezinhlotsheni ezithile zemishini yokushisela:

Umshini wokushisela we-laser ophethwe ngesandla

Imishini yokucubungula insimbi ye-laser evame kakhulu emakethe umshini wokushisela we-laser ophathwa ngesandla. Emishinini yokushisela yendabuko, inhlanganisela yolwazi olucebile lokushisela kanye nobuchwepheshe kuyadingeka ukuze kuhlangatshezwane nokukhiqizwa kwansuku zonke, futhi ijubane lihamba kancane, futhi ukubonakala kokushisela kudinga ukupholishwa okulandelayo. Ukucubungula kudla isikhathi futhi kukhathaza.

Isingeniso semodeli: Sebenzisa i-optical fiber ukuze udlulise i-laser, bese ugxilisa umsebe we-laser ngqo engxenyeni yokushisela ngesibhamu sokufutha esiphathwa ngesandla. Inezici zokunemba okuphezulu, ukusebenza kahle okuphezulu kanye nendawo ethinteke kakhulu ekushiseni, futhi ifanelekela ukushisela izingxenye ezincane, eziyinkimbinkimbi noma okunzima ukuzifinyelela.

Inzuzo eyinhloko:

1 Umsebenzi ulula, akukho lwazi lobuchwepheshe bokushisela oludingekayo, futhi umsebenzi ungaqalwa ngemva kwamahora ama-2 okuqeqeshwa okulula.

2 Ijubane lokushisela lishesha kakhulu, futhi umshini wokushisela we-laser ophathwa ngesandla ungathatha indawo yomkhiqizo wabashiseli abavamile abangu-3 kuya kwabangu-5.

3 Ukushisela kungaba mahhala ezintweni ezisetshenziswayo, okusindisa izindleko zokukhiqiza.

4 Ngemva kokushisela sekuqediwe, umthungo wokushisela uyakhanya futhi uhlanzekile, futhi ngokuyisisekelo ungenziwa ngaphandle kokugaya.

5. Amandla omshini wokushisela nge-laser agxilile, ububanzi bokukhanya kokushisa buncane, futhi umkhiqizo akulula ukuwuguqula.

6 Amandla omshini wokushisela nge-laser agxilile, futhi amandla okushisela aphezulu kakhulu.

7. Amandla kanye namandla omshini wokushisela nge-laser kulawulwa ngedijithali, okungahlangabezana nezidingo ezahlukene zokushisela, njengokungena okuphelele, ukungena, ukushisela okuqondile nokunye.

Izinto ezisebenzayo kanye nezicelo zemboni: ezisetshenziswa kakhulu ezingxenyeni ze-elekthronikhi, izingxenye zezimoto, izinsimbi, imishini enembile, imishini yokuxhumana kanye neminye imboni insimbi engagqwali, insimbi yekhabhoni, insimbi ye-silicon, i-aluminium alloy, i-titanium alloy, ishidi le-galvanized, ishidi le-galvanized, ithusi, njll. Ukushisela okusheshayo kwezinto ezahlukahlukene zensimbi kanye nokushisela phakathi kwezinto ezithile ezingafani.

Umshini wokushisela we-laser ozenzakalelayo-umshini wokushisela we-laser ozenzakalelayo onezinhlangothi ezimbili

Isingeniso Semodeli:

Umshini usebenzisa umgodi wokugxila we-ceramic onezibani ezimbili ongeniswe uvela e-UK, ngamandla anamandla, i-pulse ehleliwe kanye nokuphathwa kohlelo okuhlakaniphile. I-Z-axis yebhentshi lokusebenzela ingahamba phezulu naphansi ngogesi ukuze igxile, futhi ilawulwa yi-PC yezimboni. Ifakwe itafula elijwayelekile elihlukile le-X/Y axis elinobukhulu obuthathu elihambayo. Enye into yokushintshashintsha okuzenzakalelayo (80mm noma i-p 125mm ongayikhetha) ukuze kufezwe ukushisela kwe-laser okuzenzakalelayo okunobukhulu obubili. Uhlelo lokuqapha lusebenzisa i-microscope, isibani esibomvu kanye ne-CCD. Ifakwe uhlelo lokupholisa amanzi lwangaphandle.

Inzuzo eyinhloko:

1. Kusetshenziswa umgodi wokugxila we-ceramic onezibani ezimbili ongeniswe e-UK, omelana nokugqwala futhi omelana nokushisa okuphezulu, futhi impilo yomgodi iyiminyaka engu-8-10.

2. Ukusebenza kahle kokukhiqiza kuphezulu, isivinini sokushisela siyashesha, futhi ukukhiqizwa kwesisindo okuzenzakalelayo komugqa wokuhlanganisa kungabonakala.

3. Ikhanda le-laser lingajikeleziswa ngama-360°, kanti indlela yonke yokukhanya ingahanjiswa ngama-360° futhi yelulwe iye phambili naphambili.

4. Usayizi wendawo yokukhanya ungalungiswa ngogesi.

5. Ipulatifomu yokusebenza ingathuthwa ngogesi ngezindlela ezintathu.

Izinto ezisebenzayo kanye nezicelo zemboni:

Ifanele amaketela, izinkomishi ze-vacuum, izitsha zensimbi engagqwali, izinzwa, izintambo ze-tungsten, ama-diode anamandla aphezulu (ama-transistors), ama-aluminium alloys, ama-laptop casings, amabhethri efoni ephathekayo, izibambo zeminyango, izikhunta, izesekeli zikagesi, izihlungi, ama-nozzle, imikhiqizo yensimbi engagqwali, ikhanda lebhola legalofu, ubuciko be-zinc alloy kanye nokunye ukushisela. Ihluzo ezishiselwayo zifaka: amaphuzu, imigqa eqondile, imibuthano, izikwele noma noma yiziphi ihluzo zendiza ezidwetshwe yisofthiwe ye-AutoCAD.

Ukushisela indawo ye-laser encane okuhlanganisiwe, okuhlukile, okuhlanganisiwe kwedeskithophu

Isingeniso Semodeli:

Umshini wokushisela amabala e-laser usetshenziswa kakhulu ukulungisa imigodi kanye nama-blister okushisela amabala egolide nesiliva. Ukushisela amabala e-laser kungenye yezici ezibalulekile zokusetshenziswa kobuchwepheshe bokucubungula izinto ze-laser. Inqubo yokushisela amabala iwuhlobo lokuqhuba ukushisa, okungukuthi, imisebe ye-laser ishisa ubuso bento yokusebenza, futhi ukushisa kobuso kuyasakazeka ngaphakathi ngokushisisa ukushisa. Ngokulawula ububanzi, amandla, amandla aphezulu kanye nokuphindaphinda kwe-laser pulse, amapharamitha anjengokuphindaphindwa kwenza into yokusebenza incibilike futhi yakhe ichibi elithile elincibilikisiwe. Ngenxa yezinzuzo zayo eziyingqayizivele, isetshenziswe ngempumelelo ekucubungulweni kobucwebe begolide nesiliva kanye nokushisela izingxenye ezincane-ezincane.

Izici Zemodeli:

Isivinini esisheshayo, ukusebenza kahle okuphezulu, ukujula okukhulu, ukuguqulwa okuncane, indawo encane ethintekile ukushisa, ikhwalithi ephezulu yokushisela, akukho ukungcola kwamalunga e-solder, ukusebenza kahle okuphezulu kanye nokuvikelwa kwemvelo.

Inzuzo eyinhloko:

1. Amandla, ububanzi be-pulse, imvamisa, usayizi wamachashazi, njll. kungalungiswa ngaphakathi kobubanzi obukhulu ukuze kufezwe imiphumela ehlukahlukene yokushisela. Amapharamitha alawulwa futhi alungiswe emgodini ovaliwe, okulula futhi okusebenzayo.

2. Kusetshenziswa umgodi wokugxila we-ceramic ongeniswe e-United Kingdom, omelana nokugqwala, omelana nokushisa okuphezulu, futhi osebenza kahle kakhulu ekuguquleni i-photoelectric.

3. Sebenzisa uhlelo lokufiphaza oluzenzakalelayo oluthuthuke kakhulu emhlabeni, oluqeda ukucasuka kwamehlo ngesikhathi sokusebenza.

4. Inamandla okusebenza ngokuqhubekayo amahora angama-24, wonke umshini usebenza kahle, futhi awudingi ukulungiswa zingakapheli amahora ayi-10,000.

5. Idizayini eyenziwe ngabantu, ehambisana ne-ergonomics, ingasebenza isikhathi eside ngaphandle kokukhathala.

Umshini Wokushisela Isikhunta Se-Laser

Isingeniso Semodeli:

Umshini wokushisela isikhunta se-laser uyimodeli ekhethekile eyenzelwe imboni yokushisela. Lo mshini usetshenziswa ngokukhethekile ukufaka esikhundleni somshini wokushisela wendabuko we-argon arc wokulungisa isikhunta esinembile. Izingxenye ezibalulekile zomshini zonke ziyimikhiqizo engenisiwe. I-interface yokusebenza kwesofthiwe isebenzisa isibonisi sekristalu yoketshezi esikhulu, futhi i-interface ilula futhi icacile, futhi umqhubi kulula ukuyifunda nokusebenzisa. Izindlela zokusebenza ezahlukahlukene ezigcinwe ngaphambilini nazo zingahlelwa nguwe, futhi umsebenzi wememori ohlala njalo ungasetshenziswa ezintweni ezahlukahlukene.

Izici Zemodeli:

1. Indawo ethintekile ekushiseni incane futhi ngeke ibangele ukuguquka kwesikhunta esinembile;

2. Ukujula kokushisela kukhulu futhi ukushisela kuqinile. Kuncibilike ngokuphelele, akushiyi zimpawu zokulungisa. Akukho ukugoba endaweni ehlanganisiwe phakathi kwengxenye ephakanyisiwe yechibi elincibilikisiwe kanye nesisekelo;

3. Izinga eliphansi lokushiswa kwe-oxidation, umsebenzi ngeke ushintshe umbala;

4. Ngeke kube khona imigodi yomoya noma imigodi yesihlabathi ngemva kokushisela;

5. I-weld ingacutshungulwa, ifaneleke kakhulu ekulungisweni kwesikhunta ngezidingo zokupholisha;

6. Umsebenzi ungafinyelela ku-50~60 Rockwell hardness ngemva kokushisela.

Izicelo:

Isikhunta, ukubumba ngomjovo oqondile, ukubumba nge-die-casting, ukunyathela, insimbi engagqwali nezinye izinto eziqinile ezifana nokuqhekeka, ukuqhekeza, ukulungiswa komshini wokugaya onqenqemeni kanye nokuvala umphetho, ukushisela; ukunemba okuphezulu, ububanzi bendawo yokushisela nge-laser bungu-0.2nm ~ 1.5nm kuphela; indawo yokushisa incane, ukucutshungulwa Umsebenzi ngeke uguqulwe; ungaqoshwa ngemva kokushisela ngaphandle kokuthinta umphumela.

Umshini wokushisela we-laser othomathikhi wokudlulisa i-fiber othomathikhi

Isingeniso Semodeli:

Umshini wokushisela we-laser wokudlulisa i-optical fiber uwuhlobo lwemishini yokushisela ye-laser ehlanganisa umsebe we-laser onamandla aphezulu ne-optical fiber, ngemva kokudluliselwa ibanga elide, ihlanganisa ukukhanya okuhambisanayo ngesibuko esijikelezayo, futhi ishisele endaweni yokusebenza. Shisele isikhunta esikhulu nezingxenye eziqondile ezingafinyeleleki, futhi isebenzise ukushisela okungenakuthintana okuguqukayo, okunokuguquguquka okukhulu. Umsebe we-laser ungafinyelela ukuhlukana kwesikhathi namandla, futhi ungacubungula imishayo eminingi ngesikhathi esisodwa, unikeze izimo ezilula kakhulu zokushisela.

Isici esiyinhloko:

1. Uhlelo lokuqapha ikhamera ye-CCD olukhethwayo, olulungele ukubonwa kanye nokubekwa okunembile;

2. Ukusatshalaliswa kwamandla kwendawo yokushisela kuyafana, futhi kunendawo yokukhanya engcono kakhulu edingekayo ukuze kube nezici zokushisela;

3. Zivumelanise nama-weld ahlukahlukene ayinkimbinkimbi, ukushisela amabala kwamadivayisi ahlukahlukene, kanye nama-weld amapuleti amancane ngaphakathi kwe-1mm;

4. Kusetshenziswa umgodi wokugxila we-ceramic ongenisiwe, omelana nokugqwala, omelana nokushisa okuphezulu, futhi impilo yomgodi iyiminyaka engu-8 kuya kweyi-10), futhi impilo yesibani se-argon ingaphezu kwezigidi ezingu-8; amathuluzi akhethekile okuzenzakalelayo kanye nezinto zokulungisa zingenziwa ngezifiso ukuze kufezwe ukukhiqizwa kwemikhiqizo ngobuningi.

Izicelo:

Isetshenziswa kabanzi ekukhiqizweni okukhulu kwamadivayisi okuxhumana kwe-optical, izingxenye ze-elekthronikhi, imishini yezokwelapha, amawashi, izibuko, imikhiqizo yokuxhumana yedijithali, izingxenye ezinembile, ihadiwe kanye neminye imboni, kanye nokulungiswa kokushisela isikhunta esikhulu, ukubumba nge-die kanye nokubumba nge-injection.

Isikhathi sokuthunyelwe: Juni-02-2023