Mochini oa ho Wellisa oa Laser oa Fortune Laser oa 200W oa Silevera ea Khauta ea Koporo oa YAG o nang le Microscope

Mochini oa ho Wellisa oa Laser oa Fortune Laser oa 200W oa Silevera ea Khauta ea Koporo oa YAG o nang le Microscope

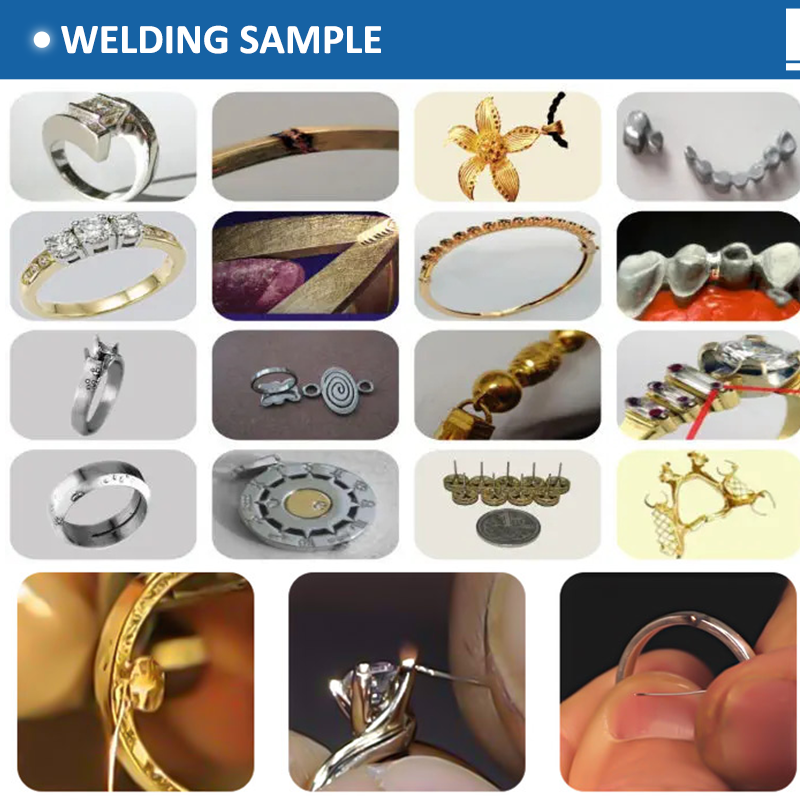

Molao-motheo oa ho sebetsa oa mochini oa ho tjheseletsa mabenyane

Mabenyane esale e le indasteri e tšoarellang. Ho phehella mabenyane ha batho esale e le ho tsoela pele ho ntlafala, empa mabenyane a matle hangata ho thata ho a etsa. Ka tsoelo-pele ea theknoloji, litsebi tsa mabenyane tsa setso lia nyamela butle-butle. Ka lebaka la ts'ebetso ea eona e rarahaneng, ho thata ho e sebelisa. Mokhoa oa ho sila o etsa hore litšenyehelo tsa ts'ebetso li be holimo le ts'ebetso e be tlase, 'me ponahalo ea mochini oa ho tjheseletsa oa laser e fokotsa ts'ebetso ea ts'ebetso ea indasteri ea mabenyane, e leng se etsang hore ts'ebetso ea mabenyane e be ntho e ntle.

Mochini oa ho tjheseletsa oa laser ke mofuta oa lisebelisoa tsa ho sebetsana le thepa ea laser. Mochini oa ho tjheseletsa oa laser o sebelisa li-pulse tsa laser tse nang le matla a mangata ho futhumatsa thepa sebakeng se senyenyane. Matla a mahlaseli a laser a kenella butle-butle ka hare ho thepa ka ho tsamaisa mocheso. Kamora ho fihla mochesong o itseng, letamo le itseng le qhibilihisitsoeng lea thehoa ho fihlela morero oa ho tjheseletsa.

Mabenyane ke karolo e nyane haholo ts'ebetsong ea ho sebetsana le ho bentša. Lebone la xenon la mochini oa ho tjheseletsa mabenyane oa laser le bonesoa haholo-holo ke phepelo ea motlakase oa laser 'me le bonesa molamu oa kristale oa YAG. Ka nako e ts'oanang, pompo ea mochini oa ho tjheseletsa mabenyane oa laser e ka ba le matla a itseng a matla a laser ka seipone se halofo le seipone se felletseng, ebe e ntlafatsa boleng ba laser ka expander ea beam le ho bonahatsa laser e hlahisoang ka galvanometer, e ka tjheseletsoang ka ho toba karolong ea thepa.

200W Mabenyane a ho tjheseletsa ka laser Likarolo tsa Mochini

● Sebaka sa mosebetsi se bobebe, lebelo le potlakileng la ho tjheseletsa le bokgoni bo phahameng.

● Sekoti se shebaneng le letsopa se tswang kantle ho naha, ho hanyetsa mafome, ho hanyetsa mocheso o phahameng, bokgoni bo phahameng ba ho fetola motlakase ka photoelectric, bophelo ba lebone la xenon bo fetang makgetlo a dimilione tse 8.

● Bongata, bophara ba pulse, maqhubu, boholo ba matheba, jj. li ka fetoloa ka har'a mefuta e mengata ho fihlela litlamorao tse fapaneng tsa ho tjheseletsa. Liparamente li fetoloa ke molamu oa taolo ka kamoreng e koetsoeng, e leng se bonolo le se sebetsang hantle.

● Sistimi e tsoetseng pele ea ho lahla moriti ka boiketsetso e felisa ho teneha ha mahlo nakong ea lihora tsa mosebetsi.

● Ka bokhoni ba ho sebetsa bo tsoelang pele ba lihora tse 24, mochini oohle o na le ts'ebetso e tsitsitseng ea ts'ebetso 'me ha o hloke tlhokomelo nakong ea lihora tse 10,000.

● Moralo o entsoeng ka botho, ergonomics, e sebetsang nako e telele ntle le mokhathala.