Mochini oa ho tjheseletsa oa laser o sebetsa joang?

Mochini oa ho tjheseletsa ka laser o sebelisa matla a maholo a pulse ea laser ho futhumatsa thepa e lokelang ho sebetsoa ka tekanyo e nyane, 'me qetellong oa e qhibilihisa ho etsa letamo le itseng le qhibilihisitsoeng, le ka etsang hore ho be le ho tjheseletsa ha matheba, ho tjheseletsa ha marako, ho tjheseletsa ha mahlakore, ho tjheseletsa ha sekwahelo, ho tjheseletsa ha sekwahelo, jj. Melemo ea eona e ikhethang e bula tšimo e ncha ea ts'ebeliso ea ho tjheseletsa ka laser, e fanang ka ho tjheseletsa ka nepo bakeng sa thepa e nang le mabota a masesaane le likarolo tse nyane.

Mochini oa ho tjheseletsa oa laser o sebelisetsoa eng?

1. Ho tjheseletsa

Morero o ka sehloohong oa mochini oa ho tjheseletsa oa laser ntle ho pelaelo ke ho tjheseletsa. Ha e khone feela ho tjheseletsa thepa ea tšepe e nang le mabota a masesaane joalo ka lipoleiti tsa tšepe tse sa hloekang, lipoleiti tsa aluminium le lipoleiti tsa galvanized, empa hape e ka sebelisoa bakeng sa ho tjheseletsa likarolo tsa tšepe tsa lakane, joalo ka lisebelisoa tsa kichine. E loketse ho tjheseletsa e bataletseng, e otlolohileng, e otlolohileng le ho tjheseletsa ea sebopeho sefe kapa sefe e sebelisoa haholo mechineng e nepahetseng, mabenyane, likarolo tsa elektroniki, libeteri, lioache, puisano, mesebetsi ea matsoho le liindasteri tse ling. E ka phethela ho tjheseletsa hantle libakeng tse fapaneng tse rarahaneng 'me e na le bokhoni bo phahameng ba tlhahiso. Ha e bapisoa le ho tjheseletsa ea argon ea setso le ho tjheseletsa ea motlakase 'Me lits'ebetso tse ling li na le melemo e totobetseng haholoanyane.

Ka ho sebedisa mochini wa ho tjheseletsa wa laser, moalo wa ho tjheseletsa o na le bophara bo bonyenyane, botebo bo boholo, sebaka se senyenyane sa ho tshoha ha mocheso, phetoho e nyane, moalo o boreledi le o motle wa ho tjheseletsa, boleng bo hodimo ba ho tjheseletsa, ha ho na masoba a moya, taolo e nepahetseng, boleng bo tsitsitseng ba ho tjheseletsa, ha ho hlokahale kalafo kapa kalafo e bonolo kamora ho tjheseletsa.

2. Tokiso

Tšebeliso ea mochini oa ho tjheseletsa oa laser ha e felle feela ho tjheseletsa, empa hape e lokisa ho tsofala, sekoli, maqeba a hlobo, le lesoba la lehlabathe, mapetso, ho fetoha ha sebopeho le liphoso tse ling tsa mosebetsi oa tšepe. Hlobo e tla fela ka mor'a nako e telele ea tšebeliso. Haeba e lahloa ka ho toba, tahlehelo e tla ba kholo. Hlobo e nang le bothata e ka sebelisoa ka botlalo hape ka ho lokisa hlobo e nang le bothata ka mochini oa ho tjheseletsa oa laser, haholo-holo ha ho lokisoa bokaholimo bo botle, ho qoba mathata a mabeli a khatello ea mocheso le kalafo ea kamora ho tjheseletsa. Ts'ebetso e le 'ngoe, e boloka nako ea tlhahiso le litšenyehelo tsa tlhahiso haholo.

Mochini oa ho tjheseletsa oa laser o na le ts'ebetso efe ea ho tjheseletsa?

1. Ho tjheseletsa pakeng tsa dikotwana

Ho kenyeletsoa ho tjheseletsa marago, ho tjheseletsa qetellong, ho tjheseletsa ho kenella bohareng, le ho tjheseletsa ho kenella bohareng.

2. Ho tjheseletsa terata ho ya ho terata

Ho kenyeletsoa ho tjheseletsa terata ho ya ho terata, ho tjheseletsa ka sefapano, ho tjheseletsa ka mahlakoreng a bapileng, le ho tjheseletsa ka sebopeho sa T.

3. Ho tjheseletsa terata ya tshepe le dikarolo tsa boloko

Ho tjheseletsa ka laser ho ka atleha ho etsa hore ho hokahane ha terata ea tšepe le likarolo tsa liboloko ho be teng, 'me boholo ba likarolo tsa liboloko e ka ba bo sa reroang. Ela hloko litekanyo tsa jeometri tsa likarolo tsa filamentary nakong ea ho tjheseletsa.

4. Ho tjheseletsa litšepe tse fapaneng

Ho tjheseletsa mefuta e fapaneng ya tshepe ho sebetsana le mefuta ya diparamitha tsa ho tjheseletsa le ho tjheseletsa. Ho tjheseletsa ka laser pakeng tsa thepa e fapaneng ho kgoneha feela ka metswako e itseng ya thepa.

Mokhoa oa ho khetha mohloli o nepahetseng oa laser?

Mohloli oa laser oa Yg:

Tšepe ea lakane, lihokelo tsa mabenyane a khauta, li-pacemaker tsa titanium, mahare a lehare bakeng sa ho tjheseletsa ka laser e pulsed.

Mofuta ona oa laser o thibela tšepe ho qhibiliha kapa ho senyeha.

Bakeng sa litšepe tse tšesaane le tse bobebe.

Mohloli oa laser oa CW:

Sena se theko e boima haholo ha se bapisoa le li-laser tse pulsed. Hape se fokotsa litšenyehelo tsa ts'ebetso.

E sebetsa hantle haholo ho litšepe tse hanyetsang.

E kgothaletswa bakeng sa ho tjheseletsa dikarolo tse teteaneng.

E ka baka mathata haeba e sebelisoa holim'a tšepe kapa likarolo tse tšesaane haholo. Tabeng ena, laser e ka senya, ea qhibilihisa kapa ea senya karolo.

Ke mefuta efe ea mechini ea ho tjheseletsa e teng ka kakaretso?

Mechini ea ho tjheseletsa ka laser e boetse e tsejoa e le mechini ea ho tjheseletsa ka laser le mechini ea ho tjheseletsa ka laser. Lihlopha tse ikhethileng ke tse latelang:

1. Mochini oa ho tjheseletsa oa laser o tšoaroang ka letsoho:

Mohlomong ena ke mofuta o tloaelehileng haholo oa lisebelisoa tsa ho tjheseletsa 'marakeng. Hangata e sebelisoa bakeng sa ho tjheseletsa maqephe a fapaneng a tšepe.

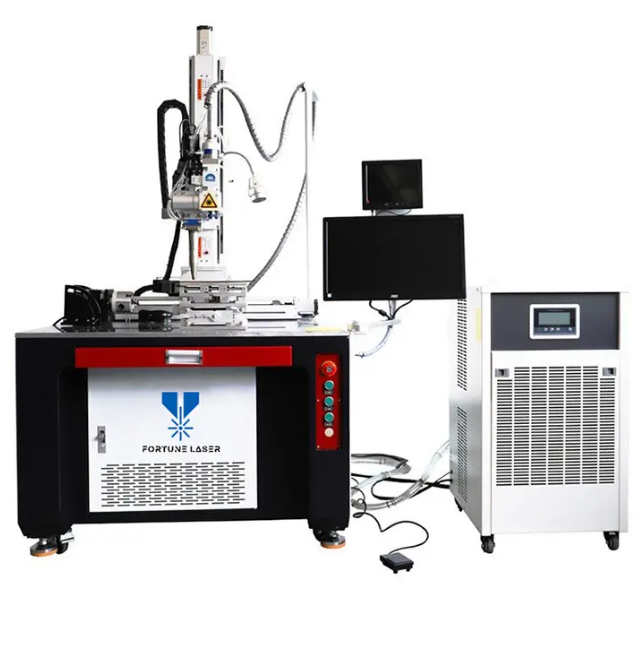

2. Mochini oa ho tjheseletsa oa laser:

E ka sebelisoa bakeng sa mabenyane a khauta le silevera, ho tlatsa masoba a likarolo tsa elektroniki, li-blister tsa ho tjheseletsa matheba, li-inlays tsa ho tjheseletsa, jj.

3. Mochini oa ho tjheseletsa oa laser o iketsang:

E loketse ho tjheseletsa ka boiketsetso mela e otlolohileng le disekoere tsa mesebetsi ya tshepe, mme hangata e sebediswa diindastering tse kang dibetri tsa mehala ya thekeng, mabenyane, dikarolo tsa elektroniki, disensara, dioache le dioache, mechini e nepahetseng, puisano le mesebetsi ya matsoho.

4. Mochini oa ho tjheseletsa hlobo oa laser:

E sebelisoa haholo bakeng sa ho lokisa hlobo indastering ea tlhahiso le ea ho bopa hlobo joalo ka lifono tsa thekeng, lihlahisoa tsa dijithale, likoloi le lithuthuthu, 'me hape e sebelisoa haholo bakeng sa ho tjheseletsa ka letsoho.

5. Mochini oa ho tjheseletsa oa laser oa phetiso ea faeba ea optical:

Bakeng sa likarolo tse thata ho fihlella bakeng sa ho tjheseletsa, ho tjheseletsa phetiso e tenyetsehang e sa amaneng le motlakase ho a kenngwa tshebetsong, e nang le ho tenyetseha ho hoholo. Lehlasedi la laser le ka kgona ho arola nako le matla, mme le ka sebetsana le mahlasedi a mangata ka nako e le nngwe, e leng se fanang ka maemo a ho tjheseletsa ka nepo.

6. Mochini oa ho tjheseletsa oa laser oa galvanometer oa faeba ea optical:

Motsoako o phethahetseng oa sistimi ea motsamao oa galvanometer le sistimi ea ho welding ka laser. Boloka nako ea ho beha lintho tse se nang letho nakong ea ho welding ka ntlha e le 'ngoe, 'me u ntlafatse bokhoni ka makhetlo a 3-5 ha ho bapisoa le benche ea motlakase ea setso.

Selelekela sa mefuta e itseng ea mechini ea ho tjheseletsa:

Mochini oa ho tjheseletsa oa laser o tšoaroang ka letsoho

Sesebelisoa se tloaelehileng sa ho sebetsana le tšepe ea laser 'marakeng ke mochini oa ho tjheseletsa oa laser o tšoaroang ka letsoho. Lisebelisoang tsa setso tsa ho tjheseletsa, motsoako oa boiphihlelo bo bongata ba ho tjheseletsa le theknoloji lia hlokahala ho fihlela tlhahiso ea letsatsi le letsatsi, 'me lebelo lea lieha,' me ponahalo ea ho tjheseletsa e hloka ho bentšoa hamorao. Ho sebetsana le hona ho nka nako ebile hoa khathatsa.

Selelekela sa mohlala: Sebelisa faeba ea optical ho fetisetsa laser, 'me u tsepamise lebone la laser ka ho toba karolong ea ho tjheseletsa ka sethunya sa spray se tšoaroang ka letsoho. E na le litšobotsi tsa ho nepahala ho hoholo, bokhoni bo phahameng le sebaka se nang le mocheso o tlase, 'me e loketse ho tjheseletsa likarolo tse nyane, tse rarahaneng kapa tse thata ho li fihlela.

Molemo o ka sehloohong:

1 Tshebetso e bonolo, ha ho hlokahale boiphihlelo ba profeshenale ba theknoloji ya ho tjheseletsa, mme tshebetso e ka qalwa kamora dihora tse 2 tsa koetliso e bonolo.

2 Lebelo la ho tjheseletsa le potlakile haholo, mme setjhini sa laser se tshwarwang ka letsoho se ka nka sebaka sa tlhahiso ya ditjhini tse 3 ho isa ho tse 5 tse tlwaelehileng.

3 Ho tjheseletsa ho ka ba ntle le dintho tse ka jewang, e leng se bolokang ditjeo tlhahisong.

4 Kamora hore ho tjheseletsa ho phethelwe, moalo wa ho tjheseletsa o kganya ebile o hlwekile, mme ha e le hantle o ka etswa ntle le ho sila.

5. Matla a mochini oa ho tjheseletsa oa laser a tiile, boholo ba khanya ea mocheso bo bonyenyane, 'me sehlahisoa ha se bonolo ho se fetola sebopeho.

6 Matla a mochini oa ho tjheseletsa oa laser a tiile, 'me matla a ho tjheseletsa a phahame haholo.

7. Matla le matla a mochini oa ho tjheseletsa oa laser li laoloa ka dijithale, tse ka fihlelang litlhoko tse fapaneng tsa ho tjheseletsa, tse kang ho kenella ka botlalo, ho kenella, ho tjheseletsa ka libaka le tse ling.

Lisebelisoa tse sebetsang le lits'ebetso tsa indasteri: li sebelisoa haholo-holo likarolong tsa elektroniki, likarolo tsa likoloi, lisebelisoa, mechini e nepahetseng, lisebelisoa tsa puisano le liindasteri tse ling tšepe e sa hloekang, tšepe ea carbon, tšepe ea silicon, motsoako oa aluminium, motsoako oa titanium, leqephe la galvanized, leqephe la galvanized, koporo, jj. Ho tjheseletsa ka potlako lisebelisoa tse fapaneng tsa tšepe le ho tjheseletsa pakeng tsa lisebelisoa tse ling tse fapaneng.

Mochini oa ho tjheseletsa oa laser o iketsang - mochini oa ho tjheseletsa oa laser o iketsang oa mahlakore a mabeli

Selelekela sa Mohlala:

Mochini o amohela sekoti sa ho tsepamisa maikutlo sa ceramic sa mabone a mabeli se tsoang UK, ka matla a matla, pulse e ka hlophisoang le tsamaiso e bohlale ea sistimi. Mokhahlelo oa Z oa benche ea mosebetsi o ka tsamaea holimo le tlase ka motlakase ho tsepamisa maikutlo, 'me o laoloa ke PC ea indasteri. E na le tafole e tloaelehileng e arohaneng ea X/Y axis e nang le mahlakore a mararo e tsamaeang ka boiketsetso. Sesebelisoa se seng sa ho potoloha se ikhethelang (80mm kapa p 125mm ea boikhethelo) ho fihlela ho tjheseletsa laser ea boiketsetso ea mahlakore a mabeli. Sistimi ea ho beha leihlo e sebelisa microscope, leseli le lefubelu le CCD. E na le sistimi ea ho pholisa metsi ea kantle.

Molemo o ka sehloohong:

1. Ho sebelisoa sekoti sa concentrator sa mabone a mabeli se tsoang UK, se hanelang mafome le mocheso o phahameng, 'me bophelo ba sekoti ke lilemo tse 8-10.

2. Bokgoni ba tlhahiso bo hodimo, lebelo la ho tjheseletsa le potlakile, mme tlhahiso ya boima ba mohala wa kopano e ka phethahala ka boiketsetso.

3. Hlooho ea laser e ka potolosoa ka 360°, 'me tsela ea optical ka kakaretso e ka tsamaisoa ka 360° le ho otlolloa pele le morao.

4. Boholo ba sebaka sa leseli bo ka fetoloa ka motlakase.

5. Sethala se sebetsang se ka tsamaisoa ka motlakase ka litekanyo tse tharo.

Lisebelisoa tse sebetsang le lits'ebetso tsa indasteri:

E loketse liketlele, likopi tsa vacuum, likotlolo tsa tšepe e sa ruseng, li-sensor, lithapo tsa tungsten, li-diode tse matla haholo (li-transistors), li-alloy tsa aluminium, li-casing tsa laptop, libeteri tsa mohala oa thekeng, li-handle tsa mamati, li-mold, lisebelisoa tsa motlakase, li-filter, li-nozzle, lihlahisoa tsa tšepe e sa ruseng, hlooho ea bolo ea kolofo, mesebetsi ea matsoho ea alloy ea zinki le ho tjheseletsa tse ling. Litšoantšo tse ka tjheseletsoang li kenyelletsa: lintlha, mela e otlolohileng, li-circles, lisekoere kapa litšoantšo life kapa life tse foreshe tse takiloeng ke software ea AutoCAD.

Ho tjheseletsa sebaka sa lebone le lenyenyane la laser ho kopantsoe, ho arohane le komporo

Selelekela sa Mohlala:

Mochini oa ho tjheseletsa matheba a laser o sebelisoa haholo-holo bakeng sa ho lokisa masoba le matheba a ho tjheseletsa matheba a mabenyane a khauta le silevera. Ho tjheseletsa matheba a laser ke e 'ngoe ea likarolo tsa bohlokoa tsa ts'ebeliso ea theknoloji ea ts'ebetso ea thepa ea laser. Ts'ebetso ea ho tjheseletsa matheba ke ea mofuta oa ho tjheseletsa mocheso, ke hore, mahlaseli a laser a futhumatsa bokaholimo ba sesebelisoa sa mosebetsi, 'me mocheso oa bokaholimo o hasane ho ea kahare ka ho tjheseletsa mocheso. Ka ho laola bophara, matla, matla a tlhoro le ho pheta-pheta ha pulse ea laser, Li-parameter tse kang maqhubu li etsa hore sesebelisoa sa mosebetsi se qhibilihe 'me se thehe letamo le itseng le qhibilihisitsoeng. Ka lebaka la melemo ea sona e ikhethang, se sebelisitsoe ka katleho ts'ebetsong ea mabenyane a khauta le silevera le ho tjheseletsa likarolo tse nyane-nyane.

Likarolo tsa Mohlala:

Lebelo le potlakileng, bokgoni bo phahameng, botebo bo boholo, phetoho e nyane, sebaka se senyenyane se amehileng ke mocheso, boleng bo phahameng ba ho tjheseletsa, ho se silafale ha manonyeletso a solder, bokgoni bo phahameng le tshireletso ya tikoloho.

Molemo o ka sehloohong:

1. Matla, bophara ba pulse, maqhubu, boholo ba matheba, jj. li ka fetoloa ka har'a mefuta e mengata ho fihlela litlamorao tse fapaneng tsa ho tjheseletsa. Liparamente li laoloa le ho lokisoa ka har'a sekoti se koetsoeng, e leng se bonolo le se sebetsang hantle.

2. Ho sebediswa mokoti o kopanyang letsopa o tswang United Kingdom, o hanelang mafome, o hanelang mocheso o phahameng, mme o na le bokgoni bo phahameng ba ho fetola motlakase ka photoelectric.

3. Amohela sistimi e tsoetseng pele ka ho fetisisa ea ho lahla moriti lefatšeng, e felisang ho teneha ha mahlo nakong ea lihora tsa mosebetsi.

4. E na le bokhoni ba ho sebetsa ka ho tsoelang pele lihora tse 24, mochini oohle o na le ts'ebetso e tsitsitseng ea ts'ebetso, 'me ha o hloke tlhokomelo nakong ea lihora tse 10,000.

5. Moralo o entsoeng ka botho, o tsamaellanang le ergonomics, o ka sebetsa nako e telele ntle le mokhathala.

Mochini oa ho tjheseletsa oa Laser Hlobo

Selelekela sa Mohlala:

Mochini oa ho tjheseletsa hlobo oa laser ke mohlala o khethehileng o etselitsoeng indasteri ea hlobo. Mochini ona o sebelisoa ka ho khetheha ho nkela mochini oa khale oa ho tjheseletsa oa argon arc sebaka bakeng sa ho lokisa hlobo e nepahetseng. Likarolo tsa bohlokoa tsa mochini kaofela ke lihlahisoa tse tsoang kantle ho naha. Sebopeho sa ts'ebetso ea software se amohela ponts'o ea kristale ea metsi ea skrine e kholo, 'me sebopeho se bonolo ebile se hlakile,' me opereishene e bonolo ho ithuta le ho e sebelisa. Mefuta e fapaneng ea mekhoa ea ts'ebetso e bolokiloeng esale pele le eona e ka hlophisoa ke uena, 'me ts'ebetso ea memori ea kamehla e ka sebelisoa lisebelisoa tse fapaneng.

Likarolo tsa Mohlala:

1. Sebaka se amehileng ke mocheso se senyenyane 'me se ke ke sa baka ho fetoha ha hlobo e nepahetseng;

2. Botebo ba ho tjheseletsa bo boholo mme ho tjheseletsa ho tiile. Ho qhibilihile ka botlalo, ha ho sa siee masalla a tokiso. Ha ho na lekhalo le kopaneng pakeng tsa karolo e phahamisitsweng ya letamo le qhibilihisitsweng le substrate;

3. Sekhahla se tlase sa oxidation, mosebetsi o ke ke oa fetola 'mala;

4. Ho ke ke ha e-ba le masoba a moea kapa masoba a lehlabathe ka mor'a ho tjheseletsa;

5. Weld e ka sebetsoa, haholo-holo e loketse ho lokisa hlobo ka litlhoko tsa ho bentša;

6. Mosebetsi o ka fihla ho 50~60 Rockwell thatafalo kamora ho tjheseletsa.

Likopo:

Hlobo, ho enta ka nepo, ho lahla ka die-casting, ho hatakela, tshepe e sa ruseng le thepa e meng e thata e kang mapetso, ho tjhesa, ho tsofala ha mochini o silang le ho tiisa mathoko, ho tjhesa; ho nepahala ho hoholo, bophara ba sebaka sa ho tjhesa ka laser ke 0.2nm ~ 1.5nm feela; sebaka sa ho futhumatsa se senyenyane, ho sebetswa. Mosebetsi o ke ke wa senyeha; o ka tjheswa ka mora ho tjhesa ntle le ho ama phello.

Optical faeba phetiso mochini o iketsang oa laser tjheseletsa

Selelekela sa Mohlala:

Mochini oa ho tjheseletsa oa laser o fetisang faeba ea optical ke mofuta oa lisebelisoa tsa ho tjheseletsa tsa laser tse kopanyang lebone la laser le nang le matla a mangata le lebone la optical, kamora ho tjheseletsa sebaka se selelele, o kopanya leseli le bapileng ka seiponeng se kopanyang, 'me o etsa ho tjheseletsa holim'a mosebetsi. O tjheseletsa hlobo e kholo le likarolo tse nepahetseng tse sa fihlelleheng, 'me o kenya tšebetsong ho tjheseletsa ho feto-fetoha ho sa amaneng le phetiso, e nang le ho tenyetseha ho hoholo. Lebone la laser le ka fihlella nako le ho arohana ha matla, 'me le ka sebetsana le mabone a mangata ka nako e le' ngoe, e leng se fanang ka maemo a bonolo haholoanyane bakeng sa ho tjheseletsa.

Tšobotsi e ka sehloohong:

1. Sistimi ea tlhokomelo ea khamera ea CCD ea boikhethelo, e loketseng ho shebella le ho beha sebaka ka nepo;

2. Kabo ea matla ea sebaka sa ho tjheseletsa e tšoana, 'me e na le sebaka se setle ka ho fetisisa sa khanya se hlokahalang bakeng sa litšobotsi tsa ho tjheseletsa;

3. Ikamahanya le li-weld tse fapaneng tse rarahaneng, ho tjheseletsa libaka tsa lisebelisoa tse fapaneng, le ho tjheseletsa lipoleiti tse tšesaane ka hare ho 1mm;

4. Ho sebelisoa lesoba la ho tsepamisa mohopolo la letsopa le tsoang kantle ho naha, le hanelang mafome, le hanelang mocheso o phahameng, 'me bophelo ba lesoba ke lilemo tse 8 ho isa ho tse 10), 'me bophelo ba lebone la argon bo feta limilione tse 8; lisebelisoa le lisebelisoa tse ikhethileng tse ikhethileng li ka fetoloa ho fihlela tlhahiso ea lihlahisoa ka bongata.

Likopo:

E sebelisoa haholo tlhahisong e kholo ea lisebelisoa tsa puisano tsa optical, likarolo tsa elektroniki, mechini ea bongaka, lioache, likhalase, lihlahisoa tsa puisano tsa dijithale, likarolo tse nepahetseng, lisebelisoa tsa hardware le liindasteri tse ling, hammoho le ho lokisa ho tjheseletsa hlobo e kholo, ho lahla ka tšepe le ho enta ka ente.

Nako ea poso: Phuptjane-02-2023