Na'urar tsaftacewa ta Fortune Laser CW 1000W/1500W/2000W, faɗin tsaftacewa mai girman 650mm, injin tsaftacewa mai girma

Na'urar tsaftacewa ta Fortune Laser CW 1000W/1500W/2000W, faɗin tsaftacewa mai girman 650mm, injin tsaftacewa mai girma

Amfani da injin tsabtace laser a masana'antu

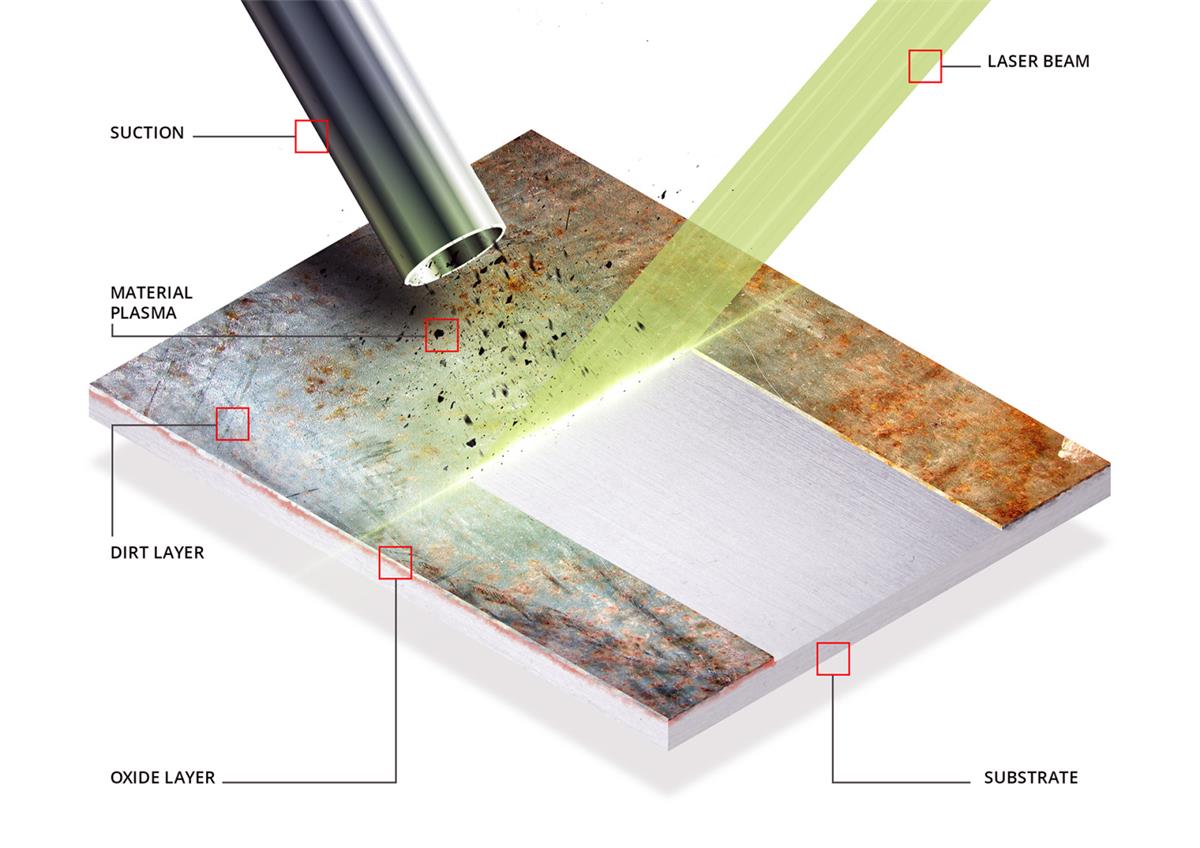

A cikin tsarin samar da kayayyaki da masana'antu, domin tabbatar da ingancin samfurin, ya zama dole a tsaftace tabo, tabon mai, tsatsa da sauran gurɓatattun abubuwa a saman samfurin. Hanyoyin tsaftacewa na gargajiya na goge yashi da gogewa sun haifar da gurɓatawa mai yawa da lalata muhalli da kayan da kanta, wanda ba shi da amfani ga kulawa da amfani daga baya. Yanzu amfani da sabuwar fasahar tsaftacewa ta laser yana sauƙaƙa tsaftacewa a masana'antar masana'antu.

Fasali na Injin Tsaftace Laser 1000W 1500W 2000W

Sigogi na Fasaha na Injin Tsaftace Laser na Fortune Laser Mini

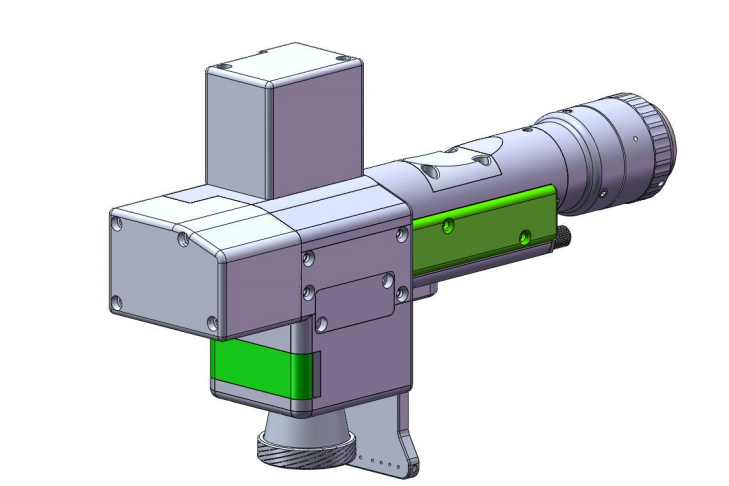

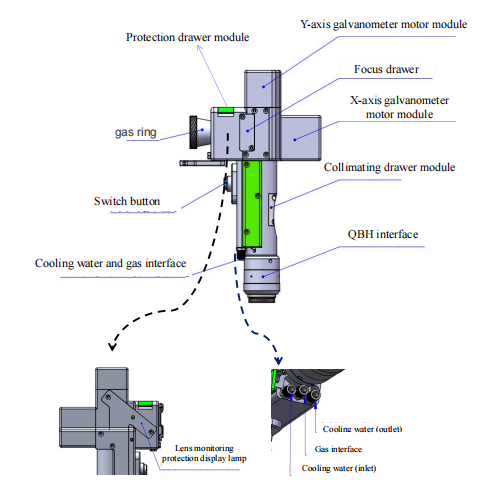

Babban tsari

● Kan laser mai amfani biyu, wanda aka yi da hannu da kuma atomatik, mai siffar laser 2D. Mai sauƙin riƙewa da haɗawa tare da sarrafa kansa; mai sauƙin aiki kuma yana da ayyuka daban-daban;

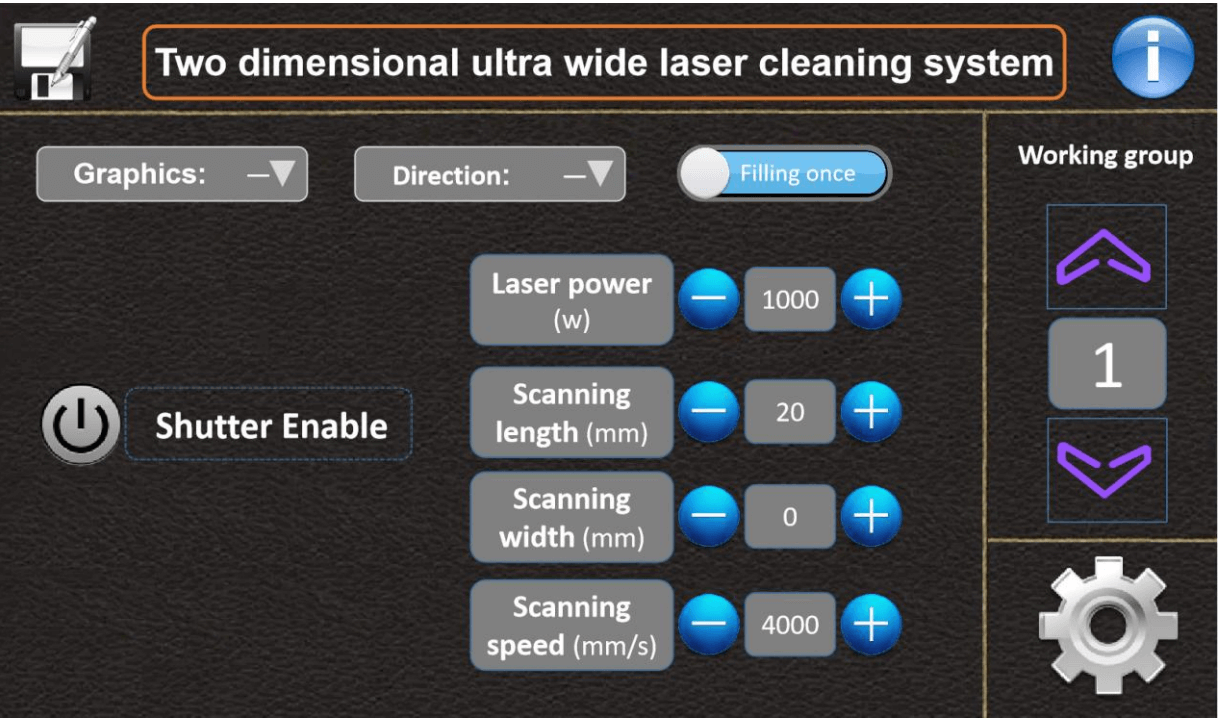

● SOFTWARE MAI SAUƘI

PRESTORE NA RUBUTU MAI SAUƘI DABAN-DABAN

1. Manhaja mai sauƙi tana zaɓar sigogin da aka riga aka adana kai tsaye

2. Ajiye duk nau'ikan zane-zane na sigogi guda shida, ana iya zaɓar su a layi madaidaiciya/karkace/ da'ira/kusurwoyi murabba'i/cike da'ira.

3. Mai sauƙin amfani da aiki

4. Sauƙin dubawa

5. Harshen zai iya zama Turanci/Sinanci ko wasu harsuna (idan ana buƙata)

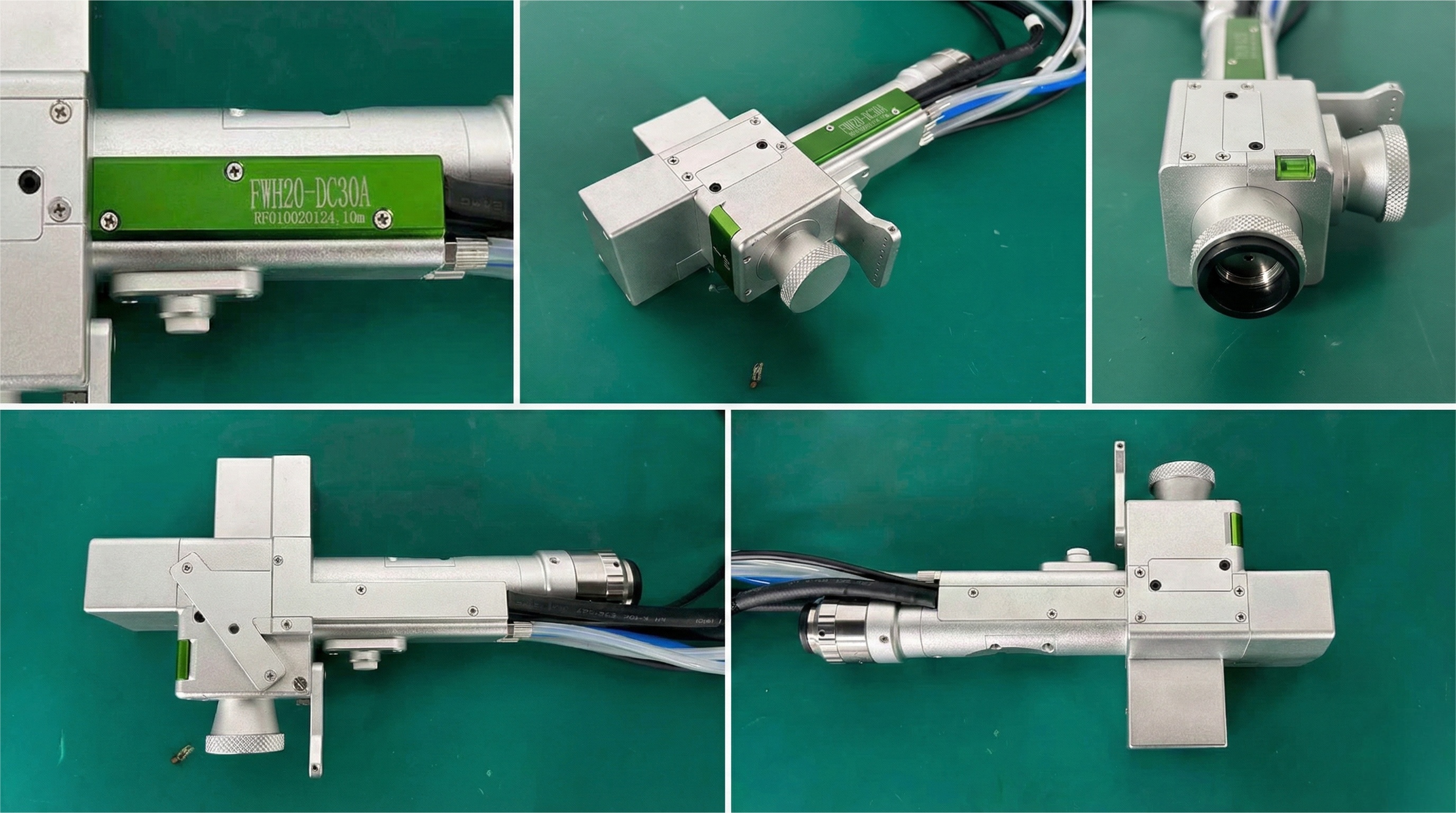

Gabatar da Shugaban Laser

Danna babban maɓallin allo sannan ka danna maɓallin tsaro, kuma hasken ja zai yi juyawa don yin samfoti. Idan kana buƙatar canza zane-zane da sauran sigogi, kana buƙatar shigar da kalmar sirri don shigar da hanyar haɗin da aka ci gaba. Lura: Bayan danna maɓallin tsaro, maɓallin izinin fitarwa yana cikin yanayin buɗewa, sannan ka danna maɓallin sarrafawa, ana iya fitar da hasken.

Shin kun san aikace-aikace guda 5 na injunan tsaftacewa na laser a masana'antar masana'antu?

1. Tsaftacewa a masana'antar lantarki

Masana'antar lantarki tana amfani da na'urorin laser don tsaftace abubuwan da ke haifar da iskar shaka, kuma masana'antar lantarki ta dace da amfani da na'urorin laser don tsaftace abubuwan da ke haifar da iskar shaka. Kafin a haɗa allon da'ira, dole ne a haɗa fil ɗin abubuwan da ke haifar da iskar shaka gaba ɗaya don tabbatar da tasirin hulɗar lantarki, kuma kada a lalata fil ɗin yayin aikin kawar da gurɓatawa. Tsaftace na'urar laser na iya cika buƙatun amfani, kuma ingancin aikin yana da yawa sosai. Allura tana buƙatar a haskaka ta da na'urar sau ɗaya kawai.

2. Gyaran kafin a fara yin brazing da walda.

Shirye-shiryen walda na Laser yana ɗaya daga cikin aikace-aikacen da ake amfani da su wajen tsaftace laser, wanda ke da amfani wajen tsaftace saman ƙarfe da aluminum daga gurɓatattun abubuwa kamar ƙarfe da ƙarfe marasa ƙarfe, man shafawa, da sauransu, a shirye-shiryen walda mai inganci. Hakanan yana tabbatar da haɗin gwiwa masu santsi da laushi ba tare da ramuka ba.

3. Tsaftace mold ɗin

Tsaftace taya yayin samarwa dole ne ya kasance mai aminci kuma abin dogaro don rage lokacin aiki. Domin ana iya haɗa hanyar tsaftacewa ta laser ta hanyar fiber na gani don tsaftace kusurwar da ba ta da kyau ko sassan da haske ke haifarwa, yana da matuƙar dacewa a yi amfani da shi.

4. Tsaftace tsohon fenti na jirgin sama

Bayan jirgin ya daɗe yana aiki, ana buƙatar sake fenti saman jirgin, don haka ya zama dole a nemo hanyar cire tsohon fenti. Tsarin tsaftacewa da fenti na gargajiya yana da sauƙin lalata saman ƙarfe na jirgin, wanda ke haifar da ɓoyayyun haɗari ga tashi na jirgin. Ba abu ne mai sauƙi a lalata saman jirgin ba yayin amfani da injin wanki.

5. Rufin tsaftacewa na gida

Tsaftace Laser na iya tsaftace fenti da fenti a masana'antu kamar motoci, yana kiyaye amincin kayan substrate.

Kula da keɓancewar gama gari

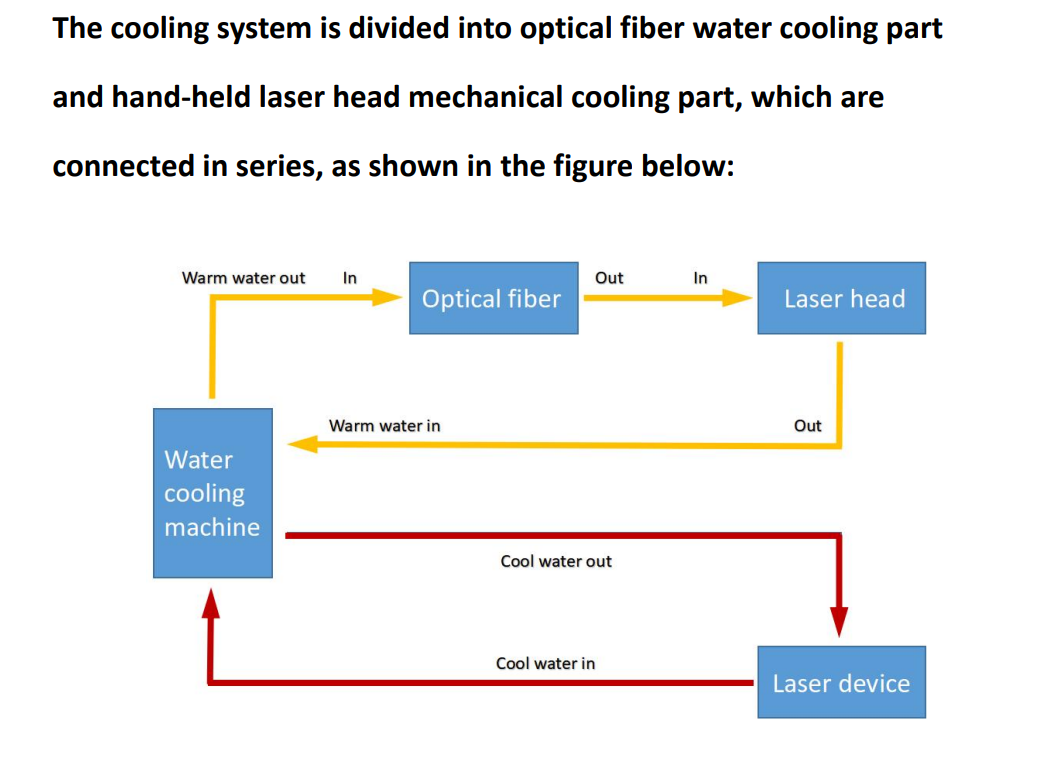

1. Ƙararrawa ta Laser da ruwa mai sanyaya:

(1) Ƙararrawar Laser: Ba a kunna na'urar sanyaya ruwa ba. Kashe na'urar sannan a sake kunna ta.

(2) Ƙararrawar sanyaya ruwa: Zafin tankin ruwa ya yi yawa, matsewar sanyaya ruwa ta lalace, na'urar sanyaya ruwa ta ɓace, ko kuma na'urar sanyaya ruwa ba ta da isasshen ƙarfin sanyaya ruwa. Idan matakin ruwan tankin ruwa bai isa ba, sai a ƙara ruwan sanyaya.

2Allon da ba a saba gani ba:

Idan allon yana kashe, duba ko wayoyin tsakiya guda huɗu na akwatin sarrafawa da allon suna da haɗin kai yadda ya kamata, da kuma ko akwai haɗin yanar gizo.

3. Babu hasken da ke fitowa:

(1) Ko an fara amfani da laser yadda ya kamata.

(2) Ko allon yana da izinin buɗewa.

(3) Ko allon nuni yana aiki lokacin da aka fitar da hasken.

(4) Ko akwai wata matsala game da haɗin laser ɗin.

(5) Gilashin kariya mai datti: ainihin hasken yana da rauni kuma ba a iya gani.

(6) Ko hanyar gani tana tsakiya.

4Dakatarwar hasken da ke fitowa kwatsam yayin sarrafawa:

Ƙararrawar Laser (matsalolin da aka saba fuskanta: zafin laser ya yi yawa)

Menene ya kamata a kula da shi lokacin siyan injin tsabtace laser?

1. Gabaɗaya, farashin injin tsabtace laser yana da alaƙa da ƙarfinsa, yawan ƙarfin laser ɗin, farashin yana ƙara tsada. Amma siyan laser har yanzu ya dogara da takamaiman buƙatunku, kamar tsaftace tsatsa mai iyo, injin tsabtace laser mai ƙarancin ƙarfi zai iya biya, amma injin tsabtace laser mai ƙarfi zai iya haifar da lalacewa ga kayan aikin.

2. Domin cimma mafi kyawun tasirin tsaftacewa ga substrate ɗin da ya dace da za a tsaftace, yawanci yana da mahimmanci a daidaita sigogi masu dacewa kamar tsawon zare, zurfin ruwan tabarau na filin, ƙarfin fitarwa, faɗin bugun jini da saurin dubawa bisa ga halayen substrates daban-daban.

3. Injinan tsaftacewa na Laser an raba su zuwa injinan tsaftacewa na Laser da hannu da kuma manyan injinan tsaftacewa na Laser na tebur. Injinan tsaftacewa na Laser daban-daban suna da ayyuka da wurare daban-daban. Misali, wasu injinan tsaftacewa na Laser da hannu sun dace da kayan aikin semiconductor kawai, saboda yanayin semiconductor yana buƙatar ƙarin kariya daga muhalli, kuma gurɓatattun sinadarai ba za su iya bayyana ba. Duk da haka, wasu manyan jiragen ruwa sun bambanta, kuma muhalli ya bambanta, kuma za a sami gibi daban-daban a cikin iyakokin amfani. Ta hanyar zaɓar kayan aikin tsaftacewa da aka yi niyya kuma suka dace ne kawai za mu iya cimma tasirin da ake so.

4. Cancanta na masana'antar injin tsabtace laser zai shafi jerin matsalolin sabis. A matsayin injin tsaftacewa, kayan aikin tsaftacewa na laser suna da wasu buƙatun tsari. Farashin zai bambanta sosai dangane da tsarin, kuma haka yake ga kayan aikin masana'antu. Kafin zaɓar kayan tsaftacewa, ana ba da shawarar yin la'akari da cancantar masana'antun kayan tsaftacewa na laser. Ya fi dacewa a sake gano ƙwarewarsu ta hanyar ziyartar abokan cinikin haɗin gwiwa da ke akwai.