Impumelelo yensimbi ngeukushisela nge-laserkuncike ezicini zayo zomzimba eziyinhloko. Isibonelo, ukubuyisa okuphezulu kungaphambukisa amandla e-laser, kuyilapho ukuhanjiswa okuphezulu kokushisa kususa ukushisa ngokushesha kakhulu endaweni yokushisela. Lezi zici, kanye nendawo yokuncibilika, kunquma ukuthi into imunca amandla kahle kangakanani ukuze yakhe i-weld eqinile neqondile.

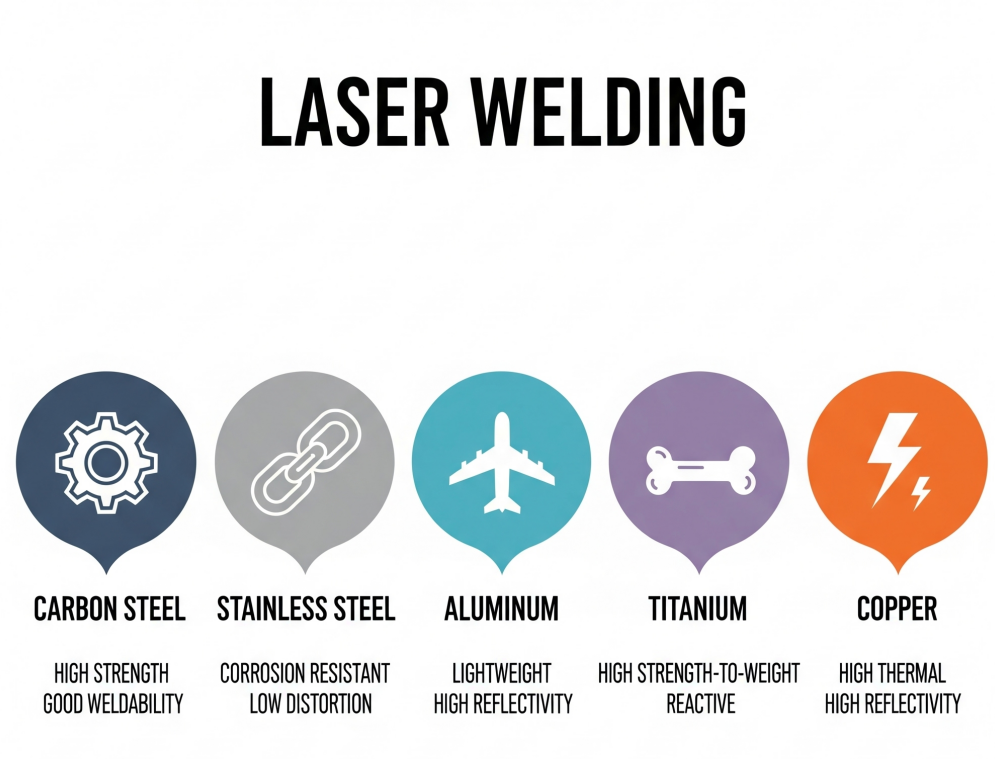

Nansi incazelo yezinsimbi ezivamile nokuthi izakhiwo zazo ziqala kanjani ukusebenza.

Ukushisela nge-laser Insimbi Yekhabhoni

Insimbi yekhabhoni iyinhlanganisela yensimbi nekhabhoni enokuqukethwe kwekhabhoni okufika ku-2.1%. Okuqukethwe kwekhabhoni yikona okuyinhloko okunquma izakhiwo zayo.

Insimbi ephansi yekhabhoni(ngaphansi kuka-0.25% wekhabhoni) ithambile, iqinile, futhi kulula ukuyilungisa futhi ishibilika. Ivame ukusetshenziselwa amaphaneli omzimba, ucingo, namapayipi.

Insimbi yekhabhoni ephakathi nendawo(ikhabhoni engu-0.25% kuya ku-0.60%) inamandla futhi ilukhuni kunensimbi engenakhabhoni eningi. Lokhu kuyenza ifaneleke ezingxenyeni ezidinga amandla amaningi kanye nokumelana nokuguguleka, njengegiya, imiphini, namasondo esitimela.

Insimbi enekhabhoni ephezulu(ngaphezu kuka-0.60% wekhabhoni) iyona enamandla kakhulu futhi enzima kakhulu kulezo ezintathu, kodwa futhi ayinamatheli kakhulu futhi ayiboli kakhulu. Ubulukhuni bayo buyenza ifaneleke kakhulu ekusikeni amathuluzi, izipilingi, kanye nezintambo ezinamandla aphezulu, kodwa idinga ukuphathwa ngokucophelela ngesikhathi sokushisela ukuze kuvinjelwe ukuqhekeka.

Insimbi yekhabhoni iwumsebenzi onzima ekukhiqizeni, futhi kudinga ukushiselwa nge-laser kahle.

Izinzuzo: Uthola ama-weld aqinile, ajulile ngokunemba okumangalisayo kanye nokuphambuka okuncane kakhulu. Ijubane liyinzuzo enkulu, likhulisa umkhiqizo phansi efektri.

Izinto okufanele uzicabangele: Ukupholisa okusheshayo kwenqubo ye-laser kungenza ukushintshwa kwe-weld kuqhekeke futhi kuthambekele ekuqhekekeni. Ngezinye izikhathi, ukushisa ingxenye kusengaphambili kuyadingeka ukuze kuncishiswe ukupholisa futhi kuvinjelwe izinkinga.

Ukushisela Nge-Laser Insimbi Engagqwali

Lokhu kufana okwenziwe ezulwini. Ukushisela nge-laser kuyinqubo ephelele yensimbi engagqwali, ikakhulukazi ezimbonini ezifuna ukuhlanzeka.

Izinzuzo: Ukufakwa kokushisa okuphansi, okugxile kakhulu kuyinzuzo enkulu. Kugcina izakhiwo zensimbi engagqwali ezingamelani nokugqwala ngokuvimbela into ebizwa ngokuthi “i-carbide precipitation.” Lokhu kuphumela ekushiseni okuhlanzekile nokunembile ngokuhlinzwa, yingakho kuthandwa kangaka embonini yezokwelapha neyokudla.

Izinto okufanele uzicabangele: Izinsimbi ezingagqwali ezivame kakhulu, njengochungechunge lwama-300 (isb., 304, 316), zishibilika kahle kakhulu. Kodwa-ke, ezinye izinhlobo, njengochungechunge lwama-400, zingaba buthakathaka endaweni ethintekile ukushisa.

Ukushisela i-Aluminium nge-Laser

Ukushisela i-aluminiyamu bekulokhu kunzima, kodwa ukushisela nge-laser kuyawushintsha umdlalo.

Izinzuzo: I-Aluminium iyisiqhubi sokushisa esihle kakhulu, okusho ukuthi ngokushisela okuvamile, ukushisa kuyasabalala futhi kubangele ukuthi yonke ingxenye igobe. Amandla agxile ku-laser kanye nokufakwa kokushisa okuphansi kuxazulula le nkinga, kunciphisa kakhulu ukuphambuka.

Izinto okufanele uzicabangele: I-Aluminium ikhanya kakhulu. Ubuso obukhazimulayo bungagxuma umsebe we-laser ngokushesha. Impumelelo incike ezintweni ezimbalwa ezibalulekile: ukuhlanza ubuso obungenasici, igesi yokuvikela efanele, kanye nokusebenzisa uhlobo olufanele lwe-laser (ama-fiber laser avame ukuthandwa) ukuqinisekisa ukuthi amandla ayamuncwa.

Ukushisela i-Laser Titanium

Uma udinga ukushisela i-titanium, i-laser ingenye yamathuluzi akho amahle kakhulu kulo msebenzi.

Izinzuzo: I-Titanium iyinsimbi esabelayo, okusho ukuthi ingcoliswa kalula umoya-mpilo emoyeni uma incibilika, okuholela ekushiseni okubuthakathaka nokuqhekeka. Ijubane kanye nokunemba kwe-laser kunciphisa isikhathi lapho insimbi incibilika futhi ivezwa khona, kunciphisa ingozi yokungcola kanye nokuqhekeka.

Izinto okufanele uzicabangele: Njengoba kunjalo nge-TIG welding titanium, kusadingeka uqaphele kakhulu. Ukuhlanzeka okuphelele kanye nokuvikela okuphelele ngegesi engangenisi (njenge-argon) akunakuxoxiswana ngakho.

Ukushisela Nge-Laser Ithusi Nezinye Izinsimbi Ezikhanyayo

Yilapho ukushisela nge-laser kucindezela khona imingcele yalokho okungenzeka.

Izinzuzo: Umshini wokushisela we-laser ungahlanganisa izinto ezikhanya kakhulu njengethusi, okunzima kakhulu ukuzishisela cishe nganoma iyiphi enye indlela. Lokhu kubalulekile ezisetshenziswayo ezifana namabhethri ezimoto zikagesi (EV), lapho ithusi ne-aluminium kumele kuhlanganiswe khona.

Izinto okufanele uzicabangele: Lokhu kuyinto esezingeni lochwepheshe. Ukukhanya okuphezulu kanye nokushisa kungalimaza i-optics ye-laser uma kungaphathwa kahle. Ngokuvamile kudinga imishini ekhethekile, kanye namasu athuthukile.

Yini i-Lukulingisa ukushisela nge-laser?

Nakuba kuzwakala njengethuluzi eliyisimangaliso, alilungele yonke imisebenzi. Kubalulekile ukuqonda umehluko.

1.Izindleko Zokuqala Eziphezulu: Umshini wokushisela we-laser ochwepheshe uwutshalomali olukhulu, ubiza kakhulu kunezilungiselelo ze-MIG noma ze-TIG zendabuko.

2.Izidingo Eziqinile ZokuhlanganaNjengoba kushiwo, ama-laser adinga ukulingana okucishe kufane. Uma izingxenye zakho zinezikhala noma zingasikwanga kahle, i-laser ngeke ikwazi ukuzihlanganisa ngempumelelo.

3.Izinkinga ZokuzindlaIzinto ezicwebezelayo njenge-aluminium nethusi kungaba nzima ukuzishibiliza ngaphandle kwama-laser namasu akhethekile.

4.Ukukhathazeka Ngokuphepha: Ukukhanya kwe-laser okunamandla kakhulu kuyingozi kakhulu futhi kungabangela ukulimala okukhulu kwamehlo kanye nokusha kwesikhumba, ngisho noma kuvela ekukhanyeni. Izivikelo zokuphepha ezifanele kanye nemishini yokuzivikela yomuntu siqu (PPE) kuyimpoqo ngokuphelele.

Izindlela Ezinhle Kakhulu Zokushisela I-Laser Engenaphutha

Ukuze uthole okuningi enkambisweni yakho yokushisela nge-laser, udinga ukugxila ezintweni eziyisisekelo.

Ukulungiselela Kuyikho Konke

Ukufaneleka Kwamalunga: Asikwazi ukusho okwanele: izingxenye zakho kumele zihlangane kahle. Hlosa igebe elingaphansi kuka-10% wobukhulu bezinto zokwakha ukuze uthole imiphumela emihle kakhulu.

Ukuhlanza Okungaphezulu: Lahla konke okungeyona insimbi. Lokhu kusho ukususa wonke amafutha, amafutha, ama-oxide, nanoma yikuphi okunye ukungcola. Indawo ehlanzekile ibalulekile ukuvimbela ama-pores kanye nezinye izinkinga ku-weld yakho.

Lawula Inqubo Yakho

Igesi Yokuvikela: Njenge-TIG ne-MIG, ukushisela nge-laser kusebenzisa igesi engangenisi (ngokuvamile i-argon noma i-helium) ukuvikela ichibi lokushisela elincibilikisiwe emoyeni nomoya-mpilo kanye ne-nitrogen emoyeni, okuqinisekisa ukushisela okuqinile nokuhlanzekile.

Ukuthuthukisa Ipharamitha: Kufanele ushayele kuzilungiselelo zakho. Amandla e-laser, isivinini sokushisela, kanye nebanga lokugxila kumele kulinganiswe kahle ukuze kuhambisane nezinto ezithile kanye nobukhulu obuthile osebenza ngabo.

Ukuphepha Kuqala, Njalo

Ukushisela nge-laser akuyona inqubo ongaba ngumuntu ongajwayelekile ngayo. Ukukhanya okugxilile kunamandla amakhulu. Noma ubani oseduze nendawo yokusebenza kumele agqoke izibuko zokuphepha ze-laser ezikhethekile ezilinganiselwe ubude be-laser yakho.

Ingabe Umshini Wokushisela Nge-Laser Uyisinqumo Esifanele Kuwe?

Ngakho-ke, kufanele utshale imali ekushiseni nge-laser?

Ake sifingqe. Ukushisela nge-laser kuyithuluzi lokukhiqiza elithuthukisiwe eliletha isivinini esingenakuqhathaniswa, ukunemba, kanye nekhwalithi. Ukushintshana yizindleko zokuqala eziphezulu kanye nezidingo eziqinile zezingxenye ezihlanzekile nezilingana kahle.

Umcabango wethu wokugcinaUma umsebenzi wakho udinga ivolumu ephezulu, ukuzenzekela, kanye nokunemba okuqondile—ikakhulukazi ezintweni ezibucayi noma eziyinselele—khona-ke ukushisela nge-laser akuyona nje enye indlela. Yisisombululo esingcono kakhulu esingaguqula umkhiqizo wakho.

Isikhathi sokuthunyelwe: Agasti-15-2025