Lo mhlahlandlela wezinyathelo zokuphepha zokushisela nge-laser ophathwa ngesandla uyisinyathelo sakho sokuqala sokufunda lobu buchwepheshe ngaphandle kokufaka impilo yakho engozini. Abashisela nge-laser abaphathwa ngesandla bashintsha ama-workshop ngesivinini esikhulu nokunemba, kodwa la mandla eza nezingozi ezinkulu, ezivame ukungabonakali.

Lo mhlahlandlela unikeza izinyathelo zokuphepha ezibalulekileukushisela nge-laser okuphathwa ngesandlafuthi kuhloswe ukwengeza, hhayi ukufaka esikhundleni, incwadi yemiyalelo yokuphepha ethile enikezwe umenzi wemishini yakho. Njalo bheka incwadi yemiyalelo yomenzi wakho ukuze uthole imiyalelo eningiliziwe yokusebenza kanye nokuphepha.

Umzila Wakho Wokuqala Wokuzivikela: Imishini Yokuzivikela Yomuntu Siqu Edingekayo

Ingabe abashiseli be-laser abaphathwa ngesandla baphephile? Yebo, kodwa kuphela uma usebenzisa igiya elifanele. Imishini yakho ejwayelekile yokushisela i-arc ayifanelekeli ukusebenza nge-laser. Wonke umuntu osendaweni yokushisela noma eduze kwayo kumele ahlonyiswe kahle.

Izibuko Zokuphepha Ze-Laser:Lena ingxenye ebaluleke kakhulu ye-PPE. Kumelwe ilinganiswe nge-Optical Density (OD) ye-OD≥7+ ngqo ngobude be-laser yakho (ngokuvamile cishe i-1070 nm). Ngaphambi kokusebenzisa ngakunye, kufanele uhlole ngokoqobo izibuko zamehlo ukuqinisekisa ukuthi lezi zilinganiso ziphrintiwe kahle ku-lens noma kufreyimu. Ungalokothi usebenzise izibuko ezingaphawuliwe noma ezonakele. Wonke umuntu onethuba lokubona i-laser uyazidinga.

Izingubo Ezingalawuli:Ukumbozwa kwesikhumba okuphelele kubalulekile. Gqoka izingubo ezilinganiselwe i-FR ukuze uvikeleke ekushiseni kwe-laser, izinhlansi kanye nokushisa.

Amagilavu Amelana Nokushisa:Vikela izandla zakho emandleni okushisa kanye nokukhanya kwemisebe ngengozi.

Umshini wokuphefumula:Intuthu yokushisela nge-laser iqukethe izinhlayiya ezincane kakhulu ezingaba yingozi. Sebenzisa uhlelo lokukhipha intuthu, futhi uma kudingeka, gqoka umshini wokuphefumula (N95 noma ngaphezulu) ukuze uvikele amaphaphu akho.

Izicathulo Zokuphepha:Izicathulo ezijwayelekile zezinga lezimboni ziyadingeka ukuze kuvikelwe ezingxenyeni eziwayo kanye nezinye izingozi zasesitolo.

Ukudala Inqaba: Indlela Yokusetha Indawo Ephephile Ye-Laser

Ukusetha kahle indawo yokusebenza kubaluleke njengokugqokapokomuntu siqupimishini yokuvikela. Kumelwe udale indawo elawulwa nge-laser esemthethweni(LCA)ukuvimba ugongolo.

Ukuqonda Ama-Laser Ekilasi 4

Abashiseli be-laser abaphathwa ngesandla bavame ukuwela ku-Class 4 yohlelo lokuhlukaniswa kwe-laser lwe-ANSI Z136.1. Lokhu kuhlukaniswa kubonisa izinhlelo ze-laser eziyingozi kakhulu. Ama-laser e-Class 4 ayakwazi ukubangela umonakalo wamehlo unomphela ovela emisebeni eqondile, ekhanyayo, noma esakazeke kabanzi, futhi angabangela ukusha kwesikhumba nokushisa imililo. Lawa mandla aphezulu agcizelela isidingo esiphelele sezinqubo zokuphepha eziqinile.

Misa Isithiyo Esingokomzimba

Kumelwe ufake umsebenzi wokushisela ukuze uvikele abanye. Lokhu kungenziwa ngokusebenzisa:

1.Amakhethini noma izikrini zokuphepha ze-laser eziqinisekisiwe.

2.Izindonga zesakhiwo ezihlala njalo.

3.Amaphaneli e-aluminium anodized alinganiswe ngama-laser e-Class 4.

Lawula Ukufinyelela

Abasebenzi abagunyaziwe, abaqeqeshwe kahle, nabahlonyiswe ngokugcwele kuphela okufanele bangene e-LCA.

Izimpawu Zesexwayiso

Beka izimpawu ezicacile "ZENGOZI" kuyo yonke indawo yokungena, njengoba kudingeka ngokwezinga le-ANSI Z136.1. Isibonakaliso kumele sibe nophawu lwelaser bese sithi “Ilaser Yekilasi 4 – Gwema ukuchayeka kwamehlo noma kwesikhumba emisebeni eqondile noma esakazekile.”

Nciphisa Izingozi Zomlilo Nentuthu

Ukuvimbela Umlilo:Susa zonke izinto ezivuthayo nezivuthayo ngaphakathi okungenani kwerediyasi yamamitha ayi-10 ukusuka ku-LCA. Gcina isicisha-mlilo esifanelekile nesinakekelwayo (isib. uhlobo lwe-ABC, noma i-Class D yezinsimbi ezivuthayo) esitholakala kalula.

Ukukhishwa kwentuthu:Iyiphi ingozi enkulu kakhulu lapho kushiswa nge-laser? Nakuba ukulimala kwamehlo kuyinto yokuqala, umusi uyinkinga enkulu. Sebenzisa i-fume extractor yendawo lapho i-input ibekwe eduze kwe-weld ngangokunokwenzeka ukuze ubambe izinhlayiya eziyingozi emthonjeni.

Isimiso Sokushisela Nge-Laser Ephathwayo

Cabanga ngomshini wokushisela we-laser ophathwa ngesandla njengengilazi yokukhulisa enamandla kakhulu futhi enembile. Esikhundleni sokugxila elangeni, ukhiqiza futhi ugxilise ukukhanya okunamandla amakhulu endaweni encane.

Inqubo iqala emthonjeni we-laser, ngokuvamile i-fiber laser generator. Le yunithi idala ukukhanya okugxile kakhulu kwe-infrared. Lokhu kukhanya kuhamba ngekhebula le-fiber optic eliguquguqukayo kuye esitotshini sokushisela esiphathwayo.

Ngaphakathi kwethoshi, uchungechunge lwe-optics lugxila lo msebe onamandla phansi endaweni ethile. Lapho umqhubi edonsa i-trigger, la mandla agxile ashaya insimbi, okwenza incibilike cishe ngokushesha bese yakha ichibi lokushisela. Njengoba umqhubi ehambisa ithoshi eceleni kwejoyinti, insimbi encibilikisiwe igeleza ndawonye futhi iqine, idale umthungo oqinile, ohlanzekile.

Lesi simiso yisona esenza ukushisela nge-laser kube nezinzuzo eziyinhloko.

Ukufakwa Kokushisa Okuphansi Nokuhlanekezelwa Okuncishisiwe

Ubuningi bamandla obuphezulu kakhulu bufaka amandla ezintweni cishe ngokushesha. Lokhu kushisa okusheshayo kubangela ukuthi insimbi esendaweni yokugxila incibilike futhi iphele ngisho nangaphambi kokuba ukushisa okukhulu kungene ezintweni ezizungezile.

Indawo Encane Ethintekile Ekushiseni (HAZ):Ngenxa yokuthi isikhathi sokusabalalisa ukushisa sincane, indawo yezinto eziguqulwa ngokwesakhiwo ukushisa kodwa ezingancibilikisiwe—i-HAZ—incane kakhulu.

Ukugoba Okuncishisiwe:Ukuphambuka kokushisa kubangelwa ukwanda nokufinyela kwezinto ezifudunyezwayo. Njengoba ivolumu encane kakhulu yensimbi ifudunyezwa, ukucindezeleka kokushisa okuphelele kuphansi kakhulu, okuholela ekugobeni okuncane kanye nomkhiqizo wokugcina ozinzile ngokwezinga elithile.

Ukunemba Okuphezulu Nokulawula

Ukunemba kokushisela nge-laser kuwumphumela oqondile wobukhulu obuncane, obulawulekayo bomsebe we-laser.

Usayizi Wendawo Encane:I-laser ingagxiliswa phansi ibe usayizi wendawo ongama-milimitha ambalwa nje. Lokhu kuvumela ukudalwa kwama-weld amancane kakhulu, amancane angenakwenzeka ngezindlela ezivamile ezifana ne-MIG noma i-TIG welding.

Amandla Aqondisiwe:Lokhu kunemba kwenza kube kuhle kakhulu ekushiseleni izinto ezincane, izingxenye eziyinkimbinkimbi, noma ukusebenza eduze kwezinto zikagesi ezithinta ukushisa ngaphandle kokudala umonakalo.

Isivinini Esimangalisayo Nokungena Okujulile

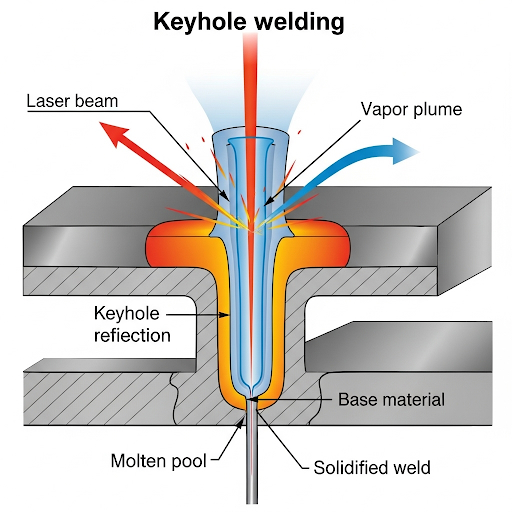

Ubuningi bamandla amakhulu buholela endleleni yokushisela esebenza kahle kakhulu eyaziwa ngokuthi ukushisela imigodi yokhiye.

Ukwakheka kwe-Keyhole:Ubuningi bamandla buphakeme kakhulu kangangokuthi abugcini nje ngokuncibilikisa insimbi; buyayishisa, kwenze umgoqo ojulile, omncane womusi wensimbi obizwa ngokuthi “imbobo yokhiye.”

Ukudluliselwa Kwamandla Okusebenzayo:Lo mgodi wokhiye usebenza njengomsele, ovumela umsebe we-laser ukuthi ungene ujule ezintweni. Amandla e-laser amuncwa kahle kuyo yonke imbobo yokhiye, hhayi nje ebusweni.

Ukushisela Okusheshayo:Njengoba i-laser ihamba eduze kwejoyinti, insimbi encibilikisiwe igeleza izungeze imbobo yokhiye bese iqina ngemuva kwayo, idale ukushibilika okujulile nokuncane. Le nqubo ishesha kakhulu kunezindlela zendabuko ezithembele ekuqhutshweni kokushisa okuhamba kancane ukuze kuncibilikiswe izinto. Lokhu kuphumela ekushibilikeni okujulile ngesivinini esikhulu sokuhamba, okukhulisa umkhiqizo.

Uhlu Lokuhlola Lomqhubi: Izinyathelo Zokuqapha Ezibalulekile Zokuphepha Ekusetshenzisweni

Uma igiya selivuliwe futhi indawo isiphephile, ukusebenza okuphephile kubalulekile.

Yenza Ukuhlolwa Kwangaphambi Kokusetshenziswa:Ngaphambi kokusebenzisa konke, hlola imishini ngokubona. Hlola ikhebula le-fiber optic ukuthi alinawo ama-kink noma umonakalo, qiniseka ukuthi umlomo wokushisela uhlanzekile futhi uvikelekile, bese uqinisekisa ukuthi zonke izici zokuphepha zisebenza kahle.

Ukulungiswa Okuvamile:Ngaphandle kokuhlolwa kwansuku zonke, sungula futhi unamathele esimisweni sokugcinwa okuvamile kohlelo lwe-laser. Lokhu kuhlanganisa ukuhlola izinhlelo zokupholisafuthiukuhlanzeka kwamehlo.Qinisekisa ukuthi izinhlelo zokukhipha intuthu zihlanzwa njalo futhi izihlungi zishintshwa ukuze kulondolozwe ukusebenza kahle. Ukunakekelwa okufanele kuvimbela ukungasebenzi kahle kwemishini okungaholela ezimweni eziyingozi.

Izingozi Zokuzindla Ngenhlonipho:Ukukhanya okubonakalayo (okufana nesibuko) okuvela ezindaweni ezicwebezelayo njenge-aluminium noma insimbi engagqwali kuyingozi kakhulu ngemva kokukhanya okuqondile.

Yazi Indlela Oma Ngayo Ne-Engela Yakho:Gcina umzimba wakho ungangeni ezindleleni eziqondile nezingaba khona zokubonisa. Gcina i-engeli yokushisela ephakathi kwama-degree angu-30 no-70 ukuze unciphise ukubonakalisa okuyingozi okubuyela kuwe.

Sebenzisa Izici Zokuphepha Ezakhelwe Ngaphakathi:Ungalokothi udlule izindlela zokuphepha.

Ukushintsha Ukhiye:Ivimbela ukusetshenziswa okungagunyaziwe.

Isiqalisi Sezinyathelo Ezimbili:Kuvimbela ukudubula ngengozi.

Isifunda Sokuxhumana Sezinto Zokusebenza:Kuqinisekisa ukuthi i-laser ingadubula kuphela uma umlomo uthinta i-workpiece.

Qinisekisa Ukusikwa Okufanele:Njalo namathisela isibambo somhlaba ngokuphephile endaweni yokusebenza ngaphambi kokuqala. Lokhu kuvimbela isivalo somshini ukuthi singabi namandla ayingozi.

Impendulo Ephuthumayo: Okufanele Ukwenze Esigamekweni

Ngisho noma ngabe yiziphi izinyathelo zokuphepha, kufanele ulungele ukuthatha isinyathelo ngokushesha. Wonke umuntu osebenza e-LCA noma eduze kwayo kumele azi lezi zinyathelo.

Ukuvezwa Kwamehlo Okusolwayo

Noma yikuphi ukucashelwa kwamehlo okusolwayo emsebeni oqondile noma okhanyayo kuyisimo esiphuthumayo sezokwelapha.

1.Misa ukusebenza ngokushesha bese uvala uhlelo lwe-laser.

2.Yazisa i-Laser Safety Officer (LSO) noma umphathi wakho ngokushesha.

3.Funa ukuhlolwa kwezokwelapha okusheshayo kudokotela wamehlo. Yiba nemininingwane ye-laser (Uhlobo, ubude besikhathi, amandla) ilungele abasebenzi bezokwelapha.

4.Ungahlikihli iso.

Ukusha Kwesikhumba Noma Umlilo

Ukusha Kwesikhumba:Yiphathe njengokusha kokushisa. Pholisa indawo ngokushesha ngamanzi bese ucela usizo lokuqala. Bika i-LSO yakho ngalesi sigameko.

Ngomlilo:Uma umlilo omncane uqala, sebenzisa isicisha-mlilo esifanele. Uma umlilo ungalawuleki ngokushesha, vula i-alamu yomlilo eseduze bese ususa indawo.

Ulwazi Lunamandla: Isikhulu Sokuphepha Kwe-Laser (LSO)

Ngokwezinga le-ANSI Z136.1, noma yisiphi isikhungo esisebenzisa i-laser yekilasi lesi-4 kumele siqoke i-Laser Safety Officer (LSO).

I-LSO ingumuntu ophethe uhlelo lonke lokuphepha nge-laser. Abadingi isitifiketi sangaphandle esikhethekile, kodwa kumele babe nokuqeqeshwa okwanele ukuqonda izingozi, basebenzise izinyathelo zokulawula, bavume izinqubo, futhi baqinisekise ukuthi bonke abasebenzi baqeqeshwe kahle. Lo msebenzi uyisisekelo sesiko lakho lokuphepha.

Imibuzo Evame Ukubuzwa (Imibuzo Evame Ukubuzwa)

Q: Ingabe abashiseli be-laser abaphathwa ngesandla baphephile endaweni yokusebenzela encane?

A: Yebo, uma ulandela yonke inqubo. Izindinganiso zokuphepha, okuhlanganisa nokuqoka i-LSO nokudala i-LCA, zisebenza kuyo yonke inhlangano esebenzisa i-laser yekilasi lesi-4, kungakhathaliseki ukuthi ingakanani.

U: Yisiphi isivikelo osidingayo ukuze ushise nge-laser?

A: Udinga izibuko zokuphepha ze-laser eziqondene nobude besikhathi,Izingubo ze-FR, amagilavu, kanye nesivikelo sokuphefumula endaweni elawulwa yi-laser (LCA) eklanywe kahle.

Q: Hlobo luni lokuqeqeshwa oludingwa yiSikhulu Sokuphepha seLaser?

A: Izinga le-ANSI Z136.1 lidinga ukuthi i-LSO ibe nolwazi futhi ikwazi ukusebenza kahle, kodwa ayifuni isitifiketi esithile sangaphandle. Ukuqeqeshwa kwabo kufanele kwanele ukuqonda i-laser physics kanye nezingozi, ukuhlola izingozi, ukunquma izinyathelo zokulawula ezifanele, nokuphatha uhlelo lokuphepha oluphelele, okuhlanganisa amarekhodi okuqeqesha kanye nokuhlolwa.

Isikhathi sokuthunyelwe: Agasti-01-2025