Ukusebenza ngokushesha, okujwayelekileumsiki we-laserukulungiswayisici esibaluleke kakhulu ekusebenzeni komshini wakho, ukuthembeka, kanye nesikhathi sokusebenza. Ukubheka ukulungiswa hhayi njengomsebenzi onzima, kodwa njengokutshalwa kwezimali okunesu, kukuvumela ukuthi uvimbele isikhathi sokungasebenzi esibizayo, esingahleliwe futhi uqinisekise umphumela oqhubekayo nosezingeni eliphezulu. Umshini onakekelwa kahle wandisa impilo yezingxenye ezibizayo njenge-laser tube kanye ne-optics, kunciphisa kakhulu ingozi yomlilo, futhi kuvikela utshalomali lwakho.

Uhlu Lwakho Lokuhlola Lokulungisa Oluqala Ngokushesha

Lolu hlu lokuhlola oluskenwayo luhlanganisa imisebenzi ebaluleke kakhulu. Ukuze uthole ukuqonda okujulile kwesinyathelo ngasinye, bheka izigaba ezinemininingwane ngezansi.

Imisebenzi Yansuku Zonke (Ngaphambi Kweshifti Ngayinye)

-

Hlola futhi uhlanze ilensi yokugxila kanye ne-nozzle.

-

Hlola izinga lamanzi abandayo kanye nezinga lokushisa.

-

Thulula ithreyi yemvuthuluka/ye-slag ukuze uvimbele izingozi zomlilo.

-

Sula phansi umbhede wokusebenzela kanye nengaphakathi ukuze ususe udoti.

Imisebenzi Yamasonto Onke (Njalo Ngemva Kwamahora Angu-40-50 Okusetshenziswa)

-

Hlanza ngokujulile zonke izibuko kanye nelensi yokugxila.

-

Hlanza izihlungi zomoya ze-chiller kanye nezihlungi zokungenisa umoya zomshini.

-

Sula bese uthambisa izinsimbi zokuqondisa.

-

Hlola futhi uhlanze ifeni yokukhipha intuthu kanye nepayipi.

Imisebenzi Yanyanga Zonke Neyesigamu Sonyaka

-

Hlola amabhande okushayela ukuze ubone ukuthi aqinile futhi agugile kahle.

-

Hlanza ngokujulile umbhede wokusebenzela (i-honeycomb noma i-slat).

-

Hlola ukuxhumeka kukagesi ekhabhinethini yokulawula.

-

Hlanza bese ubuyisela amanzi okupholisa njalo ezinyangeni ezi-3-6.

Izinqubo Zokuphepha Ezibalulekile Kuzo Zonke Izinsizakalo Zokulungisa

Ukuphepha akuxoxiswana ngakho. Nakuba umshini wokusika nge-laser ungumkhiqizo we-laser we-Class 1 ngesikhathi sokusebenza okuvamile, izingxenye zawo zangaphakathi zivame ukuba yi-Class 3B noma 4, ezingabangela ukulimala okukhulu kwamehlo nesikhumba.

-

Cisha Njalo:Ngaphambi kwanoma yikuphi ukulungiswa ngokomzimba, cisha ngokuphelele umshini bese uwukhipha kugesi. Lesi isinyathelo esibalulekile sokukhiya/ukukhipha i-tagout (LOTO).

-

Gqoka i-PPE efanele:Sebenzisa izibuko zokuphepha ukuze uvikele emfucumfucwini kanye namagilavu ahlanzekile, angenampuphu lapho uphatha ama-optics ukuze uvimbele ukungcoliswa ngamafutha esikhumba.

-

Ukuvimbela Umlilo Kubalulekile:Inqubo ye-laser idala ingozi yomlilo ngokwemvelo. Gcina umshini nendawo ezungezile ingenazo izinto eziningi ezingafuneki kanye nemfucumfucu evuthayo. Isicisha-mlilo se-CO2 esifanelekile nesihlolwa njalo kumele sitholakale kalula eduze komshini.

-

Gcina Irekhodi Lokulungisa:Incwadi yokubhalisa iyithuluzi lakho elibaluleke kakhulu lokulandelela imisebenzi, ukuhlonza izitayela zokusebenza, nokuqinisekisa ukuzibophezela.

Indlela Yokubona: Indlela Yokugcina Ukukhanya Kwakho Kwe-Laser Kunamandla Futhi Kunembile

Ama-optics angcolile yiwona avame kakhulu ukubangela ukusebenza kabi kokusika. Ukungcola okukulensi noma esibukweni akugcini nje ngokuvimba umsebe—kumunca amandla, kudale ukushisa okukhulu okungalimaza unomphela uqweqwe olubucayi futhi kuqhekeze ngisho ne-optics.

Kungani Ama-Dirty Optics Ebulala Amandla E-Laser

Noma yikuphi ukusala, kusukela kumunwe kuya kothuli oluncane, kumunca amandla e-laser. Lokhu kushisa okusendaweni kungabangela ukuqhekeka okuncane kakhulu ezimbozweni ezivimbela ukukhanya, okuholela ekuqhekekeni kwemigodi kanye nokwehluleka okubi kakhulu. Ukuhlanza indlela yokukhanya kubalulekile ukuvimbela lo monakalo.

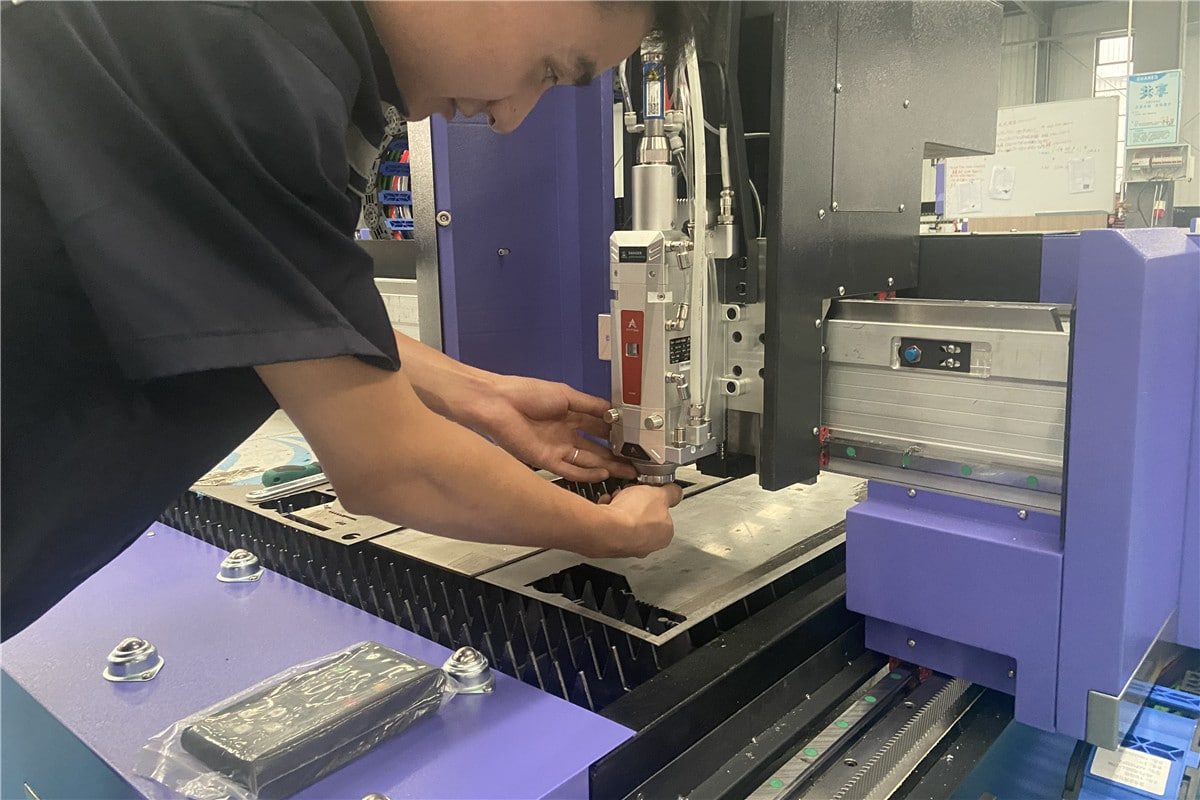

Umhlahlandlela Wesinyathelo Ngesinyathelo: Amalensi Okuhlanza Nezibuko

Izinto Ezidingekayo:

-

I-isopropyl alcohol (IPA) noma i-denatured alcohol enobumsulwa obuphezulu (90% noma ngaphezulu).

-

Izicubu zelensi ezisezingeni lokubona, ezingenayo i-lint noma ama-swabs kakotini amasha, ahlanzekile.

-

Isivuvuzi somoya sokususa uthuli olukhululekile kuqala.

Okufanele Ukugweme:

-

Ungalokothi usebenzise izihlanzi ezisekelwe ku-ammonianjengeWindex, njengoba zizolimaza unomphela uqweqwe.

-

Gwema amathawula ajwayelekile ephepha noma ama-snags esitolo, akhuhlayo futhi ashiye i-lint.

Inqubo Yokuhlanza:

-

Ukuphepha Kuqala:Vala umshini bese uvumela ama-optics ukuthi aphole. Gqoka amagilavu ahlanzekile.

-

Ukususwa Kothuli:Sebenzisa umshini womoya ovunguzayo ukuze uvunguze kancane izinhlayiya ezikhululekile ebusweni.

-

Sebenzisa i-solvent:Manzisa i-applicator yakho (izicubu zelensi noma i-swab) nge-IPA.Ungalokothi ufake i-solvent ngqo ku-optic, njengoba ingangena entabeni.

-

Sula Kancane:Sebenzisa ukunyakaza okukodwa, okuthambile kokudonsa phezu kobuso, bese ulahla izicubu. Kuma-optics ayindilinga, iphethini ejikelezayo kusukela phakathi nendawo iyaphumelela. Umgomo uwukuphakamisa ukungcola, hhayi ukukuhlafuna.

Uhlelo Lokunyakaza: Ukuqinisekisa Ukunyakaza Okubushelelezi Nokunemba

Ukunemba kokusikwa kwakho kuncike ngokuphelele ekuqineni komshini wohlelo lokunyakaza. Ukugcinwa kahle kususa izinkinga ezifana nokungalungi kobukhulu kanye nokuboshwa.

Ukugcoba 101: Hlanza Ngaphambi Kokugcoba

Lona umthetho wegolide wokugcoba. Ungalokothi ufake i-lubricant entsha phezu kwamafutha amadala, angcolile. Ingxube ye-lubricant entsha kanye nokungcola okudala idala i-abrasive paste esheshisa ukuguguleka kwama-bearings nama-rails. Sula njalo ama-rails ngendwangu engena-lint ngaphambi kokufaka ungqimba oluncane nolulinganayo lwe-lubricant.

-

Izinto Zokugcoba Ezinconywayo:Sebenzisa izithambisi ezichazwe ngumenzi njenge-white lithium grease noma i-dry lubricant esekelwe ku-PTFE, ikakhulukazi ezindaweni ezinothuli.

-

Gwema:Ungasebenzisi amafutha asetshenziswa kabanzi njenge-WD-40. Ancane kakhulu ukuthi angagcotshwa isikhathi eside futhi adonsela uthuli, okubangela umonakalo omkhulu kunokuba kube kuhle.

Indlela Yokuhlola Nokulungisa Ukucindezeleka Kwebhande

Ukuqina kwebhande okufanele kuyibhalansi. Ibhande elixegayo libangela ukungezwani, okuholela "ekubonakaleni" kokuqoshwa noma ezindilinga ezisikwa njengeziyindilinga. Ibhande eliqine kakhulu licindezela amabheringi emoto futhi lingalula ibhande unomphela.

-

Hlola Ukucindezeleka:Amabhande kufanele aqine kancane uma ecindezelwa ngokuqinile, kodwa anganciphisi ukubonakala. Uma uhambisa i-gantry ngesandla, akufanele kube khona ukulibaziseka noma "ukushelela."

Uhlelo Lokupholisa: Ukusekelwa Kokuphila Kwe-Laser Tube Yakho

I-water chiller iyisistimu yokusekela impilo ye-laser tube yakho. Ukwehluleka ukupholisa i-tube kahle kuzoholela ekubhujisweni kwayo okusheshayo nokungenakuguqulwa.

Umthetho Wegolide: Amanzi Ahluziwe Kuphela

Lokhu kuyimfuneko engaxoxiswana ngayo. Amanzi ompompi aqukethe amaminerali azoshaya futhi akhe ungqimba oluvikelayo lwesikali ngaphakathi kwepayipi le-laser, okubangela ukuthi lishise ngokweqile. Ngaphezu kwalokho, la maminerali enza amanzi ompompi aqhube ugesi ngendlela eqhubekayo, okudala ingozi yokuqhuma kwamandla kagesi aphezulu okungabhubhisa ukunikezwa kwamandla.

Uhlu Lokuhlola Ukulungiswa Kwe-Chiller

-

Izihlungi Ezihlanzekile:Masonto onke, hlanza izihlungi zothuli ezinemeshi ezindaweni zokungenisa umoya ze-chiller ukuqinisekisa ukuhamba komoya okufanele.

-

I-Condenser Ehlanzekile:Nyanga zonke, cima iyunithi bese usebenzisa ibhulashi elithambile noma umoya ocindezelwe ukuze uhlanze uthuli oluvela emaphinini e-condenser afana ne-radiator.

-

Shintsha Amanzi:Khipha amanzi bese uwashintsha njalo ezinyangeni ezi-3-6 ukuze uvimbele ukungcola nokukhula kwe-algae.

Ukugeleza Komoya Nokukhipha: Ukuvikela Amaphaphu Akho Nelensi Yakho

Izinhlelo zokukhipha intuthu kanye nokusiza umoya zibalulekile ekuphepheni komqhubi kanye nempilo yomshini. Zisusa intuthu eyingozi futhi zivimbele izinsalela ekungcoliseni i-optics yakho kanye nezingxenye zemishini.

Ukulungiswa Kokukhishwa Kwentuthu

Izinsalela zinganqwabelana phezu kwezinsika zefeni eyinhloko yokukhipha umoya, zivimbele ukuhamba komoya futhi zenze ifeni ingalingani. Njalo ngesonto noma ngenyanga, nqamula ifeni kugesi bese uhlanza kahle izinsika ze-impeller. Hlola yonke imibhobho yokuhambisa amanzi ukuze ubone ukuthi ayivimbekile noma ayivuzi bese uvala noma yimuphi umonakalo ngokushesha.

Usizo Lomoya: Iqhawe Elingaculwanga

Uhlelo lokusiza umoya lwenza imisebenzi emithathu ebalulekile: lukhipha izinto ezincibilikisiwe esitsheni, lucime amalangabi, futhi ludale ikhethini lomoya elinomfutho ophezulu elivikela ngenkuthalo ilensi yokugxila entuthwini nasezingcoleni. I-nozzle evalekile noma i-air compressor ehlulekayo iyingozi ngqo kulensi yakho yokugxila ebizayo futhi kufanele ixazululwe ngokushesha.

Ukuxazulula Izinkinga Ezivamile: Indlela Yokulungisa-Okokuqala

| Inkinga | Imbangela Yokulungiswa Okungenzeka | Isixazululo |

| Ukusika Okubuthakathaka Noma Okungaguquguquki | 1. Ilensi/izibuko ezingcolile. 2. Ukungalingani kwemisebe. | 1. Hlanza wonke ama-optics ngokwesiqondiso esingenhla. 2. Yenza ukuhlolwa kokulungiswa kwe-beam.

|

| Imigqa Egobile noma Izimo Ezigobile | 1. Amabhande okushayela akhululekile. 2. Udoti odongeni lwezinsika. | 1. Hlola futhi ulungise ukuqina kwebhande. 2. Hlanza futhi uthambise izinsimbi.

|

| Amalangabi Adlulele Noma Ukusha | 1. I-nozzle yokusiza umoya evalekile. 2. Ukukhishwa kwentuthu okubuthakathaka. | 1. Hlanza noma ushintshe umlomo wombhobho. 2. Hlanza ifeni yokukhipha umoya kanye nepayipi lokuhambisa umoya.

|

| I-alamu ethi “Iphutha Lamanzi” | 1. Amanzi aphansi ku-chiller. 2. Isihlungi se-chiller esivalekile. | 1. Faka amanzi acwengekile. 2. Hlanza isihlungi somoya se-chiller.

|

Imibuzo Evame Ukubuzwa Mayelana Nokulungiswa Kokusika I-Laser

Kufanele ngihlanze kangaki ngempela ilensi yami ye-laser?

Kuncike ezintweni ezisetshenziswayo. Ezintweni ezithunqayo njengokhuni, zihlole nsuku zonke. Ezintweni ezihlanzekile njenge-acrylic, ukuhlola njalo ngeviki kunganele. Umthetho omuhle ukuhlola ilensi nezibuko nsuku zonke.

Iyiphi ingozi enkulu yomlilo okufanele ngiyiqaphele?

Ukuqongelela kwezingcezu ezincane ezisikiwe kanye nezinsalela ezisele kuthreyi yemvuthuluka noma embhedeni wokusebenza yiwona uphethiloli ovame kakhulu womlilo womshini. Thulula ithreyi yemvuthuluka nsuku zonke ukuze unciphise le ngozi.

Ngingawasebenzisa yini amanzi ompompi efrijini lami kanye nje?

Cha. Ukusebenzisa amanzi ompompi, ngisho noma kanye kuphela, kuletha amaminerali angaqala ngokushesha ukubangela ukwakheka kwezikali kanye nezinkinga zokuqhuba ugesi. Namathela emanzini acwengekile kuphela ukuze uvikele ithubhu lakho le-laser kanye nokunikezwa kwamandla.

Isiphetho

OkuvumelanayoUkugcinwa kwe-laser ye-CO2kuyisihluthulelo sokuvula amandla aphelele omshini wakho nokuvikela utshalomali lwakho. Ngokulandela isimiso esivamile, uguqula ukulungiswa kusuka emsebenzini osheshayo kuya isu elisebenzayo eliqinisekisa ikhwalithi, ukuphepha, kanye nenzuzo. Imizuzu embalwa yokuvimbela ifanele amahora amaningi okuxazulula izinkinga nokulungisa.

Udinga usizo lochwepheshe? Hlela ukuhlolwa kwesevisi yobungcweti nochwepheshe bethu ukuqinisekisa ukuthi umshini wakho ulinganisiwe ukuze usebenze kahle kakhulu.

Isikhathi sokuthunyelwe: Okthoba-08-2025