Ukuphepha nokusebenza kahle kwezinhlelo zesitimela zanamuhla kuncike ezingxenyeni zokukhiqiza ezindinganisweni eziphakeme kakhulu zokunemba. Inhliziyo yale nqubo yezimboni ukusika nge-laser, ubuchwepheshe obusebenzisa ukukhanya okugxilile ukwakha izingxenye zensimbi ngokunemba okungenakuqhathaniswa.

Lo mhlahlandlela unikeza ukubuka okuningiliziwe kwezimiso zobunjiniyela ezilawulayoumsiki we-laser, ihlola ukusetshenziswa kwayo okuhlukahlukene kusukela ezindikimbeni zezitimela kuya emishinini eseceleni komzila, futhi ichaza ukuthi kungani isibe ithuluzi eliyisisekelo embonini yezitimela.

Ubuchwepheshe: Indlela I-Laser Esika Ngayo Insimbi Ngempela

Akuyona nje "umsebe wokukhanya" ojwayelekile.Le nqubo iwukuxhumana okulawulwa kakhulu phakathi kokukhanya, igesi, kanye nensimbi.

Nansi inqubo yesinyathelo ngesinyathelo:

1. Isizukulwane:Ngaphakathi komthombo wamandla, uchungechunge lwama-diode “lupompa” amandla ezintanjeni ze-fiber optic ezifakwe izakhi zomhlaba ezingavamile. Lokhu kuvusa ama-athomu futhi kukhiqize ukukhanya okukhulu, okunamandla aphezulu.

2. Ukugxila:Lo msebe, uvame ukulinganiselwa phakathi kwama-kilowatts angu-6 nama-20 (kW) ukuze isetshenziswe kakhulu ezimbonini, idluliselwa ngekhebula le-fiber optic iye ekhanda lokusika. Lapho, uchungechunge lwamalensi luyigxilisa endaweni encane, enamandla kakhulu, ngezinye izikhathi encane kune-0.1 mm.

3. Ukusiza Ukusika Nokuphehla Igesi:Ugongolo olugxilile luyancibilika futhi lushise insimbi. Ngesikhathi esifanayo, igesi yokusiza enomfutho ophezulu ikhishwa nge-nozzle efanayo nogongolo lwe-laser. Le gesi ibalulekile futhi ifeza izinjongo ezimbili: ishaya insimbi encibilikisiwe kahle iphume ekusikeni (okwaziwa ngokuthi “i-kerf”) futhi ithonya ikhwalithi yokusikwa.

I-nitrogen (N)2)iyigesi engasebenzi kahle esetshenziselwa ukusika insimbi engagqwali kanye ne-aluminium. Ikhiqiza unqenqema oluhlanzekile ngokuphelele, oluyisiliva, olungena-oxide olulungele ukushiselwa ngokushesha. Lokhu kubizwa ngokuthi “ukusika okuhlanzekile okunomfutho ophezulu”.

I-oksijini (O2)2)isetshenziselwa ukusika insimbi yekhabhoni. I-oksijini idala ukusabela kwe-exothermic (ivutha ngenkuthalo nensimbi), okuvumela isivinini sokusika esisheshayo kakhulu. Unqenqema oluvelayo lunengqimba encane ye-oxide eyamukelekayo ekusetshenzisweni okuningi.

Isicelo: Kusukela Kumafreyimu Ayinhloko Kuya Kuzingxenye Ezincane

Ubuchwepheshe bokusika nge-laser busetshenziswa kuyo yonke inqubo yokukhiqiza izitimela, kusukela ozimele abakhulu besakhiwo abaqinisekisa ukuphepha kwabagibeli kuya ezingxenyeni zangaphakathi ezincane kakhulu neziyinkimbinkimbi. Ukuguquguquka kobuchwepheshe kuvumela ukuthi busetshenziswe ezingxenyeni eziningi, okubonisa indima yalo ebalulekile ekwakheni izitimela zesimanje kanye nengqalasizinda ezizisekelayo.

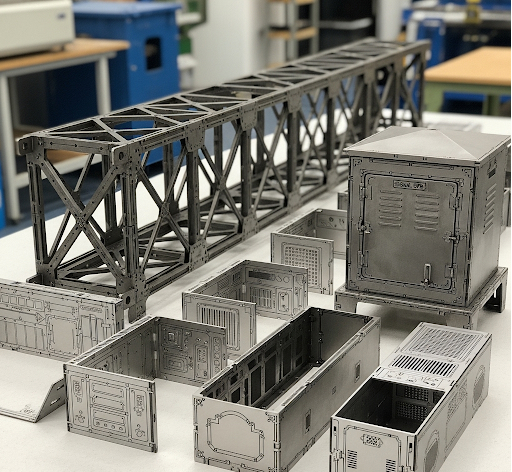

Izingxenye Zesakhiwo:Lena yindawo ebaluleke kakhulu. Ama-laser asetshenziselwa ukusika amabhlogo okwakha ayinhloko esitimela, okuhlanganisa amagobolondo omzimba wemoto, izinhlaka ezingaphansi ezisindayo ezisekela phansi, kanye nezingxenye ze-bogie ezibalulekile ngokuphepha njengezinhlaka eziseceleni, imishayo ewela, kanye nama-bolster. Lokhu kuvame ukwenziwa ngezinto ezikhethekile njengensimbi enamandla aphezulu ene-alloy ephansi, insimbi ye-corten yokumelana nokugqwala, noma ama-aluminium alloy angu-5000 no-6000 ochungechunge lwezitimela ezinesivinini esikhulu ezilula.

Izinhlelo Zangaphakathi Nezingaphansi:Ukunemba kubalulekile nalapha. Lokhu kufaka phakathi imigudu ye-HVAC yensimbi engagqwali okumele ilingane ezindaweni eziqinile, amaphaneli ophahla lwe-aluminium kanye nodonga anezicucu eziqondile zezibani nezipikha, ozimele bezihlalo, kanye nezindawo zokuvala zensimbi ezihlanganisiwe ze-elekthronikhi ezizwelayo.

Ingqalasizinda kanye neziteshi:Ukusetshenziswa kudlulela ngale kwezitimela ngokwazo. Ama-laser asika amapuleti ensimbi asindayo ezinsimbi ezisindayo zezinsika ze-catenary, izindawo zokugcina imishini yokubonisa eceleni kwendlela, kanye namaphaneli okwakha ayinkimbinkimbi asetshenziselwa ukwenza i-facade yesiteshi ibe yesimanje.

Inzuzo Eqondile: Ukucwila Okujulile

Igama elithi “ukunemba” linezinzuzo zobunjiniyela ezingokoqobo ezidlula nje “ukulingana okuhle”.

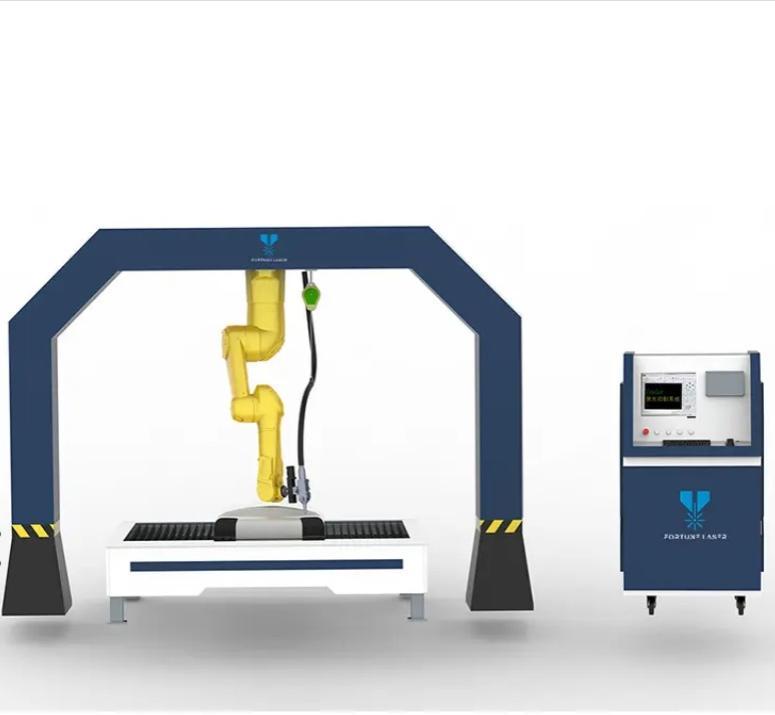

Ukunika amandla i-Robotic Automation:Ukuvumelana okungavamile kwezingxenye ezisikiwe nge-laser yikho okwenza ukushisela kwerobhothi okusheshayo kube ngokoqobo. Irobhothi lokushisela lilandela indlela eqondile, ehlelwe kusengaphambili futhi alikwazi ukuzivumelanisa nokwehluka phakathi kwezingxenye. Uma ingxenye ingekho ngisho ne-millimeter endaweni, yonke i-weld ingahluleka. Ngenxa yokuthi ukusika kwe-laser kukhiqiza izingxenye ezifanayo ngosayizi njalo, kunikeza ukuthembeka okungantengantengi okudingwa izinhlelo ezenzakalelayo ukuze zisebenze kahle nangokushelela.

Ukunciphisa Indawo Ethintekile Ekushiseni (HAZ):Uma usika insimbi ngokushisa, indawo ezungeze ukusika nayo iyashisa, okungashintsha izakhiwo zayo (njengokuyenza ibe buthakathaka kakhulu). Lena yi-Heat-Affected Zone (HAZ). Ngenxa yokuthi i-laser igxile kakhulu, ingenisa ukushisa okuncane kakhulu engxenyeni, idale i-HAZ encane. Lokhu kubalulekile ngoba kusho ukuthi ubuqotho besakhiwo sensimbi eduze kokusika abushintshi, ukuqinisekisa ukuthi izinto zisebenza kahle njengoba onjiniyela baklama.

Icala Lebhizinisi: Ukulinganisa Izinzuzo

Izinkampani azitshali izigidi kulobu buchwepheshe ngoba nje bunembile. Imbuyiselo yezezimali neyezokuthutha ibalulekile.

Ukusetshenziswa Kwezinto Ezithuthukisiwe:Isofthiwe ehlakaniphile "yokwakha izidleke" ibalulekile. Ayigcini nje ngokuhlanganisa izingxenye ndawonye njengephazili kodwa futhi isebenzisa amasu athuthukile njengokusika umugqa ojwayelekile, lapho izingxenye ezimbili eziseduze zisikwa ngomugqa owodwa, okususa ngokuphelele ukungcola phakathi kwazo. Lokhu kungasunduza ukusetshenziswa kwezinto kusuka ku-75% okuvamile kuye ngaphezu kuka-90%, konge imali enkulu ezindlekweni zezinto zokusetshenziswa.

Ukukhiqiza "Ukucima Izibani":Izicucu ze-laser zesimanje zivame ukuhlanganiswa nemibhoshongo yokulayisha/yokukhipha ngokuzenzakalelayo. Lezi zinhlelo zingabamba amaphepha amaningi ezinto zokusetshenziswa futhi zigcine izingxenye eziqediwe. Lokhu kuvumela umshini ukuthi usebenze njalo ubusuku nempelasonto ngaphandle kokugadwa komuntu—umqondo owaziwa ngokuthi “ukukhiqiza izibani”—okwandisa kakhulu umkhiqizo.

Ukunciphisa Umjikelezo Wokusebenza Wonke:Izinzuzo ziyanda njalo.

1. Akukho Ukususa Imfucuza:Ukusika kokuqala okuhlanzekile kuqeda isidingo sesiteshi sokugaya sesibili ukuze kususwe imiphetho ebukhali. Lokhu kusindisa ngqo izindleko zabasebenzi, kuthuthukisa ukuphepha kwabasebenzi ngokususa izingozi zokugaya, futhi kusheshise umsebenzi wokukhiqiza jikelele.

2. Akukho Ukuphinda Kusebenze:Izingxenye ezisikwe kahle ziqinisekisa ukulingana okuhle, zisusa ukulungiswa ngesandla okuchitha isikhathi ngesikhathi sokuhlanganiswa. Lokhu kusheshisa ngqo isivinini sokukhiqiza, kwandisa umkhiqizo, futhi kuholele kumkhiqizo wokugcina osezingeni eliphezulu.

3. Uchungechunge Lokunikezela Olulula:Ukususa izingxenye ezidingekayo kumafayela edijithali kunciphisa isidingo sokugcina impahla enkulu, kunciphisa izindleko zokugcina, ukunciphisa imfucuza, kanye nokwandisa ukusebenza kahle.

Ithuluzi Elifanele Lomsebenzi: Ukuqhathanisa Okubanzi

Ukukhethwa kwamathuluzi okuhle kakhulu endaweni yokukhiqiza yobungcweti kunqunywa ukuhlaziywa okuguquguqukayo okuningi kwesivinini sokukhiqiza, ukubekezelelana ngokunemba, izindleko zokusebenza, kanye nezakhiwo zezinto ezibonakalayo. Ngenxa yalokho, i-laser ayisona isisombululo esisebenza kuwo wonke umuntu.

| Indlela | Okuhle Kakhulu Kwaba | Inzuzo Eyinhloko | Ububi Obuyinhloko |

| Ukusika Nge-Fiber Laser | Ukusika ngokunemba okuphezulu kumashidi afinyelela ku-~25mm (1 intshi) ubukhulu. Kuhle kakhulu ngensimbi engagqwali kanye ne-aluminium. | Ukunemba okungenakuqhathaniswa, imiphetho ehlanzekile, i-HAZ encane kakhulu, kanye nesivinini esikhulu ezintweni ezincane. | Izindleko zokuqala eziphezulu. Azisebenzi kahle kumapuleti aqinile kakhulu. |

| I-Plasma | Ukusika amapuleti ensimbi aqinile (>25mm) ngokushesha lapho ikhwalithi ephelele yomphetho ingeyona into eza kuqala. | Isivinini esikhulu kakhulu sokusika ezintweni ezijiyile futhi izindleko zokuqala ziphansi kune-laser enamandla amakhulu. | I-HAZ enkulu, ayiqondile kangako, futhi ikhiqiza unqenqema olugobile oluvame ukudinga ukugaywa. |

| I-Waterjet | Ukusika noma yiziphi izinto (insimbi, itshe, ingilazi, izinhlanganisela) ngaphandle kokushisa, ikakhulukazi ama-alloy azwela ukushisa noma insimbi ejiyile kakhulu. | Akukho HAZ nhlobo, ukuqeda komphetho okubushelelezi kakhulu, kanye nokuguquguquka okumangalisayo kwezinto ezibonakalayo. | Ihamba kancane kakhulu kune-laser noma i-plasma, futhi inezindleko zokusebenza eziphakeme ngenxa yokukhuhla kanye nokugcinwa kwephampu. |

Ekuphetheni, ukusika i-fiber laser kungaphezu nje kwendlela yokubumba insimbi; kuwubuchwepheshe obuyisisekelo ohlelweni lokukhiqiza lwedijithali embonini yezitimela zanamuhla. Inani layo lisekuhlanganisweni okunamandla kokunemba okukhulu, ukukhiqizwa okusheshayo, kanye nokuhlanganiswa okujulile nezinhlelo zasefektri.

Ngokuvumela ukuzenzekela okuthuthukisiwe njengokushisela kwerobhothi, ukunciphisa Indawo Ethintekile Ekushiseni ukuze kulondolozwe amandla ezinto ezibonakalayo, kanye nokunikeza ikhwalithi engenaphutha yomphetho edingekayo ukuze kuhlangatshezwane nezindinganiso zokuphepha eziqinile njenge-EN 15085, sekuyindlela engaxoxiswana ngayo.

Ekugcineni, ukusika nge-laser kunikeza ukuqiniseka kobunjiniyela kanye nokuqinisekiswa kwekhwalithi okudingekayo ukwakha izinhlelo zesitimela eziphephile, ezinokwethenjelwa, nezithuthukisiwe kwezobuchwepheshe zanamuhla.

Isikhathi sokuthunyelwe: Agasti-22-2025