Incwadi Yokusebenza Yerobhothi Lokushisela Nge-Laser isebenza njengomhlahlandlela ophelele ohlinzeka ngolwazi oluyisisekelo mayelana nokusetshenziswa nokusebenza kwemishini ezenzakalelayo esebenzisa imisebe ye-laser yokushisela. Le ncwadi yenzelwe ukusiza abasebenzisi baqonde izinyathelo zokufaka, izinqubo zokulungisa amaphutha kanye nezinqubo zokusebenza ezidingekayo ukuze kusetshenziswe amarobhothi okushisela nge-laser ngempumelelo nangokuphepha. Ngezinzuzo zawo zokusebenza kahle kakhulu, ukunemba okuphezulu, kanye nekhwalithi ephezulu, amarobhothi okushisela nge-laser amukelwa kabanzi ezimbonini ezahlukahlukene njengokukhiqiza izimoto, izindiza, kanye ne-elekthronikhi.

Incazelo Yomkhiqizo

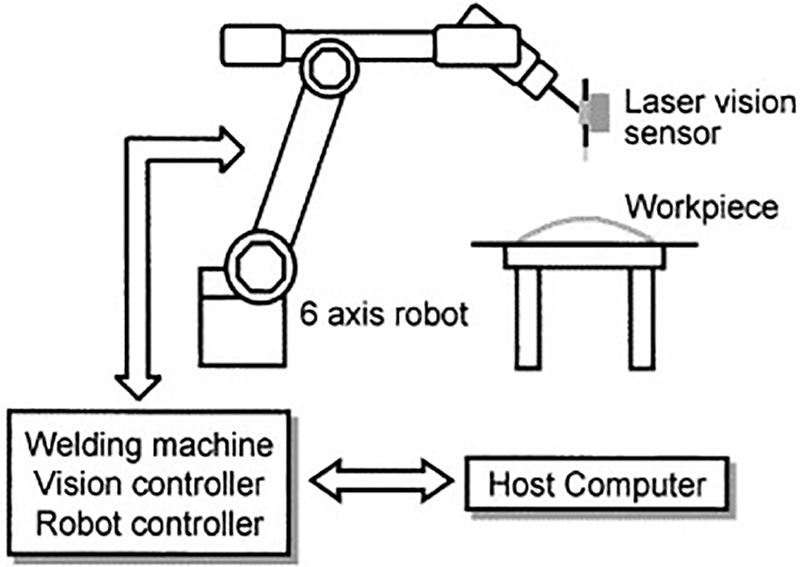

Irobhothi lokushisela nge-laser liyithuluzi elizenzakalelayo elisebenzisa umsebe we-laser ukwenza imisebenzi yokushisela. Inhloso eyinhloko yokushisela nge-laser ukushisa nokuncibilikisa izingxenye ezishiselwe, ukubopha ngempumelelo nokuhlanganisa izinto ndawonye. Le nqubo ivumela ukushisela okunembile, okuholela kumkhiqizo wekhwalithi ephezulu. Amarobhothi okushisela nge-laser adumile ngekhono lawo lokuletha imiphumela emihle kakhulu yokushisela, okwenza afaneleke kakhulu ezimbonini ezifuna ukuphelela nokuthembeka.

Izinyathelo zokufaka

Ukufakwa kahle kwerobhothi lokushisela nge-laser kubalulekile ekusebenzeni kahle kwayo kanye nokuphila isikhathi eside. Izinyathelo ezilandelayo zichaza inqubo yokufaka:

1. Ukufakwa kwesakhiwo semishini: Okokuqala hlanganisa bese ufaka isakhiwo semishini serobhothi yokushisela nge-laser. Qiniseka ukuthi zonke izingxenye zixhunywe ngokuphephile futhi ziqondile ukuze zinikeze ukuzinza ngesikhathi sokusebenza.

2. Ukufakwa kohlelo lokulawula: Faka uhlelo lokulawula lwerobhothi lokushisela nge-laser. Lolu hlelo lunesibopho sokulawula ukunyakaza nemisebenzi yerobhothi futhi ludlala indima ebalulekile ekufinyeleleni imiphumela eqondile yokushisela.

3. Ukuxhumeka kokunikezwa kwamandla kanye nomugqa wesignali: Xhuma kahle ukunikezwa kwamandla kanye nomugqa wesignali werobhothi yokushisela nge-laser ukuqinisekisa ukunikezwa kwamandla okuthembekile nokungaphazanyiswa. Landela ngokucophelela umdwebo wezintambo onikeziwe futhi uqiniseke ukuthi konke ukuxhumana kunembile.

Izinyathelo zokulungisa iphutha

Ngemva kokufakwa kwerobhothi lokushisela nge-laser, kumele lilungiswe kahle ukuze lisebenze kahle. Izinyathelo ezilandelayo zichaza inqubo yokulungisa amaphutha:

1. Ukugxila kanye nokulungiswa kokuqina kwe-laser beam: Lungisa ukugxila kanye nokuqina kwe-laser beam ukuze kufezwe umphumela omuhle kakhulu wokushisela. Lesi sinyathelo sidinga ukulinganiswa okunembile nokucophelela ukuqinisekisa ukushisela okunembile.

2. Ukulungiswa kokunemba kokunyakaza kwesakhiwo semishini: Lungisa ukunemba kokunyakaza kwesakhiwo semishini ukuze ususe ukungahambisani noma ukungalungi. Lesi sinyathelo sibalulekile ekufinyeleleni ukushintshwa okunembile nokulinganayo.

Inqubo yokusebenza

Ukuqinisekisa ukusebenza okuphephile nokusebenza kahle, izinqubo zokusebenza ezifanele kumele zilandelwe. Izinyathelo ezilandelayo zichaza ukuhamba okuvamile kokusebenza kwerobhothi lokushisela nge-laser:

1. Qala ukulungiselela: Ngaphambi kokuqala irobhothi lokushisela nge-laser, hlola ngokucophelela zonke izingxenye kanye nokuxhumeka ukuqinisekisa ukuthi zisesimweni esijwayelekile sokusebenza. Hlola noma yiziphi izingozi noma ukungasebenzi kahle okungenzeka.

2. Ukulungiswa kwe-laser beam: Lungisa ngokucophelela amapharamitha e-laser beam ngokuya ngezidingo zokushisela. Qiniseka ukuthi ukugxila, ukuqina, kanye nezinye izilungiselelo kuhambisana nemininingwane yokushisela edingekayo.

3. Ukulawula inqubo yokushisela: qala inqubo yokushisela ngokwezidingo ezithile. Qapha futhi ulawule amapharamitha okushisela kulo lonke umsebenzi ukuze uthole ukushisela okunembile nokungaguquguquki.

4. Ukuvala: Ngemva kokuqeda inqubo yokushisela, sebenzisa uchungechunge lwezinqubo zokuvala ukuze ucime amandla erobhothi lokushisela nge-laser ngokuphephile. Lokhu kuhlanganisa ukuqinisekisa izinhlelo zokupholisa nezokulawula ukuvala ezifanele.

Izinto okufanele uzicabangele ngokuphepha

Uma usebenzisa irobhothi lokushisela nge-laser, ukuphepha kumele kubekwe phambili ukuze kuvinjelwe ukulimala kwabasebenzi kanye nemishini. Ugongolo lwe-laser olusetshenziswa kule nqubo lungaba yingozi uma lungaphathwa kahle. Ngakho-ke, kubalulekile ukunamathela kulezi ziqondiso zokuphepha ezilandelayo:

1. Imishini Yokuzivikela Yomuntu Siqu (PPE): Qinisekisa ukuthi bonke abasebenzi abahilelekile kulo msebenzi bagqoka i-PPE efanele, okuhlanganisa nezibuko zokuphepha ezinezivikelo ezithile ze-laser kanye neminye imishini edingekayo.

2. Isivikelo somsebe we-laser: Nikeza indawo yokusebenza evalekile kahle yerobhothi yokushisela nge-laser ngezinto ezifanele zokuvikela ukuvimbela ukudalulwa ngengozi komsebe we-laser.

3. Ukuma Okuphuthumayo: Faka inkinobho yokuma okuphuthumayo okulula ukuyisebenzisa bese uyenza ijwayeleke kubo bonke abaqhubi. Lokhu kungasetshenziswa njengesinyathelo sokuphepha uma kwenzeka ingozi noma ukuphuka kwemoto okuphuthumayo.

4. Ukulungiswa kwemishini njalo: Hlela uhlelo lokugcinwa kwansuku zonke ukuqinisekisa ukuthi irobhothi lokushisela nge-laser lisesimweni esijwayelekile sokusebenza. Hlola futhi uhlanze zonke izingxenye zerobhothi njalo, okuhlanganisa izinhlelo ze-laser, izakhiwo zemishini, izinhlelo zokulawula, njll.

Ekuphetheni

Incwadi Yokusebenza Yerobhothi Lokushisela Nge-Laser iyinsiza ebalulekile kubasebenzisi bemishini ezenzakalelayo esebenzisa imisebe ye-laser ukuze kusebenze kahle futhi kusebenze kahle ukushisela. Ngokunaka izinyathelo zokufaka, izinqubo zokugunyaza kanye nezinqubo zokusebenza ezichazwe kule ncwadi, abasebenzisi bangakhulisa amakhono amarobhothi okushisela nge-laser ezimbonini ezahlukahlukene. Ukubeka phambili ukuphepha nokulandela isiqondiso esinikezwe kule ncwadi kubalulekile enhlalakahleni yabasebenzi kanye nesikhathi eside semishini. Ngezinzuzo zokusebenza kahle kakhulu, ukunemba okuphezulu kanye nokushisela kwekhwalithi ephezulu, amarobhothi okushisela nge-laser ayaqhubeka nokuthuthukisa izinqubo zokushisela futhi anikele ekuthuthukisweni kokukhiqizwa kwezimoto, izindiza, izinto zikagesi kanye neminye imikhakha.

Isikhathi sokuthunyelwe: Novemba-22-2023