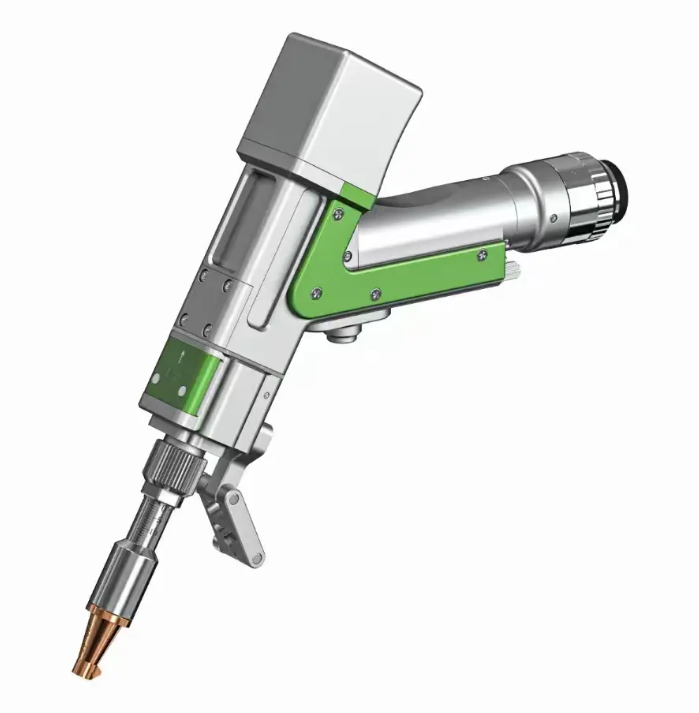

Umaumshini wokushisela nge-laserKuyehla, ukukhiqiza kuyama. Isikhathi esinqunyiwe sephrojekthi esasibonakala silawuleka sisengozini ngokuzumayo, futhi ithemba locingo lwenkonzo olubizayo noluthatha isikhathi libonakala likhulu. Kodwa kuthiwani uma ikhambi selivele lisezandleni zakho?

Amaphutha angaphezu kuka-80% okushiswa nge-laser avamile angatholakala futhi axazululwe ngaphakathi ngendlela ehlelekile. Lo mhlahlandlela ophelele udlulela ngale kwezisekelo ukuze unikeze uhlu lokuhlola olunemininingwane, oluhamba ngesinyathelo lokuxazulula yonke into kusukela emshinini ofile kuya kumaphutha amancane okushiswa. Zijwayeze lezi zinyathelo ukuze unciphise isikhathi sokungasebenzi, unciphise izindleko, futhi ube umugqa wokuqala wokuzivikela wemishini yakho.

Izinga 1: Umshini Awusabeli Noma Uyehluleka Ukuqala

Lena inkinga eyisisekelo kakhulu: umshini awubonisi zimpawu zokuphila noma wenqaba ukungena esimweni "sokulungela". Ngaphambi kokuzama ukuthola izifo eziyinkimbinkimbi, qala njalo ngendlela yamandla nokuphepha.

Izimpawu:

1.Isikrini sokulawula simnyama.

2.Azikho izibani zesikhombisi ezivuliwe.

3.Awekho amafeni noma amaphampu azwakalayo.

4.Uhlelo luyaqala kodwa ngokushesha lubonisa iphutha elithi “Not Ready” noma “Interlock”.

Uhlu Lokuhlola Lokuxazulula Izinkinga Oluhlelekile:

1.Qinisekisa Indlela Eyinhloko Yamandla

I-Outlet Yodonga Neplagi:Ingabe intambo kagesi eyinhloko ihlezi kahle kokubili emshinini kanye nasesokhethini lodonga?

Iphaneli Eyinhloko Yokuphula:Ingabe i-circuit breaker enikezelwe kumshini wokushisela nge-laser ikhubekile? Uma kunjalo, yibuyisele kabusha kanye. Uma ikhubeka futhi ngokushesha, ungayibuyiseli kabusha futhi; kungase kube ne-short circuit edinga uchwepheshe kagesi.

I-Main Breaker Yomshini:Imishini eminingi yezimboni ineswishi yayo yamandla eyinhloko noma i-circuit breaker. Qinisekisa ukuthi isesimweni esithi “VULIWE”.

2.Hlola Izitobhi Eziphuthumayo Nama-Fuse

Inkinobho Yokuma Eziphuthumayo:Lokhu kuyimbangela evamile.eukuhlanganasIngabe inkinobho ephezulu emshinini, kuphaneli yokulawula, noma kumjikelezo wokuphepha icindezelwe? Zenzelwe ukuba zibonakale (ngokuvamile zibe nkulu futhi zibe bomvu).

AmaFusi Angaphakathi:Bheka incwadi yomsebenzisi yomshini wakho ukuze uthole ama-fuse okulawula ayinhloko. Hlola isici se-fuse ngamehlo. Uma siphukile noma sibonakala sishile, sishintshe nge-fuse ene-amperage efanayo nohlobo olufanayo. Ukusebenzisa i-fuse engalungile kuyingozi enkulu yomlilo.

Yenza Ukuqalisa Kabusha Okugcwele Kwesistimu:Amaphutha esofthiwe angamisa umshini. Ukuqalisa kabusha ngendlela efanele kungasusa amaphutha ememori yesikhashana.Okokuqala, tCima iswishi yamandla eyinhloko emshinini. Linda imizuzwana engu-60-90 egcwele. Lokhu kubalulekile njengoba kuvumela ama-capacitor angaphakathi ukuthi akhiphe ngokuphelele, okuqinisekisa ukusetha kabusha okuphelele kwawo wonke amabhodi okulawula.Bese kuba u-tvula umshini futhi.

Hlola Ama-Interlock Okuphepha:Abashiseli be-laser banamuhla banezikhiye eziningi zokuphepha ezizovimbela i-laser ekudubuleni—futhi ngezinye izikhathi zivimbele umshini ekuqaliseni—uma zingabanjwanga.

Amaswishi Omnyango:Ingabe wonke amaphaneli okungena kanye neminyango yezindlu zomshini ivaliwe kahle?

Ukuxhumeka kwe-Chiller negesi:Eminye imishini inezikhiye ezihlonza ukuxhumana okufanele kanye nengcindezi evela kumshini wokupholisa amanzi kanye nogesi ovikelayo.

Izinhlelo Zokuphepha Zangaphandle:Uma umshini wakho usesitokisini serobhothi, hlola amakhethini akhanyayo, omata bokuphepha, kanye nezingidi zeminyango yeseli.

Izinga 2: Ukuthola Amaphutha Okushisela Nge-Laser Evamile

Uma umshini unamandla kodwa ikhwalithi yokushisela ingamukeleki, inkinga ingaphakathi kwenqubo. Sizobhekana namaphutha ngokuhlonza izinkomba zawo ezibonakalayo bese sizilandelela emuva ezimbangela zawo.

Inkinga 1: Ukushibiliza Okubuthakathaka, Okungajulile, Noma Okungaguquguquki

Izimpawu Ezibonakalayo:Ubuhlalu bokushisela buncane kakhulu, abungeni ekujuleni okuphelele kwezinto, noma buyahlukahluka ngobubanzi nokujula eduze komthungo.

1. Ilensi ingcolile noma yonakele

Ilensi evikelayo ku-laser yakho ifana nengilazi ekhamera—ukungcola, uthuli, noma umonakalo kuzokonakalisa umphumela.

Indaba:Umswakama, ukuchitheka, noma imifantu emincane ebhodini lelensi elivikelayo bese uhlakaza umsebe we-laser ngaphambi kokuba ufinyelele ngisho nezinto zakho.

Isixazululo: 1.Susa ngokucophelela ilensi evikelayo.

2.Yiphakamisele esibanini ukuze uhlole ukuthi icacile yini.

3.Yihlanze kuphela ngama-lens wipes avunyelwe kanye ne-isopropyl alcohol engu-99%+.

4.Uma ingakacaci kahle ngemva kokuhlanzwa, yishintshe.

Kungani kubalulekile:Ilensi engcolile noma eyonakele ingashisa kakhulu futhi iqhekeke, ibhubhise ilensi eyinhloko ebiza kakhulu ngaphakathi komshini.

2. Ukugxila akulungile

Amandla e-laser agxiliswa endaweni encane. Uma leyo ndawo ingaqondiswanga kahle ezintweni zakho, amandla ayasabalala abe buthaka.

Indaba:Ibanga eliphakathi komlomo we-laser kanye nobuso bezinto ezibonakalayo alilungile, okwenza umsebe ufiphale futhi ungasebenzi kahle.

Isixazululo:Hlola incwadi yemiyalelo yomshini wakho ukuze uthole indlela efanele yokusetha ukugxila. Kungase kudingeke wenze “ukuhlolwa kokushisa” esiqeshini esilahliwe ukuze uthole iphuzu elibukhali nelinamandla kakhulu.

3. Ukusetha Amandla Kuphansi Kakhulu

Ngezinye izikhathi, ikhambi lilula njengokukhulisa ugesi.

IOkubalulekile:Ukusetha kwamandla kwe-laser akuphakeme ngokwanele ngohlobo kanye nobukhulu bensimbi oyishiselayo.

Isixazululo:Engxenyeni yokuhlola, khulisa amandla ngezinyathelo ezincane (njengo-5% ngesikhathi) uze uthole ukushiselwa okujulile okudingayo. Khumbula, amandla engeziwe angasho ukuthi udinga nokulungisa isivinini sakho.

4. Isivinini Sokuhamba Sishesha Kakhulu

I-laser idinga isikhathi esithile ukuze ilahle amandla ayo ensimbini ukuze iyincibilikise.

Indaba:Ikhanda le-laser lihamba ngokushesha kakhulu ezintweni kangangokuthi ugongolo alunaso isikhathi esanele kunoma iyiphi indawo eyodwa ukudala ukushintshwa okufanele.

Isixazululo:Yehlisa ijubane lokuhamba. Lokhu kunikeza i-laser isikhathi esengeziwe sokuletha amandla, okuholela ekushiseni okujulile nokunamandla.

Inkinga 2: Ama-Porosity (Ama-Pinholes noma Amabhamuza Egesi) ku-Weld

Izimpawu Ezibonakalayo:Umthungo wokushisela oqediwe uqukethe imigodi noma imigodi emincane, eyindilinga, kungaba ngaphezulu noma ebonakala engxenyeni evundlile. Lokhu kuyenza buthaka kakhulu ijoyinti.

1. Igesi Yokuvikela Enganele

Igesi yokuvikela (ngokuvamile i-Argon noma i-Nitrogen) yakha ibhamuza elivikelayo phezu kwensimbi encibilikisiwe, ivimbela umoya ukungena. Uma leli bhamuza lihluleka, umoya ungcolisa i-weld, okubangela ukubhoboka.

Indaba:Ukugeleza kwegesi yokuvikela kuphansi kakhulu, kuphazanyisiwe, noma kuyavuza ngaphambi kokuba kufinyelele ku-weld.

Isixazululo:

Hlola ithangi:Qiniseka ukuthi ivalvu yesilinda ivulekile ngokuphelele futhi ithangi alinalutho.

Hlola uMlawuli:Qinisekisa ukuthi ingcindezi iyanele nokuthi izinga lokugeleza lihlelwe kahle emsebenzini wakho.

Ukufuna Ukuvuza:Njengoba igesi igeleza, lalela noma yimiphi imisindo yokufutha epayipini nasezixhumeni. Ungafafaza amanzi anensipho ezifakelweni; uma iqhuma, kuvuza.

2. I-Nozzle Engcolile noma Eyonakele

Umsebenzi we-nozzle ukuqondisa igesi yokuvikela iye emfudlaneni obushelelezi nozinzile endaweni yokushisela.

Indaba:Ukuchitheka noma imfucumfucu ngaphakathi kwe-nozzle kungavimba igesi, kanti i-tip egobile noma ekhubazekile izokwenza ukugeleza kuphazamiseke futhi kungasebenzi kahle.

Isixazululo:Susa umlomo bese uwuhlola. Hlanza noma yikuphi ukuchitheka ngaphakathi. Uma imbobo ingamile kahle noma i-oval esikhundleni sokuba yindilinga ngokuphelele, yishintshe ngokushesha. Futhi, qiniseka ukuthi ugcina ibanga elifanele phakathi komlomo nendawo yokusebenza.

3. Ukungcola Kwezinto Zokusebenza

Noma yikuphi ukungcola, uwoyela, ukugqwala, noma umswakama ebusweni bensimbi kuzophuma ngokushesha ekushiseni okukhulu kwe-laser, kudale igesi ebhajwa ku-weld.

Indaba: Ubuso bento eshibilikayo abuhlanzekile ngokuphelele.

Isixazululo: 1.Hlanza kahle izindawo ezihlangene ngaphambi nje kokushisela.

2.Sebenzisa isinyibilikisi esinjenge-acetone ukususa wonke amafutha namafutha.

3.Sebenzisa ibhulashi lensimbi ukuze uhlanze noma yikuphi ukugqwala, isikali, noma uqweqwe.

4.Okokugcina, qiniseka ukuthi impahla yomile ngokuphelele.

Izinga 3: Uhlelo Lokulungisa Oluphelele

Ukuxazulula izinkinga okusebenza kahle kakhulu ukuvimbela amaphutha ukuthi angenzeki kwasekuqaleni. Isimiso sokulungisa esihlelekile sishibhile kunanoma yikuphi ukulungiswa futhi sithatha isikhathi esincane kunanoma yisiphi isikhathi sokungasebenzi.

Ukuhlolwa Kwansuku Zonke (Imizuzu emi-5)

Ukuhlolwa Kokukhanya:Hlola ilensi yokuvikela ukuze ithole ukuchaphaza nokuhlanzeka. Hlanza uma kudingeka.

Ukuhlolwa Kwegesi:Bheka isilinda segesi kanye nokucindezela komlawuli ukuqinisekisa ukuthi kukhona okwanele emsebenzini wosuku.

Ukuhlolwa Kwe-Nozzle:Hlola i-nozzle ukuthi ayinawo yini umfudlana ongaphazamisa ukuhamba kwegesi.

Indawo Ejwayelekile:Qinisekisa ukuthi indawo yokusebenza ezungeze umshini ihlanzekile futhi ayinazo izinto eziningi ezingafuneki.

Ukuhlolwa Kwamasonto Onke (Imizuzu eyi-15-20)

Isimo se-Chiller:Hlola izinga lamanzi echibini lokupholisa. Qinisekisa ukuthi izinga lokushisa lamanzi lingaphakathi kwebanga elinconywayo. Amanzi kufanele acwebe; uma ebonakala enamafu noma enokukhula kwe-algae, hlela ukushintsha amanzi.

Ukuhlanza Isihlungi Somoya:Ikhabhinethi yelaser kanye ne-water chiller zombili zinezihlungi zomoya zokuvimbela uthuli ukungena ezingxenyeni ezibalulekile. Zisuse bese uzihlanza ngomoya ocindezelwe. Izihlungi ezivalekile ziholela ekushiseni ngokweqile.

Ukuhlolwa Okubonakalayo:Hambahamba emshinini bese uhlola ngokubonakalayo zonke izintambo namapayipi ukuze ubone ukuthi azikhubeki, ziyaguguleka, noma izimpawu zokuguguleka.

Ukuhlolwa Kwanyanga Zonke (Imizuzu engama-30-45)

Ukuhlolwa Kwe-Optics Yangaphakathi:Ukulandela inqubo yomenzi, susa ngokucophelela bese uhlola ilensi yokugxila (kanye nelensi yokuhlanganisa, uma itholakala kalula). Zihlanze ngendlela efanele kanye nezinto zokwakha.

Ikhwalithi Yamanzi Abandayo:Sebenzisa imichilo yokuhlola ukudlulisa amanzi ukuze uhlole ikhwalithi yamanzi acwengekile ku-chiller. Uma ukudlulisa amanzi kuphezulu kakhulu, kusho ukuthi amanzi angcoliswe ama-ion angabangela ukugqwala futhi alimaze umthombo we-laser. Shintsha amanzi nesihlungi sangaphakathi uma kudingeka.

Hlola Imisebenzi Yokuphepha:Hlola ngamabomueukuhlanganasinkinobho ephezulu kanye ne-interlock yomnyango (ngenkathi umshini usesimeni esiphephile) ukuqinisekisa ukuthi zisebenza kahle.

Nini Ukubiza Uchwepheshe Wezinsizakalo Zochwepheshe

Lo mhlahlandlela ukunika amandla okuxazulula izinkinga eziningi, kodwa kubalulekile ukwazi imikhawulo yakho yokuphepha nokuvimbela umonakalo owengeziwe. Xhumana nochwepheshe oqinisekisiwe uma:

1.Usulihlolile lonke lolu hlu lokuhlola futhi inkinga isaqhubeka.

2.Umshini uphinda ukhubeke i-circuit breaker, okubonisa ukuthi kungenzeka kube nokuphazamiseka kukagesi.

3.Uthola amakhodi ephutha angachazwanga encwadini yomsebenzisi.

4.Usola ukuthi ikhebula le-fiber optic noma umthombo we-laser wangaphakathi ulimele.

5.Inkinga idinga ukuvula amakhabethe kagesi avaliwe noma indlu yomthombo we-laser.

Isiphetho: Kusukela ku-Operator kuya ku-First Responder

Ukwazi kahle umshini wakho wokushisela nge-laser kuwuhambo oluvela ekukhathazekeni okubangelwa ukusabela kuya ekuxazululeni izinkinga ngokushesha. Lolu hlu lokuhlola luyindlela yakho. Ngokubhekana nodaba ngalunye ngendlela ehlelekile, kusukela entanjeni kagesi kuya embotsheni yegesi, nokwamukela inqubo yokulungisa ngenkuthalo, awusasebenzi emshinini wakho. Uba ngumlingani wawo.

Lo mhlahlandlela ukunika amandla okuba umugqa wokuqala wokuzivikela—uchwepheshe ongakwazi ukuxilonga amaphutha, aqinisekise ikhwalithi ehambisanayo, futhi aguqule isikhathi sokungasebenzi sibe yisikhashana esincane. Lobu buchwepheshe abugcini nje ngokusindisa isikhathi nemali ebalulekile kodwa futhi bakha ukuzethemba kokugcina imisebenzi yakho isebenza ngokuphepha futhi isebenza kahle kakhulu. Sebenzisa lolu lwazi kahle, futhi umshini wakho wokushisela nge-laser uzohlala uyimpahla ethembekile nekhiqizayo iminyaka ezayo.

Isikhathi sokuthunyelwe: Agasti-28-2025