1. Umthamo wokusika weumshini wokusika nge-laser

1. Umthamo wokusika weumshini wokusika nge-laser

a. Ukusika ubukhulu

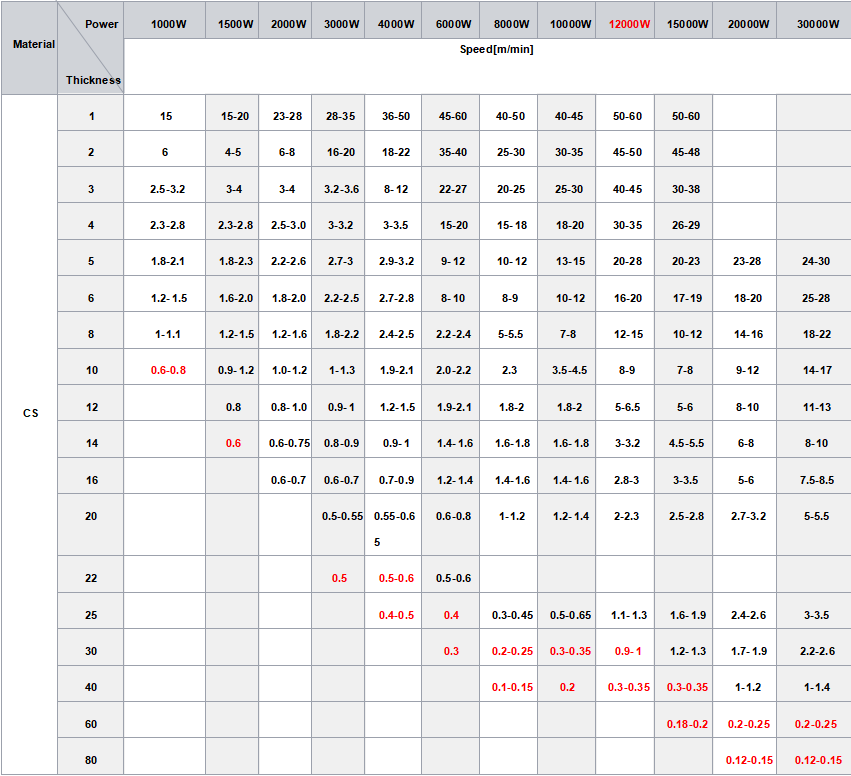

Ubukhulu bokusikaumshini wokusika nge-laserkuthinteka yizici eziningi ezifana namandla e-laser, isivinini sokusika, uhlobo lwezinto, njll. Ngokuvamile, ububanzi bokujiya obungasikwa umshini wokusika i-laser ongu-3000W bungu-0.5mm-20mm. Ngokuqondile:

1) Ngensimbi yekhabhoni, ububanzi bokujiya obungasikwa ngumshini wokusika nge-laser ongu-3000W bungu-0.5mm-20mm.

2) Ngensimbi engagqwali, ububanzi bokujiya obungasikwa umshini wokusika nge-laser ongu-3000W bungu-0.5mm-12mm.

3) Nge-aluminium alloy, ububanzi bokujiya obungasikwa umshini wokusika nge-laser ongu-3000W bungu-0.5mm-8mm.

4) Ngezinsimbi ezingezona i-ferrous njengethusi nama-noodle, ububanzi bokujiya obungasikwa umshini wokusika nge-laser ongu-3000W bungu-0.5mm-6mm.

Kufanele kuqashelwe ukuthi ngemva kokuba le datha ibhekiselwe kuyo, umphumela wangempela wokusika uphinde uthintwe yizici ezifana nokusebenza kwemishini kanye namakhono okusebenza.

Ijubane lokusika lomshini wokusika nge-laser ongu-3000W lithintwa yizici ezifana nohlobo lwezinto ezibonakalayo, ukujiya, kanye nemodi yokusika. Ngokuvamile, ijubane lokusika lomshini wokusika nge-laser lingafinyelela amamitha amaningana kuya kumamitha ayi-1000 ngomzuzu. Ngokuqondile:

1) Ngensimbi yekhabhoni, isivinini sokusika somshini wokusika we-laser ongu-3000W singafinyelela kumamitha ayi-10-30 ngomzuzu.

2) Ngensimbi engagqwali, isivinini sokusika somshini wokusika nge-laser ongu-3000W singafinyelela kumamitha angu-5-20 ngomzuzu.

3) Nge-aluminium alloy, isivinini sokusika somshini wokusika we-laser ongu-3000W singafinyelela kumamitha ayi-10-25 ngomzuzu.

4) Ngezinsimbi ezingezona i-ferrous njengethusi nama-noodle, isivinini sokusika somshini wokusika we-laser ongu-3000W singafinyelela kumamitha angu-5-15 ngomzuzu.

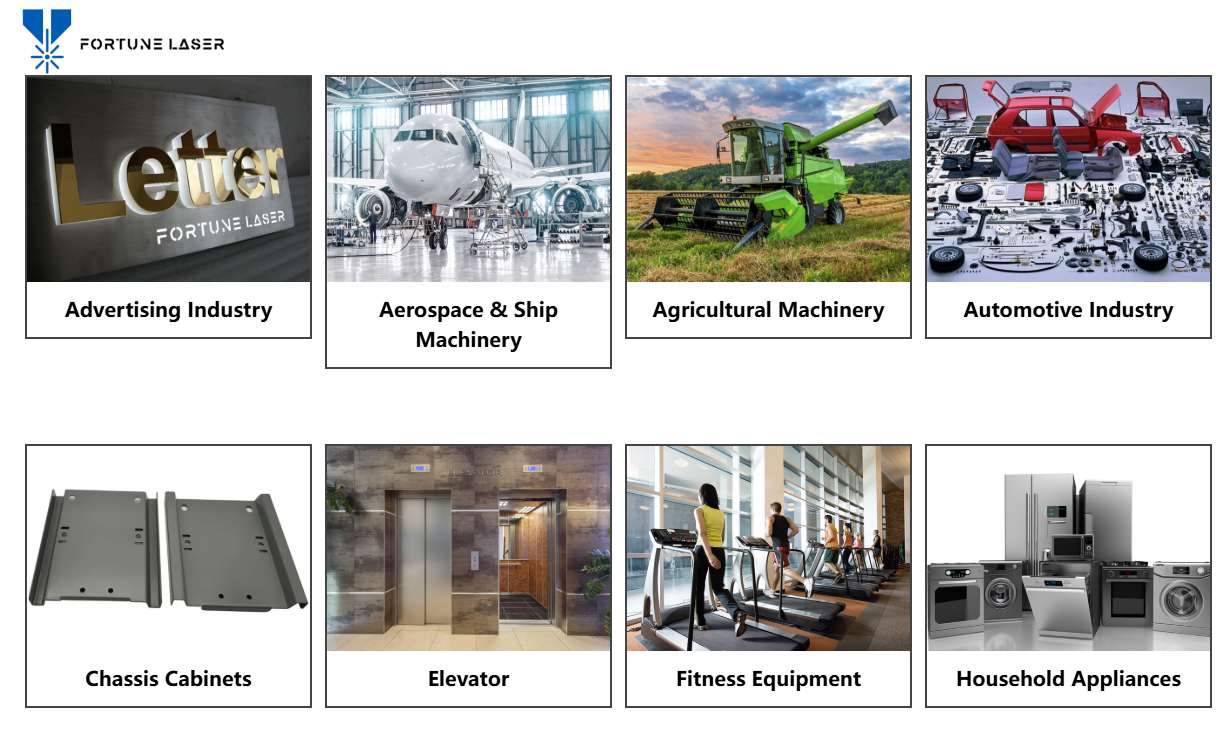

2. Ububanzi bokusetshenziswa kweumshini wokusika nge-laser

Umshini wokusika i-laser ongu-3000W usetshenziswa kabanzi ekucubungulweni kwensimbi, ekukhiqizeni imishini, ekukhiqizeni izimoto, ezindiza, ezintweni zikagesi, emishinini yezokwelapha, ekuhlobiseni izakhiwo nakwezinye izinkambu. Ngokukhethekile, ungasetshenziswa ukusika nokucubungula izinto ezilandelayo:

1) Izinto zensimbi ezifana nensimbi yekhabhoni kanye nensimbi engagqwali.

2) Izinsimbi ezilula njenge-magnesium alloy kanye ne-magnesium alloy.

3) Umthofu, ithusi, ama-noodle, ithini, nezinye izinsimbi ezingezona i-ferrous.

4) Izinto ezingezona ezensimbi ezifana nokhuni, ipulasitiki, irabha, kanye nesikhumba.

5) Izinto ezithambile njengengilazi, izinto zobumba, kanye netshe.

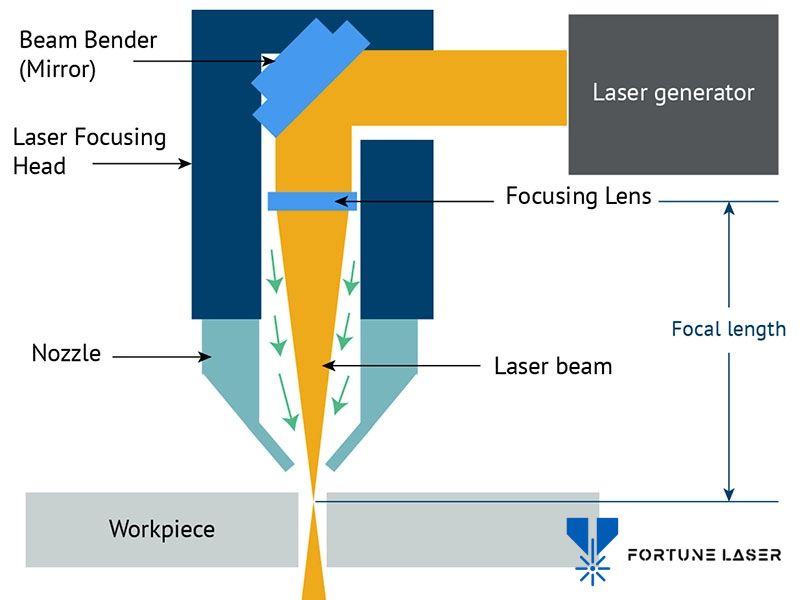

3. Isimiso sokusebenzaumshini wokusika nge-laser

Umgomo wokusebenza womshini wokusika nge-laser ukusebenzisa umsebe we-laser onamandla amakhulu ukuze kukhanye ubuso bento, ukuze into ikwazi ukuncibilika ngokushesha, ishiswe noma ishiswe, ngaleyo ndlela kufezwe injongo yokusika. Ngokukhethekile, umgomo wokusebenza womshini wokusika nge-laser ongu-3000W uhlanganisa izinyathelo ezilandelayo:

1. Ijeneretha yelaser ikhiqiza umsebe welaser onamandla amakhulu.

2. Ugongolo lwelaser lugxilwe uhlelo lwe-optical ukuze kwakheke ugongolo lwelaser olunamandla aphezulu.

3. Ugongolo lwe-laser olunamandla aphezulu lukhanyiswa ebusweni bento, ukuze into ikwazi ukuncibilika ngokushesha, ishiswe noma ishiswe.

4. Ikhanda lokusika lihamba ngendlela enqunyiwe, futhi umsebe we-laser ulandelela ukunyakaza ukuze kufezwe ukusika okuqhubekayo.

5. I-slag kanye negesi ekhiqizwa ngesikhathi senqubo yokusika ipheshulwa amagesi asekelayo (njenge-oxygen, i-oxygen, njll.) ukuqinisekisa ukuhlanzeka kwendawo yokusika.

4. Izinyathelo zokuphepha zokusebenzaUmshini wokusika we-laser ongu-3000W

1. Abaqhubi kudingeka baqeqeshwe ngobungcweti futhi bajwayelane nezinqubo zokusebenza kanye nezidingo zokuphepha zemishini.

2. Gqoka imishini yokuzivikela, amagilavu neminye imishini yokuzivikela ngesikhathi sokusebenza ukuze uvimbele imisebe ye-laser kanye nomonakalo we-splash.

3. Hlola ukusebenza nokunemba kwemishini njalo ukuqinisekisa ukuthi imishini isebenza kahle.

4. Sebenzisa ngokuqinile ngokwemigomo yokusika yezinto ukuze ugweme umphumela omubi wokusika noma umonakalo wemishini ngenxa yemigomo engafanele.

5. Naka umphumela wokusika ngesikhathi sokusika. Uma kutholakala noma yikuphi ukungajwayelekile, kuhlole ngokushesha.

6. Ngemva kokusika, hlanza indawo yokusika ngesikhathi ukuze ususe uketshezi olusele kanye nama-oxide ukuqinisekisa ukuhlanzeka nokunemba kwendawo yokusika.

Isikhathi sokuthunyelwe: Jan-09-2025