Umshini wakho wokushisela nge-laser uyimpahla enamandla futhi utshalomali olukhulu. Kodwa isikhathi sokungasebenzi esingalindelekile, ukusebenza okungaguquki, kanye nokwehluleka kwangaphambi kwesikhathi kungashintsha leyo mpahla ibe yisibopho esikhulu. Izindleko zokushintsha umthombo we-laser noma i-critical optics zingaba zinkulu.

Kuthiwani uma ungayandisa kakhulu impilo yayo yokukhiqiza, uqinisekise ikhwalithi eqhubekayo futhi wandise inzuzo yakho ekutshalweni kwezimali? Akukhona ngenhlanhla; kumayelana nesu. Lo mhlahlandlela unikeza uhlaka oluphelele lokwandisa isikhathi sokuphila komshini wakho wokushisela nge-laser, oluhlanganisa konke kusukela ekulungisweni kwansuku zonke kuya ekuhleleni amasu kwesikhathi eside.

Izinto Ezibalulekile Okufanele Uzicabangele

Isikhathi Sokuphila Esimaphakathi: Umshini onakekelwa kahle uvame ukuhlala amahora ayi-10,000 kuya kwangu-30,000, kodwa lokhu kungandiswa kakhulu ngokunakekelwa okufanele.

Izinsika Eziyinhloko Zokuphila Isikhathi Eside: Ukuphila komshini kuncike ezindaweni ezine ezibalulekile: Indawo yawo Yokusebenza, Amaphethini Okusetshenziswa, Ukuqina Kokulungisa, kanye Nekhono Lokusebenza.

Izinsongo Ezinkulu Kumuntu Osebenzisa I-Laser Welder: Izitha eziyinhloko zomshini wakho ukushisa ngokweqile, uthuli, umswakama ophezulu, amandla angazinzile, kanye nokusebenza okuqhubekayo okungaphezu kwamandla awo alinganiselwe.

Iyini Isilinganiso Sokuphila Komshini Wokushisela Nge-Laser?

Umshini wokushisela we-laser onakekelwa kahle ngokuvamile unokuphila kwenkonzo okulinganiselwa kumahora angu-10,000 kuya kwangu-30,000 okusebenza. Kodwa-ke, lokhu kuyisilinganiso esibanzi. Njengoba sesixoxile, izici ezifana nokugcinwa ngokucophelela kanye nezimo zemvelo ezinhle kakhulu zingathonya kakhulu ukuthi umshini wakho usebenza kahle yini ekugcineni okuphansi noma okuphezulu kwalolu hlu—noma ngisho nokudlula kakhulu.

Ngenxa yentuthuko kwezobuchwepheshe, imithombo eminingi yesimanje nekhwalithi ephezulu ye-fiber laser ngokwayo inesikhathi sokuphila esimangalisayo esingamahora angaba yi-100,000. Kodwa ubude bomshini bubonke buncike empilweni yokusebenzisana kwazo zonke izingxenye zawo ezihlanganisiwe, hhayi umthombo kuphela.

Izinto Ezi-6 Ezithinta Ngokuqondile Ubude Bomshini

Ukuqonda izinto ezibangela ukucindezeleka okuyisisekelo kukunika amandla okusebenzisa izinyathelo zokuvimbela eziphumelela kakhulu.

1. Indawo Yokusebenza

Ama-elekthronikhi abucayi kanye nama-optics abucayi asengozini enkulu yokubhekana nendawo ezungezile.

Izinga Lokushisa Nomswakama: Izinga lokushisa eliphakeme kakhulu licindezela izingxenye, kuyilapho umswakama ophezulu ungabangela ukuminyana okugqwalayo. Isibonelo, ukwehla okungazelelwe kwezinga lokushisa kungabangela ukuminyana kuma-optics angaphakathi, okuholela ekulimaleni okungapheli.

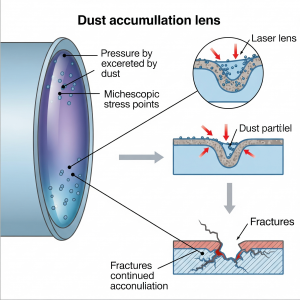

Ukuhlanzeka: Uthuli kanye nemfucumfucu ephuma emoyeni kuyizinto ezibulala buthule. Zingahlala kumalensi, okubangela ukuthi umsebe we-laser ulahlekelwe amandla, noma uvale amaphiko okupholisa, okuholela ekushiseni ngokweqile kanye nokwehluleka kwezingxenye.

2. Ukuvama Kokusetshenziswa kanye Nomthwalo Wokusebenza

Indlela osebenzisa ngayo umshini ngamandla ithonya ngqo izinga lokuguguleka kwawo.

Ukusetshenziswa Okudlulele: Ukusebenzisa umshini njalo ngaphandle kokuphazamiseka okwanele kuholela ekucindezelekeni okukhulu kokushisa kanye nokuguguleka okusheshayo komthombo we-laser kanye nohlelo lokupholisa.

Imithwalo Eminingi: Ukusebenza njalo ngomthamo omkhulu noma eduze komthamo omkhulu kubeka ingcindezi enkulu yemishini ezingxenyeni ezihambayo. Yingakho ukuqonda umjikelezo womsebenzi womshini wakho—isikhathi esiphezulu sokusebenza ngamandla athile okukhipha—kubalulekile.

3. Ukuzinza Kwezingxenye Ze-elekthronikhi

Ukuthembeka kokusebenza kohlelo lokushisela nge-laser kuhlobene ngokuyisisekelo nokuzinza kwezingxenye zalo ze-elekthronikhi. Amabhodi okulawula, izinsiza zikagesi, kanye nezifunda zomshayeli zisengozini yokuwohloka ngenxa yezici eziningana ezingathinta ngqo ukusebenza, ukunemba, kanye nesikhathi sokuphila kohlelo.

Ukucindezeleka Kokushisa: Ukujikeleza kokushisa kanye nokushisa okuqhubekayo kubangela ukucindezeleka emajoyintini e-solder futhi kusheshise ukuwohloka kwezingxenye ezifana nama-capacitor, okuphazamisa ukuzinza kohlelo kanye nokulawulwa kwamandla.

Ukuphela Kwempilo Yengxenye: Zonke izingxenye zinesikhathi sokuphila esinqunyiwe. Ukuwohloka kwezinto okungenakugwenywa kuholela ekushintsheni kokusebenza, amaphutha ngezikhathi ezithile, kanye nokwehluleka kohlelo ekugcineni, okudinga isu lokushintsha elisebenzayo.

4. Amandla Kagesi Angazinzile

Ama-elekthronikhi azwelayo omshini wakho wokushisela nge-laser awakwazi ukuzivikela ekuhlinzekweni kwamandla okungazinzile. Ukunyuka kwamandla, ukuwohloka, nokunye ukushintshashintsha kukagesi kungadala umonakalo kumabhodi okulawula kanye nomthombo wamandla, okuholela ekuhlulekeni okungazelelwe noma ekulimaleni okufihliwe okufinyeza isikhathi sawo sokuphila. Ukunikeza umugqa wamandla ozinikele, olungiswe ngobuchwepheshe akuyona into eyengeziwe ongayikhetha—kuyisidingo esiyisisekelo sokuvikela impahla yakho nokuqinisekisa ukusebenza okuthembekile.

5. Yamukela Isu Lokulungisa Okusebenzayo

Indlela “yokulungisa uma kuphuka” ingenye yezindlela ezisheshayo zokufinyeza impilo yomshiseli wakho. Uhlelo lokulungisa oluhlelekile nolusebenzayo lwenzelwe ukubamba nokuxazulula izinkinga ezincane, njengesihlungi esingcolile noma uphawu olugugile, ngaphambi kokuba zingene enhlekeleleni enkulu. Lokhu kubuka kusengaphambili akugcini nje ngokuvimbela ukulungiswa okubizayo, okuphuthumayo kanye nesikhathi sokungasebenzi esihleliwe kodwa futhi kunciphisa kakhulu izindleko zobunikazi bomshini esikhathini sokuphila kwawo.

6. Ikhono Lokusebenza Nokuziphatha

Ngisho nomshini oqinile kakhulu usengozini yamaphutha abantu. Umsebenzisi osebenzisa njalo amapharamitha angalungile, ongazinaki izexwayiso zesistimu, noma ophatha kabi izingxenye ezibonakalayo ezibucayi angabangela ngqo ukuguguleka okusheshayo noma ngisho nomonakalo osheshayo. Ukuziphatha kahle kokusebenza kanye nokunamathela ku-Standard Operating Procedures (SOPs) kubalulekile. Ukuqeqeshwa okuphelele kuguqula osebenza nabo babe umugqa wokuqala wokuzivikela, kubanike amandla okusebenzisa umshini kahle nangokuphepha ngenkathi bekhulisa impilo yawo yesevisi.

Umhlahlandlela Wesinyathelo Ngesinyathelo Wokwandisa Isikhathi Sokuphila Sakho Sokushisela I-Laser

Isinyathelo 1: Dala Indawo Efanele Yokusebenza

Ukulawula Izinga Lokushisa Nomswakama: Gcina indawo ezinzile, ngokuvamile ephakathi kuka-15℃ no-30℃ (59℉no-86℉), enomswakama ongaphansi kuka-70%.

Qinisekisa Ukuhlanzeka Komoya: Sebenzisa umoya oqinile futhi ucabangele izinhlelo zokuhlunga umoya ezithuthukisiwe, ikakhulukazi ezindaweni zezimboni, ukuvikela izingxenye zokukhanya kanye nezinto zikagesi othulini.

Isinyathelo 2: Sebenzisa Ukuhlela Ukusetshenziswa Kwamasu

Gwema Ukusebenza Okunamandla Aphezulu Okuqhubekayo: Vumela izikhathi zokuphola ezihleliwe noma imisebenzi enamandla aphansi ukuze unciphise ukucindezeleka kokushisa. Cabanga ngakho njengokushintsha umbala wenjini yemoto—akuklanyelwe ukusebenza kahle okuqhubekayo.

Sebenzisa Ngaphakathi Komthamo Olinganiselwe: Hlala uhlonipha amapharamitha aklanyelwe umshini kanye nomjikelezo womsebenzi ukuze uvimbele ukucindezeleka ngokweqile ezingxenyeni zemishini nezikagesi.

Isinyathelo 3: Zibophezele kuHlelo Lokulungisa Oluqinile

Ukuhlanza Nokugcoba Okuvamile: Hlanza njalo izingxenye zokukhanya (amalensi, izibuko) ngezixazululo ezivunyiwe bese uthambisa izingxenye ezihambayo (ama-guide rails, ama-bearings) ukuze unciphise ukungqubuzana.

Ukushintsha Ingxenye Esebenzayo: Ungalindi ukuthi izingxenye ziphuke. Hlela isimiso sokushintsha izinto ezisetshenziswayo ezisengozini njengezihlungi nezivalo ngokusekelwe ezincomweni zomkhiqizi. Izindleko zokushintsha njalo ingxenye esetshenziswayo, kungaba ifasitela elibonakalayo noma isihlungi samanzi, zincane kakhulu uma ziqhathaniswa nezindleko zokwehluleka okubi okwenzelwe ukuvimbela.

Isinyathelo 4: Tshala imali ekuqeqeshweni kwabaqhubi kanye nokusekelwa kochwepheshe

Ukuqeqeshwa Okuphelele Kwabasebenzi: Abasebenzi abanamakhono abaqonda amakhono omshini, izilungiselelo ezifanele zamapharamitha, kanye nokuxazulula izinkinga eziyisisekelo babaluleke kakhulu. Banciphisa ukucindezeleka emshinini futhi bavimbele umonakalo ongalindelekile.

Sebenzisa Ukunakekelwa Kochwepheshe: Ukuze uthole ukuxilongwa okuyinkimbinkimbi, ukulinganisa, kanye nokulungisa, thembela kochwepheshe abangochwepheshe. Ukunakekelwa kochwepheshe njalo kungabona izinkinga ezicashile ngaphambi kokuba zibe izinkinga ezinkulu.

Isinyathelo 5: Qapha Impilo Yomshini Njalo

Sebenzisa Ukuqapha Ukusebenza: Sebenzisa amathuluzi atholakalayo ukulandelela izinkomba ezibalulekile zezempilo njengokukhishwa kwamandla e-laser, ukuzinza kokushisa kwe-chiller, kanye namakhodi amaphutha. Imishini eminingi yesimanje inikeza ukuxilongwa okunikwe amandla yi-IoT ukuze kulungiswe kusengaphambili.

Misa Ukuxilongwa Kwephutha Okusheshayo: Dala uhlelo olucacile lokuhlonza nokulungisa izinkinga ngokushesha. Isinyathelo esisheshayo singavimba izinkinga ukuthi zingabi umonakalo omkhulu kanye nesikhathi eside sokuphumula.

Isinyathelo 6: Hlela Ukubuyekezwa Kwamasu Nokuthuthukiswa

Hlala Unolwazi Ngobuchwepheshe: Izibuyekezo zesofthiwe zingathuthukisa ukusebenza kahle kanye nokusebenza, ngezinye izikhathi zandise impilo yezingxenye ngokusebenzisa ama-algorithm okulawula athuthukisiwe.

Hlola Ukuthuthukiswa Kwemishini: Kufika isikhathi lapho ukuthuthukisa umshini omdala kuphumelela kakhulu kunokulungisa okuqhubekayo. Cabanga ngalokhu lapho izindleko zokulungisa ziba zinkulu noma ubuchwepheshe obusha bunikeza inzuzo enkulu.

Isiphetho: Vikela Ukutshalwa Kwezimali Kwakho Eminyakeni Ezayo

Ukwandisa impilo yesevisi yomshini wakho wokushisela nge-laser akusho ukuthi uzosebenza isikhathi eside; kumayelana nokwamukela isu eliphelele nelisebenzayo. Ngokulawula ngokucophelela indawo yokusebenza kwawo, ukuhlela ukusetshenziswa kwawo ngokucabangela, ukuzibophezela ekunakekelweni okuqinile, nokuqinisekisa ukuthi opharetha bakho banekhono eliphezulu, ungakhulisa kakhulu ukutshalwa kwezimali kwakho, unciphise kakhulu isikhathi sokungasebenzi esibizayo, futhi uqinisekise ukuthi umshini wakho uletha imiphumela esezingeni eliphezulu iminyaka eminingi ekhiqizayo.

Imibuzo Evame Ukubuzwa (Imibuzo Evame Ukubuzwa)

Q1: Kufanele ilungiswe kangaki i-laser welder?

A: Lokhu kuncike ekusetshenzisweni kanye nendawo yokusebenza. Umthetho ojwayelekile ukulandela izikhawu zesevisi ezinconywe ngumenzi. Ukuhlolwa okubonakalayo kwansuku zonke ngumqhubi kubalulekile, ngenkonzo yobungcweti ebanzi kakhulu eyenziwa njalo ngekota, kabili ngonyaka, noma ngonyaka.

Umbuzo 2: Iyiphi ingxenye ebiza kakhulu ongayishintsha emshinini wokushisela nge-laser?

A: Umthombo we-laser ngokuvamile uyisici esisodwa esibiza kakhulu, ngokuvamile esibangela ingxenye enkulu yezindleko zomshini. Yingakho ukuwuvikela ekushiseni ngokweqile nasekungcoleni kubaluleke kakhulu.

Umbuzo 3: Ingabe uthuli lungalimaza ngempela umshini wokushisela nge-laser?

A: Impela. Uthuli oluhlala kulensi noma esibukweni esigxilile lungamunca amandla e-laser, okubangela ukuthi lishise futhi liqhekeke, lishise, noma liqhekeke. Lokhu kulimaza unomphela i-optic futhi kwehlisa kakhulu ukusebenza komshini.

Umbuzo 4: Ingabe ukusebenzisa i-laser ngamandla aphansi kwandisa isikhathi sayo sokuphila?

A: Yebo. Ukusebenzisa noma yimuphi umshini njalo ngaphansi komthamo wawo olinganiselwe kunciphisa ukucindezeleka kokushisa nogesi kuzo zonke izingxenye, ikakhulukazi umthombo we-laser kanye nokunikezwa kwamandla, okungasiza ekusebenzeni isikhathi eside.

Udinga usizo lokudala uhlelo lokulungisa imishini yakho? Xhumana nethimba lethu lezinsizakalo zochwepheshe namuhla ukuze uthole ukubonisana.

Isikhathi sokuthunyelwe: Julayi-29-2025