Umshini wokusika i-fiber laser uyithuluzi elibalulekile lokusika ngokunemba embonini yokukhiqiza. Kodwa-ke, ukuze kufezwe ikhwalithi yokusika oyifunayo, amapharamitha athile kudingeka anakwe. Amapharamitha athinta ikhwalithi yokusika afaka ukuphakama kokusika, uhlobo lwe-nozzle, indawo yokugxila, amandla, imvamisa, umjikelezo womsebenzi, umfutho womoya, kanye nesivinini. Uma ikhwalithi yokusika yomshini wokusika i-fiber laser imbi, kunconywa ukuthi kwenziwe ukuhlolwa okuphelele kuqala. Lesi sihloko sizokwethula indlela yokwenza ngcono amapharamitha kanye nezimo zehadiwe zomshini wokusika i-fiber laser ukuze kuthuthukisweikhwalithi yokusika.

Enye yemingcele eyisisekelo okufanele uyicabangele lapho wenza ngcono imingcele yomshini wokusika i-fiber laser ukuphakama kokusika. Ukuphakama kokusika ibanga eliphakathi kwe-nozzle yokusika kanye ne-workpiece. Ukuphakama kokusika okuhle kakhulu kuncike ezintweni ezisikiwe. Ukubeka ukuphakama kokusika okufanele kuqinisekisa ukuthi umsebe we-laser ugxile ezintweni ezisikiwe ngokunembile. Ngaphezu kwalokho, uhlobo lwe-nozzle yokusika ludlala indima ebalulekile enqubweni yokusika. Ukukhetha uhlobo lwe-nozzle kuncike ezintweni ezisikiwe futhi kuthinta ikhwalithi yomkhiqizo wokugcina.

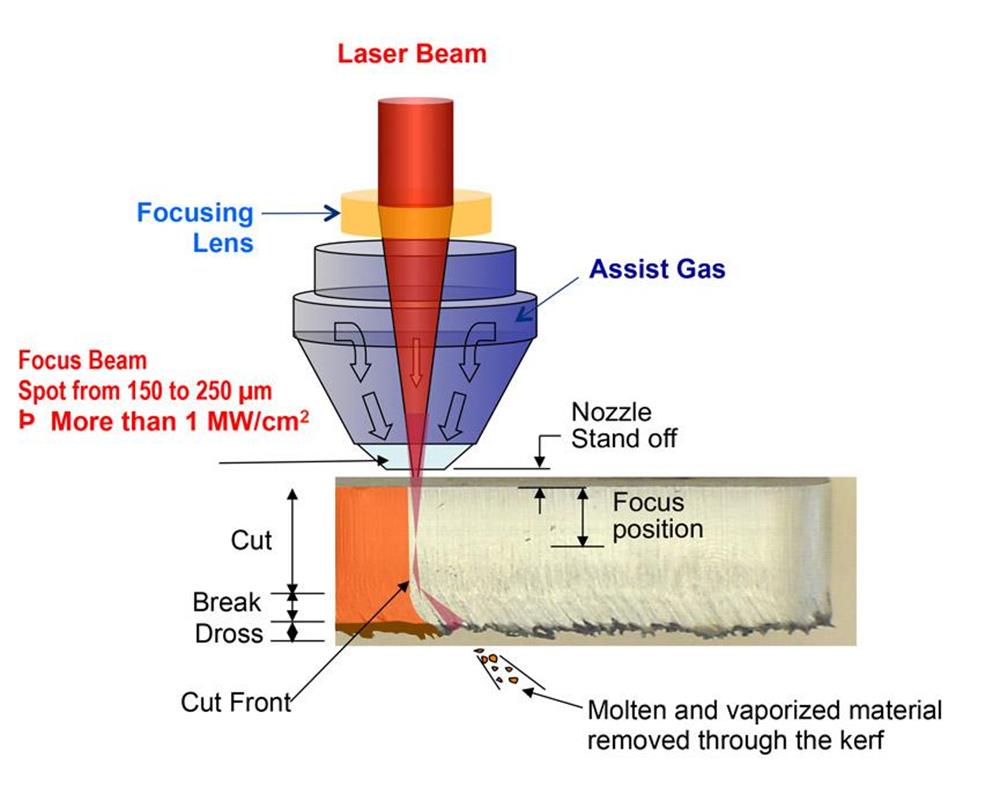

Enye ipharamitha ebalulekile yindawo yokugxila. Indawo yokugxila ibanga eliphakathi kwelensi nendawo yokusebenza. Indawo yokugxila inquma usayizi kanye nesimo somsebe we-laser. Indawo yokugxila ebekwe kahle inegalelo ekuhlanzeni imiphetho yokusika futhi inciphisa isidingo sokuphathwa ngemva kokusika.

Amandla okusikakanye nemvamisa kungenye imingcele ethinta kakhulu ikhwalithi yokusikwa. Amandla okusika abhekisela enanini lamandla alethwa ezintweni nge-laser beam. Ngakolunye uhlangothi, imvamisa ibhekisela enanini lama-laser pulses alethwa ezintweni ngeyunithi yesikhathi. Amandla okusika kanye nemvamisa kudingeka kulungiselelwe kahle ukuze kufezwe ukusikwa okufiselekayo. Amandla aphezulu kanye nemvamisa kungabangela ukuncibilika ngokweqile kwezinto, kuyilapho amandla aphansi kanye nemvamisa kungabangela ukusikwa okungaphelele.

Umjikelezo womsebenzi nawo uyipharamitha ebalulekile okufanele uyicabangele lapho kwenziwa ngcono amapharamitha e-umshini wokusika we-fiber laser. Umjikelezo womsebenzi unquma isilinganiso sesikhathi lapho i-laser isebenza khona nesikhathi lapho i-laser isebenza khona. Umjikelezo womsebenzi uthinta izinga lokushisa lomsebe we-laser futhi kumele ubekwe kahle ukuze kufezwe ikhwalithi yokusika oyifunayo. Imijikelezo yomthwalo ophezulu ibangela ukwanda kokukhiqizwa kokushisa, okungagcini nje ngokunciphisa ikhwalithi yokusika, kodwa futhi okungalimaza umshini.

Ukunciphisa umfutho womoya kungenye ipharamitha evame ukunganakwa lapho kwenziwa ngconoumshini wokusika we-fiber laserImingcele. Ukucindezela komoya okusikayo yingcindezi lapho umoya ocindezelwe ulethwa khona embotsheni yokusika. Ukucindezela komoya okusikayo okufanele kuqinisekisa ukuthi imfucumfucu yezinto ezibonakalayo iyapheshulwa, kunciphisa amathuba omlilo futhi kuthuthukiswe ikhwalithi yokusika.

Okokugcina, isivinini sokusika yisivinini lapho umsebe we-laser uhamba khona ezintweni. Ukulungisa isivinini sokusika kungathinta kakhulu ikhwalithi yokusika. Isivinini sokusika esiphezulu sizoholela ekusikeni okungaphelele, kanti isivinini sokusika esiphansi sizobangela ukuba izinto zincibilike.

Izimo zehadiwe nazo zibalulekile ekufinyeleleni ikhwalithi yokusika enhle kakhulu. Ama-optics avikelayo, ubumsulwa begesi, ikhwalithi yepuleti, ama-optics e-condenser, kanye nama-optics e-collimating ngezinye zezimo zehadiwe ezingathinta kakhulu ikhwalithi yokusika.

Amalensi okuvikela aqinisekisa ukuthi ikhwalithi yokukhanya kwe-laser iphuma futhi kumele ahlolwe njalo ukuze kutholakale umonakalo noma ukungcola. Ukuhlanzeka kwegesi nakho kubalulekile ekufinyeleleni ukunqunywa okunembile. Ukuhlanzeka kwegesi okuphezulu kunciphisa amathuba okungcola futhi kunciphisa isidingo sezinqubo ezengeziwe zangemva kokusika.

Ikhwalithi yamakhasi nayo inomthelela ekhwalithini yokusika. Amashidi acwebezelayo avame ukubonakalisa umsebe we-laser okubangela ukuphambuka, kuyilapho amashidi angaphelele angabangela ukunqunywa okungaphelele. Amalensi e-Condenser kanye ne-collimator aqinisekisa ukuthi umsebe we-laser ugxile kahle ezintweni zokwakha.ukusika okunembile.

Ekuphetheni, ukwenza ngcono amapharamitha omshini wokusika i-fiber laser kanye nezimo zehadiwe kubalulekile ukuze kufezwe ikhwalithi yokusika efanele. Ukuphakama kokusika, uhlobo lwe-nozzle, indawo yokugxila, amandla, imvamisa, umjikelezo womsebenzi, umfutho womoya kanye nesivinini kungenye yemingcele okumele ilungiselelwe. Izimo zehadiwe ezifana namalensi okuvikela, ubumsulwa begesi, ikhwalithi yepuleti lokuphrinta, amalensi okuqoqa, kanye namalensi e-collimating nawo kumele acatshangelwe. Ngokwenza ngcono amapharamitha ngendlela efanele, abakhiqizi bangathuthukisa ikhwalithi yokusika, banciphise ukusebenza kwangemva kokusika futhi bandise umkhiqizo.

Uma ufuna ukufunda kabanzi ngokusika nge-laser, noma ufuna ukuthenga umshini wokusika nge-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Juni-09-2023