Ukukhetha phakathi kwe-handheld kanye ne-robotic laser welder kuyisinqumo esibalulekile esizochaza isu lakho lokusebenza. Lokhu akusikho nje ukukhetha phakathi kwamathuluzi; kungukutshala imali kwifilosofi yokukhiqiza. Impendulo efanele incike ngokuphelele emgomweni wakho oyinhloko webhizinisi: Ingabe udinga ukuguquguquka okungenakuqhathaniswa komsebenzi owenziwe ngokwezifiso, noma udinga isivinini esingaguquki kanye nokunemba kokukhiqizwa kwesisindo okuzenzakalelayo?

Lo mhlahlandlela unikeza uhlaka olucacile lokukusiza ukuthi wenze utshalomali oluhle kakhulu lwekusasa lenkampani yakho.

Impendulo Emfushane: Ukuguquguquka vs. Isikali

Abashiseli Be-Laser Ababanjwe Ngesandlakuyisinqumo esiqondile sezitolo zemisebenzi, izinsizakalo zokulungisa, kanye nabakhiqizi abangokwezifiso. Uma umsebenzi wakho wansuku zonke uhilela ingxube ephezulu yezingxenye ezahlukene, ukukhiqiza okuncane, noma izingcezu zokusebenza ezinkulu nezinzima, ukuqina kohlelo oluphathwayo kubalulekile.

Abashiseli be-Robotic Laserzakhiwe ngenhloso yokukhiqiza ngobuningi obukhulu, okuphindaphindwayo. Uma imodeli yebhizinisi lakho incike esivinini, ukuhambisana okuphelele, kanye nokwandisa umkhiqizo wezimboni ezifana nezimoto, izindiza, noma amadivayisi ezokwelapha, uhlelo lwerobhothi luyindlela edingekayo yokuqhubekela phambili.

Ukubuka Kafushane: Uhlelo Oluphathwa Ngesandla vs. Uhlelo Lwerobhothi

| Isici | Umshiseli We-Laser Ophathwa Ngesandla | Umshiseli We-Laser Oyirobhothi |

| Okuhle Kakhulu Kwaba | Ukwenziwa ngokwezifiso, ama-prototype, ukulungiswa, izingxenye ezinkulu nezingavamile. | Imigqa yokukhiqiza enomthamo omkhulu, ephindaphindwayo kakhulu. |

| Inzuzo Eyinhloko | Ukuguquguquka Okuphelele Nokuthwaleka | Isivinini Esingafani, Ukunemba Nokuphindeka |

| Ukunemba | Kuphezulu, kodwa kuncike ekhonweni lomqhubi. | Kuphezulu kakhulu futhi kuvumelana ngokuphelele. |

| Isivinini | Ngokushesha emisebenzini eyodwa. | Ukusebenza okungu-24/7. |

| Izindleko Zokuqala | Okuphansi kuya Okuphakathi | Phezulu |

| Indima Yomqhubi | Umqhubi onekhono osebenza ngezandla. Kulula ukufunda izisekelo, kunzima ukuzazi kahle. | Uchwepheshe wezinhlelo onekhono eliphezulu kanye nochwepheshe wezinhlelo. |

| Ukushintsha Umsebenzi | Ngokushesha | Kungadla isikhathi futhi kudinga ukuhleleka kabusha. |

Indaba Yokuguquguquka: Nini Ukukhetha I-Laser Welder Ephathwayo

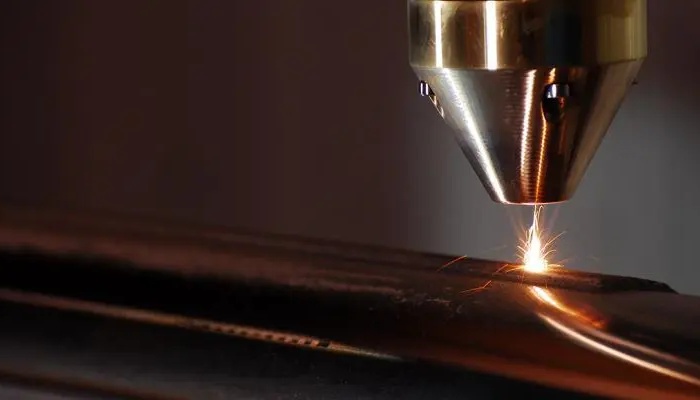

Umshiseli we-laser ophathwa ngesandla unika amandla umqhubi onekhono ngokunemba namandla, okwenza kube yiqhawe lokushesha emsebenzini wesimanje. Kuyisinqumo esihle kakhulu uma imodeli yebhizinisi lakho yakhelwe ekuguquguqukeni.

Ukukhiqizwa Okuxutshwe Kakhulu, Okunomthamo Ophansi:Izinhlelo eziphathwa ngesandla ziwumgogodla wezitolo zemisebenzi lapho yonke iphrojekthi ihlukile. Umsebenzisi angashintsha kusukela ekushiseleni ikhawuntara yensimbi engagqwali eyenziwe ngokwezifiso aye ekulungiseni isikhunta esiyinkimbinkimbi noma ekwakheni iphrothokholi ngaphandle kwesikhathi sokushintsha ubuchwepheshe.

Amajiyometri Amakhulu Noma Ayinkimbinkimbi:Inkululeko yethoshi eliphathwa ngesandla ibalulekile uma usebenza ezingxenyeni ezingakwazi ukungena endaweni ebiyelwe yamarobhothi. Lokhu kufaka phakathi amaphrojekthi amakhulu afana namathangi ezimboni, ishasi yezimoto ezenziwe ngokwezifiso, noma umsebenzi wensimbi wokwakha.

Ukulungiswa Nokufakwa Kwasendaweni:Ukuphatheka kalula kwamayunithi amaningi aphathwa ngesandla kukuvumela ukuthi ulethe ikhono lokushisela ngqo endaweni yomsebenzi. Lokhu kushintsha umdlalo ekulungiseni imishini esindayo endaweni noma ekwenzeni ukufakwa kwezakhiwo, ukunciphisa isikhathi sokungasebenzi kwamakhasimende kanye nezinselele zezokuthutha.

Icala Lokulinganisa: Nini Ukukhetha I-Robotic Laser Welder

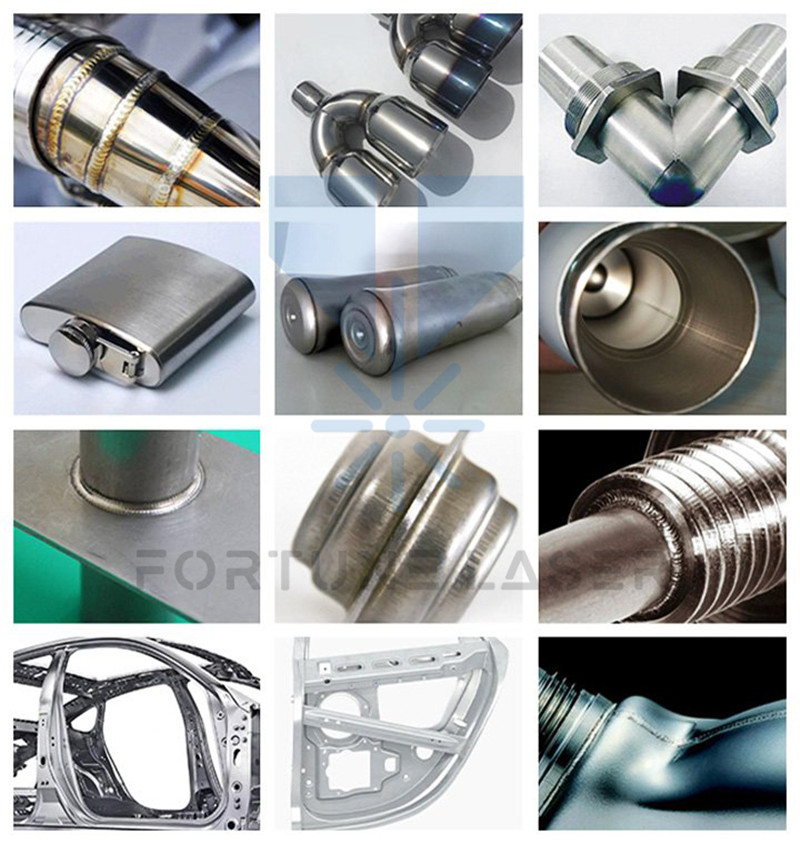

I-robotic laser welder ingaphezu nje kwethuluzi—iyisistimu yokukhiqiza ehlanganisiwe eyenzelwe ukukhipha umkhiqizo osezingeni lezimboni. Iyinjini yabakhiqizi ababeka phambili ukusebenza kahle, ukuhambisana, kanye nomthamo.

Ukunemba Okungaguquki Nokuphindeka:Ezimbonini lapho ukwehluleka kungeyona inketho, izinhlelo zamarobhothi zibalulekile. Ngokususa ukuguquguquka kwabantu, ziletha ukushintshwa okufanayo, okungenaphutha njalo. Lokhu kubalulekile ezifakelweni zezokwelapha, izingxenye zezindiza, kanye nezindawo zokuvala ezibucayi ze-elekthronikhi.

Isivinini Esiphezulu:Irobhothi lenzelwe ukukhiqiza “izibani ezicimayo” amahora angama-24 ngosuku, izinsuku eziyi-7 ngesonto. Lisebenza ngaphandle kokuphazamiseka noma ukukhathala, linciphisa kakhulu izikhathi zomjikelezo futhi lenze umkhiqizo ube ngcono, okubaluleke kakhulu kumaketanga okuphakelwa aphezulu njengezimoto (amathreyi ebhethri le-EV, ozimele) kanye nezinto zikagesi zabathengi.

Ubuqotho Bokushintshwa Okuphezulu:Irobhothi lingagcina kahle i-engeli yethoshi efanele, isivinini sokuhamba, kanye nebanga lokuma, okuyinto engenakwenzeka ngomuntu osebenzayo ukuyenza njalo. Lokhu kuphumela ekushiseni okuqinile, okujulile, nokufana kakhulu okunezakhiwo ezingcono zensimbi.

Ukucwila Okujulile: Amaqiniso Ezezimali Nezobuchwepheshe

Ukuze wenze isinqumo esinolwazi oluphelele, kufanele ubheke ngale kwesilinganiso sokuqala bese uhlaziya umthelela wezezimali kanye nokusebenza okuphelele.

Ukuqonda Izindleko Eziphelele Zobunikazi (i-TCO)

Intengo yesitikha imane nje iyisiqalo. I-TCO inikeza isithombe esiphelele sezindleko zempahla esikhathini sayo sokuphila, iveza inzuzo yayo yangempela.

1.Ukutshalwa Kwezimali Kokuqala (Izindleko Zemali – CapEx)

Lona umehluko wezezimali osobala kakhulu.

Umshiseli Obanjwe Ngesandla:Lokhu kuyindlela engabizi kakhulu yokungena ekushiseni nge-laser, njengoba empeleni uthenga ithuluzi elizimele. Intengo ifaka phakathi umthombo wamandla we-laser kanye nekhanda lokushisisa eliphathwa ngesandla. Lezi zindleko eziphansi kakhulu kusengaphambili zenza kube inketho efinyelelekayo ezitolo ezincane, izinkampani ezintsha, noma amabhizinisi anesabelomali esincane semali afuna ukwengeza ikhono elisha.

Umshiseli Werobhothi:Lokhu kuwukutshalwa kwezimali okukhulu ngoba uthenga uhlelo lokukhiqiza oluphelele noluhlanganisiwe. Izindleko ziphezulu kakhulu njengoba zingahlanganisi nje umthombo we-laser, kodwa futhi nengalo yerobhothi ene-axis eningi, indawo yokuphepha eqinile, izingxenye ezenziwe ngokwezifiso, kanye nobunjiniyela obuyinkimbinkimbi obudingekayo ukuhlela nokuhlanganisa zonke izingxenye zengxenye yakho ethile. Lokhu kwenza kube yisinqumo sezezimali esibalulekile esifanele ukukhiqizwa okuzinikele, okunomthamo omkhulu.

2.Izindleko Zokusebenza (Izindleko Zokusebenza - OpEx)

Lezi zindleko eziqhubekayo zibalulekile ukuze kube nenzuzo yesikhathi eside.

Umsebenzi:Lesi yisici esiyinhloko sokuhlukanisa. Uhlelo oluphathwa ngesandla ludinga umqhubi ozinikele kuyo yonke iminithi olusebenza ngayo. Iseli lerobhothi, uma selihlelwe, lingasebenza ngokuqapha okuncane, kunciphisa kakhulu izindleko zomsebenzi ngengxenye ngayinye.

Izinto Ezisetshenziswayo Nezinsiza:Zombili lezi zinhlelo zisebenzisa igesi yokuvikela, ama-nozzle, kanye nogesi. Kodwa-ke, uhlelo lwerobhothi olusebenza njalo ngamandla aphezulu luzoba namazinga aphezulu okusetshenziswa kune-welder ephathwayo esetshenziswa ngezikhathi ezithile.

3.Imbuyiselo Ekutshalweni Kwezimali (i-ROI) kanye ne-“Crossover Point”

Lokhu kubalwa kunquma ukuthi umshini obiza kakhulu uba nini onenzuzo enkulu.

Ngomsebenzi ophansi, izindleko eziphansi zomshini wokushisela ophathwayo zenza kube nenzuzo enkulu.

Njengoba ivolumu yokukhiqiza ikhuphuka, kufinyelelwa "iphuzu lokuhlangana" lapho ukonga okuqongelelekayo emsebenzini ovela ohlelweni lwerobhothi kudlula ukutshalwa kwezimali kwalo okuphezulu kokuqala. Ngale kwaleli phuzu, yonke ingxenye eyenziwe emgqeni werobhothi inenzuzo enkulu kakhulu. Kumelwe ubikezele ngokunembile ivolumu yakho yokukhiqiza ukuze unqume ukuthi ungafinyelela yini kuleli phuzu lokuhlangana ngesikhathi esifanele.

Ukuhambisana Kwezinto Ezibalulekile Nezidingo Zamandla

Inzuzo eyinhloko yama-fiber lasers anamuhla—aphathwa ngesandla kanye nangamarobhothi—ikhono lawo lokushisela izinsimbi eziningi ezahlukene, okuhlanganisa:

Insimbi Engagqwali Insimbi Yekhabhoni I-Aluminium Ithusi I-Titanium

Isici esibalulekile ukufanisa amandla e-laser nohlobo lwezinto kanye nobukhulu. I-laser engu-1 kW kuya ku-1.5 kW ilungele kakhulu izinsimbi ezincane ze-gauge, kuyilapho izingxenye ezijiyile, ikakhulukazi izinsimbi ezikhanyayo njenge-aluminium nethusi, zidinga amandla aphezulu ebangeni eliphakathi kuka-2 kW kuya ku-3 kW noma ngaphezulu ukuze kube nesivinini esiphezulu kanye nokungena.

Isiphetho: Ukwenza OkwakhoSUkukhetha Okufanelekile

Isinqumo phakathi kwe-laser welder ephathwa ngesandla kanye ne-robotic laser welder siyindlela yokuhweba ehlakaniphile phakathi kokuguquguquka kanye nokuphindaphinda.

Khetha i-Handbald uma:Ibhizinisi lakho lichazwa ngokuhlukahluka, umsebenzi owenziwe ngokwezifiso, kanye nokushesha. Udinga ukuzivumelanisa ngokushesha nemisebenzi ehlukene futhi uphathe ukutshalwa kwezimali kwakho kokuqala ngokucophelela.

Khetha iRobotic uma:Ibhizinisi lakho ligxile ekwandiseni ukukhiqizwa kweqoqo elithile lezingxenye. Imigomo yakho eyinhloko ukufeza isivinini esiphezulu, ukuhambisana okungenaphutha, kanye nokunciphisa izindleko zabasebenzi zesikhathi eside.

Ngokuhlaziya ngokucophelela ubunzima bengxenye yakho, umthamo wokukhiqiza, isabelomali, kanye nemigomo yebhizinisi yesikhathi eside, ungenza utshalomali olunamandla oluzoqhuba ukusebenza kahle kwenkampani yakho, ikhwalithi, kanye nokukhula kwayo iminyaka ezayo.

Isikhathi sokuthunyelwe: Agasti-04-2025