Amarobhothi okushisela nge-laserbashintshe insimu yokushisela ngokwethula izici ezithuthukisiwe ezandisa ukusebenza kahle kanye nokukhiqiza. Lawa marobhothi anikeza imisebenzi eminingi eyenza inqubo yokushisela ibe lula, andise ukunemba futhi aqinisekise ukuphepha okuphezulu. Lesi sihloko sihlose ukuhlolisisa amakhono amarobhothi okushisela nge-laser, sigcizelela indima yawo ekwandiseni ukusebenza kahle kokushisela kanye nokwenza okuzenzakalelayo okuphelele. Sizohlola futhi izincazelo ezahlukahlukene zomkhiqizo ezifana nomsebenzi wokujikijela, umsebenzi wokuzivikela, umsebenzi wokuzwa ukushisela, umsebenzi wokulwa nokushayisana, umsebenzi wokuthola amaphutha, umsebenzi wokuxhumana ngentambo enamathelayo, umsebenzi wokuqalisa kabusha i-arc break.

1. Umsebenzi wokushintshashintsha:

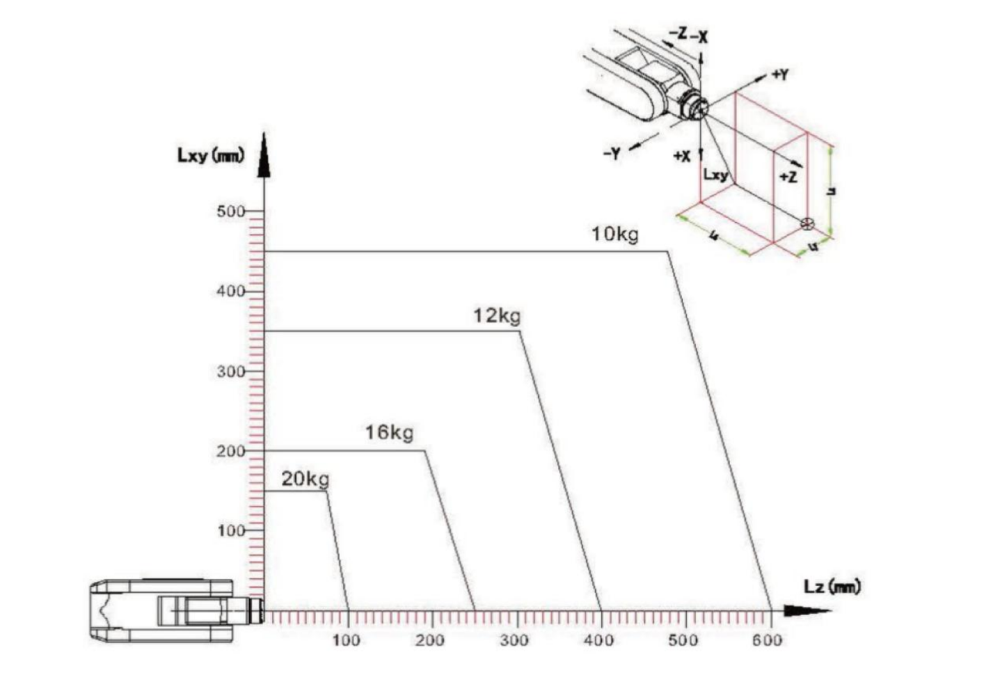

Esinye sezici ezibalulekile ze-irobhothi lokushisela nge-laserumsebenzi wayo wokunyakazisa. Lesi sici sivumela irobhothi ukuthi lihambe ngokunyakaza okunyakazisayo, limboze indawo enkulu kunezindlela zokushisela zendabuko. Isici sokunyakazisa siqinisekisa ukuthi umsebe we-laser umboza indawo ebanzi, okunciphisa isikhathi sokushisela esidingekayo kumaphrojekthi amakhulu. Ngokwandisa indawo yokumboza, isici sokujikisa sisiza ekufezeni umkhiqizo ophezulu kanye nokusebenza kahle ekusetshenzisweni kokushisela.

2. Umsebenzi wokuzivikela:

Amarobhothi okushisela nge-laser ahlonyiswe ngezici zokuzivikela ukuqinisekisa ukuthi ahlala isikhathi eside futhi avimbele umonakalo ongaba khona. Lesi sici sisebenza njengesivikelo sokuvikela ezimweni ezimbi njengokushisa ngokweqile, ukuphambuka kwamandla kagesi noma ukushintshashintsha kwamandla. Izici zokuzivikela zerobhothi azigcini nje ngokuvikela izingxenye zalo zangaphakathi, kodwa futhi zivimbela noma yimuphi umonakalo wangaphandle ovela ezinhlansini zokushisela noma udoti. Ngokugcina ubuqotho balo, irobhothi lingaletha njalo imiphumela yokushisela esezingeni eliphezulu futhi landise isikhathi salo sokuphila.

3. Umsebenzi wokuzwa ukushisela:

Amakhono okuzwa ukushintshwa kwe-weld ayingxenye ebalulekileamarobhothi okushisela nge-laser, okubenza bakwazi ukubona nokuphendula izinguquko endaweni yokushisela. Lesi sici sisebenzisa izinzwa ezithuthukisiwe ukukala ngokunembile izinto eziguquguqukayo ezifana nobukhulu bensimbi, ukuhambisana kwamalunga kanye nokushisa kwe-ambient. Ngokuzivumelanisa nalezi zinguquko ngesikhathi sangempela, irobhothi lokushisela liqinisekisa ukushisela okunembile endleleni oyifunayo, okuholela ekhwalithini yokushisela engenaphutha futhi kunciphisa isidingo sokulungiswa ngesandla.

4. Umsebenzi wokulwa nokushayisana:

Ukuphepha kubaluleke kakhulu kunoma iyiphi indawo yezimboni, futhiamarobhothi okushisela nge-laserzihlonyiswe ngezici zokulwa nokushayisana ukuze kuvinjelwe ukushayisana ukuthi kungabangela izingozi noma umonakalo. Lesi sici sisebenzisa inhlanganisela yezinzwa, amakhamera, kanye nama-algorithm esofthiwe ukuthola izithiyo endleleni yerobhothi. Uma selitholakele, irobhothi lilungisa ngokuzenzakalelayo indlela yalo ukuze ligweme ukushayisana. Lesi sici asivikeli nje kuphela irobhothi ekulimaleni, kodwa futhi siqinisekisa ukuphepha kwabasebenzi abaseduze nemishini, sisuse ingozi yezingozi nokulungiswa okubizayo.

5. Umsebenzi wokuthola amaphutha:

Ukuze kuqinisekiswe ukusebenza kokushisela okuqhubekayo nokungaphazanyiswa, irobhothi lokushisela nge-laser linomsebenzi wokuthola amaphutha. Lesi sici sihlala siqapha ukusebenza kwerobhothi, okuhlanganisa izingxenye ezifana nezintambo, izinsiza zikagesi, kanye nezinhlelo zokupholisa. Ngokubona ukungasebenzi kahle noma ukwehluleka okungenzeka kusenesikhathi, amarobhothi angathatha isinyathelo sokuvimbela noma azise abaqhubi ngenkinga. Ukuthola nokuxazulula ukwehluleka ngesikhathi kungasiza ekwandiseni ukusebenza kahle, ukunciphisa isikhathi sokungasebenzi kanye nokwandisa umkhiqizo.

6. Umsebenzi wokuxhumana ngentambo enamathelayo kanye nomsebenzi wokuqalisa kabusha ngemva kokuphuka kwe-arc:

Isici esihlukile samarobhothi okushisela nge-laser yikhono lokuphatha ukuxhumana kwentambo okunamathelayo nokuqala kabusha inqubo yokushisela ngaphandle kokuphazamiseka ngemva kokuphuka kwe-arc. Umsebenzi wokuxhumana kwentambo okunamathelayo kokushisela uvumela irobhothi ukuzwa nokulungisa ukuxhumana nentambo yokushisela, ukuqinisekisa imiphumela emihle kakhulu yokushisela ngisho nasezintweni eziyinselele. Ngaphezu kwalokho, umsebenzi wokuqalisa kabusha i-arc break uvumela irobhothi ukuthi liqale kabusha ngokuzenzakalelayo ukushisela ngemva kokuphazamiseka kwesikhashana ngaphandle kokungenelela komuntu. Lezi zici zivumela ukushisela okusezingeni eliphezulu okuqhubekayo, ukunciphisa amaphutha nokuthuthukisa ukusebenza kahle kokushisela jikelele.

Ekuphetheni:

Amarobhothi okushisela nge-laserinikeza izici eziningi ezithuthukisiwe ezandisa ukusebenza kahle kokushisela futhi zivumele ukuzenzekela okugcwele kuzinhlelo zokusebenza ezahlukahlukene. Isici sokujikisa senza kube lula ukumbozwa okunembile nokusheshayo, okwandisa umkhiqizo. Ukuzivikela, ukuzwa ukushisela, ukulwa nokushayisana, ukutholwa kwamaphutha kanye neminye imisebenzi kuqinisekisa ukusebenza okuphephile, okunembile nokuqhubekayo. Ngaphezu kwalokho, ukuxhumana kwentambo okunamathelayo kanye nemisebenzi yokuqalisa kabusha ukuphuka kwe-arc kusiza ukuthuthukisa ikhwalithi yokushisela kanye nokusebenza kahle okuphelele. Ngokusebenzisa la makhono athuthukile, amarobhothi okushisela nge-laser ashintshe kakhulu insimu yokushisela, okwenza abakhiqizi bakwazi ukuthola imiphumela emihle yokushisela ngokwandisa ukuzenzekela kanye nokukhiqiza.

Isikhathi sokuthunyelwe: Agasti-03-2023