Ezweni lanamuhla elisheshayo, ukuzenzakalela sekuyisici esibalulekile sezimboni emhlabeni wonke. Ikakhulukazi, ukusetshenziswa kweamarobhothi okushisela nge-laseriguqule izinqubo zokukhiqiza emikhakheni eminingana. Lawa marobhothi anikeza izinzuzo eziningi, kusukela ekunembeni nasekuqondeni kuya ekusebenzeni kahle okukhulu kanye nezindleko zabasebenzi ezincishisiwe. Kulesi sihloko, sihlola uhla olubanzi lwezicelo zamarobhothi okushisela nge-laser nokuthi ashintsha kanjani izimboni ezahlukene.

Imboni yezimoto izuza kakhulu ekuhlanganisweni kwamarobhothi okushisela nge-laser. Lawa marobhothi asetshenziswa kabanzi ezinqubweni zokushisela umzimba kanye nokushisela izingxenye. Ngokunemba kwawo okumangalisayo kanye nesivinini, amarobhothi okushisela nge-laser aqinisekisa ukwakheka okuphelele kwamalunga futhi anegalelo ekuqineni nasekuqineni kwemoto. Le nqubo ezenzakalelayo ayigcini nje ngokwandisa umkhiqizo, kodwa futhi inciphisa umkhawulo wamaphutha, okuholela ezimotweni ezisezingeni eliphezulu ezihlangabezana futhi zidlule okulindelwe amakhasimende.

Ukukhiqizwa kwezinto zikagesi kungenye indawo lapho ukusetshenziswa kwamarobhothi okushisela nge-laser kukhule khona kakhulu. Lawa marobhothi asetshenziselwa ukushisela ingxenye, ukuqinisekisa ukuxhumana okusebenzayo nokuthembekile ngaphakathi kwamadivayisi kagesi. Ngaphezu kwalokho,amarobhothi okushisela nge-laserzidlala indima ebalulekile ekushiseleni amabhodi wesekethe, ziqinisekisa ukuxhumana okunembile phakathi kwezingxenye ngazinye. Ngokwenza inqubo yokukhiqiza ibe lula, lawa marobhothi athuthukisa ikhwalithi nokuqina kwemikhiqizo kagesi ngenkathi enciphisa ingozi yokukhubazeka nokwehluleka.

Imboni yezindiza, eyaziwa ngezindinganiso zayo eziqinile zekhwalithi, isiqalile nokusebenzisa amarobhothi okushisela nge-laser. Lawa marobhothi asetshenziswa kabanzi ekushiseleni izingxenye, okuqinisekisa ubuqotho namandla ezingxenye ezibalulekile zezindiza. Isibonelo, amarobhothi okushisela nge-laser asiza ekushiseleni amaphiko ezindiza, okusiza ekuthuthukiseni ukuphepha nokuqina kwalezi zakhiwo ezibalulekile. Ngokuzenzakalela inqubo yokushisela, lawa marobhothi awakhulisi nje kuphela ukunemba nokunemba, kodwa futhi anciphisa ingozi yamaphutha abantu, angafaka engcupheni ubuqotho besakhiwo sendiza.

Imboni yokukhiqiza amadivayisi ezokwelapha ithembele kakhulu kumarobhothi okushisela nge-laser ukuze kusetshenziswe ukushisela izingxenye kanye nezinqubo zokuhlanganisa amadivayisi ezokwelapha. Lawa marobhothi aqinisekisa ukushisela okunembile nokungaguquguquki kwezingxenye zedivayisi yezokwelapha eziyinkimbinkimbi njengezinsimbi zokuhlinzwa kanye nezifakelwe. Ngokugcina amazinga ekhwalithi ephezulu ngesikhathi senqubo yokukhiqiza,amarobhothi okushisela nge-laserkusiza ekuthuthukiseni ukuphepha nokusebenza kahle kwala madivayisi ezokwelapha, ekugcineni kuzuze imiphumela yeziguli. Ngaphezu kwalokho, uhlobo lwawo oluzenzakalelayo lwandisa ukusebenza kahle kokukhiqiza, okuvumela abakhiqizi ukuthi bahlangabezane nesidingo esikhulayo sala madivayisi asindisa impilo.

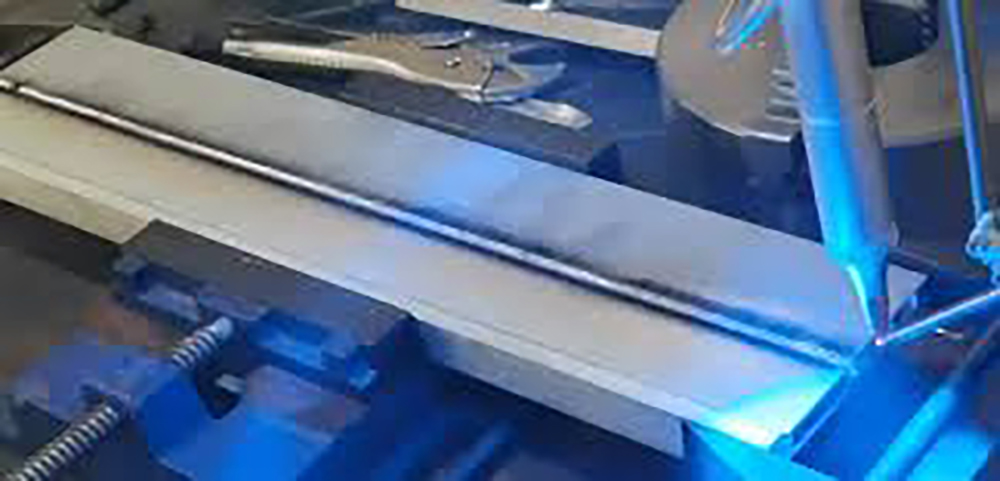

Embonini yokwakha, amarobhothi okushisela nge-laser athole indawo yawo ekusetshenzisweni kokushisela ngamapayipi kanye nokushisela phansi. Ikhono lala marobhothi lokwenza ukushisela okunembile ezindaweni eziqinile libe negalelo elikhulu ekuthuthukiseni ikhwalithi kanye namandla amapayipi asetshenziswa kumaphrojekthi amapayipi kanye nengqalasizinda. Ngaphezu kwalokho, amarobhothi okushisela nge-laser asiza ekushiseleni izakhiwo zaphansi, ukuqinisekisa ukuqina kanye nokuphila isikhathi eside kwemisebenzi yamaphrojekthi okwakha. Lawa marobhothi andisa umkhiqizo futhi asheshise inqubo yokwakha, okuholela ekuqedweni kwamaphrojekthi ngesikhathi esifanele ngenkathi kugcinwa amazinga ekhwalithi ephezulu.

Ngaphezu kokusetshenziswa kwezimboni, amarobhothi okushisela nge-laser enza iminikelo ebalulekile kwezemfundo nasocwaningweni lwesayensi.amarobhothiziye zabonakala zibaluleke kakhulu ocwaningweni nasekuthuthukisweni, amalabhorethri aseyunivesithi kanye nezikhungo zocwaningo lwesayensi. Amarobhothi okushisela nge-laser avumela abacwaningi ukuthi bahlole amasu amasha okushisela nezinto zokwakha, okuthuthukisa insimu yobuchwepheshe bokushisela. Uhlobo lwawo oluzenzakalelayo kanye nokunemba okuphezulu kuvumela ososayensi ukuthi benze izivivinyo ngokunemba okungenakuqhathaniswa, okuholela ekutholakaleni okuphumelelayo kanye nokusungula izinto ezintsha emikhakheni eyahlukene.

Ngamafuphi, ukusetshenziswa kweamarobhothi okushisela nge-laserkushintshe izimboni eziningi, kwashintsha izinqubo zokukhiqiza kanye nekhwalithi yomkhiqizo ethuthukisiwe. Kusukela ekukhiqizweni kwezimoto kuya kuma-elekthronikhi, izindiza, ukukhiqizwa kwamadivayisi ezokwelapha, ukwakhiwa, kanye nemfundo kanye nocwaningo lwesayensi, umthelela wamarobhothi okushisela nge-laser awunakuphikwa. Ngokuzenzakalela imisebenzi yokushisela, lawa marobhothi ahlinzeka ngokunemba okungenakuqhathaniswa, ukuhambisana kanye nokusebenza kahle, ekugcineni andise umkhiqizo futhi anciphise izindleko. Njengoba izimboni ziqhubeka nokwamukela ukuzenzakalela, ikusasa lamarobhothi okushisela nge-laser libukeka lithembisa njengoba eqhubeka nokuthuthuka futhi eguqula umhlaba wokukhiqiza.

Isikhathi sokuthunyelwe: Agasti-15-2023