Ukushisela nge-laser kuyindlela ethandwa kakhulu ekukhiqizeni ngenxa yokunemba nokusebenza kahle kwayo. Enye yezingxenye ezibalulekile zomshini wokushisela nge-laser uhlelo lokulandelela umthungo, oluqinisekisa indawo enembile ye-laser. Kulesi sihloko, sizohlaziya izinzuzo zokulandelela umthungo wemishini yokushisela nge-laser nokuthi ingathuthukisa kanjani umkhiqizo kanye nekhwalithi yokushisela. Sizoxoxa futhi ngezinzuzo zokusebenzisa irobhothi elinohlelo lokulandelela umthungo we-laser.

Ukuma okunembile kuncike ku-laser

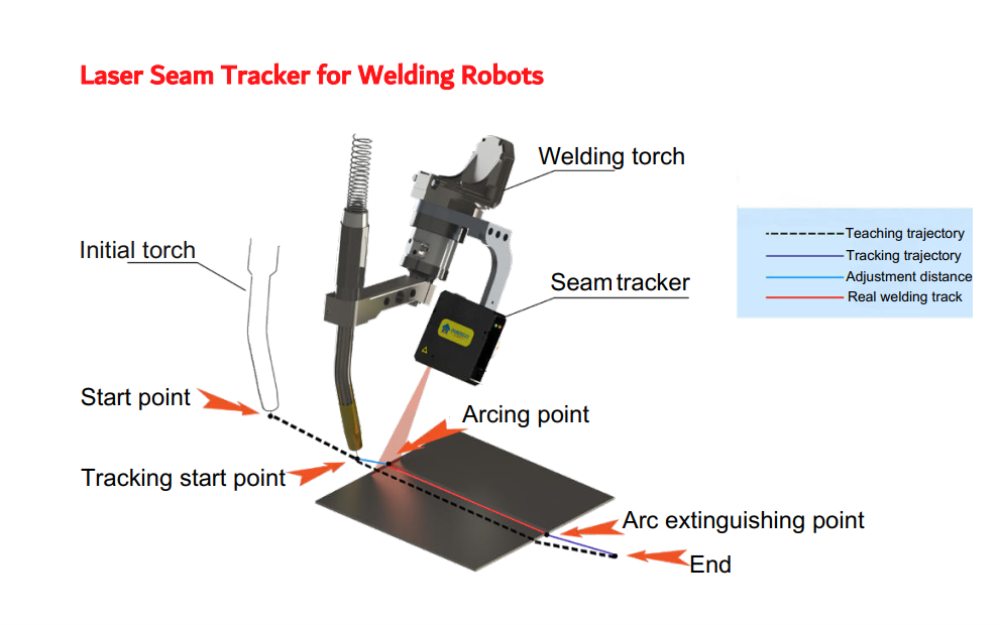

Ukunemba kweukushisela nge-laserIthembele kakhulu ekubekweni okunembile kogongolo lwe-laser. Izinhlelo zokulandelela umthungo emishinini yokushisela nge-laser zidlala indima ebalulekile ekufezeni lokhu kunemba. Ngokusebenzisa ubuchwepheshe obuthuthukisiwe bokuzwa, uhlelo lungalandelela futhi lulungise indawo ye-laser njengoba ihamba eduze komthungo ukuze ishiselwe. Lokhu kuqinisekisa ukuphambuka okuncane lapho i-laser idubula. Ngenxa yalokho, abakhiqizi bangafinyelela ukushisela okulinganayo nokunembile okuqinisekisa ikhwalithi yomkhiqizo wokugcina.

Ikhwalithi enhle nentengo ephansi

Lapho bekhetha umshini wokushisela nge-laser, amakhasimende avame ukukhathazeka ngokusebenzisa imali eningi kakhulu. Kodwa-ke, ngohlelo lokulandelela umthungo, akudingeki badele ikhwalithi ukuze bahlale ngaphakathi kwesabelomali. Ngokubeka kahle ugongolo lwe-laser, uhlelo lokulandelela umthungo luqinisekisa ukuthi yonke i-weld isezingeni eliphezulu futhi ihlangabezana nezindinganiso ezidingekayo. Lokhu kuqeda isidingo sokulungiswa kabusha okubizayo futhi kunciphisa izindleko zomkhiqizi. Ukuhlanganiswa kwekhwalithi enhle nentengo ephansi kwenza umshini wokushisela nge-laser kanye nokulandelela umthungo kube utshalomali oluhle kakhulu kunoma yisiphi isikhungo sokukhiqiza.

Inzuzo yesicelo

Ngaphezu kokunemba okwandisiwe kanye nokusebenza kahle kwezindleko, izinhlelo zokulandelela umthungo ziletha izinzuzo ezibalulekile enqubweni yokushisela. Isibonelo, ingafeza ukulungiswa okuhlakaniphile kohlelo lokushisela, ngaleyo ndlela ithuthukise kakhulu ukusebenza kahle kokukhiqiza kanye nekhwalithi yokushisela. Uhlelo lungamukela izinguquko emsebenzini, njengemithungo engahlelekile noma ukungalungi okuncane. Lokhu kuguquguquka kwenza inqubo yokushisela ibe lula futhi ithembeke kakhudlwana, iqinisekisa ukushisela okuhambisanayo nokusezingeni eliphezulu njalo.

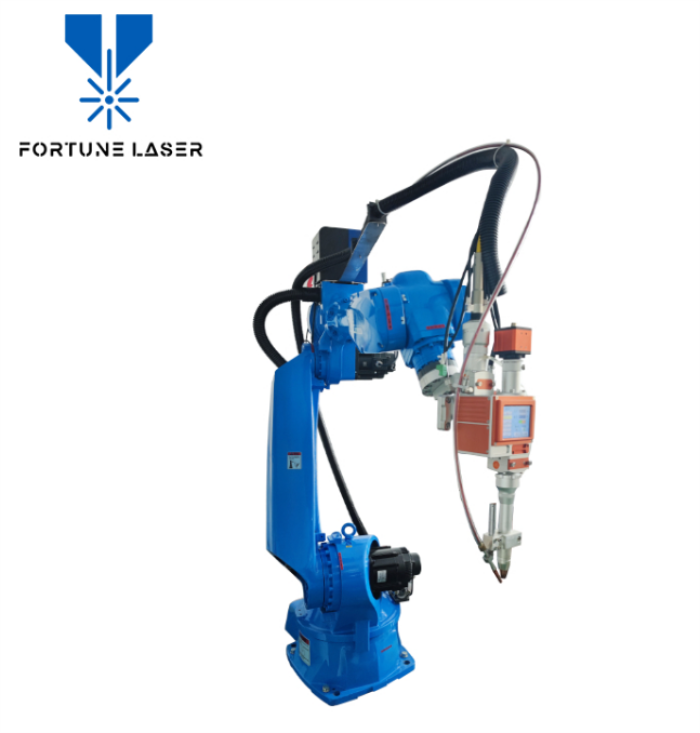

Enye inzuzo yesistimu yokulandelela umthungo yikhono layo lokusebenza namarobhothi. Ngokuhlanganisa izinhlelo zokulandelela umthungo we-laser kuukushisela kwerobhothiNgokusebenzisa amasethingi, abakhiqizi bangathuthukisa kakhulu ikhwalithi yokushisela kanye nokukhiqiza. Ngaphansi kwesiqondiso sohlelo lokulandelela umthungo, irobhothi lingakwazi ukulandelela ngokunembile umthungo futhi libeke ngokunembile umthungo we-laser, ukuze kufezwe ukushisela okusezingeni eliphezulu okuqhubekayo. Ngaphezu kwalokho, ukusetshenziswa kwamarobhothi kuqeda isidingo somsebenzi wezandla futhi kunciphisa ingozi yamaphutha abantu, okwandisa ukusebenza kahle kwenqubo yokushisela.

Thuthukisa ikhwalithi yokushisela futhi unciphise isikhathi sokusebenza kabusha

Omunye wemiphumela efiseleka kakhulu yanoma iyiphi inqubo yokushisela ukufeza ukushisela kwekhwalithi ephezulu okungadingi ukulungiswa kabusha. Izinhlelo zokulandelela umthungo zidlala indima ebalulekile kulokhu. Ngokuqinisekisa ukubekwa okunembile kwe-laser, uhlelo lunciphisa ingozi yokulungiswa kabusha ngenxa yeziphambeko zokushisela. Lokhu akugcini nje ngokusindisa isikhathi, kodwa futhi kunciphisa nezindleko ezihlobene nokulungiswa kabusha, njengomsebenzi owengeziwe kanye nezinto zokwakha. Ngosizo lwezinhlelo zokulandelela umthungo, abakhiqizi banganciphisa iziphambeko zokushisela, ngaleyo ndlela bathuthukise ikhwalithi yokushisela iyonke.

Ngaphezu kwalokho, izinhlelo zokulandelela umthungo zisiza ukunciphisa isikhathi esidingekayo sokusebenza kabusha. Njengoba zikhiqiza ukushibilika okunembile nokungaguquguquki, akukho ukulungiswa noma ukulungiswa okudingekayo ngemva kokuba ukushibilika kokuqala sekuqediwe. Lokhu kusindisa isikhathi nomzamo, okuvumela abakhiqizi ukuthi babelane ngezinsizakusebenza kahle futhi bahlangabezane nezinhlelo zokukhiqiza eziqinile. Uhlelo lokulandelela umthungo lwenza inqubo yokushibilika ibe lula, luqede ukubambezeleka okungadingekile, futhi lwandise umkhiqizo.

Khulisa umkhiqizo

Ukuhlanganisa uhlelo lokulandelela umthungo we-laser kanye nokusetha kwe-robotic welding kungakhuphula kakhulu umkhiqizo. Inhlanganisela yeukuzenzekela kwerobhothikanye nokubekwa kwe-laser okunembile akugcini nje ngokunciphisa isikhathi esidingekayo sokusebenza kabusha, kodwa futhi kwandisa isivinini senqubo yokushisela. Ngokuqeda umsebenzi wezandla, abakhiqizi bangafinyelela imigqa yokukhiqiza esheshayo nephumelelayo kakhudlwana.

Ngaphezu kwalokho, uhlelo lokulandelela umthungo luqinisekisa ukushintshwa okulinganayo nokusezingeni eliphezulu kuyo yonke inqubo yokukhiqiza. Lokhu kuqeda isidingo sokuqapha nokulungisa njalo, njengoba uhlelo luqhubeka nokulandelela nokulungisa umsebe we-laser ngesikhathi sangempela. Lokhu kuvumela opharetha ukuthi bagxile kweminye imisebenzi, okwandisa umkhiqizo. Ngemishini yokushintshwa kwe-laser efakwe izinhlelo zokulandelela umthungo, abakhiqizi bangenza ngcono izinsiza, bandise umkhiqizo futhi bahlangabezane nezidingo zamakhasimende ngendlela ephumelelayo.

Ekuphetheni, uhlelo lokulandelela umthungo lomshini wokushisela we-laser lunezinzuzo eziningi, ezingathuthukisa ukusebenza kahle kokukhiqiza kanyeukushiselaikhwalithi. Kusukela ekubekweni kwe-laser okunembile kuya ezinqubweni zokukhiqiza ezithuthukisiwe, uhlelo luqinisekisa ukushintshwa okunembile nokungaguquguquki ngenkathi kunciphisa isikhathi sokusebenza kabusha kanye nezindleko. Uma kuhlanganiswa namayunithi okushintshwa kwamarobhothi, izinhlelo zokulandelela umthungo we-laser zingathuthukisa ukusebenza kahle, okuvumela abakhiqizi ukwandisa ukukhiqizwa futhi bahlangabezane nezidingo zamakhasimende ngempumelelo enkulu. Ngokutshala imali emshinini wokushintshwa kwe-laser onesistimu yokulandelela umthungo, abakhiqizi bangalindela ukuthuthukisa ikhwalithi yokushintshwa, bandise ukusebenza kahle kwezindleko, futhi bathuthukise ukukhiqiza okuphelele.

Uma ufuna ukufunda kabanzi ngokushisela nge-laser, noma ufuna ukuthenga umshini wokushisela nge-laser ongcono kakhulu kuwe, sicela ushiye umlayezo kuwebhusayithi yethu bese usithumelela i-imeyili ngqo!

Isikhathi sokuthunyelwe: Julayi-08-2023