Ama-alloy e-aluminium asetshenziswa kabanzi ezimbonini ze-semiconductor kanye ne-microelectronics ngenxa yezakhiwo zawo ezinhle zomzimba nezamakhemikhali kanye nezakhiwo ezinhle kakhulu zemishini. Njengoba imikhiqizo yezimboni yesimanje ithuthuka ibe namandla aphezulu, ilula, kanye nokusebenza okuphezulu, izindlela zokusika nge-laser ye-aluminium alloy nazo ziyathuthuka zibe ukunemba, ukusebenza kahle, kanye nokuguquguquka. Ukusika nge-laser kunezinzuzo zomngxunya wokusika omncane, indawo encane ethintekile ekushiseni, ukusebenza kahle okuphezulu, kanye nokungabi nokucindezeleka kwemishini emaphethelweni okusika. Sekuyindlela ebalulekile yokucubungula ngokunemba kwama-alloy e-aluminium.

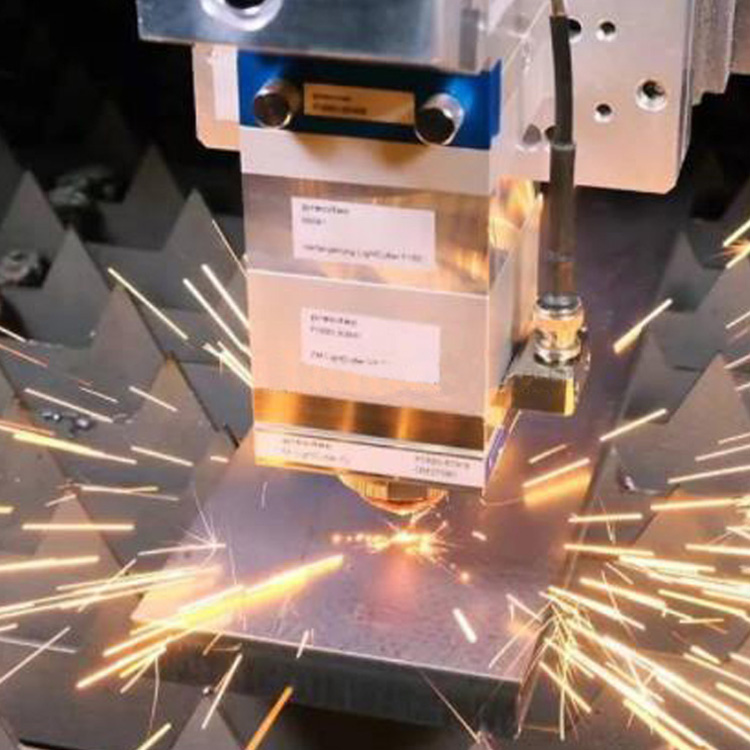

Ukusika kwe-laser okukhona nge-aluminium alloy ngokuvamile kusebenzisa ikhanda lokusika kanye negesi elisizayo. Indlela esebenza ngayo ukuthi i-laser igxile ngaphakathi kwe-aluminium alloy, i-gasification enamandla aphezulu incibilikisa i-aluminium alloy, kanti igesi elisizayo elinomfutho ophezulu liphephula izinto ezincibilikisiwe.

Le ndlela yokusika isebenzisa kakhulu ama-laser amabili anama-wavelength angaba ngu-10640nm kanye no-1064nm, womabili angaphansi kobubanzi bama-wavelength e-infrared. Ukuze kusikwe ngokunembile amashidi e-aluminium alloy anokunemba kosayizi wokusika ezingeni le-micron, ngenxa yendawo yayo enkulu yokukhanya nendawo enkulu ethintekile ekushiseni, kulula uku-Slag kanye nokuqhekeka okuncane kwenzeka emphethweni wokusika, okugcina kuthinta ukunemba kanye nomphumela wokusika.

Uhlelo lokusika lwe-laser oluxutshwe nge-aluminium kanye nendlela yokwenziwa kwalolu hlelo kwenza ukusika kwengxenye yokusebenza okumelwe inqunywe ngendlela engathintani ngokusebenzisa ububanzi obuncane bokushaya kanye nobude obufushane bomsebe we-laser, kugwenywe ukulahlekelwa ukucindezeleka kokuxhumana kwengxenye yokusebenza okumelwe inqunywe ngezindlela zemishini, futhi ngesikhathi sokusika. Ngesikhathi sokucubungula, izinkinga ezifana nokuqhekeka okuncane kanye nokulenga kwe-slag kubangelwa indlela yokucubungula ukushisa; ngokusebenzisa isithako esithile ukulungisa ingxenye yokusebenza okumelwe inqunywe ngokuvundlile, ngenkathi kugcinwa indawo yokuqhekeka emoyeni, indawo yokusika yengxenye yokusebenza okumelwe inqunywe isekelwa kusukela ngemuva ukuze ivimbele ukuthi iwe ngesikhathi sokusika. Ikhiqiza ukucindezeleka ukuze ibhubhise umphumela wokusika; isebenzisa amanzi apholile ajikelezayo kudivayisi yethangi lamanzi ukupholisa ingxenye yokusebenza okumelwe inqunywe, inciphisa umthelela wokushisa ezintweni ezizungezile, futhi ithuthukise kakhulu ikhwalithi yokusika; inquma inhlanganisela yezindlela eziningi zokusika ukuze yandise umthungo wokusika. Ububanzi buthuthukisa ukusebenza kahle kokusika.

Izindlela ezingenhla ziyizindlela ezikhethwayo zokusebenzisa, kodwa ukusetshenziswa akukhawulelwe yizindlela ezingenhla. Noma yiziphi ezinye izinguquko, izinguquko, ukushintsha, ukuhlanganiswa, kanye nokwenza lula okungaphambuki emoyeni nasezimisweni kufanele kwenziwe kanje. Izindlela zokufaka esikhundleni ezisebenzayo zonke zifakiwe emkhakheni wokuvikela izindlela zokusika nge-laser ze-aluminium alloy.

Isikhathi sokuthunyelwe: Meyi-23-2024