Emakethe eqhutshwa ukusungula izinto ezintsha kanye nokusebenza kahle,ukushisela nge-laserinikeza izinkampani zefenisha yensimbi inzuzo ehlukile ngokuthuthukisa inzuzo, ukuqina, kanye nekhwalithi yokubonakala.

Ubuchwepheshe bukhiqiza ukushintshwa okunembe kangangokuthi kudinga ukuqedwa okuncane, okuyisihluthulelo salokhu kuthuthukiswa. Lokhu kuholela emijikelezweni yokukhiqiza esheshayo, izindleko eziphansi zabasebenzi, kanye nenkululeko enkulu yokuklama, okuvumela ukudalwa kwefenisha eqinile futhi ecwengekile ngobuhle ngenkathi kuthuthukiswa ukusebenza kahle kokukhiqiza.

Umklamo Ongenamingcele: Umthelela Wokushisela Nge-Laser kuIfenisha

Izindlela zokushisela zendabuko zazivame ukuphoqa abaklami ukuba bavumelane. Ukushisela okubonakalayo, okukhulu kwakudingeka kufihlwe noma kwamukelwe njengengxenye yokubukeka. Ukushisela nge-laser kuyayiqeda leyo mingcele.

Ukufeza Iphupho Elincane Ngokusebenzisa Ama-Weld Angabonakali

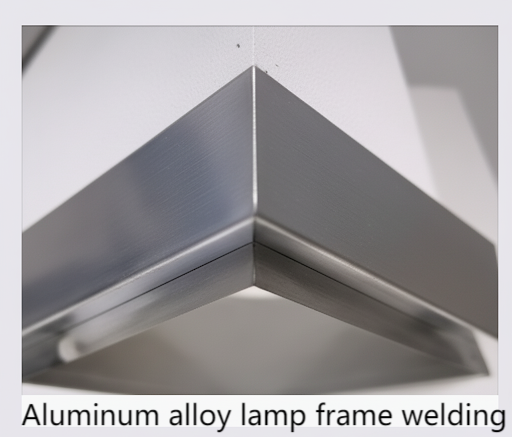

Umklamo wefenisha yesimanje uyachuma ngemigqa ehlanzekile kanye nobuhle obuncane. Ukushisela nge-laser kungumlingani ofanele kakhulu kulo mkhuba. Kwakha amajoyinti abushelelezi kakhulu, angenamthungo afanele ifenisha esezingeni eliphezulu lapho ukushisela okubonakalayo kungamukeleki khona. Umphumela uba umkhiqizo obukeka sengathi wenziwe ngensimbi eyodwa.

Ukwakha Amaphethini Ayinkimbinkimbi Namajiyometri

Wake wafuna ukudala izinsimbi zokuhlobisa ezithambile neziyinkimbinkimbi? Ukunemba kogongolo lwe-laser kwenza kube nokwenzeka. Lobu buchwepheshe buvumela ukwenziwa kwamaphethini ayinkimbinkimbi kanye nezimo zejiyometri ezingenakwenzeka ngezindlela zendabuko, ezivame ukubangela ukuphazamiseka kokushisa futhi zonakalise imininingwane emincane.

Ukuqamba Izinto Ezixubile Ngefenisha

Ukufakwa kokushisa okuphansi kwenqubo yokushisela nge-laser kungenye inzuzo enkulu. Lokhu kuvumela insimbi ukuthi ishiselwe eduze kakhulu nezinye izinto ezifana nokhuni, ingilazi, noma upholstery ngaphandle kokulimaza. Lokhu kuvula umhlaba omusha wemiklamo yefenisha emisha, exubile.

Ukukhetha Okucacile: Kungani Ukushisela Nge-Laser Kuphumelela Kakhulu Emasu Endabuko

Uma kukhulunywa ngokukhiqiza ifenisha yensimbi, ukukhetha phakathi kokushisela nge-laser kanye nezindlela zendabuko ze-MIG noma ze-TIG kuya ngokuya kucaca.

Isivinini kanye Nokusebenza Okuphezulu

Isikhathi siyimali efektri. Ukushisela nge-laser kushesha ngokuphindwe kayishumi kunezindlela zendabuko. Lesi sivinini esimangalisayo sinciphisa kakhulu isikhathi sokukhiqiza ngengxenye ngayinye, sikhulisa umkhiqizo wakho wonke, futhi senza imikhiqizo ithengiswe ngokushesha.

Ikhwalithi Nokuqeda

Khohlwa izinyathelo zesibili ezithatha isikhathi zokugaya, ukusanta, kanye nokupholisha. Ukushisela nge-laser kukhiqiza ukushisela okune-spatter encane kanye nendawo encane kakhulu ethintekile ekushiseni (HAZ). Lokhu kusho ukuthi umkhiqizo oqediwe uphuma emgqeni cishe uphelele, ususa izindleko ezibizayo nezidinga umsebenzi omkhulu ngemuva kokucutshungulwa.

Amandla Nokunemba

Ungavumeli ukubukeka okuhlanzekile kukukhohlise; lawa ma-weld aqine kakhulu. Ama-weld ajulile, amancane adalwe yi-laser avame ukuba namandla kunezinto eziyinhloko ngokwazo. Inqubo nayo inembe kakhulu, okunciphisa ukuphambuka kwezinto kanye nokuchithakala kwazo.

Ukuqhathanisa Indlela Yokushisela: I-Laser vs. MIG vs. TIG

| I-Metric | Ukushisela nge-laser | Ukushisela kwe-MIG | Ukushisela kwe-TIG |

| Isivinini | Phezulu Kakhulu | Phezulu | Kancane kancane |

| Ukunemba | Okungavamile | Okumaphakathi | Phezulu |

| Ikhwalithi Yokuqeda | Kuhle kakhulu (Akunamthungo) | Okulungile (Kudinga Ukugaywa) | Kuhle (Kudinga Ukuhlanzwa) |

| Ngemva Kokucubungula | Okuncane kuya Kokungekho | Okubanzi | Okumaphakathi |

| Ikhono Lokusebenzal | Kulula Ukufunda | Okumaphakathi | Phezulu |

| Izindleko Zokuqala | Phezulu | Phansi | Phansi |

Kusukela Kumafreyimu Kuya Ku-Filigree: Izicelo Zokushisela Nge-Laser Zangempela

Ngakho-ke, lobu buchwepheshe busebenza kanjani emikhiqizweni yakho yangempela? Nazi ezinye izibonelo ezisebenzayo:

Izingxenye Zesakhiwo:Hlanganisa kalula ozimele, imilenze, kanye nezisekelo zamatafula nezihlalo ngamandla aphezulu kanye nokuvumelana okuphelele njalo.

Imisebenzi Yensimbi Yokuhlobisa:Dala ukushintshwa okuhle nokunemininingwane ezintweni zokuhlobisa, njengezinsika zezihlalo ezinephethini noma izisekelo zamatafula obuciko, okugcina inani eliphelele lobuhle.

Izinto Ezincane Namakhabethe:Hlanganisa insimbi encane egawuni lamakhabethe, amalokha, namaphaneli ngaphandle kokugoba noma ukusha okuvamile kwezinye izindlela.

Lezi zinhlelo zokusebenza zibonisa ukuthi kungakhathaliseki ukuthi umsebenzi udinga ubuqotho besakhiwo noma imininingwane yokuhlobisa eyinkimbinkimbi, ukushisela nge-laser kuyisisombululo esivumelana nezimo. Kuvula umnyango wamathuba amasha okuklama kanye nezinga eliphezulu lekhwalithi, okuqinisekisa ukuthi imikhiqizo yakho ayakhelwe ukuhlala isikhathi eside kuphela kodwa futhi yenziwe ngendlela ephelele.

Vula Amandla Okushisela Nge-Laser: Izihluthulelo Ezintathu Zokuqala Okungenaphutha

Ukwamukela ukushisela nge-laser kuyindlela enamandla yokuthuthukisa amakhono akho okukhiqiza. Ukuze usebenzise amandla ayo aphelele kusukela osukwini lokuqala, hlanganisa lezi zimiso eziyisisekelo emsebenzini wakho wokusebenza.

Ukunemba kuyisisekelo sokusebenza kahle

Ukunemba okumangalisayo kokushisela nge-laser kuqala isikhathi eside ngaphambi kokuba kusebenze ugongolo. Kuncike ekuhlanganisweni okuphelele phakathi kwezingxenye. Ngokulungisa izinqubo zakho zokusika nokwakha ezingenhla ukuze ukhiqize izingxenye ezinezikhala ezincane, ubeka isiteji sokushisela okuqinile, okuhlanzekile, nokungaguquguquki.

Ubumsulwa Buvula Amandla

Ubuso obuhlanzekile bubalulekile ukuze kube nokushibilika okuphelele. Noma yiliphi i-oyili, ukungcola, noma ngisho nengqimba ye-oxide yemvelo ku-aluminium ingaletha amaphutha futhi ibeke engcupheni ubuqotho bejoyinti. Ukufaka isinyathelo sokuhlanza nokulungiselela esiyimpoqo kuqinisekisa ukuthi i-laser idala umthungo omsulwa, onamandla, futhi ophelele ngaso sonke isikhathi.

Isiko Lokuphepha Liholela Empumelelweni

Ama-laser anamandla aphezulu adinga indlela yokubhekana nokuphepha. Ukuvikela ithimba lakho kuyinto eza kuqala kuwe. Lokhu kusho ukuklama indawo ephephile enezindawo zokusebenza ezizinikele, ezivalekile, ukuphatha ikhwalithi yomoya ngokukhipha intuthu ngempumelelo, nokuhlomisa wonke umuntu endaweni ngezibuko zamehlo eziqinisekisiwe eziphephile nge-laser. Ukusebenza okuphephile kuyindlela ephumelelayo neqhubekayo.

Ukuhlala Uhamba Phambili Kwejika: Ikusasa Lokushisela Okuzenzakalelayo

Ubuchwepheshe busathuthuka, bucindezela imingcele yalokho okungenzeka ekukhiqizeni ifenisha yensimbi.

Ukuvela Kwamarobhothi Nama-Cobot

Ukuzenzakalela kwenza ukushisela nge-laser kusebenze kahle nakakhulu. Ukuhlanganisa abashiseli be-laser nezingalo zamarobhothi kanye namarobhothi asebenzisanayo (ama-cobot) kuvumela ukukhiqizwa okungu-24/7 ngokuhambisana okungenakuqhathaniswa, okwenza ubuchwepheshe butholakale kalula kubakhiqizi babo bonke osayizi.

Ukukhiqiza Okuhlakaniphile nge-AI kanye nokufunda komshini

Ikusasa lihlakaniphile. Ngokusho kwemibiko yakamuva yemboni, i-AI kanye nokufunda komshini kuhlanganiswa ezinhlelweni zokushisela ukuze kulawulwe ikhwalithi ngesikhathi sangempela, izexwayiso zokulungisa okubikezelayo, kanye nokwenza ngcono inqubo ngokuzenzakalelayo, ukuqinisekisa ukuthi yonke i-weld iphelele.

Isahluko Esisha Ekukhiqizeni Ifenisha

Ngamafuphi, ukushisela nge-laser kungaphezu nje kwethuluzi elisha. Kuwutshalomali olunesu olunikeza ikhwalithi yobuhle engenakuqhathaniswa, isivinini sokukhiqiza, kanye nenkululeko yokuklama. Kukunika amandla okuletha imikhiqizo emihle kakhulu ebonakala kahle enezithungo ezingabonakali, uyikhiqize ngesivinini esidlula abancintisana nabo, futhi unikeze abaklami bakho inkululeko yokudala yokuqamba izinto ezintsha ngaphandle kokuvinjelwa. Leli yithuba lakho lokuthola isikhundla esiphambili embonini yefenisha.

Ake sikubonise izinzuzo ezibonakalayo zomkhiqizo wakho. Xhumana nochwepheshe bethu bokukhiqiza ukuze uthole ukubonisana komuntu siqu bese uthatha isinyathelo sokuqala esiya esikhathini esizayo sefenisha.

Isikhathi sokuthunyelwe: Agasti-28-2025