Ukuhlanza nge-laser kuyindlela yesimanje yokuhlanza izindawo. Lobu buchwepheshe obumangalisayo busebenzisa imisebe enamandla ye-laser ukususa ukungcola, upende omdala, kanye nokugqwala ezintweni ezahlukene ngendlela elawulwa kakhulu futhi enembile. I-laser ishaya izinto ezingafuneki. Uma lokhu kwenzeka, ukungcola noma uqweqwe luphenduka umhwamuko noma luqhekeke ebusweni ngoba i-laser iyenza ishise futhi ikhule ngokushesha okukhulu. Ukuhlanza nge-laser kungcono endaweni ezungezile kunezindlela zokuhlanza ezindala. Lobu buchwepheshe bungahlanza izinto kahle kakhulu ngaphandle kokulimaza okungaphansi.

Izimboni eziningi ezahlukene manje zisebenzisa ukuhlanza nge-laser ukwenza umsebenzi wazo. Izinkampani ezenza izindiza, izimoto, izinto zikagesi, ngisho nabantu abalungisa izinto ezindala zomlando bathole ukuthi ama-laser alungele ukuhlanza. Le ndlela isebenza kahle kakhulu ekuhlanzeni imishini yokwenza amathayi. Izisebenzi ziyisebenzisela futhi ukususa upende ezindizeni nokuhlanza ngokucophelela izingcezu ezindala zemyuziyamu ezidinga ukunakekelwa okukhethekile.

Ngaphambi kokuhlanza nge-laser, abantu babesebenzisa ezinye izindlela eziningana zokuhlanza izinto:

1. Ukuqhuma kwesihlabathi kususa izingcezu ezincane zesihlabathi ngesivinini esikhulu ukuze kuhlanzwe izindawo. Nakuba le ndlela isebenza kahle, ingaklwebha izinto futhi idale uthuli olungaphefumuli kahle.

2. Ukuhlanza ngamakhemikhali kusebenzisa uketshezi olukhethekile ukuphula ukungcola. La makhemikhali angalimaza imvelo futhi ngezinye izikhathi alimaze izinto ezihlanzwayo.

3. Ukuhlanza nge-ultrasonic kudala amabhamuza amancane kusetshenziswa amaza omsindo ongawezwa. Le ndlela emnene isebenza kahle ezintweni ezincane, ezithambile kodwa ayisebenzi ekuhlanzeni izinto ezinkulu.

4. Ukuhlanza iqhwa okomile kusebenzisa imishini ekhethekile ukudubula i-carbon dioxide eqandisiwe ezindaweni ezingcolile. Le ndlela ayishiyi nkinga ngemuva, kodwa ukusebenzisa imishini kubiza imali eningi.

Ukuhlanza nge-laser kunezinzuzo eziningi uma kuqhathaniswa nezinye izindlela zokuhlanza. Lezi zici eziwusizo zikwenza kuvelele njengokukhetha okungcono kwemisebenzi eminingi yokuhlanza:

Ukusebenzisa ama-laser kusho ukuthi akukho lutho oluthinta indawo ehlanzwayo. Ukukhanya kwe-laser kususa ukungcola kanye nezingubo ezindala ngaphandle kokuklwebha noma ukulimaza okungaphansi, okwenza kube kuhle kakhulu ekuhlanzeni izinto ezibalulekile. Le ndlela ayisebenzisi noma yimaphi amakhemikhali ayingozi. Njengoba kungekho mfucuza eyingozi edalwayo, ukuhlanza nge-laser kusiza ekuvikeleni indawo esizungezile.

Ama-laser angahlanza izindawo ezithile ngokunemba okukhulu. Inqubo yokuhlanza igcina imali ngokuhamba kwesikhathi ngoba isebenzisa izinto ezimbalwa futhi idinga abasebenzi abambalwa ukuze umsebenzi uqedwe.

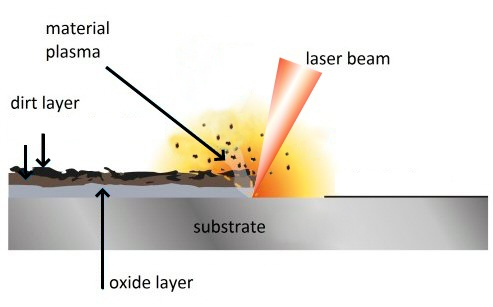

Zisebenza kanjani izihlanzi ze-laser? Lapho ukukhanya kwe-laser kushaya ukungcola noma ukugqwala, izinto ezingafuneki zimunca amandla e-laser. Lokhu kwenza ukungcola kuqhekeke, kuphenduke umhwamuko, noma kushe ngokushesha. Abantu abasebenzisa i-laser bangakwazi ukulungisa ukuthi inamandla kangakanani nokuthi isebenza isikhathi esingakanani ukuze bathole imiphumela emihle kakhulu.

Kunezindlela ezimbili eziyinhloko zokuhlanza nge-laser:

1. Indlela yokuqala isebenzisa i-laser kuphela. Ukuqhuma okusheshayo kokukhanya kwe-laser kushaya indawo engcolile, okwenza ukungcola kushise futhi kuphume noma kuthuthumele ngenxa yokudlidliza okuncane. Le ndlela isebenza kahle emisebenzini enzima yokuhlanza.

2. Indlela yesibili iqala ngokubeka ungqimba oluncane loketshezi phezu kobuso. Lapho i-laser ishaya lo mbala omanzi, iguqula uketshezi lube umhwamuko ngokushesha kangangokuthi idala ukuqhuma okuncane. Lokhu kuqhuma okuncane kusiza ukususa ukungcola ngaphandle kokulimaza izindawo ezibucayi ezingase zonakaliswe ukukhanya kwe-laser okuqondile.

· Imboni Yezingcezu Zekhompyutha Neze-elekthronikhi Ukwenza izingcezu zekhompyutha kudinga izimo ezihlanzekile kakhulu. Ukungcola okuncane kakhulu kungonakalisa lezi zingxenye ze-elekthronikhi ezibucayi, ngakho abakhiqizi basebenzisa ukuhlanza nge-laser ukususa izinhlayiya ezincane ngaphandle kokubangela umonakalo. Lokhu kusiza ukugcina umugqa wokukhiqiza usebenza kahle. Amathuluzi akhethekile afana nama-laser aqinisekisa ukuthi yonke indawo ihlanzekile ngokuphelele, okusiza izingcezu ukuthi zihlale isikhathi eside.

· Ama-Laser Okwelapha Insimbi alungele ukuhlanza insimbi. Ngaphambi kokuba abapendi noma abashiseli bakwazi ukusebenza ezindaweni zensimbi, badinga ukususa ukugqwala, ukungcola, kanye nezingubo ezindala besebenzisa imisebe enamandla ye-laser esusa izinto ezingafuneki ngaphandle kokulimaza insimbi engaphansi. Le ndlela isebenza kahle kakhulu ekuhlanzeni izindiza, izimoto, kanye nemikhumbi, lapho ukuba nezindawo ezihlanzekile kubaluleke kakhulu ekuphepheni nasekhwalithini.

· Izimboni Zezindiza Nezimoto Izindiza zidinga ukunakekelwa okukhethekile lapho zihlanzwa. Ukuhlanza nge-laser kusiza abasebenzi ukususa ngokuphephile upende omdala kanye nokungcola ezingxenyeni zezindiza ngaphandle kokwenza insimbi ibe buthaka, okungaba yingozi uma kwenziwa ngendlela engalungile. Imboni yezimoto isebenzisa nama-laser ukuhlanza isikhunta samasondo, ukwenza ama-weld angcono, kanye nokususa ukungcola ezingxenyeni ezibalulekile zenjini ngendlela esheshayo nephephile.

· Ukulondolozwa Kobuciko Nomlando Ubuciko obudala budinga ukuhlanzwa ngobumnene ukuze buhlale busesimweni esihle. Izisebenzi zasemnyuziyamu zisebenzisa ama-laser ukususa ngokucophelela ukungcola kanye nomonakalo ohlobene nokuguga okuvela ezifanekisweni ezindala kanye nemidwebo ngaphandle kokufaka engozini ukulimala kwalezi zinto eziyigugu. Le ndlela yokuhlanza ngokucophelela isize ekusindiseni imisebenzi eminingi yobuciko obudala okungenzeka ukuthi yonakaliswe izindlela zokuhlanza ezinzima.

· Amafektri Omsebenzi Wasefektri asebenzisa ukuhlanza nge-laser ukugcina imishini yawo isebenza kahle. Le ndlela yokuhlanza yesimanje isiza ukususa amafutha nokungcola ngokushesha, okusho ukuthi imishini akudingeki ihlale ivaliwe isikhathi eside ngesikhathi sokuhlanza. Izisebenzi zingahlanza izingxenye ngempumelelo ngama-laser, okusiza imishini ukuthi isebenze kangcono futhi ihlale isikhathi eside.

Ubuchwepheshe Bokuhlanza Nge-Laser: Izinzuzo

Ukuhlanza nge-laser kushintsha indlela esihlanza ngayo izinto ezimbonini eziningi ezahlukene namuhla. Kusebenzisa imisebe enamandla yokukhanya ukususa ukungcola, ukugqwala, nezinye izinto ezingafuneki ezindaweni. Le ndlela entsha yokuhlanza isiza ekuvikeleni indawo yethu ngokungadali noma yimuphi udoti oyingozi. Ubuchwepheshe busebenza ngokubhekisa ngokucophelela ukungcola kuphela ngenkathi bushiya indawo engaphansi iphephile ngokuphelele.

Izinkampani zingonga imali ngokuhlanza nge-laser ngokuhamba kwesikhathi. Ukufaka imishini kubiza kakhulu ekuqaleni, kodwa amabhizinisi ngeke kudingeke aqhubeke nokuthenga amakhemikhali okuhlanza noma izinto zokwakha ngemva kwalokho. Izisebenzi zihlala ziphephile lapho zisebenzisa ukuhlanza nge-laser esikhundleni samakhemikhali anamandla. Ubuchwepheshe bungasetshenziswa ezintweni eziningi ezahlukene nasezimbonini ezahlukahlukene, kusukela ekuhlanzeni imishini esindayo yasefektri kuya ekubuyiseleni umsebenzi wobuciko odala.

Izinselele Ukuqala ngokuhlanza nge-laser kungaba nzima. Imishini iyabiza, okwenza kube nzima ngezinkampani ezincane ukuyithenga. Ezinye izinto azisebenzi kahle ngama-laser, futhi izinkampani kudingeka zizihlole kuqala. Izisebenzi zidinga ukuqeqeshwa okukhethekile ukuze zisebenzise imishini ngendlela efanele. Ukuhlanza nge-laser nakho kungathatha isikhathi eside kunezindlela zokuhlanza ezivamile lapho kusetshenzwa kumaphrojekthi amakhulu.

Ukubheka Phambili Izinkampani eziningi zifuna izindlela zokusebenza ezihlanzekile neziluhlaza. Izinhlelo zokuhlanza nge-laser ezingcono ziyathuthukiswa ngaso sonke isikhathi. Ukuthuthukiswa okusha kuzokwenza ubuchwepheshe busheshe futhi bube bushibhile ukuzisebenzisa. Lezi zinhlelo zingase zisetshenziswe maduze ezindaweni eziningi, njengokuhlanza imishini yezokwelapha noma ukwenza izingxenye ezincane ze-elekthronikhi.

Ukuphetha Ukuhlanza nge-laser kunikeza indlela entsha nengcono yokuhlanza izinto. Lobu buchwepheshe bunikeza izinkampani ukulawula okwengeziwe futhi kusiza ukuvikela imvelo ngesikhathi esifanayo. Nakuba kunezinkinga ezithile okufanele zixazululwe, ukuhlanza nge-laser kuyaqhubeka nokuba ngcono. Ubuchwepheshe buzovame kakhulu njengoba amabhizinisi amaningi efunda ngezinzuzo zalo.

Izinkampani kufanele zifunde ngokuhlanzwa nge-laser ngaphambi kokunquma ukuyisebenzisa. Njengoba izimboni eziningi zidinga izindlela zokuhlanza ezinembile nezinobungani nomhlaba, lobu buchwepheshe buzoba yinto ebaluleke kakhulu. Ukuhlanzwa nge-laser kuzoqhubeka kuthuthuka futhi kuthola ukusetshenziswa okusha ezimbonini ezahlukene. Lokhu kuthuthuka kuzosiza ekwakheni indlela esihlanza ngayo izinto esikhathini esizayo.

Ukuhlanza nge-laser kuyindlela ewusizo yokusebenzisa ama-laser kwezobunjiniyela. Le ndlela ethuthukisiwe isebenza ngokusebenzisa amandla agxilile e-laser ukufudumala ukungcola nezinto ezingafuneki ezindaweni, okwenza zihlukaniswe ebusweni ngokushisa okusheshayo, ukuncibilika, noma ukuphenduka igesi, okudala umphumela wokuhlanza onamandla ongaphatha izinhlobo eziningi ezahlukene zokungcola nokungcola. Ukuhlanza nge-laser kuyashesha futhi akulimazi imvelo. Lobu buchwepheshe bubonakalise buwusizo ekuhlanzeni isikhunta samathayi, ukususa upende ezindizeni, kanye nokulungisa izinto ezindala ezidinga ukulungiswa ngokucophelela.

Izindlela zokuhlanza ezivamile zifaka phakathi ukuhlikihla ngokomzimba njengokuqhumisa isihlabathi kanye nokuwasha ngokucindezela, ukusebenzisa amakhemikhali, ukusebenzisa amaza omsindo, kanye nokuhlanza ngeqhwa elomile. Lezi zindlela ezahlukene zokuhlanza zisetshenziswa ezimbonini eziningi ezahlukene kanye namabhizinisi namuhla. Ukuqhumisa isihlabathi kungahlanza amabala ensimbi, kusheleleze imiphetho yensimbi erhabaxa, futhi kususe izembozo ezivikelayo emabhodini wesekethe ngokusebenzisa izinhlobo ezahlukene zezinto zokuhlanza. Ukuhlanza ngamakhemikhali kusetshenziswa yonke indawo, kusukela ekususeni uwoyela kanye nokungcola emishinini kuya ekuhlanzeni okuqongelelekile kuma-boilers nasemapayipini kawoyela. Nakuba lezi zindlela zokuhlanza ezindala zisebenza kahle futhi sezisetshenziswe isikhathi eside, zinezinkinga ezithile. Ukuqhumisa isihlabathi kungalimaza izinto ezihlanzwayo, kanti ukuhlanza ngamakhemikhali kungaba kubi emvelweni futhi kungalimaza indawo ehlanziwe uma kungenziwanga kahle.

Ukuhlanzwa nge-laser kushintshe indlela esihlanza ngayo izinto ngokuphelele. Le ndlela entsha isebenzisa amandla agxilile e-laser, ukuqondiswa okuqondile, kanye nokushisa okusheshayo ukuze kutholakale imiphumela engcono kunezindlela zokuhlanza ezindala. Ukuhlanzwa nge-laser kusebenza kangcono kakhulu kunezindlela zendabuko ngezindlela eziningi. Uma uyiqhathanisa nezindlela zokuhlanza ezindala ezisebenzisa amakhemikhali, ukuhlanzwa nge-laser ngeke kulimaze imvelo noma kulimaze indawo ehlanzwayo.

Kuyini ngempela ukuhlanza nge-laser?

Uma ukhomba umsebe we-laser entweni engcolile, ususa izinto ezingafuneki ezindaweni eziqinile noma ngezinye izikhathi eziwuketshezi ngendlela ekhethekile kakhulu. Uma usebenzisa umsebe we-laser obuthakathaka, ushisa ukungcola kuze kube yilapho kuphenduka igesi bese kuntanta. Ukusebenzisa umsebe we-laser oqinile kuguqula izinto ezingafuneki zibe igesi eshisayo kakhulu ebizwa ngokuthi i-plasma, eyisusa ngokuphelele ebusweni.

Izinhlobo zobuchwepheshe bokuhlanza nge-laser

1) Ukuhlanza okomile nge-laser: Ukuhlanza nge-laser okomile yilapho i-laser evunguziwe ikhishwa imisebe ngokuqondile ukuze ihlanze umsebenzi, okubangela ukuthi i-substrate noma izinto ezingcolisayo ezingaphezulu zimunce amandla futhi zikhuphuke izinga lokushisa, okuholela ekukhuleni kokushisa noma ukudlidliza kokushisa kwe-substrate, ngaleyo ndlela kuhlukaniswe lokhu okubili. Le ndlela ingahlukaniswa cishe ngamacala amabili: elilodwa ukuthi izinto ezingcolisayo ezingaphezulu zimunca i-laser futhi zikhule; elinye ukuthi i-substrate imunca i-laser futhi ikhiqize ukudlidliza kokushisa.

2) Ukuhlanza okumanzi nge-laser: Ngaphambi kokuba i-laser evuvukile ikhanyiswe endaweni yokusebenza ezohlanzwa, ifilimu yoketshezi ifakwa ngaphambili ebusweni. Ngaphansi kwesenzo se-laser, izinga lokushisa lefilimu yoketshezi likhuphuka ngokushesha futhi liphele. Ngesikhathi sokushisa, kukhiqizwa igagasi lokushaqeka, elisebenza ezinhlayiyeni ezingcolisayo futhi libangele ukuthi ziwele phansi. Le ndlela idinga ukuthi i-substrate kanye nefilimu yoketshezi kungasabeli, ngakho-ke ububanzi bezinto zokusetshenziswa bunqunyelwe.

Ukusetshenziswa kobuchwepheshe bokuhlanza nge-laser

Ake sixoxe ngokuhlanza ama-computer chips kanye nezingxenye zeglasi ezikhethekile. Lezi zinto zihamba ngezinyathelo ezifanayo lapho zenziwa, ngokusika nokushelela okungashiya izingcezu ezincane zokungcola ngemuva. Lo kungcola kunzima kakhulu ukuwususa futhi kuyaqhubeka nokubuya kungakhathaliseki ukuthi uwuhlanza kangaki. Uma ukungcola kufika kuma-computer chips, ngeke kusebenze kahle noma kuhlale isikhathi eside. Uhlobo olufanayo lokungcola lungabangela izinkinga uma lufika ezingcezwini zeglasi ezikhethekile, okwenza zingacaci futhi ziguge ngokushesha kunalokho okufanele. Ukusebenzisa ama-laser ukuhlanza lezi zingxenye kungazilimaza kalula. Esikhundleni salokho, abantu bathole impumelelo engcono besebenzisa inhlanganisela yezindlela zokuhlanza nge-laser, ikakhulukazi leyo edala amagagasi akhethekile okusunduza ukungcola.

1) Inkambu ye-semiconductor

Ukuhlanzwa kwama-wafer e-semiconductor kanye nama-substrate e-optical Ama-wafer e-semiconductor kanye nama-substrate e-optical anenqubo efanayo enqubweni yokucubungula, okungukuthi, izinto zokusetshenziswa zicutshungulwa zibe yisimo esidingekayo ngokusika, ukugaya, njll. Kule nqubo, kungeniswa ukungcola kwezinhlayiya, okunzima ukuzisusa futhi kube nezinkinga ezinkulu zokungcola okuphindaphindiwe. Ukungcola okusebusweni bama-wafer e-semiconductor kuzothinta ikhwalithi yokuphrinta kwebhodi lesifunda, ngaleyo ndlela kufinyeze impilo yesevisi yama-chip e-semiconductor. Ukungcola okusebusweni bama-substrate e-optical kuzothinta ikhwalithi yamadivayisi e-optical kanye nezingubo, futhi kungabangela amandla angalingani futhi kufinyeze impilo yesevisi. Njengoba ukuhlanza okomile nge-laser kungabangela umonakalo ebusweni be-substrate kalula, le ndlela yokuhlanza ayisetshenziswa kakhulu ekuhlanzweni kwama-wafer e-semiconductor kanye nama-substrate e-optical. Ukuhlanza nge-laser kanye nokuhlanza nge-laser plasma shock wave kunezinhlelo zokusebenza eziphumelela kakhulu kule nsimu.

2) Insimu yezinto zensimbi

Ukuhlanzwa kobuso bezinto zensimbi Uma kuqhathaniswa nokuhlanzwa kwama-wafer e-semiconductor kanye nama-substrate e-optical, izinto ezingcolisayo ezihlanzwa ngokuhlanza ubuso bezinto zensimbi zingaphansi kwesigaba se-macroscopic. Izinto ezingcolisayo ebusweni bezinto zensimbi zifaka kakhulu ungqimba lwe-oxide (ungqimba lokugqwala), ungqimba lopende, uqweqwe, ezinye izinamathiselo, njll., ezingahlukaniswa zibe izinto ezingcolisayo eziphilayo (njengengqimba lopende, uqweqwe) kanye nezinto ezingcolisayo ezingaphili (njengengqimba lokugqwala) ngokuya ngohlobo lwezinto ezingcolisayo. Ukuhlanzwa kwezinto ezingcolisayo ebusweni bezinto zensimbi kuhloswe kakhulu ukuhlangabezana nezidingo zokucubungula noma ukusetshenziswa okulandelayo. Isibonelo, ngaphambi kokushisela izingxenye ze-titanium alloy, ungqimba lwe-oxide oluyi-10um ubukhulu ebusweni bezinto ezisetshenziswayo ludinga ukususwa. Ngesikhathi sokulungiswa kwendiza, uqweqwe lopende lokuqala ebusweni besikhumba ludinga ukususwa ukuze luphinde lufuthwe. Izikhunta zamathayi erabha zidinga ukuhlanzwa njalo ngezinhlayiya zerabha ezinamathiselwe kuzo ukuqinisekisa ukuhlanzeka kobuso ngaleyo ndlela kuqinisekiswe ikhwalithi yamathayi akhiqizwayo kanye nokuphila kwesikhunta. Inani lomonakalo wezinto zensimbi liphakeme kunomkhawulo wokuhlanza we-laser wezinto ezingcolisayo ebusweni bazo. Ngokukhetha i-laser yamandla afanele, umphumela wokuhlanza ongcono ungatholakala.

3) Izinto Eziyigugu Zamasiko

Ukuhlanzwa Kwezinto Eziyigugu Zamasiko Nezindawo Zephepha Izinto eziyigugu zamasiko zensimbi nezetshe zinomlando omude, futhi izinto ezingcolisayo ezifana nokungcola namabala ayinki zizovela ezindaweni zazo. Lezi zinto ezingcolisayo zidinga ukuhlanzwa ukuze kubuyiselwe izinto eziyigugu zamasiko. Iphepha elifana ne-calligraphy nokupenda lizokhula isikhunta futhi lakhe ama-plaque ebusweni balo uma ligcinwe ngendlela engafanele. Lezi zingcwecwe zithinta kakhulu ukubukeka kwasekuqaleni kwephepha, ikakhulukazi ephepheni elinenani eliphezulu lamasiko noma lomlando, okuzothinta ukwamukelwa nokuvikelwa kwalo.

Njengoba izidingo zabantu zokuhlanza okuluhlaza, okunobungani nemvelo, okunembile kakhulu kanye nokusebenza kahle kakhulu zanda, ucwaningo kanye nentuthuko kanye nokusetshenziswa kobuchwepheshe bokuhlanza nge-laser nakho kuye kwathola ukunakwa okukhulu. Njengamanje, ubuchwepheshe bokuhlanza nge-laser busetshenziswe emikhakheni ye-microelectronics, ezokuthutha ngezitimela, ezokuhamba ngezindiza, kanye nokubuyiselwa kwezinsalela zamasiko, kodwa busabhekene nezinselele eziningi zokuthuthukisa izimo zokusetshenziswa, ubukhulu kanye nemiphumela. Ngamafuphi, amathuba okuthuthukiswa kobuchwepheshe bokuhlanza nge-laser abanzi kakhulu. Buzosetshenziswa emikhakheni eminingi esikhathini esizayo, futhi ngokuthuthuka kobuchwepheshe kanye nokwanda kwesabelo semakethe, ubukhulu balo kanye nokuthuthukiswa kwezimboni kuzothuthukiswa kakhulu.

Njengoba izidingo zabantu zokuhlanza okuluhlaza, okunobungani nemvelo, okunembile kakhulu kanye nokusebenza kahle kakhulu zanda, ucwaningo kanye nentuthuko kanye nokusetshenziswa kobuchwepheshe bokuhlanza nge-laser nakho kuye kwathola ukunakwa okukhulu. Njengamanje, ubuchwepheshe bokuhlanza nge-laser busetshenziswe emikhakheni ye-microelectronics, ezokuthutha ngezitimela, ezokuhamba ngezindiza, kanye nokubuyiselwa kwezinsalela zamasiko, kodwa busabhekene nezinselele eziningi zokuthuthukisa izimo zokusetshenziswa, ubukhulu kanye nemiphumela. Ngamafuphi, amathuba okuthuthukiswa kobuchwepheshe bokuhlanza nge-laser abanzi kakhulu. Buzosetshenziswa emikhakheni eminingi esikhathini esizayo, futhi ngokuthuthuka kobuchwepheshe kanye nokwanda kwesabelo semakethe, ubukhulu balo kanye nokuthuthukiswa kwezimboni kuzothuthukiswa kakhulu.

Isikhathi sokuthunyelwe: Feb-13-2025