Konjiniyela, abakhiqizi, kanye nabaphathi bokusebenza, inselele ihlala njalo: indlela yokuhlanganisa izingxenye zensimbi engagqwali ngaphandle kokugoba, ukushintsha kombala, kanye nokunciphisa ukumelana nokugqwala okuhlasela izindlela ezivamile. Isixazululo yilesi:ukushisela insimbi engagqwali nge-laser, ubuchwepheshe obuguqulayo obunikeza isivinini, ukunemba, kanye nekhwalithi engenakuqhathaniswa okungenakufaniswa nokushiswa kwe-TIG kanye ne-MIG kwendabuko.

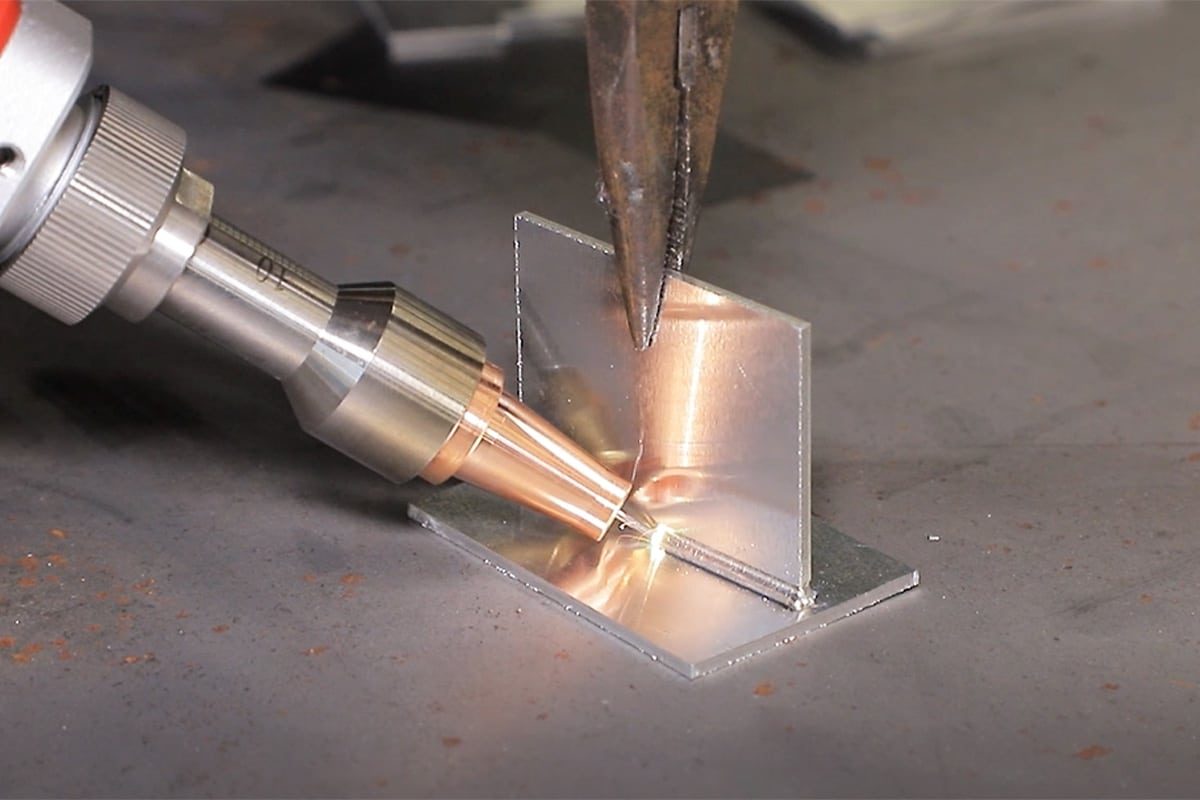

Ukushisela nge-laser kusebenzisa ukukhanya okugxile kakhulu ukuncibilikisa nokuhlanganisa insimbi engagqwali ngokufakwa kokushisa okuncane, okulawulwayo. Le nqubo eqhutshwa ngokunemba ixazulula ngqo izinkinga eziyinhloko zokuphambuka kokushisa kanye nomthamo wokushisela.

Izinzuzo Eziyinhloko Zokushisela Nge-Laser Insimbi Engagqwali:

-

Isivinini Esingavamile:Isebenza ngokushesha okuphindwe kane kuya kweyishumi kune-TIG welding, okwandisa kakhulu umkhiqizo kanye nomphumela.

-

Ukuhlanekezela Okuncane:Ukushisa okugxilile kudala indawo encane kakhulu ethintekile ekushiseni (HAZ), enciphisa noma iqeda ukugoba okukhulu, ilondoloze ukunemba kobukhulu bengxenye.

-

Ikhwalithi Ephakeme:Ikhiqiza ukushibiliza okuhlanzekile, okuqinile, nokujabulisa ubuhle okungadingi ukugaya noma ukuqeda ngemuva kokushibiliza.

-

Izakhiwo Zezinto Ezigciniwe:Ukufakwa kokushisa okuphansi kugcina amandla angaphakathi ensimbi engagqwali kanye nokumelana nokugqwala okubalulekile, kuvimbela izinkinga ezifana "nokubola kokushintshwa".

Lo mhlahlandlela unikeza ulwazi lochwepheshe oludingekayo ukuze usuke ekuqondeni okuyisisekelo uye ekusetshenzisweni okuqinisekile, okuqinisekisa ukuthi ungasebenzisa amandla aphelele ale ndlela yokukhiqiza ethuthukisiwe.

Ukushisela nge-laservs. Izindlela Zendabuko: Ukuqhathanisa Ikhanda Nekhanda

Ukukhetha inqubo efanele yokushisela kubalulekile empumelelweni yephrojekthi. Nansi indlela ukushisela nge-laser okuhlangana ngayo ne-TIG kanye ne-MIG ekusetshenzisweni kwensimbi engagqwali.

Ukushisela nge-Laser vs. Ukushisela nge-TIG

Ukushisela i-Tungsten Inert Gas (TIG) kwaziwa ngokushisela kwekhwalithi ephezulu, okwenziwe ngesandla kodwa kunzima ukuhambisana nesimo sokukhiqiza.

-

Isivinini Nokukhiqiza:Ukushisela nge-laser kushesha kakhulu, okwenza kube ukukhetha okucacile kokukhiqiza okuzenzakalelayo nokukhiqiza ngobuningi obukhulu.

-

Ukushisa Nokuhlanekezela:I-TIG arc ingumthombo wokushisa ongasebenzi kahle, osabalalayo odala i-HAZ enkulu, okuholela ekuphazamisekeni okukhulu, ikakhulukazi ensimbini encane. Ugongolo olugxile ku-laser luvimbela lo monakalo wokushisa osakazekile.

-

Ukuzenzakalela:Izinhlelo ze-laser kulula ukuzenza ngokuzenzakalela, okuvumela ukukhiqizwa okuphezulu nokuphindaphindekayo ngekhono elincane elidingekayo ngesandla kune-TIG.

Ukushisela nge-Laser vs. Ukushisela nge-MIG

Ukushisela i-Metal Inert Gas (MIG) kuyinqubo eguquguqukayo, edinga ukushintshwa okuphezulu, kodwa ayinakho ukunemba kwe-laser.

-

Ukunemba kanye nekhwalithi:Ukushisela nge-laser kuyinqubo engathintani ekhiqiza ukushisela okuhlanzekile, okungenawo ama-splitter. Ukushisela nge-MIG kuthambekele ekushiseni okudinga ukuhlanzwa ngemva kokushisela.

-

Ukubekezelelana Kwezikhala:Ukushisela kwe-MIG kuthethelela kakhulu ukulingana kwamalunga okungekuhle ngoba ucingo lwayo olusetshenziswayo lusebenza njengesigcwalisi. Ukushisela kwe-laser kudinga ukulungiswa okunembile kanye nokubekezelelana okuqinile.

-

Ubukhulu Bezinto:Nakuba ama-laser anamandla amakhulu angaphatha izingxenye ezijiyile, i-MIG ivame ukuba usizo kakhulu kuma-plate asindayo kakhulu. Ukushisela nge-laser kuhamba kahle kakhulu ekujikeni kwezinto ezincane kuya kweziphakathi lapho ukulawulwa kokuhlanekezela kubalulekile khona.

Ithebula Lokuqhathanisa Ngokubuka Nje

| Isici | Ukushisela Ugongolo Lwelaser | Ukushisela kwe-TIG | Ukushisela kwe-MIG |

| Isivinini Sokushisela | Okuphezulu Kakhulu (4-10x TIG)

| Phansi Kakhulu | Phezulu |

| Indawo Ethintekile Ekushiseni (HAZ) | Okuncane / Okuncane Kakhulu | Ububanzi | Ububanzi |

| Ukuhlanekezelwa Kwezimo Ezishisayo | Akunandaba | Phezulu | Okumaphakathi kuya Okuphezulu |

| Ukubekezelelana Kwezikhala | Phansi Kakhulu (<0.1 mm) | Phezulu | Okumaphakathi |

| Iphrofayili Yokushisela | Kuncane Futhi Kujulile | Ubanzi Futhi Awujulile | Ubanzi futhi uyaguquguquka |

| Izindleko Zokuqala Zemishini | Phezulu Kakhulu | Phansi

| Okuphansi kuya Okumaphakathi

|

| Okuhle Kakhulu Kwaba | Ukunemba, isivinini, ukuzenzekela, izinto ezincane

| Umsebenzi wezandla osezingeni eliphezulu, ubuhle

| Ukwenziwa okuvamile, izinto ezijiyile |

Isayensi Engemuva Kokushintshwa: Kuchazwa Izimiso Eziyinhloko

Ukuqonda ukuthi i-laser isebenzisana kanjani nensimbi engagqwali kubalulekile ekuqondeni inqubo. Isebenza ngokuyinhloko ngezindlela ezimbili ezihlukile ezinqunywa ukuminyana kwamandla.

Imodi Yokuqhuba vs. Imodi Yembobo Ekhiye

-

Ukushisela Kokuqhuba:Uma amandla ephansi, i-laser ishisa ubuso bento, bese ukushisa "kuholela" engxenyeni. Lokhu kudala ukushintshwa okungajulile, okubanzi, nokubushelelezi, okulungele izinto ezincane (ngaphansi kuka-1-2 mm) noma imithungo ebonakalayo lapho ukubukeka kubaluleke khona.

-

Ukushisela imbobo yokhiye (Ukungena Okujulile):Uma amandla aphezulu (cishe angu-1.5 MW/cm²), i-laser ishisa insimbi ngokushesha, idale umgodi ojulile, omncane obizwa ngokuthi “i-keyhole.” Le mbobo yokhiye ibamba amandla e-laser, iwayise ngaphakathi kwezinto ukuze kube nokushintshwa okuqinile, okugcwele okungenela ezindaweni ezijiyile.

Igagasi Eliqhubekayo (CW) vs. Ama-Laser Ashukunyiswayo

-

Igagasi Eliqhubekayo (CW):I-laser inikeza umsebe wamandla ongaguquki, ongaphazanyiswa. Le modi ilungele ukudala imithungo emide, eqhubekayo ngesivinini esikhulu ekukhiqizweni okuzenzakalelayo.

-

I-Laser Eshukunyiswayo:I-laser inikeza amandla ngokushesha okukhulu, okunamandla. Le ndlela inikeza ukulawula okunembile kokufakwa kokushisa, inciphisa i-HAZ futhi yenze kube kuhle kakhulu ekushiseni izingxenye ezithambile, ezizwela ukushisa noma ukudala ukushiswa kwamabala okugoqene ukuze kube nesivalo esiphelele.

Umhlahlandlela Wesinyathelo Ngesinyathelo Wokulungiselela Okungenaphutha

Ekushiseni nge-laser, impumelelo inqunywa ngaphambi kokuba ugongolo lusebenze. Ukunemba kwenqubo kudinga ukulungiswa ngokucophelela.

Isinyathelo 1: Ukuklama Nokuhlomisana Kwamalungu

Ngokungafani nokushisela kwe-arc, ukushisela nge-laser akubekezeleli kakhulu izikhala noma ukungalungi kahle.

-

Izinhlobo Zokuhlangana:Amalunga ezinqe yiwona asebenza kahle kakhulu kodwa adinga igebe elicishe libe yi-zero (ngokuvamile lingaphansi kuka-0.1 mm ezigabeni ezincane). Amalunga ezinqe abekezelela kakhulu ukuhlukahluka kokulingana.

-

Ukulawulwa Kwezikhala:Isikhala esiningi sizovimbela ichibi elincane elincibilikisiwe ukuthi lingahlanganisi ijoyinti, okuholela ekuhlanganisweni okungaphelele kanye nokushintshwa okubuthakathaka. Sebenzisa izindlela zokusika ezinembe kakhulu kanye nokubopha okuqinile ukuqinisekisa ukuhambisana okuphelele.

Isinyathelo 2: Ukuhlanza Okungaphezulu Nokususa Izinto Ezingcolile

Amandla amakhulu e-laser azokhipha noma yikuphi ukungcola okungaphezulu, akubambe ku-weld futhi kubangele amaphutha afana nokuvuleka.

-

Ukuhlanzeka Kubalulekile:Ubuso kumele bungabi namafutha, amafutha, uthuli kanye nezinsalela zokunamathela.

-

Indlela Yokuhlanza:Sula indawo yamalunga ngendwangu engenalo ulwelwesi ecwiliswe ku-solvent eguquguqukayo njenge-acetone noma i-99% isopropyl alcohol ngokushesha ngaphambi kokushisela.

Ukuqonda Umshini: Ukuthuthukisa Amapharamitha Okushisela Okuyisihluthulelo

Ukufeza ukushintshwa okuphelele kudinga ukulinganisela iziguquguquko eziningana ezixhumene.

I-Parameter Triad: Amandla, Isivinini, kanye Nesikhundla Sokugxila

Lezi zilungiselelo ezintathu zinquma ndawonye ukufakwa kwamandla kanye nephrofayili yokushisela.

-

Amandla e-Laser (W):Amandla aphezulu avumela ukungena okujulile kanye nesivinini esisheshayo. Kodwa-ke, amandla amaningi angabangela ukusha kwezinto ezincane.

-

Isivinini Sokushisela (mm/s):Isivinini esisheshayo sinciphisa ukufakwa kokushisa kanye nokuphambuka. Uma isivinini siphezulu kakhulu ezingeni lamandla, kungabangela ukungena okungaphelele.

-

Indawo Yokugxila:Lokhu kulungisa usayizi webala le-laser kanye nobuningi bamandla. Ukugxila ebusweni kudala ukushibilika okujulile nokuncane kakhulu. Ukugxila ngaphezu kobuso (i-defocus enhle) kudala ukushibilika kwezimonyo okubanzi nokungajulile. Ukugxila ngaphansi kobuso (i-defocus engemihle) kungathuthukisa ukungena kwezinto ezijiyile.

Ukukhethwa Kwegesi Yokuvikela: I-Argon vs. I-Nitrogen

Igesi yokuvikela ivikela ichibi lokushisela elincibilikisiwe ekungcolisweni komoya futhi izinzisa inqubo.

-

I-Argon (Ar):Ukukhetha okuvame kakhulu, okunikeza isivikelo esihle kakhulu futhi kukhiqiza ama-weld aqinile nahlanzekile.

-

I-nitrogen (N2):Ngokuvamile ikhethwa ngensimbi engagqwali, njengoba ingathuthukisa ukumelana nokugqwala kwejoyinti lokugcina.

-

Izinga Lokugeleza:Izinga lokugeleza kumele lilungiswe. Okuncane kakhulu kuzohluleka ukuvikela ukushintshwa, kuyilapho okuningi kakhulu kungadala isiyaluyalu futhi kudonsele ukungcola. Izinga lokugeleza lamalitha ayi-10 kuya kwangu-25 ngomzuzu (L/min) liyibanga elijwayelekile lokuqala.

Amaphuzu Okuqala Epharamitha: Ithebula Lokubhekisela

Okulandelayo yizindawo zokuqala zokushisela insimbi engagqwali ye-austenitic engu-304/316. Njalo yenza izivivinyo ezintweni ezilahliwe ukuze ulungise ukusetshenziswa kwakho okuthile.

| Ubukhulu Bezinto (mm) | Amandla e-Laser (W) | Isivinini Sokushisela (mm/s) | Indawo Yokugxila | Igesi Yokuvikela |

| 0.5 | 350 – 500 | 80 – 150 | Ngaphezulu | I-Argon noma i-Nitrogen |

| 1.0 | 500 – 800 | 50 – 100 | Ngaphezulu | I-Argon noma i-Nitrogen |

| 2.0 | 800 – 1500 | 25 – 60 | Ngaphansi kancane kobuso | I-Argon noma i-Nitrogen |

| 3.0 | 1500 – 2000 | 20 – 50 | Ngaphansi kobuso | I-Argon noma i-Nitrogen |

| 5.0 | 2000 – 3000 | 15 – 35 | Ngaphansi kobuso | I-Argon noma i-Nitrogen |

Ukulawulwa Kwekhwalithi: Umhlahlandlela Wokuxazulula Izinkinga Zamaphutha Avamile

Ngisho nangenqubo eqondile, amaphutha angavela. Ukuqonda imbangela yawo kuyisihluthulelo sokuvimbela.

Ukuhlonza Amaphutha Avamile Okushisela Nge-Laser

-

Ukubhoboka:Amabhamuza amancane egesi abanjwe ku-weld, avame ukubangelwa ukungcoliswa kwendawo noma ukugeleza kwegesi okuvikelayo okungafanele.

-

Ukuqhekeka Okushisayo:Imifantu ephakathi eyakheka njengoba i-weld iqina, ngezinye izikhathi ngenxa yokwakheka kwezinto noma ukucindezeleka okuphezulu kokushisa.

-

Ukungena Okungaphelele:I-weld ayihlanganisi yonke indawo ekujuleni kwejoyinti, ngokuvamile ngenxa yamandla anganele noma isivinini esikhulu.

-

Ukunqunywa okungaphansi:Umsele wancibilika ensimbini eyisisekelo emaphethelweni e-weld, okuvame ukubangelwa isivinini esikhulu noma igebe elikhulu.

-

I-Spatter:Amaconsi ancibilikisiwe akhishwa echibini lokushisela, ngokuvamile ngenxa yobuningi bamandla noma ukungcola kwendawo.

Ishadi Lokuxazulula Izinkinga: Izimbangela Nezixazululo

| Isici | Izimbangela Ezingenzeka | Izenzo Zokulungisa Ezinconyiwe |

| Ukubhoboka kwe-Porosity | Ukungcola kwendawo; ukugeleza kwegesi okuvikelayo okungafanele. | Sebenzisa ukuhlanza okuqinile ngaphambi kokushisela; qinisekisa igesi efanele futhi uthuthukise izinga lokugeleza. |

| Ukuqhekeka Okushisayo | Izinto ezithintekayo; ukucindezeleka okukhulu kokushisa. | Sebenzisa ucingo lokugcwalisa olufanele; fudumeza izinto kusengaphambili ukuze unciphise ukushaqeka kokushisa. |

| Ukungena Okungaphelele | Amandla anganele; isivinini esikhulu; ukugxila okungekuhle. | Khulisa amandla e-laser noma wehlise isivinini sokushisela; qinisekisa futhi ulungise indawo yokugxila. |

| Ukunqunywa okungaphansi | Isivinini esikhulu; igebe elikhulu lamalunga. | Nciphisa isivinini sokushisela; thuthukisa ukulingana kwezingxenye ukuze unciphise igebe. |

| I-Spatter | Ukuminyana kwamandla ngokweqile; ukungcoliswa kwendawo. | Nciphisa amandla e-laser noma sebenzisa i-defocus enhle; qinisekisa ukuthi izindawo zihlanzekile ngokucophelela. |

Izinyathelo Zokugcina: Ukuhlanzwa Ngemva Kokushiswa Nokushiswa

Inqubo yokushisela ilimaza zona kanye izakhiwo ezenza insimbi engagqwali “ingabi yinsimbi.” Ukuyibuyisela kuyisinyathelo sokugcina esiyimpoqo.

Kungani Ungeke Weqe Ukwelashwa Ngemva Kokushintshwa Kwensimbi

Ukushisa okuvela ekushiseni kubhubhisa ungqimba lwe-chromium-oxide olungabonakali, oluvikelayo ebusweni bensimbi. Lokhu kushiya ukushiseni kanye ne-HAZ ezungezile kusengozini yokugqwala nokugqwala.

Izindlela Zokudlulisa Ugqozi Zichaziwe

I-Passivation iyindlela yokwelapha ngamakhemikhali esusa ukungcola okungaphezulu futhi isize ekuguquleni ungqimba oluqinile nolulinganayo lwe-chromium-oxide.

-

Ukuqoqwa Kwamakhemikhali:Indlela yendabuko esebenzisa ama-asidi ayingozi njenge-nitric ne-hydrofluoric acid ukuhlanza nokudlulisa umoya ebusweni.

-

Ukuhlanzwa Kwamakhemikhali Kagesi:Indlela yesimanje, ephephile, futhi esheshayo esebenzisa uketshezi oluthambile lwe-electrolytic kanye nogesi oluphansi ukuze kuhlanzwe futhi kuncishiswe ukushintshwa kwensimbi ngesinyathelo esisodwa.

Ukuphepha Kuqala: Izinyathelo Ezibalulekile Zokuqapha Ngokushiswa Nge-Laser

Uhlobo lwamandla aphezulu lokushisela nge-laser luletha izingozi ezinkulu emsebenzini ezidinga izinqubo zokuphepha eziqinile.

Ingozi Efihliwe: Umusi we-Chromium (Cr(VI)) one-Hexavalent

Uma insimbi engagqwali ishiswa ukuze ishiselwe emazingeni okushisa okushiswayo, i-chromium eku-alloy ingakha i-chromium ene-hexavalent (Cr(VI)), ephenduka ibe nomoya emlilweni.

-

Izingozi Zempilo:I-Cr(VI) iwumdlavuza owaziwayo kubantu ohlotshaniswa nengozi eyengeziwe yomdlavuza wamaphaphu. Ingabangela nokucasuka okukhulu kokuphefumula, isikhumba, kanye namehlo.

-

Imikhawulo Yokuchayeka:I-OSHA ibeka umkhawulo oqinile wokuvezwa okuvumelekile (i-PEL) wama-microgram ama-5 ngemitha eyi-cubic yomoya (5 µg/m³) we-Cr(VI).

Izinyathelo Zokuphepha Ezibalulekile

-

Izilawuli Zobunjiniyela:Indlela ephumelela kakhulu yokuvikela abasebenzi ukubamba ingozi emthonjeni wayo. Ukusebenza kahle kakhuluuhlelo lokukhipha intuthuIsihlungi se-HEPA esinezigaba eziningi sibalulekile ukuze kubanjwe izinhlayiya ezi-ultrafine ezikhiqizwa yi-laser welding.

-

Izinto Zokuzivikela Zomuntu Siqu (i-PPE):Bonke abasebenzi endaweni kumele bagqoke izibuko zokuphepha ze-laser ezilinganiselwe ubude be-wavelength ethile ye-laser. Uma ukukhishwa komusi kungakwazi ukunciphisa ukuvezwa ngaphansi kwe-PEL, kudingeka ama-respirator agunyaziwe. Umsebenzi wokushisela kumele futhi wenziwe ngaphakathi kwendawo evalekile engangeni ukukhanya enezingidi zokuphepha ukuvimbela ukuvezwa ngengozi kwemisebe.

Imibuzo Evame Ukubuzwa (Imibuzo Evame Ukubuzwa)

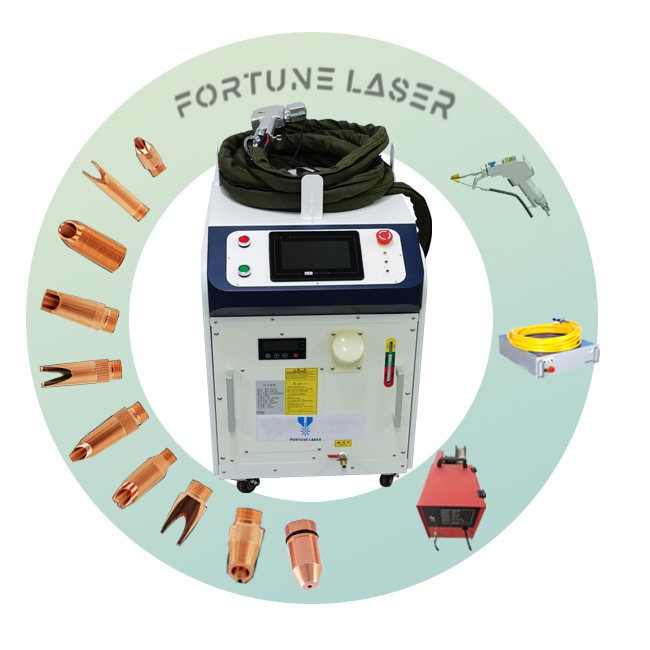

Yiluphi uhlobo lwe-laser olungcono kakhulu lokushisela insimbi engagqwali?

Ama-laser e-fibre ngokuvamile ayisinqumo esingcono kakhulu ngenxa yobude bawo obufushane, obumuncwa kalula yinsimbi engagqwali, kanye nekhwalithi yawo enhle kakhulu yokulawula okunembile.

Ungakwazi yini ukushisela nge-laser ubukhulu obuhlukene bensimbi engagqwali ndawonye?

Yebo, ukushisela nge-laser kusebenza kahle kakhulu ekuhlanganiseni ubukhulu obungafani ngokuphambuka okuncane futhi kungabikho ukusha engxenyeni encane, umsebenzi onzima kakhulu ngokushisela nge-TIG.

Ingabe intambo yokugcwalisa iyadingeka ekushiseni insimbi engagqwali nge-laser?

Ngokuvamile, cha. Ukushisela nge-laser kungakhiqiza ukushisela okuqinile, okugcwele ngaphandle kwezinto zokugcwalisa (ngokuzenzakalelayo), okwenza inqubo ibe lula. Ucingo lokugcwalisa lusetshenziswa lapho umklamo wokuhlangana unesikhala esikhulu noma lapho kudingeka izakhiwo ezithile zensimbi.

Iyini ubukhulu obukhulu bensimbi engagqwali engashintshwa nge-laser?

Ngezinhlelo ezinamandla amakhulu, kungenzeka ukushisela insimbi engagqwali efika ku-1/4″ (6mm) noma ngisho nokujiya ngephasi elilodwa. Izinqubo ze-hybrid laser-arc zingashisela izingxenye ezingaphezu kwe-intshi eyodwa ukujiya.

Isiphetho

Izinzuzo zokushisela nge-laser ngesivinini, ukunemba, kanye nekhwalithi zenza kube ukukhetha okuhle kakhulu kokwenziwa kwensimbi engagqwali yesimanje. Ikhiqiza amalunga aqinile, ahlanzekile anokuhlanekezela okuncane, okugcina ubuqotho nokubukeka kwezinto.

Kodwa-ke, ukufeza le miphumela yezinga lomhlaba kuncike endleleni ephelele. Impumelelo iwumphumela wochungechunge lokukhiqiza olunembe kakhulu—kusukela ekulungiseleleni ngokuhlanganyela okucophelelayo kanye nokulawulwa kwamapharamitha okuhlelekile kuya ekuphoqelekeni kokungasebenzi kahle ngemva kokushintshwa kanye nokuzibophezela okungantengantengi ekuphepheni. Ngokwazi le nqubo, ungavula izinga elisha lokusebenza kahle kanye nekhwalithi emisebenzini yakho.

Isikhathi sokuthunyelwe: Okthoba-08-2025