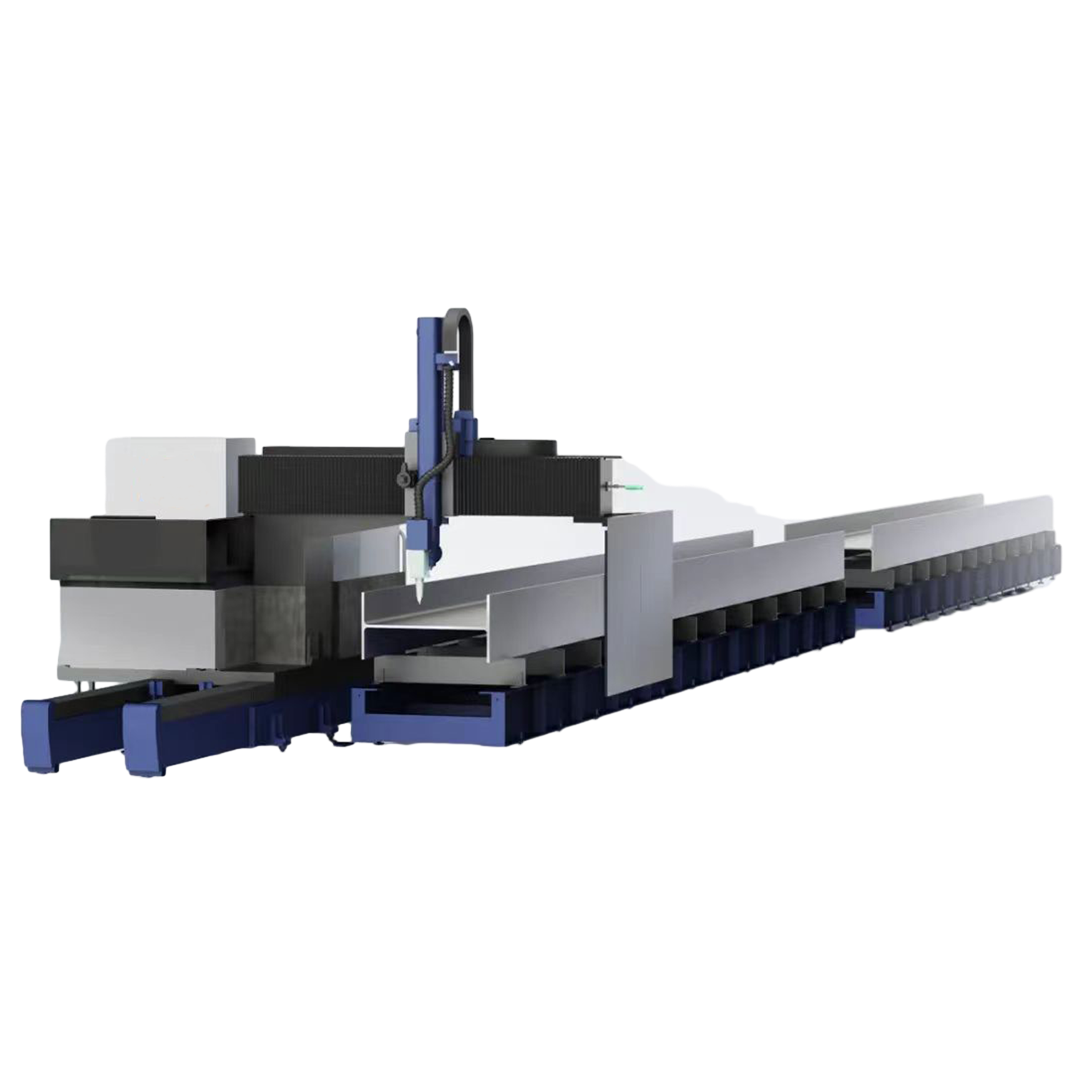

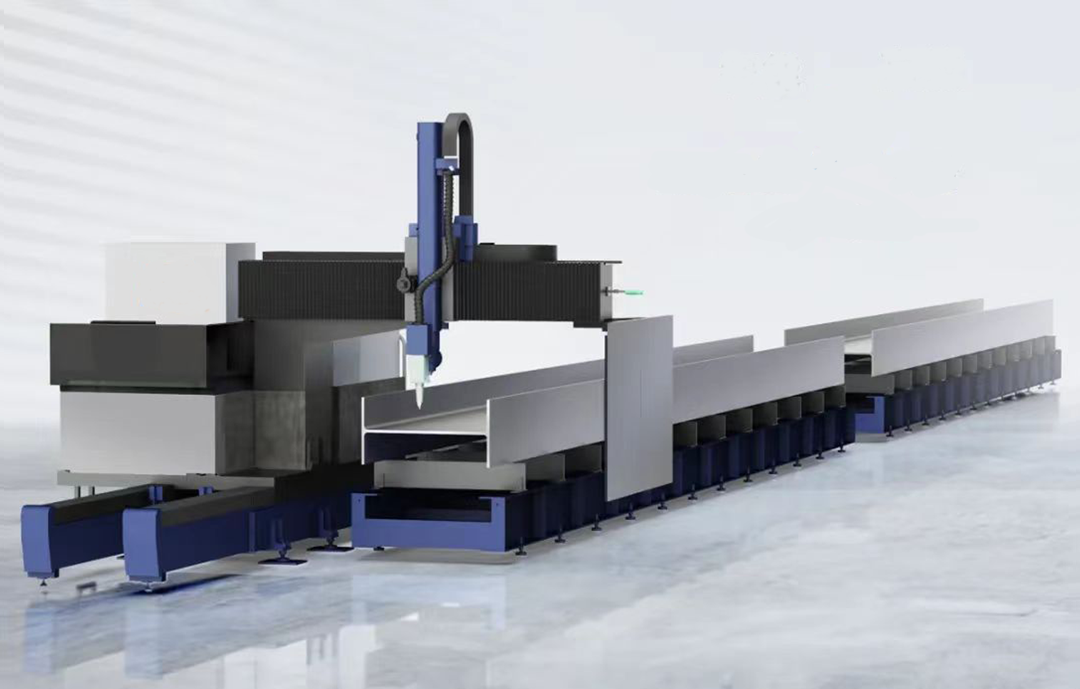

Umshini Wokusika Isistimu Yokusika I-Laser Ye-Fortune Laser Professional CNC 3D 5-Axis H Beam

Umshini Wokusika Isistimu Yokusika I-Laser Ye-Fortune Laser Professional CNC 3D 5-Axis H Beam

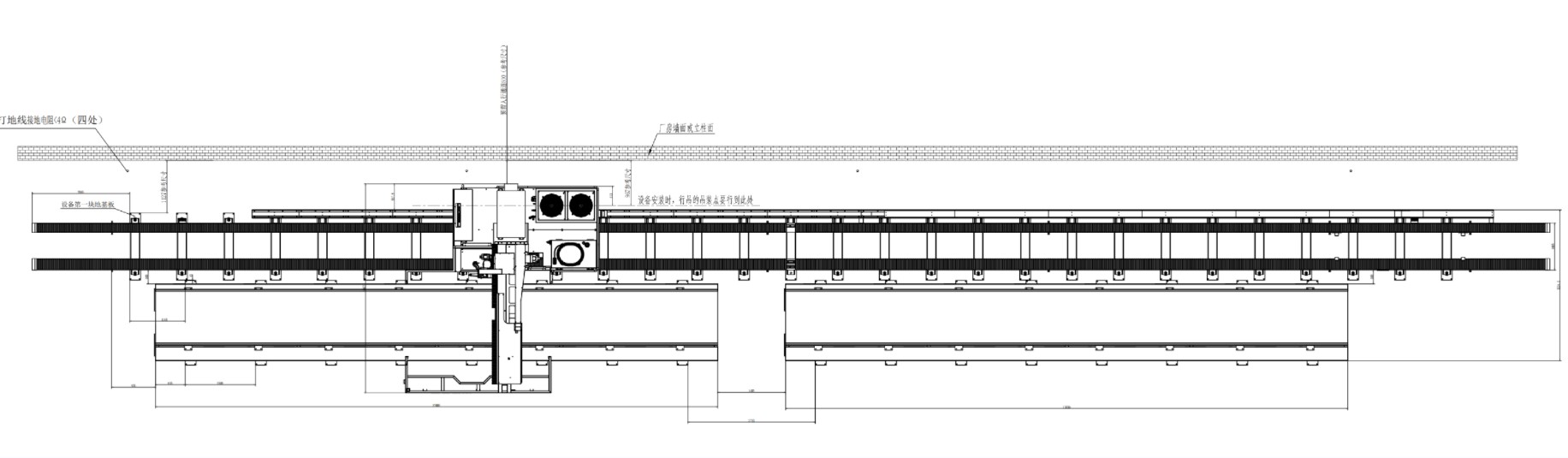

Izinhlamvu Zomshini

Umshini wokusika wensimbi engu-12m/24m omkhulu we-H steel/flat plate/bevel usebenzisa uhlelo lwe-German Beckhoff olunezinhlangothi ezintathu olunezinhlangothi ezinhlanu. Umugqa wokukhiqiza we-laser cutting five-in-one uwumkhiqizo wobuchwepheshe obuphezulu ohlanganisa ubuchwepheshe be-RTCP CNC obunezinhlangothi ezintathu obunezinhlangothi ezinhlanu, ukusika nge-laser, imishini enembile, kanye nobuchwepheshe bokuthola obuhlakaniphile. Emkhakheni wokucubungula isakhiwo sensimbi, izindlela zendabuko zokusebenzisa ngesandla, ukusika ilangabi, ukusika nge-plasma, kanye nezindlela zokulayisha nokulayisha ezizenzakalelayo zisasetshenziswa ukuthuthukisa ikhwalithi kanye nokusebenza kahle kokukhiqiza kwemikhiqizo yokucubungula isakhiwo sensimbi nokunciphisa izindleko zabasebenzi.

Umugqa wokukhiqiza we-laser wokusika i-three-in-one unokuzivumelanisa nezimo okunamandla futhi ungenziwa ngezifiso. Usetshenziswa kabanzi embonini yokukhiqiza imishini yobungcweti njengezakhiwo zensimbi, imikhumbi, imishini yobunjiniyela, imishini yezolimo, amandla omoya, uphethiloli, imboni yamakhemikhali, kanye nobunjiniyela basogwini. Usetshenziswa kabanzi ukwenza insimbi enobunjwa be-H, ukusika kwe-laser yezimboni kwensimbi yesigaba esinqamulelayo, insimbi enobunjwa be-C, insimbi eyisikwele, insimbi egobile, insimbi yesiteshi, njll.

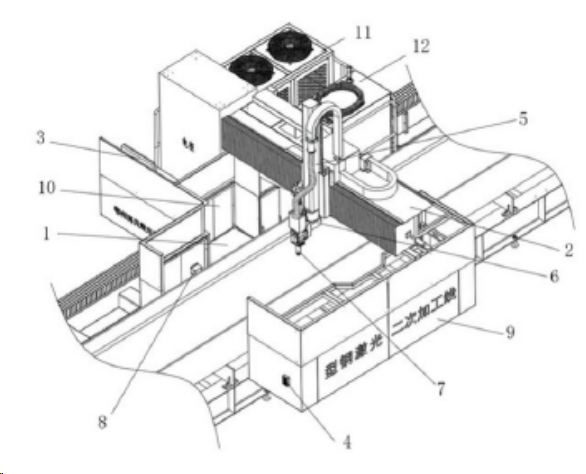

Ukucushwa komshini

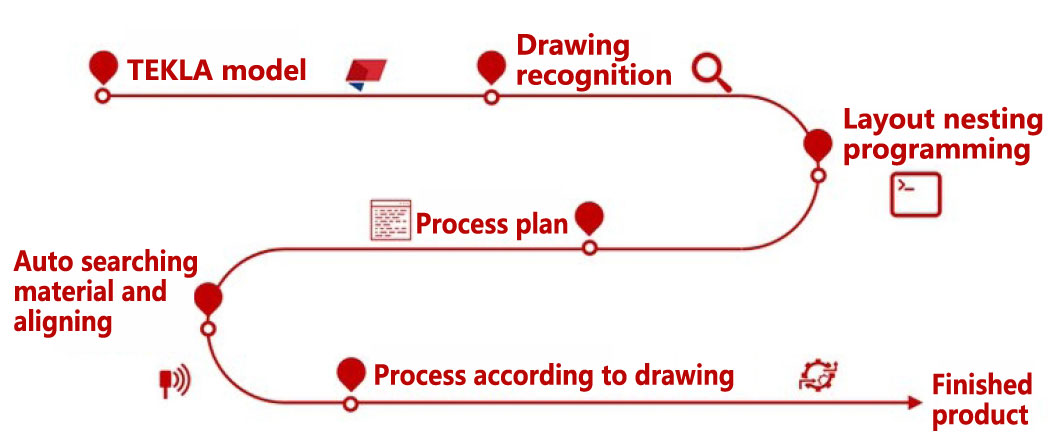

Umklamo wenqubo kanye nokugeleza kokusebenza

Izici Zomshini

1. Ipulatifomu yokuthutha

2. Uhlaka lwe-Cantilever

3. Isikhungo sokulawula

4. Isilawuli esikude

5. I-axis ka-Z

6. I-axis ye-AC

7. Ukusika ikhanda

8. Inzwa ye-laser

9. Isembozo esivikelayo

10. Isivikelo se-Graphite

11. Isiqandisi samanzi

12. Amandla e-laser

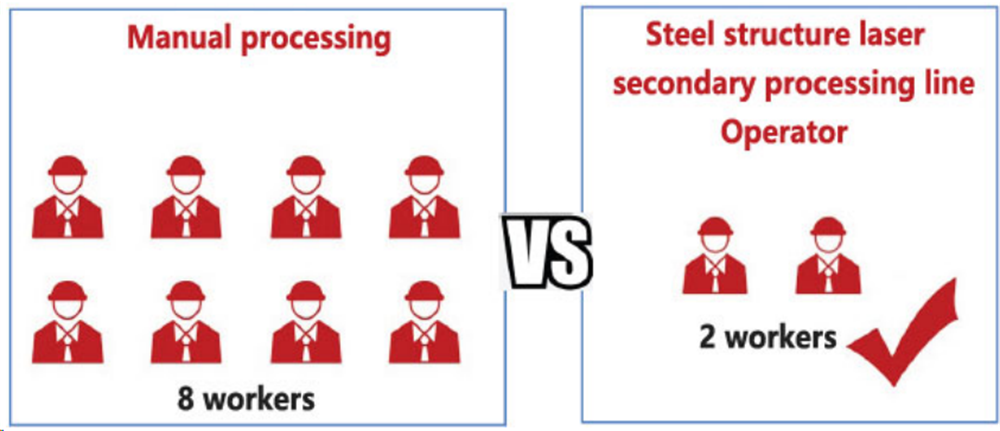

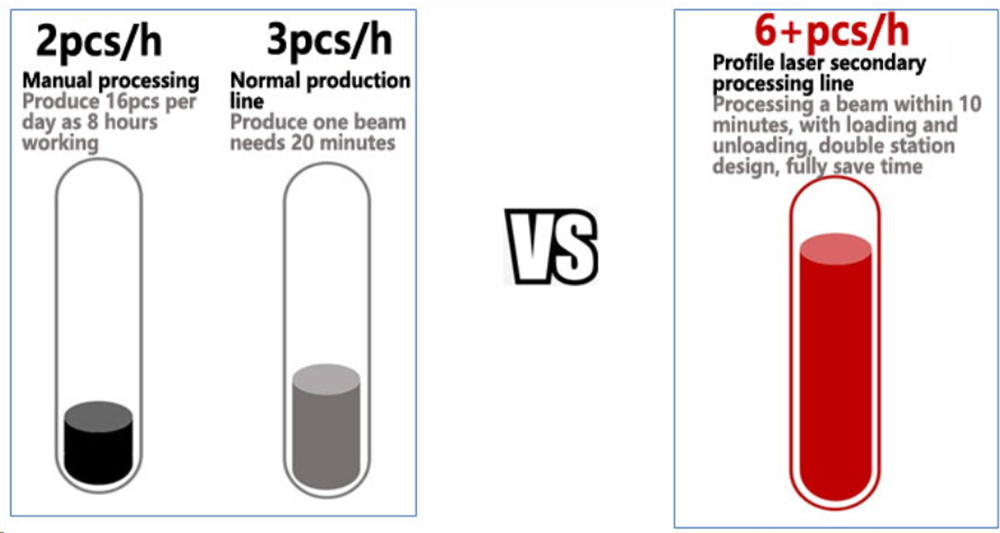

Uma kuqhathaniswa nokucubungula ngesandla kwendabuko

Ama-Multi-module CW Fiber Lasers athuthukiswe yiRaycus anokusebenza kahle kokuguqulwa kwe-electro-optical okuphezulu, ikhwalithi ephezulu yokukhanya, ubuningi bamandla aphezulu, imvamisa yokuguquguquka okubanzi, ukuthembeka okuphezulu, impilo yesevisi ende, ukusebenza okungenakulungiswa kanye nezinzuzo. Umkhiqizo ungasetshenziswa kabanzi ekushiseni, ukusika ngokunemba, ukuncibilikisa kanye nokumboza, ukucubungula ubuso, ukuphrinta kwe-3D kanye neminye imikhakha. Ukusebenza kwayo kokukhipha okubonakalayo kukusiza ukuthi uhlanganiswe kangcono namarobhothi njengemishini yokukhiqiza eguquguqukayo ukuze kuhlangatshezwane nesidingo sokucubungula i-3D.

Izici zomkhiqizo:

➣ Ukusebenza kahle kokuguqulwa kwe-electro-optical okuphezulu

➣ Ubude befayibha yokukhanya ephumayo bungenziwa ngezifiso

➣ Isixhumi se-QD

➣ ukusebenza okungenazo izilungiso

➣ Ububanzi bemvamisa yokuguquguquka

➣ ikhono lokumelana nokusabela okuphezulu

➣ Ukusika amashidi ngendlela ephumelelayo

Ulwazi lobuchwepheshe lwedivayisi ye-laser:

| Igama | Uhlobo | Ipharamitha |

| Idivayisi ye-laser (I-laser yefayibha yeRaycus 12000W) | Ubude begagasi | 1080±5nm |

| Umphumela olinganisiwe | 12000W | |

| Ikhwalithi yokukhanya (i-BPP) | 2-3 (75μm)/3-3.5(100μm) | |

| Indlela yokusebenza ye-Laser | Ukulungisa njalo | |

| Indlela yokupholisa | Ukupholisa amanzi | |

| Ukusika okuphezulu (Lapho usika ipuleti elijiyile, ngenxa yezinto ezibonakalayo nezinye izizathu, kungase kwenzeke ama-burrs) | I-CS: ≤30mmI-SS: ≤30mm |

Umthombo wamandla we-laser (Inketho 2)

Ama-Multi-module CW Fiber Lasers athuthukiswe yiRaycus asukela ku-3,000W kuya ku-30kW, anokusebenza kahle kokuguqulwa kwe-electro-optical okuphezulu, ikhwalithi ephezulu yokukhanya, ubuningi bamandla aphezulu, imvamisa yokuguquguquka okubanzi, ukuthembeka okuphezulu, impilo ende yesevisi, ukusebenza okungenakulungiswa kanye nezinzuzo. Umkhiqizo ungasetshenziswa kabanzi ekushiseni, ukusika ngokunemba, ukuncibilikisa kanye nokumboza, ukucubungula ubuso, ukuphrinta kwe-3D kanye neminye imikhakha. Ukusebenza kwawo kokukhipha okubonakalayo kukusiza ukuthi uhlanganiswe kangcono namarobhothi njengemishini yokukhiqiza eguquguqukayo ukuze kuhlangatshezwane nesidingo sokucubungula i-3D.

Izici zomkhiqizo:

➣ Ukusebenza kahle kokuguqulwa kwe-electro-optical okuphezulu

➣ Ubude befayibha yokukhanya ephumayo bungenziwa ngezifiso

➣ Isixhumi se-QD

➣ ukusebenza okungenazo izilungiso

➣ Ububanzi bemvamisa yokuguquguquka

➣ ikhono lokumelana nokusabela okuphezulu

➣ Ukusika amashidi ngendlela ephumelelayo

Ulwazi lobuchwepheshe lwedivayisi ye-laser:

| Igama | Uhlobo | Ipharamitha |

| Idivayisi ye-laser (I-laser yefayibha yeRaycus 20000W) | Ubude begagasi | 1080±5nm |

| Umphumela olinganisiwe | 20000W/30000W | |

| Ikhwalithi yokukhanya (i-BPP) | 2-3 (75μm)/3-3.5(100μm) | |

| Indlela yokusebenza ye-Laser | Ukulungisa njalo | |

| Indlela yokupholisa | Ukupholisa amanzi | |

| Ukusika okuphezulu (Lapho usika ipuleti elijiyile, ngenxa yezinto ezibonakalayo nezinye izizathu, kungase kwenzeke ama-burrs) | I-CS: ≤50mmI-SS: ≤40mm |

Isofthiwe yokulawula kanye nesofthiwe yokwakha izidleke

Uhlelo lokusebenza lwe-CNC lusebenzisa uhlelo lwe-laser lwesibili lokucubungula lwensimbi ebunjiwe eyenziwe ngokwezifiso yi-Fortune Laser, okulula ukuyisebenzisa, oluzinzile ukuyisebenzisa futhi olusebenza kahle kakhulu.

➣ Inelabhulali yenqubo yokusika ukusiza abasebenzisi ukufeza ikhwalithi yokusika engcono kakhulu.

➣ Udweba noma uhlela izindlela zemidwebo ze-2D ngqo ngaphakathi kohlelo lomshini ngaphandle kwesidingo sesofthiwe yomuntu wesithathu, okwandisa umkhiqizo futhi anikeze ukusheshisa okungalingani kanye nokubala kokunciphisa ijubane ukuze kugcotshwe ngendlela ethambile.

➣ Uhlelo lokuthambisa lukagesi luthuthukisa impilo yemishini.

➣ Ihlinzeka ngemisebenzi ejwayelekile ye-modular njengokunqamula ngokuchofoza okukodwa, ukulinganisa okuzenzakalelayo, kanye nokukhipha uthuli lwesifunda.

➣ Ukubhoboza kwepuleti elincane okungakhiqizi, ukubhoboza kombani wepuleti elikhulu, ukubhoboza kwezigaba eziningi, ukususwa kwe-slag yokubhoboza, ukucindezela kokudlidliza, i-pressure closed loop, ubuchwepheshe be-layer division fine kanye neminye imisebenzi kuthuthukisa kakhulu ukusebenza kahle kanye nokuzinza kokusika ngamandla aphezulu, kuthuthukisa ukuncintisana okuyinhloko kwemishini.

➣ Ukuthola umphetho ozenzakalelayo ngesivinini esiphezulu kanye nokunemba okuphezulu ukuze kuhlangatshezwane nezidingo zezinto ezifakwe iphrofayili kanye nokunemba okuphezulu.

➣ Qaphela ukudluliswa kwesignali yokubonisa, isignali ye-IO kanye nesignali ye-USB okulwa nokuphazamiseka okude kakhulu.

➣ Ukuvikelwa kokungqubuzana kwe-torque, ukugwema izithiyo zokuhamba komoya, ukugxumagxuma okuhlakaniphile neminye imisebenzi.

Isofthiwe yokwakha isidleke isebenzisa isofthiwe ekhethekile yomugqa wokucubungula wesibili we-laser owenziwe ngokwezifiso wensimbi yephrofayili, okulula ukuyisebenzisa, ngomsebenzi wokuhlonza okuzenzakalelayo kanye nokucubungula okusheshayo kwamadokhumenti e-batch.

➣ isekela ukungeniswa okuqondile kwe-Tekla, i-Solidworks kanye namanye amamodeli e-3D, futhi ingadweba noma ihlele ngqo indlela yokusika insimbi yesigaba kusofthiwe yokwakha isidleke, ngaphandle kokubambisana nesofthiwe yomuntu wesithathu, ithuthukisa ukusebenza kahle kokulungisa amaphutha nokulungisa.

➣ iguqula noma icubungula amafayela ngamaqoqo, isekela ukucutshungulwa okuzenzakalelayo kwama-node amaningi axhunyiwe, futhi ilungiselela ngokuzenzakalelayo izindlela zokusika ukuze isekele ukusika okuvamile komphetho.

➣ Isofthiwe inokuqina okuphezulu, futhi isizindalwazi senqubo esihambisanayo singasethwa ngokwezinto ezahlukene kanye nobukhulu bepuleti.

Amapharamitha Omshini

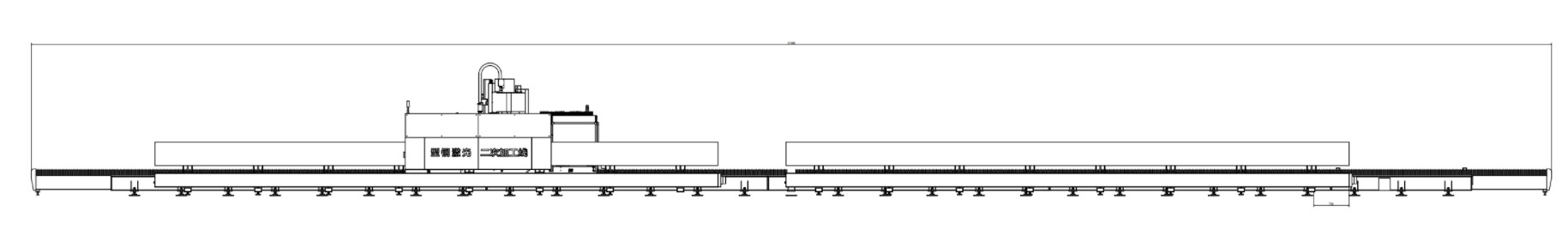

Ukuboniswa Komshini

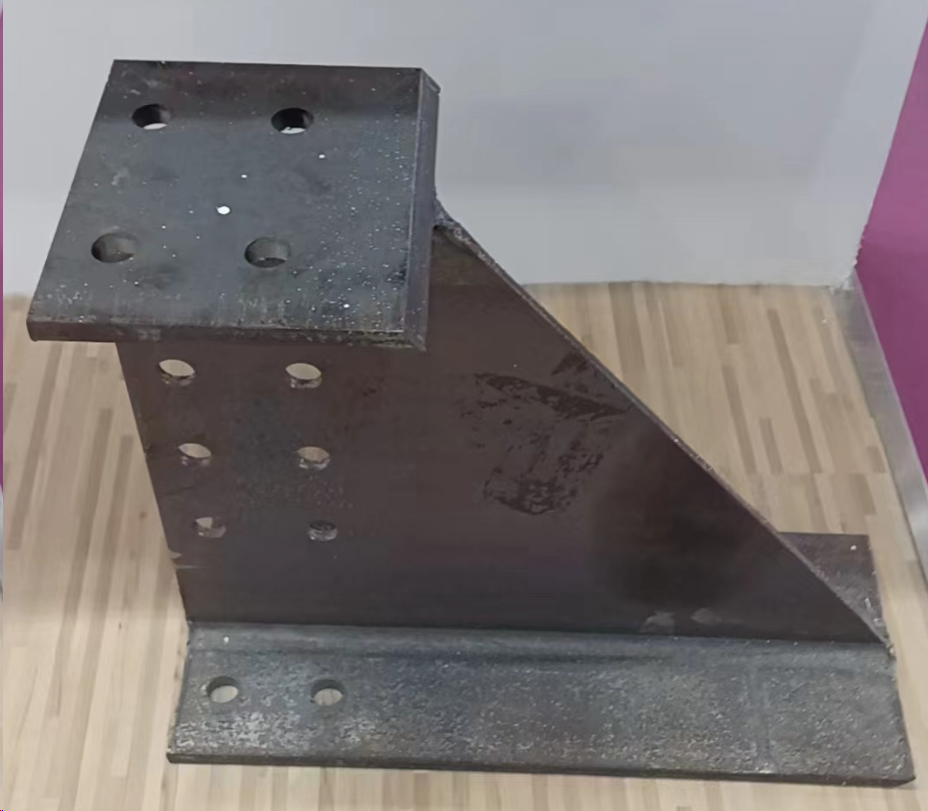

Ukuboniswa Kwamasampula

Ukuqondanisa okunembile nokufakwa okulula

Ngokusebenzisa isibonisi sokusika imbobo yokushisela njengoba kushiwo ngenhla

Isibonisi sokusika sensimbi yesigaba esingu-45 degree bevel