Umshini Wokushisela We-Fortune Laser Ozenzakalelayo Ongu-1000W/1500W/2000W Fiber Laser Oqhubekayo

Umshini Wokushisela We-Fortune Laser Ozenzakalelayo Ongu-1000W/1500W/2000W Fiber Laser Oqhubekayo

Izimiso Eziyisisekelo Zomshini We-Laser

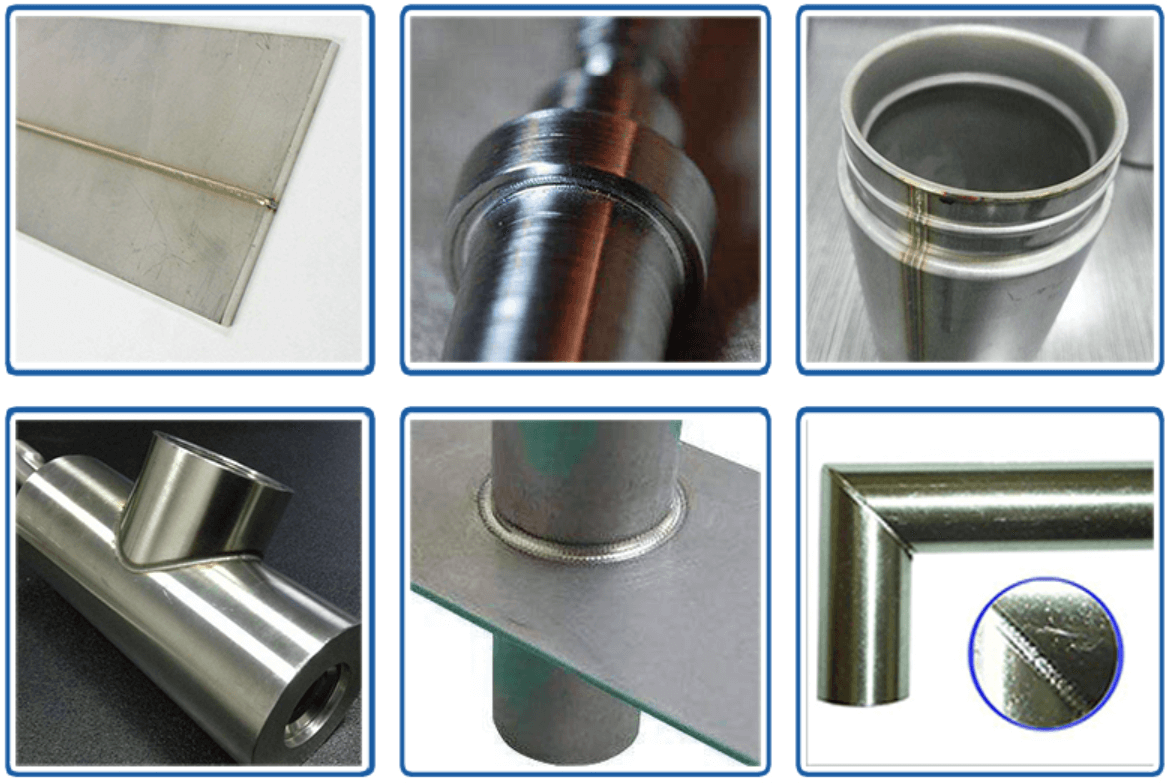

Umshini wokushisela we-laser we-fiber oqhubekayo uhlobo olusha lwendlela yokushisela. Ngokuvamile wakhiwe "i-welding host" kanye "ne-welding workbench". Ugongolo lwe-laser luhlanganiswe ne-optical fiber. Ngemva kokudluliselwa ibanga elide, lucutshungulwa lube yi-parallel light focus. Ukushisela okuqhubekayo kwenziwa endaweni yokusebenza. Ngenxa yokuqhubeka kokukhanya, umphumela wokushisela uqina futhi umthungo wokushisela uhle kakhulu futhi muhle. Ngokwezidingo ezahlukene zezimboni ezahlukene, imishini yokushisela ye-laser ingafanisa ukuma kanye ne-workbench ngokuya ngendawo yokukhiqiza futhi ifeze ukusebenza okuzenzakalelayo, okungahlangabezana ngokugcwele nezidingo zabasebenzisi ezimbonini ezahlukene.

Iningi lemishini yokushisela ye-fiber laser eqhubekayo isebenzisa ama-laser anamandla aphezulu anamandla angaphezu kwama-watts angu-500. Ngokuvamile, ama-laser anjalo kufanele asetshenziswe kumapuleti angaphezu kuka-1mm. Umshini wawo wokushisela uwukushisela okujulile okusekelwe kumphumela wembobo encane, onesilinganiso esikhulu sokujula nobubanzi, esingafinyelela ngaphezu kuka-5:1, isivinini sokushisela esisheshayo, kanye nokuguquguquka okuncane kokushisa.

Isici somshini wokushisela we-laser oqhubekayo ongu-1000W ongu-1500w ongu-2000w

Amapharamitha Obuchwepheshe Bomshini Wokushisela We-Laser Oqhubekayo We-Fortune Laser

Izesekeli

1. Umthombo we-laser

2. Intambo ye-Fiber Laser

3. Ikhanda lokushisela le-laser le-QBH

4. 1.5P ifriji

5. I-PC kanye nohlelo lokushisela

6. Isiteji Sokuhumusha Sikagesi Sesitimela Esiqondile Se-Servo 500*300*300

7. Uhlelo lokulawula olune-axis ezine ezingama-3600

8. Uhlelo lwekhamera ye-CCD

9. Ikhabethe le-Mainframe