Abavelisi bahlala bejonge ukwenza iimveliso ezomeleleyo, ezomeleleyo, nezithembekileyo, kunye nakumacandelo eemoto kunye ne-aerospace.Kolusukelo, bahlala bephucula kwaye batshintshe iinkqubo zezinto ezinoxinano olusezantsi, ubushushu obungcono kunye nokumelana nokubola kwealloyi zetsimbi.Oku kunika abavelisi indawo engcono kwimarike.

Enyanisweni, eso sisiqingatha sebali kuphela.

Olona ncedo lunamandla ngakumbi kubuchule obunokulinganiswa malunga nokomelela kwemveliso, ukuqina, kunye nokuthembeka kwayo.

Ukutshintsha izinto ezindala kwizinto ezomeleleyo kunokuba sisiqalo esihle, kodwa kukwafuna iinkqubo zokwenziwa eziphucukileyo ezixhomekeke ekucoceni nasekucocweni okusebenzayo komphezulu ukwenza izakhiwo ezomeleleyo.Izinyithi ezifana ne-aluminium alloys kunye nezixhobo eziphambili ezifana ne-carbon fiber polymer composites, ehlala isetyenziselwa ukuveliswa kweemoto kunye ne-aerospace, zifuna ukudibanisa ukunciphisa ubunzima - xa kusetyenziswa i-fasteners, ubunzima bongezwa kwisakhiwo - kunye nokudala amajoyina athembekileyo.

Iindlela zokugqiba i-aluminiyam yendabuko ziquka ukuchithwa kwesanti, ukusula i-solvent, kulandelwa ukugaya (ukusebenzisa i-pad scouring) okanye i-anodizing.I-Adhesive bonding ivula umnyango kwiinkqubo ezizenzekelayo ngakumbi apho ukugqitywa kwendabuko kungahambelani.

I-anodizing ixhaphake kakhulu kwizicelo ze-aerospace apho olu lungiselelo lubiza kakhulu kwaye lungqongqo lusetyenziselwa ukuhlangabezana nemigaqo engqongqo.Ukwahlukahlukana okwenziwa kwisanti yesanti kunye ne-manual abrasion techniques kubonisa ngokucacileyo ukuba inkqubo elawulwa ngakumbi ilungile.

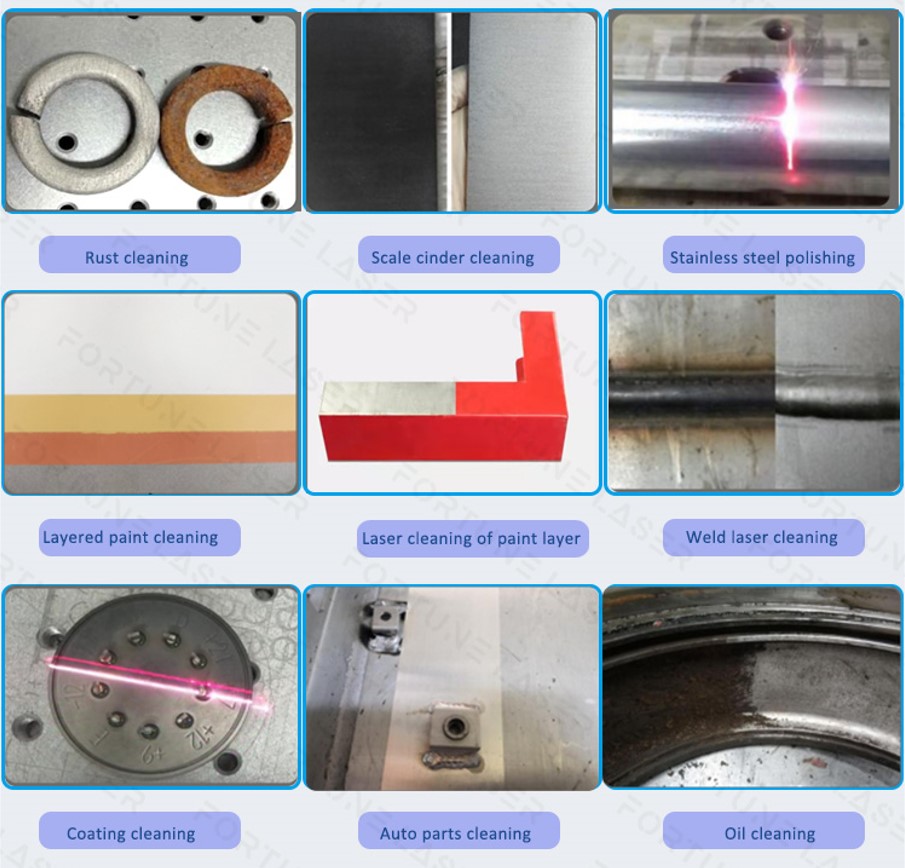

Ukucocwa kweLaser okanye i-laser ablation kuzalisa le gap yenkqubo njengendlela echanekileyo, ehambelana nokusingqongileyo, ngokuzenzekelayo kunye nendlela efanelekileyo yokuphatha isinyithi kunye neendawo ezidibeneyo zokucoca.Iindidi zokungcoliseka ezifunyenwe kumphezulu wezi zinto zisuswa ngokulula ngokulungiswa kwe-laser.

Ngenxa yokuba ukucocwa kwelaser kunamandla kakhulu, kubalulekile ukwazi ngokuthe ngqo ukuba iwuchaphazela njani umphezulu wakho.Umahluko phakathi komphezulu onyangwe ngokufanelekileyo kunye nomphezulu ongaphantsi okanye onyangelwe ngokugqithisileyo kunokuba nzima kakhulu ukuwuhlola.Ngetekhnoloji yokuqinisekiswa kwenkqubo yobungakanani njengobuthathaka kwaye ichanekile njengenkqubo yelaser ngokwayo, abavelisi banokuqiniseka ukuba isinyithi sabo kunye nemigangatho edibeneyo ilungele ngokupheleleyo ukubopha.

I-laser ilandelayo ye-Fortune iya kukunika isingeniso esicacileyo kwizizathu zokukhetha ukucocwa kwe-laser.

1 -Yintoni iLaser Cleaning?

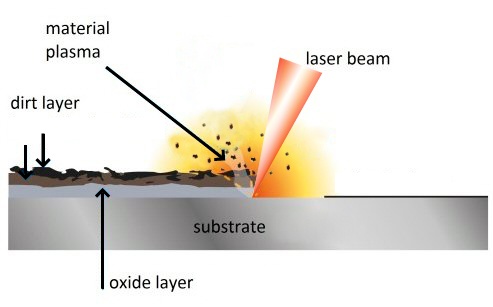

Unyango lweLaser yindlela echaneke kakhulu, yokucoca i-thermal esebenza ngokususa (i-ablation) amaqhezu amancinane omphezulu wemathiriyeli ngomqadi welaser ogxilileyo, odla ngokutsalwa.I-laser irradiate surface ukususa iiathom kwaye ingasetyenziselwa ukugrumba encinci kakhulu, imingxuma enzulu ngokusebenzisa izinto ezinzima kakhulu, ukuvelisa iifilimu ezincinci okanye i-nanoparticles phezu komhlaba.

Le nkqubo yokucoca umphezulu isebenza kakhulu ngenxa yokukwazi ukujolisa iileya ezincinci zokungcola kunye neentsalela.Imiphezulu ye-aluminiyam iqulethe ii-oksidi kunye ne-oyile ye-lubricant eyingozi kwi-adhesive edibeneyo kunye ne-composites isoloko igcina ukukhutshwa kokungunda okushiyekileyo kunye nezinye izingcoliso ze-silicone ezingakwaziyo ukwenza iibhondi zeekhemikhali ezomeleleyo kunye ne-adhesives.

Xa i-adhesive ifakwe kumphezulu kunye nenye yezi ntsalela ezikhoyo iya kuzama ukunamathela ngokwekhemikhali kwi-oyile kunye ne-silicone phezulu kwiileya zemolekyuli ezimbalwa eziphezulu.Ezi bhondi zibuthathaka kakhulu kwaye ngokuqinisekileyo ziya kusilela nokuba ngexesha lovavanyo lokusebenza okanye ngexesha lokusetyenziswa kwemveliso.Xa amajoyina aphuka kwindawo apho umphezulu kunye ne-adhesive okanye i-coating idibana khona oku kubizwa ngokuba yi-interfacial failure.Ukungaphumeleli kokubambisana ngexesha lovavanyo lokucheba i-lap kuxa ikhefu lenzeka ngaphakathi kwe-adhesive ngokwayo.Oku kubonisa ibhondi eyomeleleyo kunye nesakhiwo esihlangeneyo esinokuqina kwaye sihlala ixesha elide.

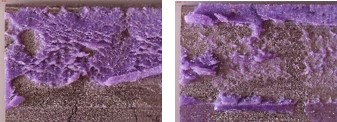

Ukungaphumeleli kokubambisana kwezi sampuli ezidibeneyo eziye zaphathwa nge-laser zibonisa i-adhesive kumacala omabini ezinto ezidibeneyo.

Ukungaphumeleli kobuso kwezi sampuli ezidibeneyo ezingakhange ziphathwe zibonisa ukuba i-adhesive ibambelele kuphela kwelinye lamacala kwaye uyeke ngokupheleleyo kwelinye.

Xa unokusilela okubambeneyo, unebhondi edibanisa ubuso obungavumeli ukuba ihambe ilize.Unyango lomphezulu lujolise ekuguquleni umphezulu ukususa ungcoliseko kunye nokudala okanye ukuveza umphezulu oya kukwazi ukuxutywa ngekhemikhali kunye ne-adhesive for ehlala kwaye ethembekileyo iibhondi.

2-Ungazi njani ukuba iLaser yakho eNyango yeLaser ilungele ukuncamathela

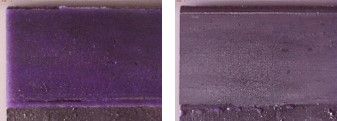

Imilinganiselo ye-engile yoqhagamshelwano, njengaleyo ikhankanyiweyo kwiphepha le-IJAA elisetyenziselwa ukuqonda ukuthotywa konyango ixesha elongezelelekileyo, yindlela entle kakhulu yokubeka iliso kunye nokuqinisekisa iinkqubo zokucoca ngelaser.

Umlinganiselo we-angle yoqhagamshelwano unovakalelo kwiinguqu zemolekyuli ezenzeka kumphezulu ophathwa ngelaser.Ithontsi yolwelo olubekwe phezu komhlaba luya kunyuka okanye lwehle ngokunxulumene ngqo nobungakanani bongcoliseko oluncinci kumphezulu.Imilinganiselo ye-angle yoqhagamshelwano yisalathisi esingapheliyo sokubambelela kwaye inokunika ukucaca kunye nokubonakala kwindlela ehambelana ngayo amandla onyango kunye neemfuno zokucoca izinto.

Imilinganiselo ye-engile yoqhagamshelwano ihambelana kakuhle notshintsho kumanqanaba ongcoliseko oluchongwe ziindlela ze-spectroscopy.Uninzi lwemilinganiselo echanekileyo yongcoliseko kumphezulu lwenziwa ngesixhobo esingenakwenzeka ukuba abavelisi bathenge kwaye esingenakusetyenziswa kwiindawo zokwenyani ezenziwayo.

Imilinganiselo ye-angle yoqhagamshelwano inokwenziwa ngokukhawuleza ngaphambi nangemva konyango kumgca wemveliso ngeincwadi yesandlaokanyeizixhobo zokulinganisa ezizenzekelayo.Kanye njengokuba ukucocwa kwelaser kuthatha indawo yeendlela zangaphambili zokulungisa umphezulu ngenxa yeemfuno ezizenzekelayo zokwenziwa kwevolumu ephezulu, ukuchaneka okuphezulu, imilinganiselo ye-engile yoqhagamshelwano nayo yenza uvavanyo lomgangatho ophezulu kunye nolungachanekanga njenge-dyne inki kunye novavanyo lwekhefu lamanzi luphelelwe lixesha.

Iimvavanyo zentsebenzo yamandla zivavanya kuphela isampulu yezinto ezicutshungulwayo, zongezwa kwireyithi ye-scrap kwaye zinganiki naluphi na uphawu lwendlela yokwenza ibhondi eyomeleleyo.Ii-angles zoqhagamshelwano, xa ziqeshwe kuwo wonke umgca wemveliso zingakhomba ngqo apho inkqubo ifuna ukuxutywa, kwaye inokubonelela ngengqiqo malunga noko kufuneka kulungiswe kwaye kungakanani ubungakanani.

3- Kutheni Usebenzisa iLaser Cleaning?

Kukho uphando oluninzi malunga neendlela unyango lomphezulu we-laser oluphucula ukunamathela.Njengokuba,iphepha elipapashwe kwiJournal of Adhesionkuphononongwe ukuba angakanani amandla adibeneyo aphuculweyo ngokucoca ngelaser ngokuchasene neendlela zemveli.

"Iziphumo zovavanyo zibonisa ukuba unyango lomphezulu we-laser preadhesion luphucule kakhulu amandla okucheba eepoksi ezidityanisiweyo zesampulu ze-aluminiyam xa zithelekiswa nezingaphathwanga kunye ne-anodized substrates.Ezona ziphumo zibalaseleyo zifunyenwe ngamandla e-laser amalunga ne-0.2 J/Pulse/cm2 apho amandla e-lap shear enye aphuculwa ngama-600-700% xa kuthelekiswa ne-Al alloy engaphathwanga, kwaye ngama-40% xa kuthelekiswa ne-chromic acid anodizing pretreatment.

Indlela yokungaphumeleli itshintshile ukusuka kwi-adhesive ukuya kwi-cohesive njengoko inani le-laser pulses liye landa ngexesha lonyango.Le nto yokugqibela iye yanxulunyaniswa notshintsho lwe-morphology njengoko lutyhilwe yi-electron microscopy, kunye nokuguqulwa kweekhemikhali njengoko kubonisiwe yi-Auger kunye ne-infrared spectroscopy.

Enye impembelelo enomdla yokukhutshwa kwelaser ngamandla enawo okudala umphezulu ongonakaliyo ekuhambeni kwexesha.

Fortune Laserwenze umsebenzi omkhulu ejonga indlela ukucocwa kwelaser kunxibelelana nomphezulu ngeendlela ezithile ezimangalisayo.Ukunyangwa kwe-aluminiyam ngelaser kwenza ama-craters amancinci kumphezulu anyibilike kwaye aphantse aqine ngaxeshanye abe ngumaleko wekristale encinci kumphezulu okwaziyo ukumelana nomhlwa ngakumbi kune-aluminiyam ngokwayo.

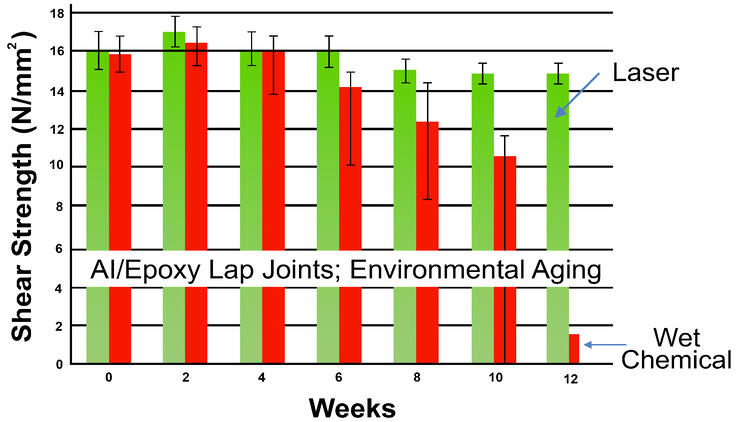

Ukujonga itshathi engezantsi, ibonisa umahluko phakathi kwamandla okucheba kwebhondi usebenzisa i-aluminium eye yaphathwa nge-laser kunye ne-aluminium eye yaphathwa ngamachiza.Ngokuhamba kwexesha, njengoko imiphezulu iye yavezwa kwindawo efumileyo, ukukwazi komphezulu onyangwa ngokwekhemikhali ukuhlangana kakuhle kuncipha kakhulu kuba ukufuma kuqala ukugqwesa umphezulu, ngelixa umphezulu onyangwa ngelaser ugcina ukuxhathisa ukubola emva kweeveki zokuvezwa.

Ixesha lokuposa: Aug-12-2022