Abavelisi bahlala befuna ukwenza iimveliso eziqinileyo, ezihlala ixesha elide, nezithembekileyo ngakumbi, kunye nakwicandelo leemoto kunye neleenqwelo-moya. Kulo msebenzi, bahlala bephucula kwaye betshintsha iinkqubo zezinto eziphathekayo nge-alloys zesinyithi eziphantsi koxinano, ubushushu obungcono kunye nokumelana nokugqwala. Oku kunika abavelisi indawo engcono kwimarike.

Enyanisweni, loo nto isiqingatha sebali kuphela.

Inzuzo enamandla ngakumbi yesicwangciso kukuqiniseka okunokulinganiswa malunga namandla emveliso, ukuqina kwayo, kunye nokuthembeka kwayo.

Ukutshintsha izinto ezindala uze uzisebenzise ezomeleleyo kunokuba sisiqalo esihle, kodwa kukwafuna neenkqubo zokuvelisa eziphucukileyo ezixhomekeke ekucoceni umphezulu okucocekileyo nokusebenzayo ukuze kudalwe izakhiwo ezomeleleyo. Iintsimbi ezifana nee-aluminium alloys kunye nezinto eziphambili ezifana nee-carbon fiber polymer composites, ezisetyenziswa rhoqo kwimveliso yeemoto kunye neenqwelo moya, zifuna ukubopha ukuze kuncitshiswe ubunzima - xa kusetyenziswa izibophelelo, ubunzima buyafakwa kwisakhiwo - kunye nokudala amalungu athembekileyo ngakumbi.

Iindlela zemveli zokugqiba i-aluminium ziquka ukuqhumisa isanti, ukusula i-solvent, kulandele ukugaywa (ukusebenzisa i-scouring pad) okanye ukuzola. Ukubopha okunamathelayo kuvula ucango kwiinkqubo ezizenzekelayo apho ukugqitywa kwendabuko kungahambelaniyo.

I-anodizing ixhaphake kakhulu kwizicelo zeenqwelo-moya apho olu lungiselelo lubiza kakhulu kwaye luqinileyo lusetyenziselwa ukuhlangabezana neemfuno ezingqongqo. Ukwahluka okukhoyo kwindlela yokuqhumisa isanti kunye neendlela zokukrazula ngesandla kubonisa ngokucacileyo ukuba inkqubo elawulwa ngakumbi ifanelekile.

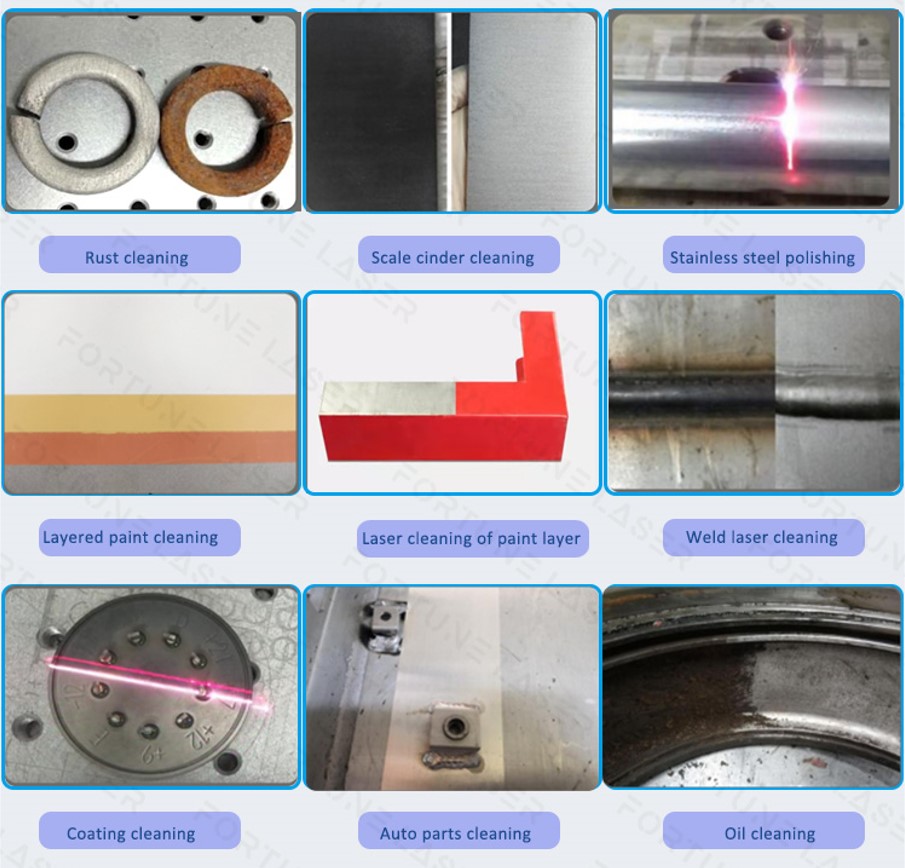

Ukucocwa nge-laser okanye ukucocwa nge-laser kuzalisa esi sikhewu senkqubo njengendlela echanekileyo, enobuhlobo nokusingqongileyo, ezenzekelayo nesebenzayo yokunyanga isinyithi kunye neendawo ezidityanisiweyo zokucoca. Iintlobo zongcoliseko olufumaneka kumphezulu wezi zinto zisuswa lula ngokucubungula nge-laser.

Ngenxa yokuba ukucocwa nge-laser kunamandla kakhulu, kubalulekile ukwazi kakuhle indlela okuchaphazela ngayo umphezulu wakho. Umahluko phakathi komphezulu ophathwe kakuhle kunye nomphezulu ongaphathwanga kakuhle okanye ophathwe kakhulu kunokuba nzima kakhulu ukuwuvavanya. Njengoko iteknoloji yokuqinisekisa inkqubo yobungakanani inobuntununtunu kwaye ichanekile njengenkqubo ye-laser ngokwayo, abavelisi banokuqiniseka ukuba umphezulu wabo wesinyithi kunye nowe-composite ukulungele ngokupheleleyo ukubopha.

Le laser ilandelayo yeFortune iza kukunika intshayelelo eneenkcukacha zezizathu zokukhetha ukucocwa ngelaser.

1 –Yintoni ukucoca ngeLaser?

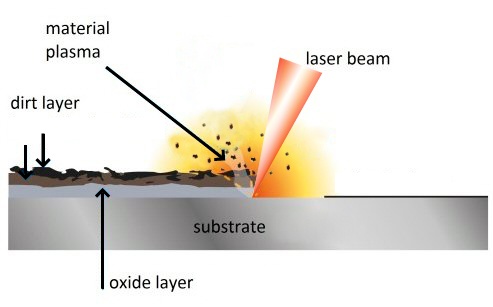

Unyango lwe-laser yindlela yokucoca echanekileyo kakhulu neshushu esebenza ngokususa (ukukhupha) amaqhezu amancinci omphezulu wezinto ezibonakalayo nge-laser beam egxile, edla ngokushukuma, nerhawuzelelwa. I-laser ikhanyisa umphezulu ukuze isuse ii-athomu kwaye ingasetyenziselwa ukugrumba imingxunya emincinci kakhulu, enzulu kwizinto eziqinileyo, ivelise iifilimu ezincinci okanye ii-nanoparticles kumphezulu.

Le nkqubo yokucoca umphezulu iyasebenza kakhulu ngenxa yokukwazi kwayo ukujolisa kwiileya ezincinci zezingcolisi kunye neentsalela. Iindawo ze-aluminium ziqulethe ii-oxides kunye neeoyile zokuthambisa eziyingozi ekudibaniseni i-adhesive kunye nee-composites zihlala zigcina ukukhululwa kwe-mold okushiyekileyo kunye nezinye izinto ezingcolisayo ze-silicone ezingenakwenza iibhondi zekhemikhali ezinamandla kunye nezincamathelisi.

Xa iglu isetyenziswa kumphezulu onenye yezi ntsalela ezikhoyo, iya kuzama ukunamathela ngokweekhemikhali kwioyile kunye nesilicone kumaleko ambalwa aphezulu eemolekyuli zezinto. Ezi zibopho zibuthathaka kakhulu kwaye ngokuqinisekileyo ziya kusilela nokuba ngexesha lovavanyo lokusebenza okanye ngexesha lokusetyenziswa kwemveliso. Xa amalungu eqhekeka kwindawo apho umphezulu kunye neglu okanye uqweqwe zidibana khona oku kubizwa ngokuba kukusilela kwe-interfacial. Ukusilela kokubambisana ngexesha lovavanyo lwe-lap shear kuxa ukuqhekeka kwenzeka ngaphakathi kweglue ngokwayo. Oku kubonisa ikhonkco eliqinileyo kakhulu kunye nesakhiwo esidibeneyo esizinzileyo nesihlala ixesha elide.

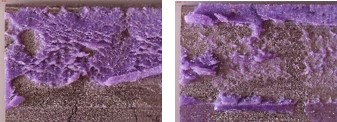

Ukungaphumeleli kokubambisana kwezi sampuli zidibeneyo eziphathwe nge-laser kubonisa i-glue kumacala omabini ezinto ezibotshelelweyo.

Ukungaphumeleli kwe-interfacial kwezi sampuli zidibeneyo ezinganyangwanga kubonisa ukuba i-adhesive inamathele kuphela kwelinye icala yaze yakhulula ngokupheleleyo elinye.

Xa unengxaki yokubambisana, uba ne-interfacial bond engavumeli ukuba ihambe. Unyango lomphezulu lujolise ekuguquleni umphezulu ukuze kususwe izinto ezingcolisayo kwaye kudale okanye kutyhile umphezulu oya kukwazi ukudibana neekhemikhali ne-adhesive ukuze kubekho ii-bond ezihlala ixesha elide nezithembekileyo.

2- Indlela Yokwazi Ukuba Umphezulu Wakho Ophathwe NgeLaser Ulungele Ukunamathela

Ukulinganiswa kwee-engile zoqhagamshelwano, njengalezo zikhankanyiweyo kwiphepha le-IJAA ezisetyenziselwa ukuqonda ukonakala konyango ngokuhamba kwexesha, yindlela elungileyo kakhulu yokujonga nokuqinisekisa iinkqubo zokucoca nge-laser.

Umlinganiselo we-engile yoqhagamshelwano ubuthathaka kutshintsho lweemolekyuli ezenzeka kumphezulu ophathwa nge-laser. Ukuwa kolwelo olubekwe kumphezulu kuya kunyuka okanye kwehle ngokumalunga nobungakanani bongcoliseko oluncinci kumphezulu. Umlinganiselo we-engile yoqhagamshelwano luphawu olungapheliyo lokunamathela kwaye lunokubonelela ngokucaca nokubonakala kwindlela amandla onyango ahambelana ngayo neemfuno zokucoca izixhobo.

Ukulinganiswa kwee-engile zoqhagamshelwano kuhambelana kakuhle notshintsho kumanqanaba ongcoliseko olufunyenwe ngeendlela ze-spectroscopy. Uninzi lokulinganiswa ngokuchanekileyo kongcoliseko olukwindawo kwenziwa ngezixhobo ezingenakwenzeka ukuba abavelisi bazithenge kwaye ezingenakusetyenziswa kwiindawo zokwenyani ezenziwayo.

Ukulinganiswa kwe-engile yoqhagamshelwano kungenziwa kwangoko ngaphambi nasemva konyango kumgca wemveliso ngeincwadi yesandlaokanyeizixhobo zokulinganisa ezenzekelayoKanye njengokuba ukucocwa nge-laser kuthatha indawo yeendlela zokulungiselela umphezulu eziphelelwe lixesha ngenxa yeemfuno zokwenza ngokuzenzekelayo zemveliso ephezulu nechanekileyo, ukulinganiswa kwe-engile yoqhagamshelwano kwenza uvavanyo lomgangatho womphezulu oluzimeleyo nolungacacanga njengee-inki ze-dyne kunye novavanyo lokuqhekeka kwamanzi luphelelwe lixesha.

Uvavanyo lokusebenza kwamandla luhlola kuphela isampulu yezinto ezicutshungulwayo, longeza kwisantya sokulahlwa kwaye alubonisi indlela yokwenza ibhondi eqinileyo. Ii-engile zoqhagamshelwano, xa zisetyenziswa kumgca wemveliso, zinokukhomba ngqo apho inkqubo ifuna ukulungiswa khona, kwaye zinokubonelela ngokuqonda ukuba yintoni ekufuneka ilungiswe kwaye ukuya kuthi ga phi.

3- Kutheni Usebenzisa Ukucoca NgeLaser?

Kuye kwenziwa uphando oluninzi oluhle malunga neendlela unyango lomphezulu welaser oluphucula ngayo ukunamathela. Umzekelo,iphepha elipapashwe kwiJournal of Adhesionbahlolisise ukuba amandla amalunga aqiniswa kangakanani ngokucoca nge-laser ngokungafaniyo neendlela zemveli.

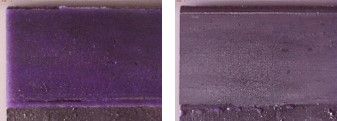

"Iziphumo zovavanyo zibonisa ukuba unyango lomphezulu welaser preadesion luphucule kakhulu amandla okucheba eesampuli ze-aluminium ezibotshelelwe kwi-modified-epoxy xa kuthelekiswa ne-substrates ezinganyangwanga nezinotyiweyo. Iziphumo ezilungileyo zifunyenwe ngamandla elaser amalunga ne-0.2 J/Pulse/cm2 apho amandla okucheba e-single lap aphuculwe ngama-600-700% xa kuthelekiswa nalawo e-al alloy enganyangwanga, kwaye ngama-40% xa kuthelekiswa nonyango lwangaphambi kokusetyenziswa kwe-chromic acid anodizing.

Indlela yokusilela yatshintsha ukusuka ekunamatheleni ukuya ekuhlanganeni njengoko inani lee-laser pulses landa ngexesha lonyango. Le meko yokugqibela inxulunyaniswe notshintsho lwemo njengoko lutyhilelwe yi-electron microscopy, kunye nokuguqulwa kweekhemikhali njengoko kubonisiwe yi-Auger kunye ne-infrared spectroscopy.

Esinye isiphumo esinomdla sokususwa kwelaser ngamandla enawo okwenza umphezulu ongawohlokiyo ngokuhamba kwexesha.

I-Fortune LaserUsebenze kakuhle kakhulu ekujongeni indlela ukucoca nge-laser okunxibelelana ngayo nomphezulu ngeendlela ezimangalisayo. Unyango lwe-aluminiyam nge-laser ludala ii-craters ezincinci kumphezulu ezinyibilikayo kwaye ziqine phantse ngaxeshanye zibe ngumaleko omncinci wekristale kumphezulu okwaziyo ukumelana nokugqwala ngaphezu kwe-aluminiyam ngokwayo.

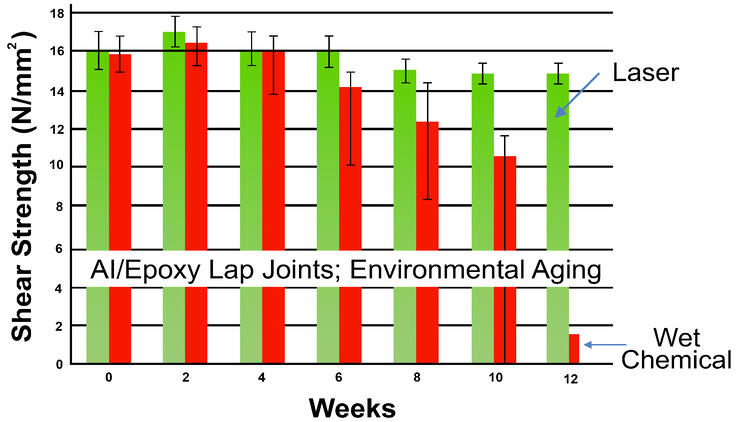

Ukujonga itshathi engasezantsi, ibonisa umahluko phakathi kwamandla okucheba kwebhondi esebenzisa i-aluminium ephathwe nge-laser kunye ne-aluminium ephathwe nge-chemical. Ngokuhamba kwexesha, njengoko iindawo eziphezu komhlaba ziye zavezwa kwindawo emanzi, amandla omphezulu ophathwe nge-chemical ukuba ubambe kakuhle ayancipha kakhulu kuba ukufuma kuqala ukubola umphezulu, ngelixa umphezulu ophathwe nge-laser ugcina ukumelana nokubola emva kweeveki zokuvezwa.

Ixesha lokuthumela: Agasti-12-2022