Njengoko amandla okuwelda kunye neemfuno zenkangeleko zokuwelda kwesinyithi zisiya zisanda, ingakumbi kwiindawo ezinexabiso elongezelelekileyo kunye neemfuno zomgangatho ophezulu wokuwelda, iindlela zokuwelda zemveli ngokuqinisekileyo ziya kukhokelela ekuguqukeni kwento yokusebenza ngenxa yokufaka ubushushu obukhulu, njl. Ingxaki, ifuna iindlela ezininzi zokusila kunye nokubumba, nto leyo ekhokelela ekunyukeni kweendleko.

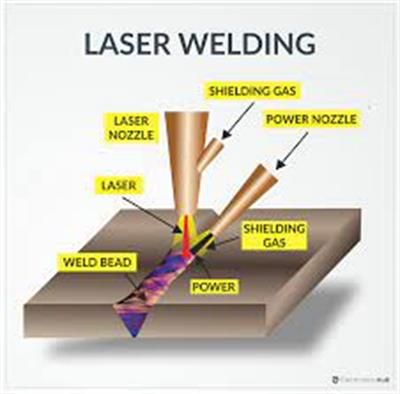

Nangona kunjalo,ukuwelda nge-laserinoxinano olukhulu kakhulu lwamandla kunye nendawo ephantsi kakhulu echaphazeleka bubushushu, nto leyo engaphuculi nje kuphela ukusebenza kakuhle kokuwelda, kodwa ikwaphucula umgangatho kwaye inciphisa ixesha emva kokucubungula.

Ngoko ke, ukusetyenziswa kwe-laser welding kwimveliso yanamhlanje yesinyithi kuya kuthandwa ngakumbi. Abathengi abaninzi baxhalabile malunga neendleko zokuthengwa kwezixhobo, ukusebenza kakuhle kunye nomgangatho we-welding, isantya sokusila, izinto ezisetyenziswayo emva kokucubungula, ukusetyenziswa kwamandla, ubunzima bokusebenza, ukhuseleko lokhuseleko, iindleko zasemva kokuthengisa kunye nezinye izinto ezininzi.

Kukho iintlobo ezininzi zoomatshini bokuwelda kwimarike. Abathengi kufuneka baqwalasele ezi zinto zilandelayo xa bekhetha umatshini wokuwelda nge-laser:

1. Iimpawu zokukhanya: ubungakanani bebala (ububanzi bentonga yelaser, ububanzi befayibha kunye nohlobo, iiparameter zentloko yokuphuma), ukuphakama kwendiza egxileyo, ubunzulu bentsimi, indawo yebala, i-engile yebala lokwenzeka kwayo;

2. Iimpawu zolawulo: ukukhethwa kwendlela yokulawula impendulo kunye nefomu yamaza ombane.

Emva kokuthelekisa iindlela ezahlukeneyo zokuwelda, inkampani yethu iqalise iintlobo ezintathu zezixhobo zokuwelda nge-laser: i-fiber optic four-dimensional automatic welding, i-robot automatic welding, kunyeukuwelda nge-laser ephathwa ngesandlangokweemfuno ezahlukeneyo zoshishino lwesinyithi. Imithombo yokukhanya yezixhobo ezintathu zonke zisebenzisa i-fiber lasers, akukho zinto zisetyenziswayo kwaye ulondolozo alufuneki, umgangatho wemitha ulungile, kwaye isantya sokuwelda siyakhawuleza, nto leyo eyona migaqo ilungileyo yokucubungula kwishishini lesinyithi.

Ukukhethwa kwezixhobo

01. I-weldin yefayibha ezenzekelayog

Ububanzi besicelo:Isetyenziswa kakhulu kwiibhetshi ezinkulu zesinyithi esiqhelekileyo esincinci nesiphakathi, imveliso inobunono obuphezulu, kwaye ukucutshungulwa kweebhetshi kunokwenziwa ngezixhobo ezifanelekileyo kunye nezixhobo.

Ukusebenza ngokuzenzekelayo okusebenzayo kakhulu:imveliso yelaser enamandla aphezulu, indawo ephindaphindwayo echanekileyo, ibhentshi yokusebenza ekude enemilinganiselo emine, inkqubo yokusebenza elula kakhulu, ukugxila ngokuzenzekelayo kunye nokujikeleza kwentloko yokudibanisa, ukuqonda umlinganiselo wokusebenza okuphezulu kokucubungula kunye nokuvelisa okuzenzakalelayo;

Uqinile kwaye umhle:i-weld inomlinganiselo ophezulu (onzulu nomncinci), akukho cingo lokuzalisa lifunekayo, ungcoliseko lwendawo yokunyibilika luncinci, i-weld inamandla aphezulu kwaye iqinile (ide idlule nezinto ezisisiseko), kwaye ikhanya kwaye intle;

Impembelelo encinci yobushushu:amandla e-laser aphezulu, kwayeinkqubo yokuweldaikhawuleza kakhulu, ngoko ke igalelo lobushushu kwindawo yokusebenza liphantsi kakhulu, indawo echaphazelekileyo bubushushu incinci, kwaye indawo yokusebenza ayiguquguquki;

Uxinano oluphezulu:Igesi iphuma ngokukhawuleza xa kusenziwa umthungo we-weld, kwaye umthungo we-weld wokungena awunazo iimbobo. Ngaphezu koko, ukupholisa ngokukhawuleza emva kokuthungela kwenza isakhiwo se-weld sibe sihle kwaye uxinano lwe-welding luphezulu kakhulu.

Ulawulo:Ingalawula yonke imisebenzi efana nokubeka umthungo we-welding, ubungakanani bebala, ukuhanjiswa kwemitha, ukulungiswa kwamandla okukhanya, ulawulo lwe-stroke, ukuma okungxamisekileyo ngesantya esiphezulu, njl.njl.;

Ukusebenza okulula:ukusebenza kwamaqhosha okuphakathi, ukujonga ngokubonakalayo isikrini, ukusebenza okulula nokukhawulezayo;

Ukusebenza okuzinzileyo:Umatshini ulawulwa ngokungqongqo liqela lobuchwephesha elisemgangathweni ukusuka kwiindawo ukuya kumatshini wonke, kwaye uya kuhlolwa kakuhle kwaye uvavanywe ngaphambi kokuba uphume kumzi-mveliso, ngoko ke ukusebenza komatshini kuzinzile kakhulu;

Uluhlu olubanzi lwezicelo:unxibelelwano olude olune-axis ezine, ii-waveforms ezahlukeneyo zinokumiselwa iiparameter zenkqubo ngokwezixhobo ezahlukeneyo zokuwelda, ukuze iiparameter zokuwelda zihambelane neemfuno zokuwelda. Ifanelekile ukuwelda kumashishini, iimveliso kunye neendlela ezahlukeneyo.

Intloko yokujika:ubungakanani kunye nokuma kwendawo yokukhanya kunokulungiswa, nto leyo engasetyenziswa kakhulu kwaye ingasetyenziswa ekudibaniseni iimveliso ezahlukeneyo.

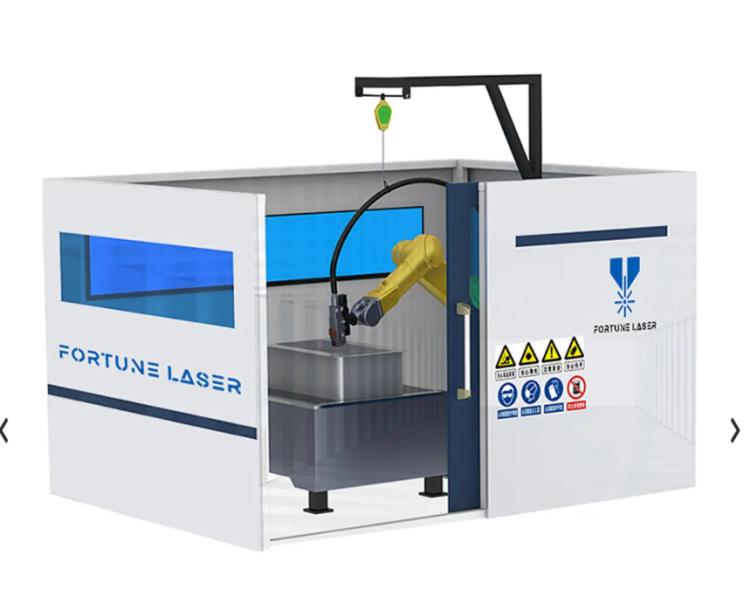

02. Ukuwelda iirobhothi

Izicelo: Isetyenziswa kakhulu kwiibhetshi ezinkulu zesinyithi esiphakathi nesinkulu esisemgangathweni. Inokuchaneka okuphezulu kokuma kwayo kunye nokuhamba okuguquguqukayo. Ifanelekile kwiindawo ezahlukeneyo zokusebenza ezinee-engile ezintsonkothileyo zendlela. Ingenziwa ibe zizikhululo ezininzi ukuphucula ukusebenza kakuhle kwe-welding. Yeyona ndlela kuphela yokutshintsha umsebenzi wesandla kunye nokunciphisa ubunzima bomsebenzi.

Ukusebenzisa ingalo yerobhothi enemijikelo emithandathu, uluhlu lokuwelda lubanzi.

Ukuchaneka kokubeka kwakhona kuphezulu, ukuya kuthi ga kwi-0.05 mm.

Irobhothi inobulukhuni obuhle kwaye iphila ixesha elide.

Ukusebenza kakuhle kwemveliso kuphuculwe kakhulu, kwaye ingasebenza ngokuqhubekayo iiyure ezingama-24. Idibene nezixhobo kunye nomgca wokudibanisa, inokuphumeza imveliso yobuninzi ngokuzenzekelayo.

Intloko yokujika: ubungakanani kunye nokuma kwendawo yokukhanya kunokulungiswa, nto leyo engasetyenziswa kakhulu kwaye ihlengahlengisweukuwelda kwezinto ezahlukeneyoiimveliso.

03. Ukuwelda nge-laser ephathwa ngesandla

Izicelo:Isetyenziswa kakhulu kwisinyithi esingaqhelekanga. Kukho iintlobo ezininzi zeemveliso, ezingafanelekanga kwizinto ezahlukeneyo, thintela utyalo-mali olugqithisileyo. Ukuchaneka kokugoba kwemveliso akuphezulu, kwaye umsantsa mkhulu kakhulu, nto leyo esombulula ingxaki yokufuna abantu abanzima. Le modeli ifumene udumo olupheleleyo kubathengi.

Ukusebenza okulula:Iumatshini wokuwelda we-laser ophathwa ngesandlaKulula ukuyifunda nokuyisebenzisa, kwaye umqhubi unokufikelela ngokulula kwiziphumo zokuwelda ezikumgangatho ophezulu.

Ukusebenza kakuhle kwe-welding:Ukuwelda nge-laser ephathwa ngesandla kukhawuleza kune-argon arc welding. Ngokusekelwe ekusindiseni abasebenzi ababini bokuwelda, ukusebenza kakuhle kwemveliso kunokuphindwa kabini ngokulula.

Akukho zinto zisetyenziswayo zokuwelda:Ukuwelda kungenziwa lula ngaphandle kocingo lokuzalisa ngexesha lokusebenza, nto leyo enciphisa iindleko zezinto zokwakha ekuveliseni nasekucubunguleni.

Isiphumo esihle sokuwelda:Ukuwelda nge-laser ephathwa ngesandla kukuwelda okunyibilikiswa ngobushushu. Xa kuthelekiswa nokuwelda kwendabuko, ukuwelda nge-laser kunamandla aphezulu kwaye kunemiphumo engcono.

Ukuguqulwa kwamandla okusebenzayo okuphezulu:Ukusebenza kakuhle kokuguqulwa kwe-photoelectric kwe-laser kufikelele kwi-30%, kwaye ukusetyenziswa kwamandla kuphantsi.

Kulula ukuyisebenzisa kwaye iguquguquka:ukuwelda nge-laser ephathwa ngesandla, simahla kwaye kuyaguquguquka, kwaye kufikeleleka lula

Akufuneki ukuba imithungo ye-weld ipholishwe: i-welding eqhubekayo, igudileyo ngaphandle kwamaxolo eentlanzi, intle kwaye ayinamanxeba, inciphisa iinkqubo zokusila ezilandelayo.

Intloko yokujika:ubungakanani kunye nokuma kwendawo yokukhanya kunokulungiswa, nto leyo engasetyenziswa kakhulu kwaye ingasetyenziswa ekudibaniseni iimveliso ezahlukeneyo.

Xa ukhetha i-laser power waveform, ngokubanzi, phantsi kwengcamango yokukhupha amandla e-laser afanayo, ububanzi be-pulse bubanzi, indawo yokuwelda inkulu; okukhona amandla aphezulu e-laser power waveform ephezulu, kokukhona indawo yokuwelda inzulu. Okwangoku, akukho seti epheleleyo yeendlela zokuseta i-laser power waveform. Abasebenzisi banokuhlola kancinci kancinci kwinkqubo yokusebenzisa ukuze bafumane i-laser power waveform efanelekileyo kwiimveliso zabo.

Ukukhethwa komatshini wokuwelda nge-laser kubaluleke kakhulu kwizinga lemveliso yokucubungula ibhetshi; ke ngoko, ukuba iimeko ziyavuma, abasebenzisi banokusebenzisa umatshini wokuwelda we-laser ngexesha langempela kangangoko kunokwenzeka ukuphucula izinga elifanelekileyo leemveliso.

Ukuba ufuna ukufunda okungakumbi malunga nokuwelda nge-laser, okanye ufuna ukuthenga umatshini wokuwelda we-laser ongcono kuwe, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngokuthe ngqo!

Ixesha lokuthumela: Feb-17-2023